|

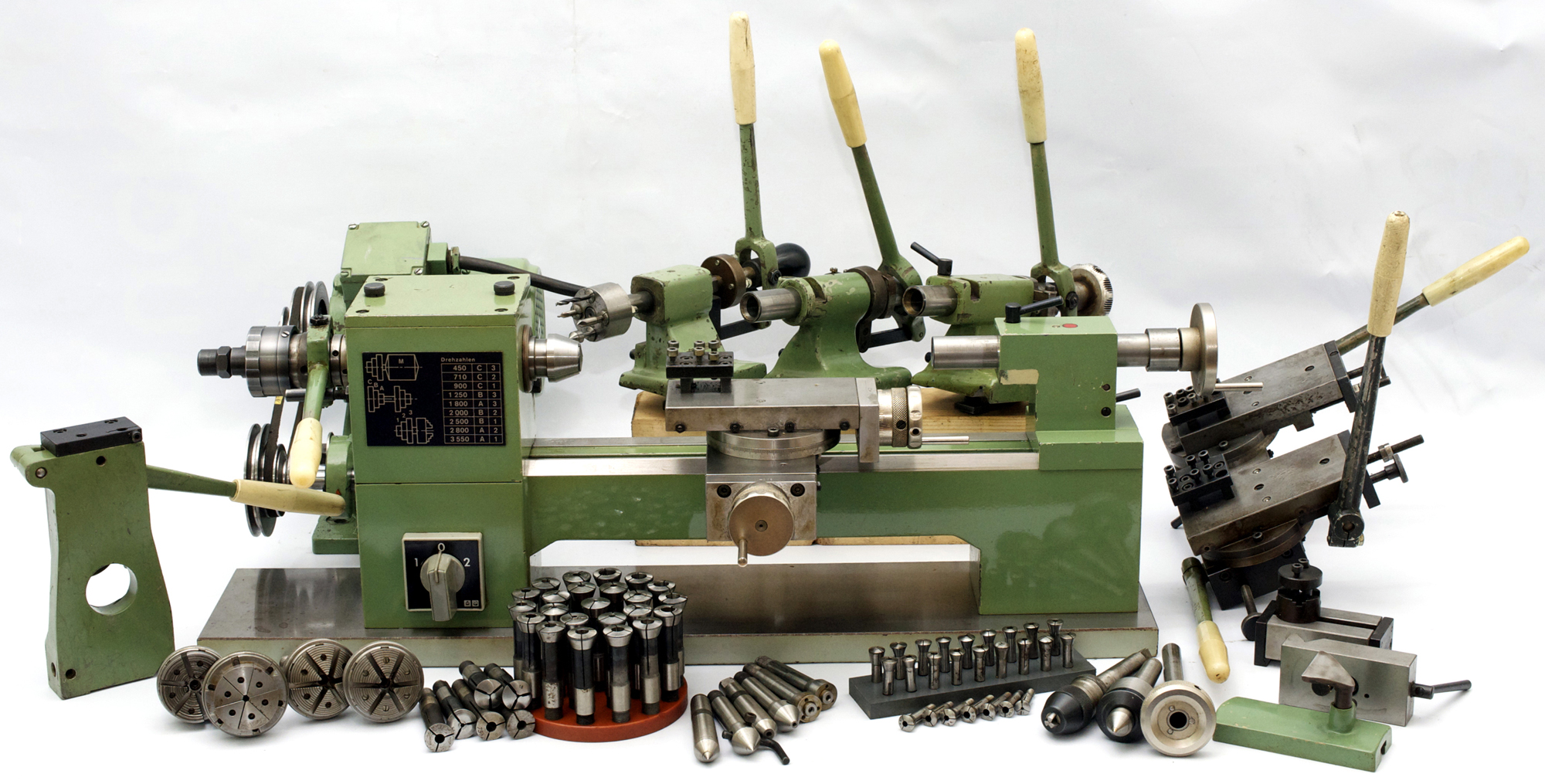

Sold through the state-controlled WMW-Export Company Saupe lathes were made by Gerhard Saupe KG of 705 Leipzig, Oststrabe 49, who were described as a "Semi-state Enterprise". Located in what was then the totalitarian, communist-controlled GDR the firm was probably no more independent than the rest of the country - yet despite this handicap a long tradition of fine-quality metal working persisted and a firm like Saupe could easily meet the quality standards expected in the West. In addition,, because of low wages and a poor exchange rate, the machines were able to be offered at bargain-basement prices. A number of Saupe models were made, including the Mini-Turn MD200, a cheaper, less well specified version of the better-known Hobbymat MD65 without that lathe's multi-speed drive system and lacking a power feed to the carriage.

