|

|

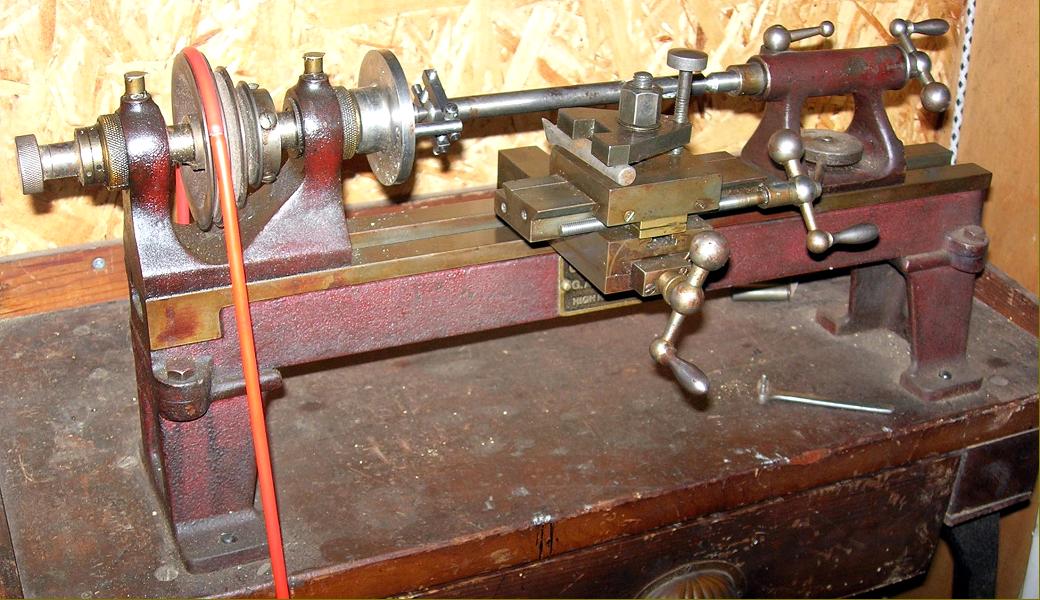

Beautifully made, the little George Adams 21/2" centre height precision lathe has been a machine sought after by generations of amateur machinists - especially clockmakers - keen to get their hands on a genuinely high-quality product (though it must be said that the design quirks, present on nearly all George Adams's products, were present on this version too). Also found badged as the R.Kelly of Manchester & Liverpool, the lathe was almost certainly inspired by German Wolf Jahn practice with very small marks - usually saying just "Germany" in tiny letters - sometimes being found stamped on various parts using that company's recognisable style. In addition the accessories also confirm such a connection, being constructed identically and so directly interchangeable with the Wolf Jahn originals. Normally sold in plain-turning form, the 21/2" could also be fitted with two types of screwcutting arrangement: the first, using a straight shaft direct from changewheels to the top slide was at odds with the normal practice of using a keyed and universally jointed shaft; the second consisted of a proper bed-mounted leadscrew - in which latter form it is particularly rare and shown on this page page.

Made for several decades, from approximately 1900 until the mid 1930s, the lathe had a bed of typically English/German pattern, being flat on top with the location for headstock, carriage and tailstock formed by vertical flat shears between the two ways. An unusual feature was the mounting of the bed feet - they were simply bolted to rather ugly-looking lugs formed at each end of the casting. However, being finely machined on both top and bottom surfaces - and located on the machined underside of the bed - the feet did add slightly to the bed's stiffness.

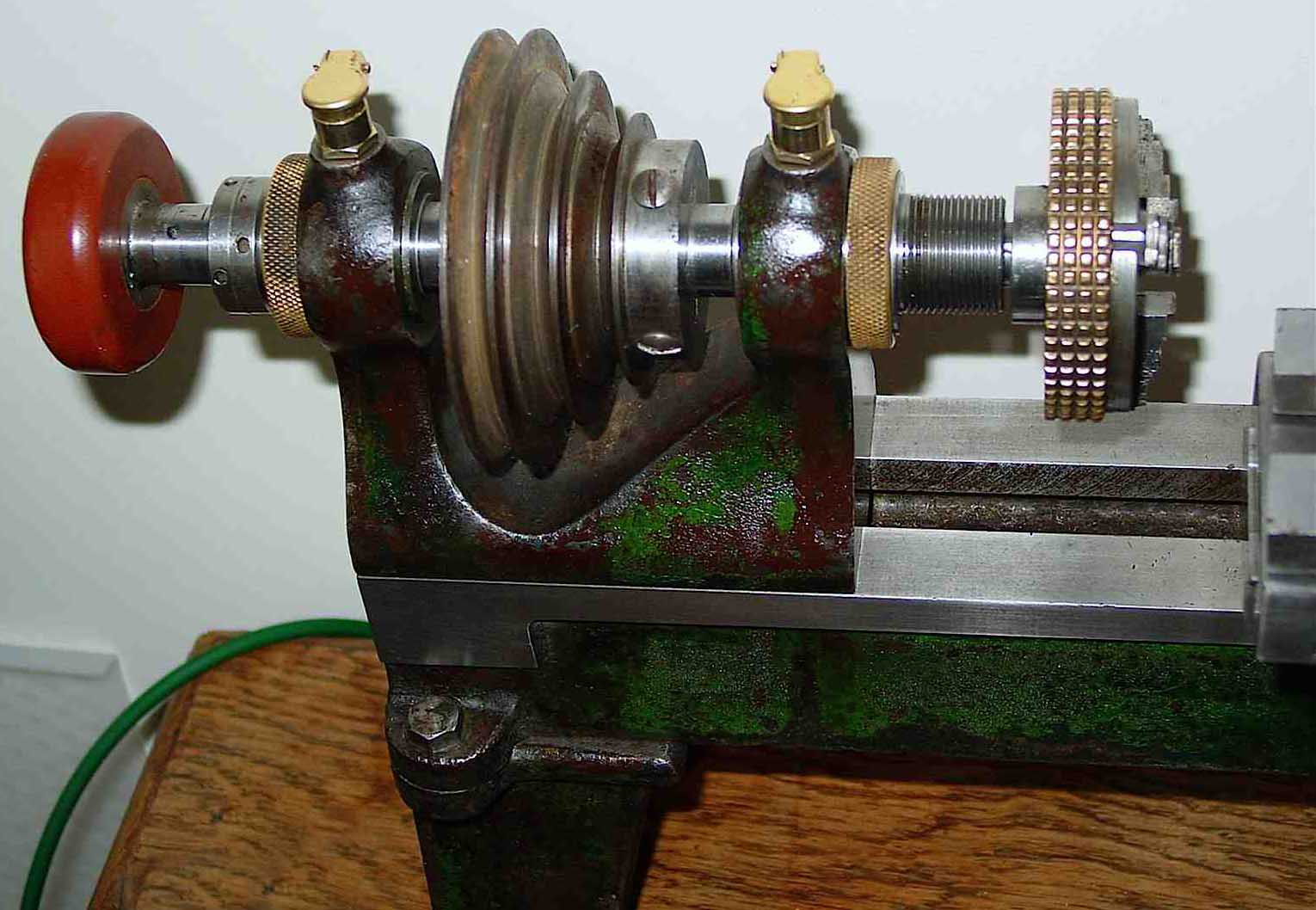

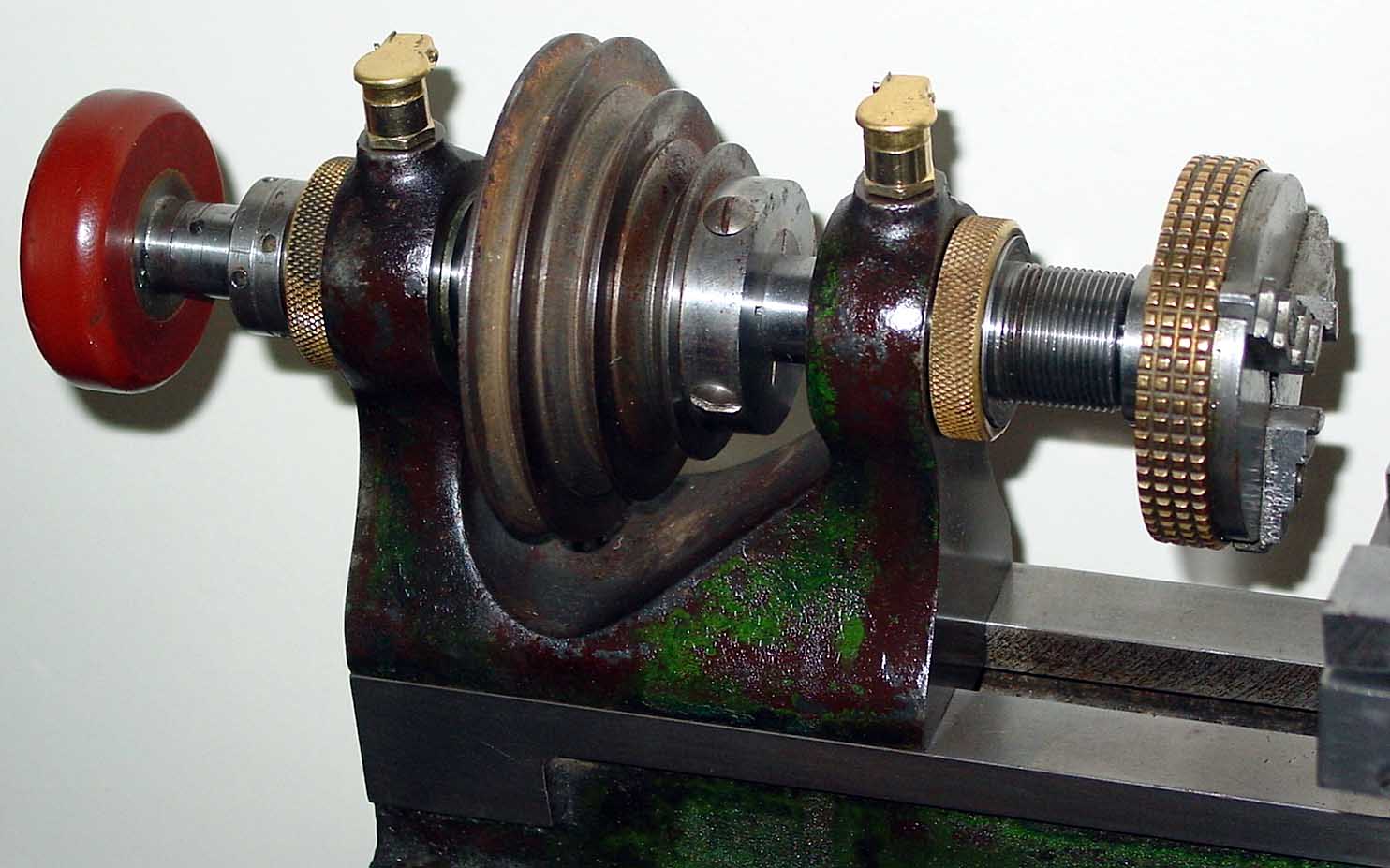

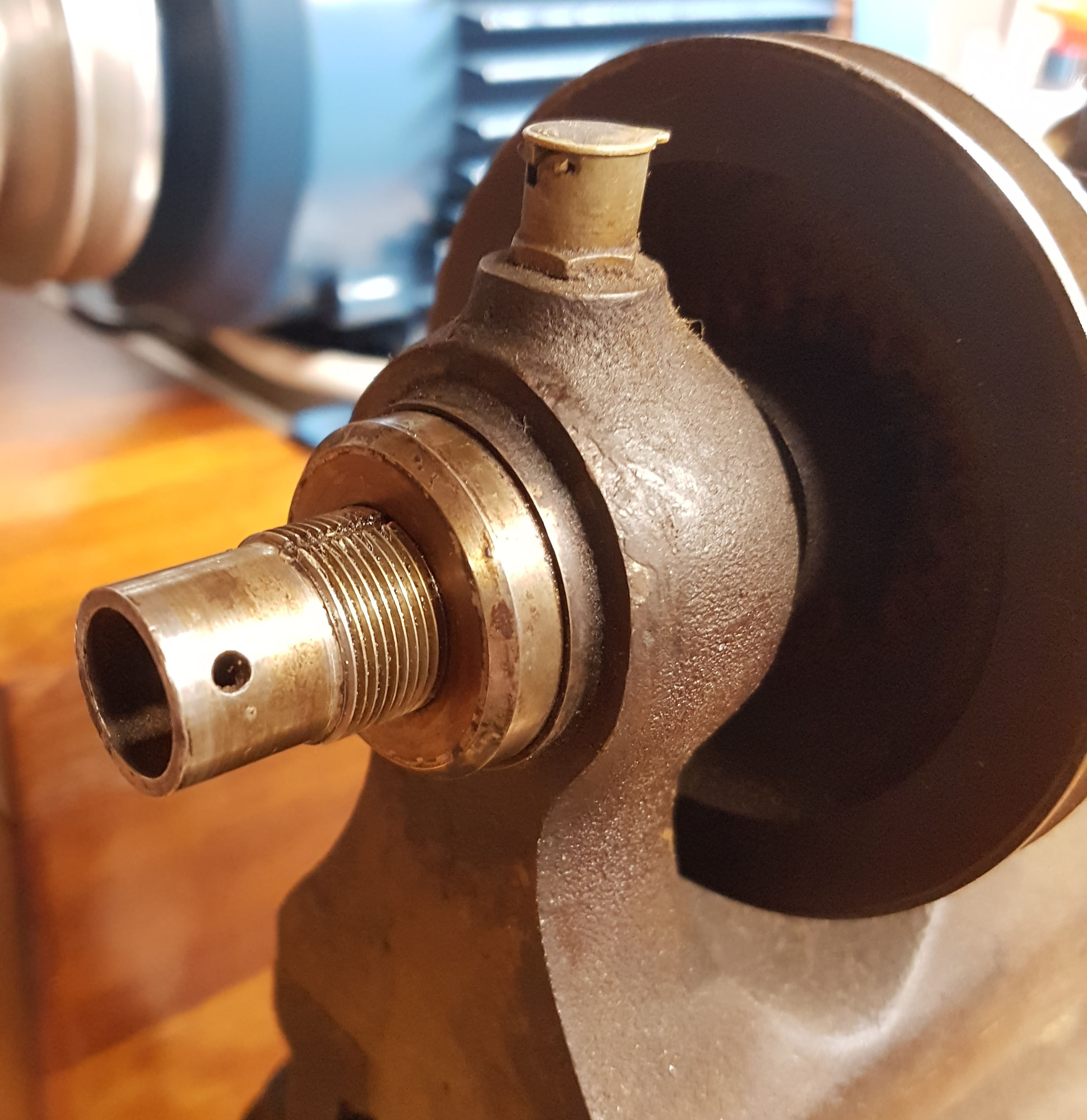

Like all "Precision" George Adams lathes, the headstock of the 21/2" followed the well-established pattern for a high-quality "Bench Lathe*" of having bearings made from opposed , hardened steel cones that closed down on similar hard cones fastened to or formed as part of the spindle (though details of the design are known to have changed). If a supply of clean oil was maintained, this type of bearing proved capable of almost infinite life - some American lathes (by Stark and Wade) having successfully absorbed over fifty years of commercial use without failure. The headstock spindle (or mandrel as it was then called) accepted a hardened, tapered insert that took standard 8 mm collets. This insert can, incidentally, be hard to see, being a very close fit within the 7/8" diameter, 20 t.p.i nose, and must be removed if use of the full spindle bore is required.

Designed to be driven by a round leather rope - or "gut" in popular contemporary parlance - the 3-step cast-iron pulley was locked to the spindle was a somewhat over-engineered (though delightful) collet-like method where the smaller end of the pulley was turned parallel for a short distance and slotted with four