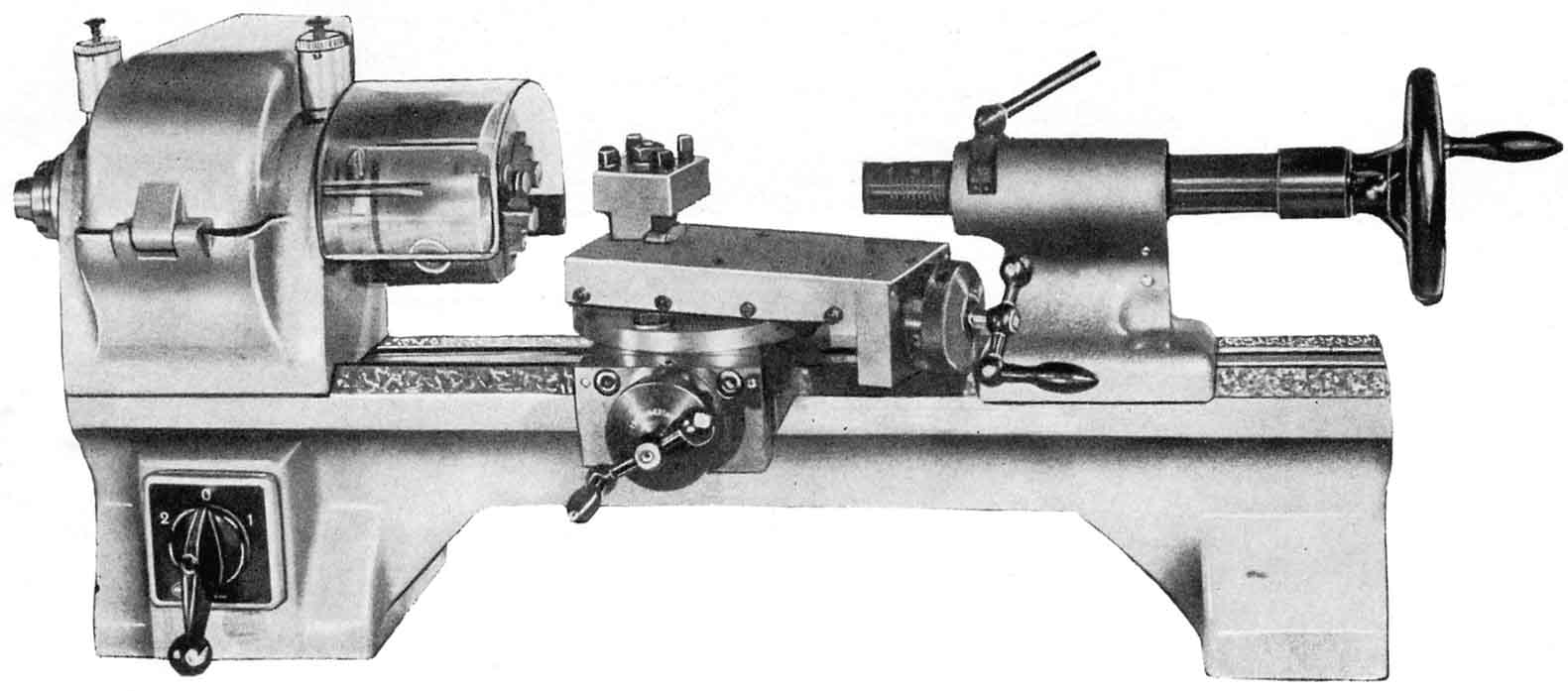

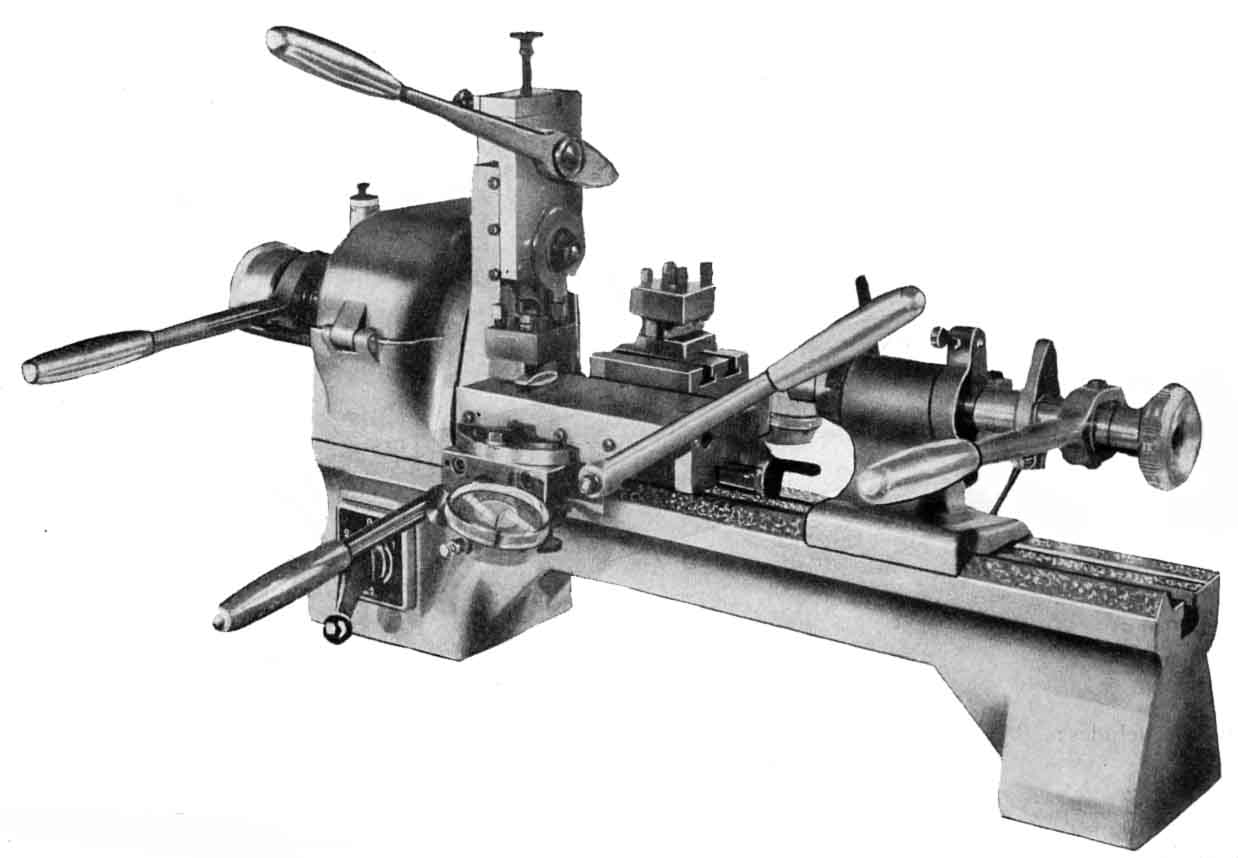

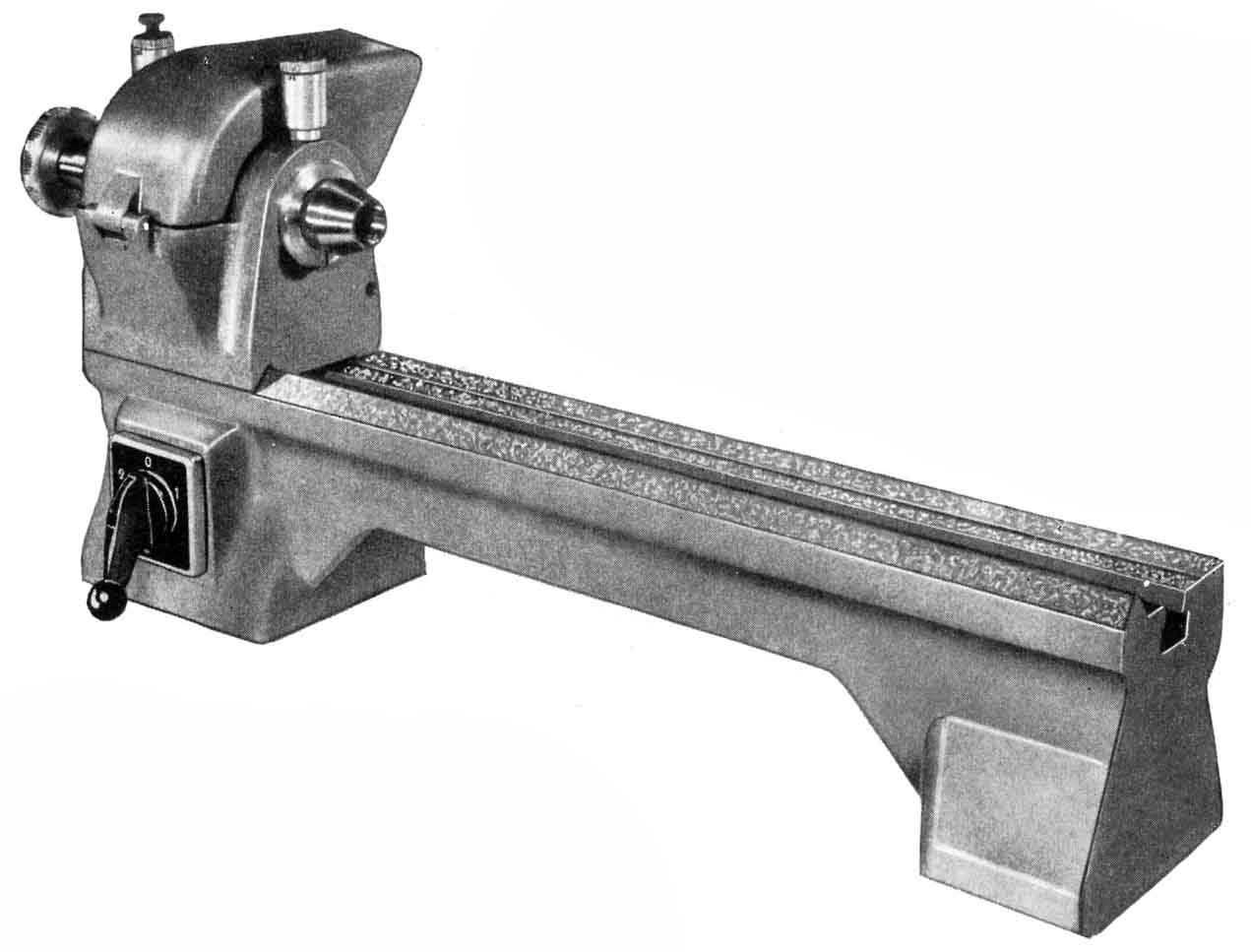

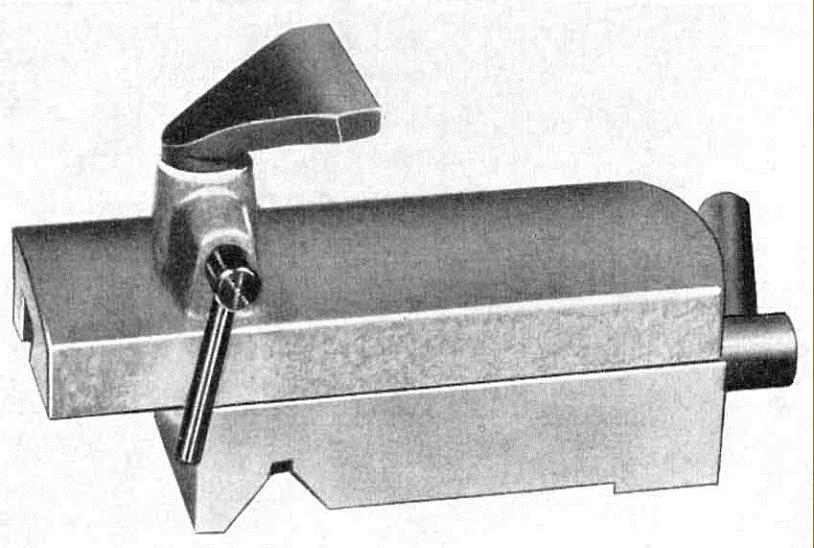

Both early and late versions of the precision were made with, shown towards the top of this page, the DMT 160, a plain-turning, precision lathe of 80 mm centre height and a capacity between centres of approximately 280 mm. The 600 mm-long and 90 mm wide V-way bed and its feet were cast as one, with a reversing switch held inside the headstock-end foot; the ways were hand-scraped to "gauge" tolerances and the makers claimed complete interchangeability and perfect accuracy of mounting for the very wide range of optional extras..

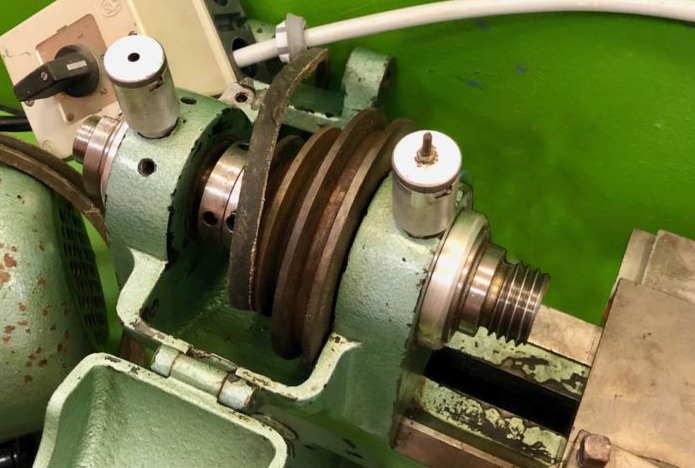

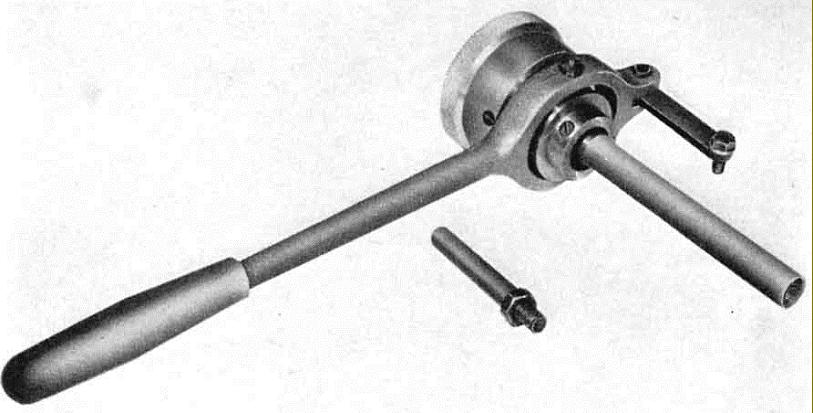

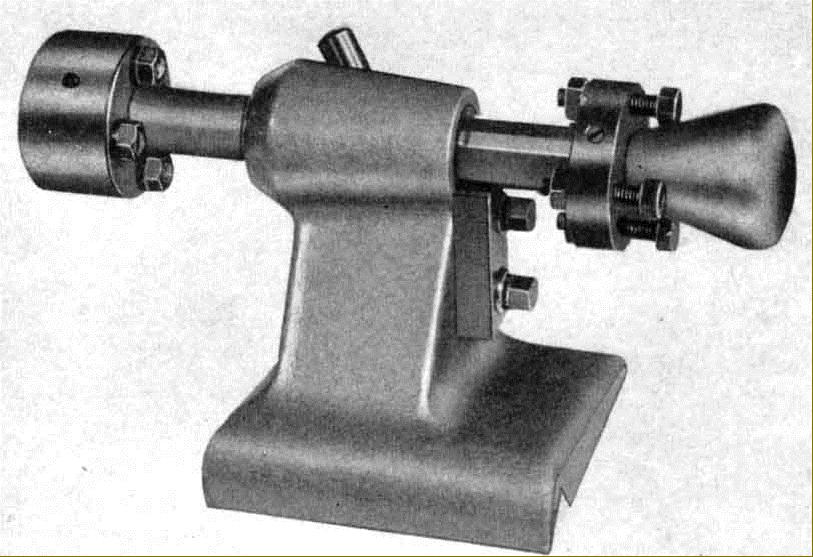

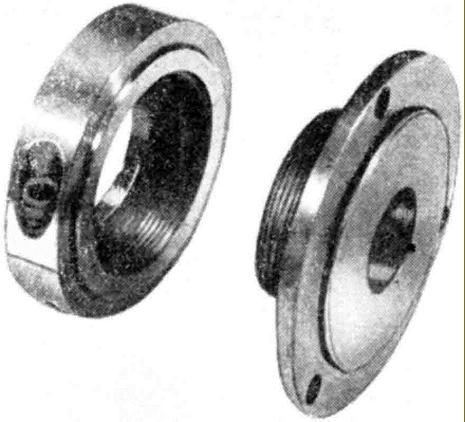

With a 15 mm-bore, the headstock spindle was hardened and ground and ran in a tapered and adjustable bronze bush at the front and a plain cylindrical bearing at the rear; end thrust was taken not by a ball race, but against hardened steel washers. The end of the spindle was, very usefully, formed with both a No. 2 Morse taper and shorter, steeper taper into which collets could be drawn by either a hand-screw tube or quick-action lever assembly - the latter allowing collets to be opened and closed with the lathe running and so adapted for some production processes. The maximum through capacity of the collets was 9 mm and the largest non-draw-through size that could be held 12 mm. Although the spindle end was not threaded, it was possible to mount ordinary 3 and 4-jaw chucks on a backplate that was held in place by a demountable, internally-threaded "safety collar". Fool-proof and easily-checked drip-feed lubricators were fitted to the headstock and were meant to be filled with a special oil "LP 2070".