equally-spaced slits; a large clamping ring was slipped over the slotted section and tightened by four screws until it closed down onto the spindle - the arrangement can clearly be seen in the pictures below.

Equally neat, though not unique - it also being employed by Rivett - was the method of securing the "balanced" ball-ended handles on the very long-travel compound slide rest; a long screw, with its slotted head moulded so as to blend in with the end of the ball, passed right down the stem of the cross piece to engage with the end of the feed screw. The design of the compound slide assembly was unusual, and incorporated some weaknesses; the feed screws were 25 t.p.i. with brass micrometer dials, finished, on early examples, with a double rim and traditional "rope" knurls, engraved with divisions of 0.002". The slide rest changed over the years with some being in proportion to the rest of the machine (with the expected lengths of travel) while other were noticeably different with considerably longer cross slides and more modern-looking micrometer dials. Unfortunately the top slide - which on all models had at least a useful 3 inches of movement - had no degree marking for its swivel settings; and, equally disappointing for a quality lathe (though in line with later Schaublin practice), was the use of a long horizontal slot in the tailstock casting to act as a clamp for locking the (short) No. 1 Morse-taper barrel. The danger of the casting being over tightened, and broken off, was mitigated against (to some extent), by the provision of two adjustable stop screws that passed through the slot - one at each side of the clamping screw; the general arrangement of the tailstock slit can be seen in the third picture below.

An unusually wide variety of accessories was available for the lathe enabling it to be used for grinding, screwcutting, precision sawing, milling and light production work.

Original colours used on George Adams lathes included plum red and emerald green.

*Including: American Watch Tool Company, Arrow, B.C.Ames, Bausch & Lomb, Benson, Boley, Bottum, Boxford, B.W.C., Carstens, Cataract, Cromwell, Crystal Lakes, CVA, Derbyshire, Elgin, Hardinge, Hjorth, Juvenia, Karger, Leinen, Levin, Lorch, Mikron, W.H.Nichols, Potter, Pratt & Whitney, Rambold, Rebmann, Remington, Rivett, Saupe, Schaublin, See (FSB), Sloan & Chace, Smart & Brown, T & L.M., U.N.D., Van Norman, Wade, Waltham Machine Works, Weisser, Wolf Jahn and (though now very rare), Frederick Pearce, Ballou & Whitcombe, Sawyer Watch Tool Co., Engineering Appliances, Fenn-Sadler and the "Cosa Corporation of New York.."

|

|