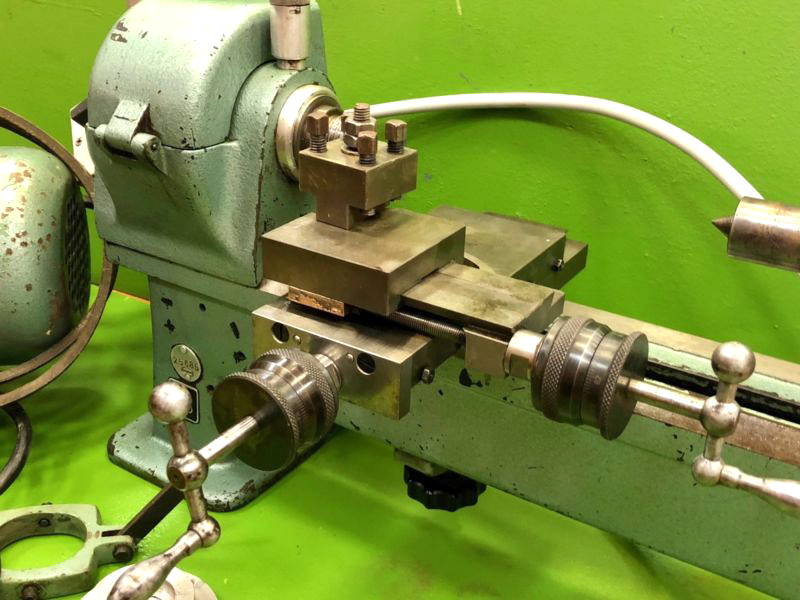

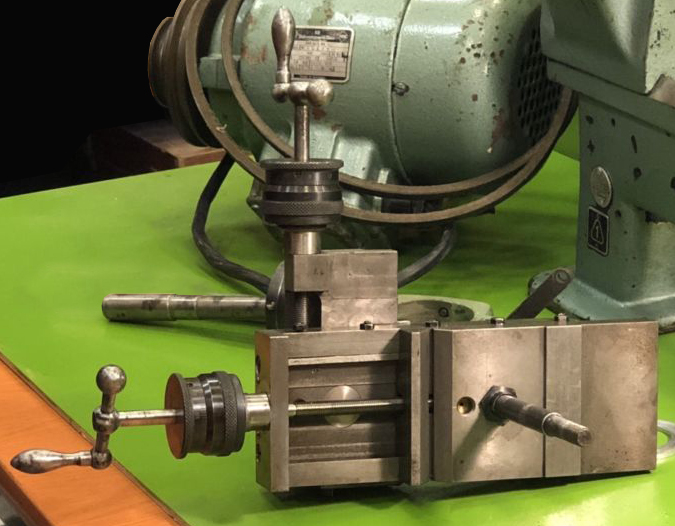

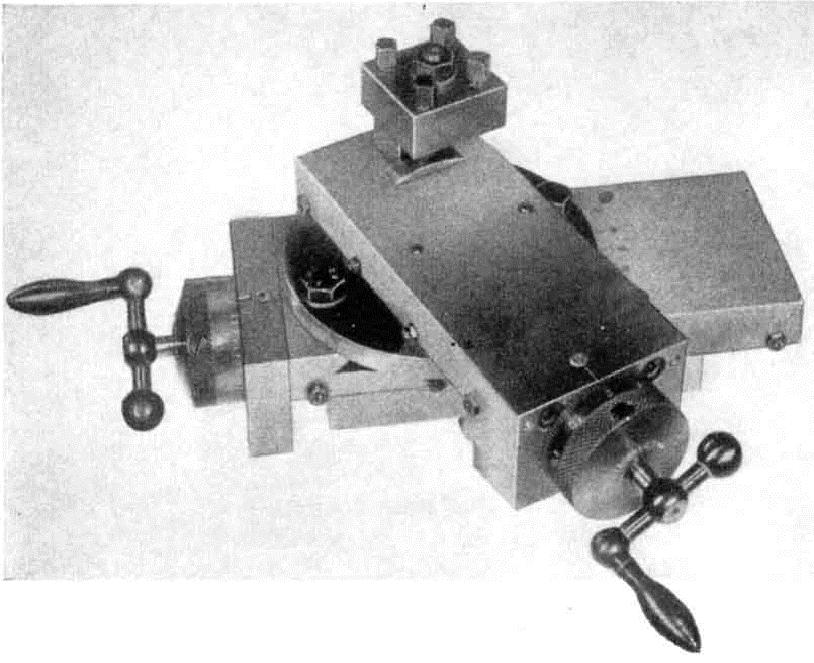

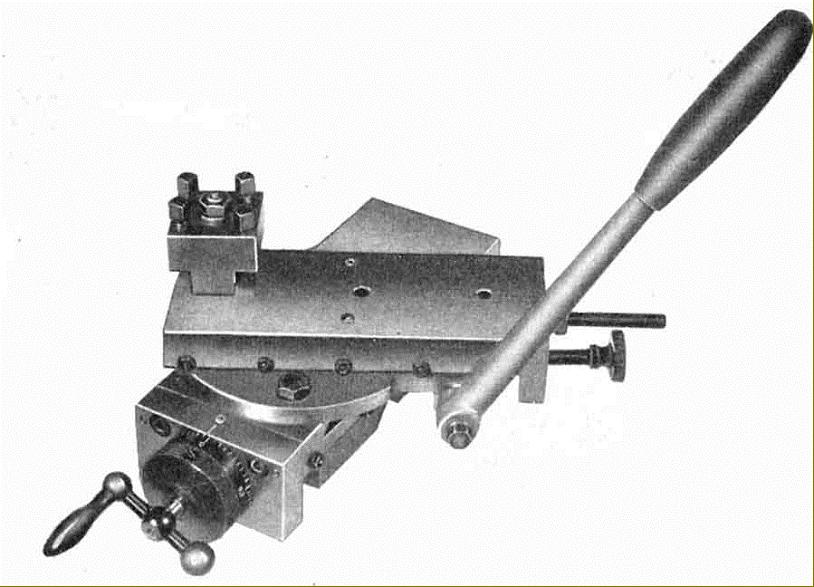

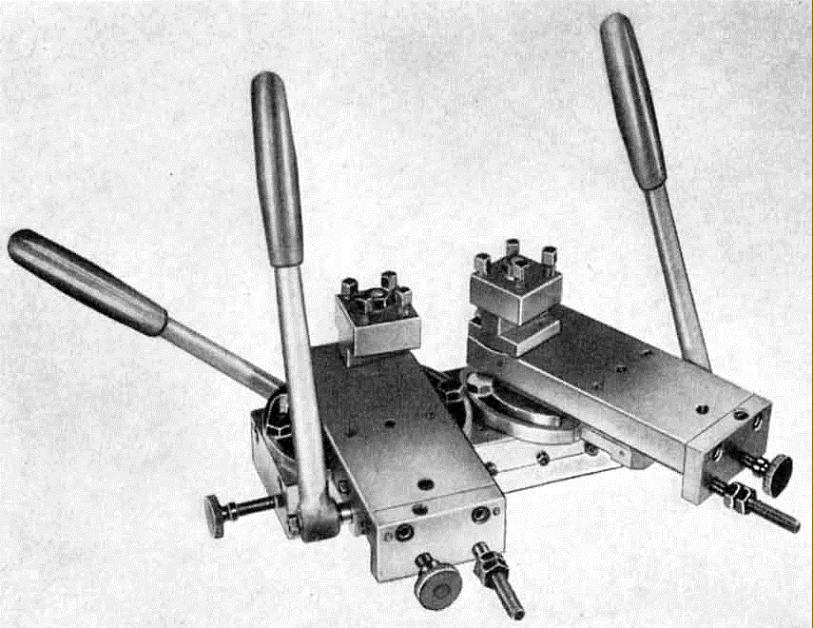

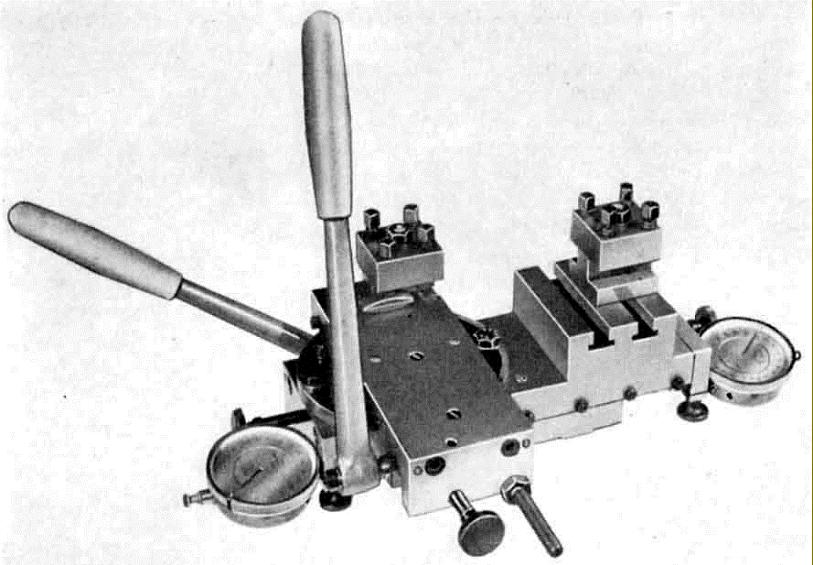

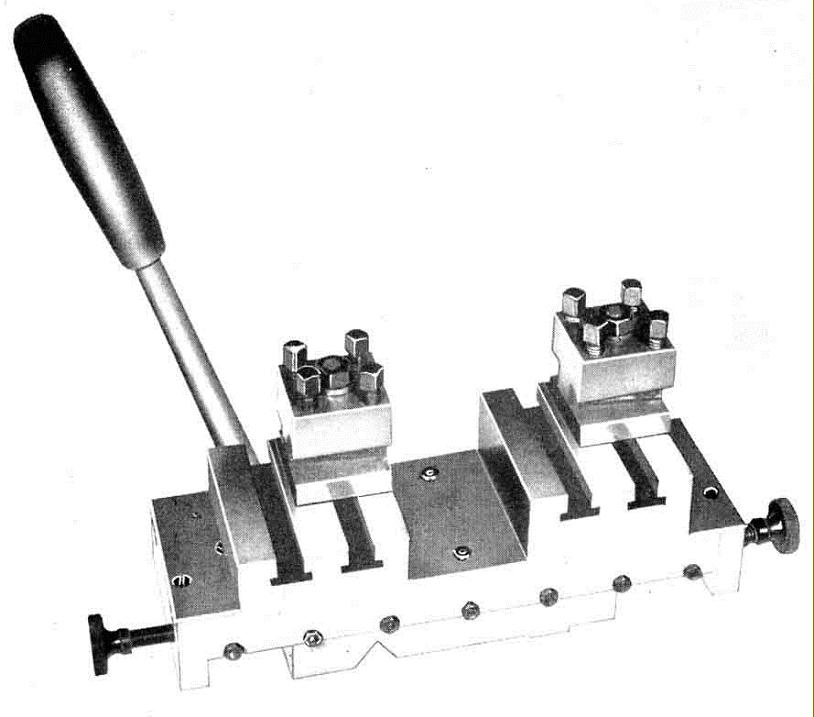

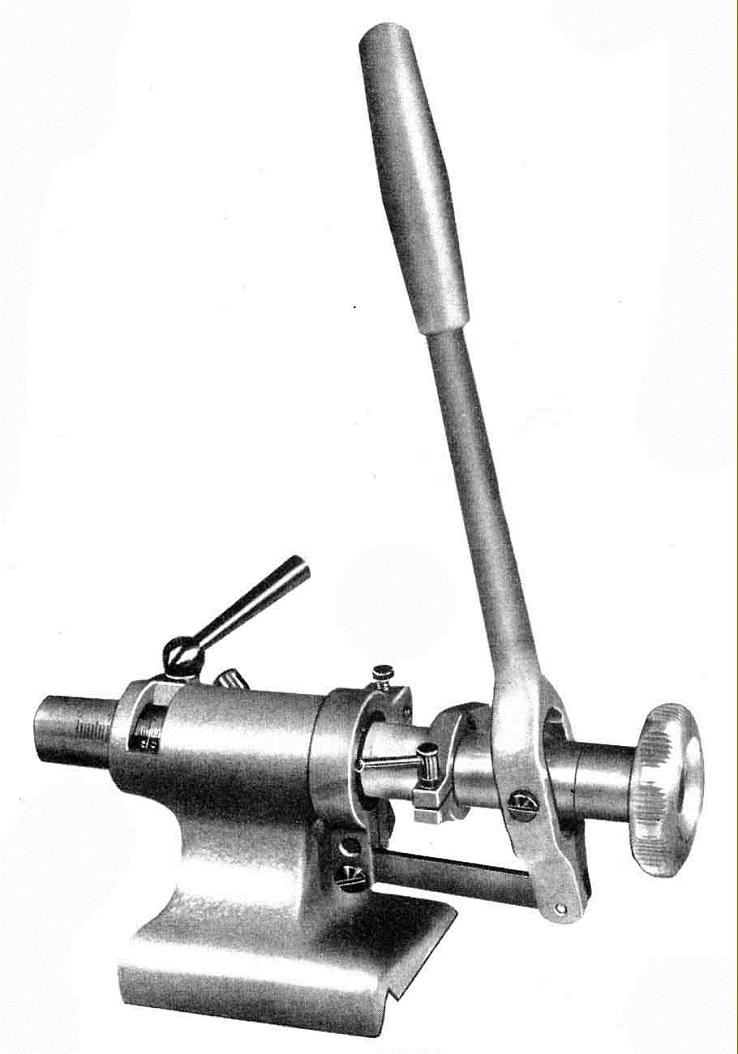

Like most precision lathe makers, Saupe offered the compound slide rest in various forms with a choice of two screw feeds, lever feed to the cross or top slide in combination with a screw feed on the other axis, lever feed to both slides, a cross slide with two lever-feed top slides and a plain cut-off slide; a special and rather unusual lever-feed vertical slide, designed for cutting bar stock was also listed. All the slides were equipped with mounting points for dial-test indicators and the 1 mm-pitch screws of the precision screw-feed slide were hardened and ground. A hand T-rest was also offered, mounted on a neat, quickly-adjustable base.

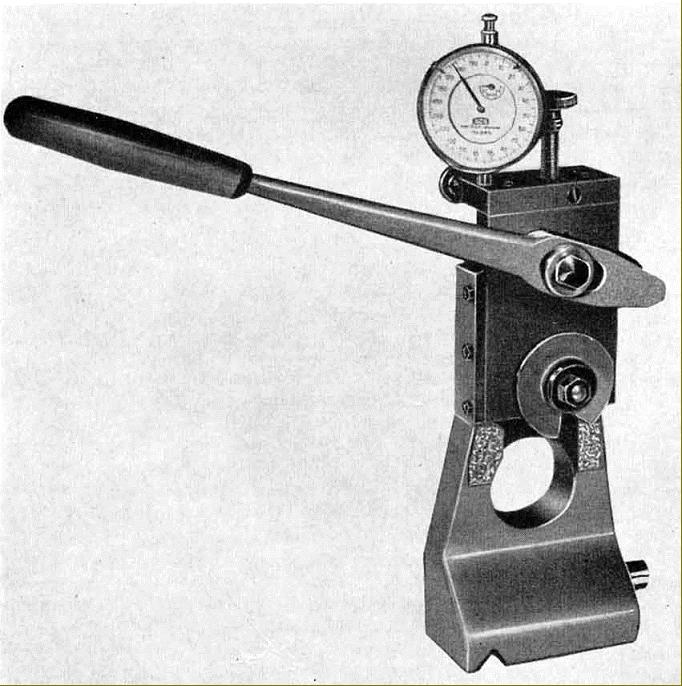

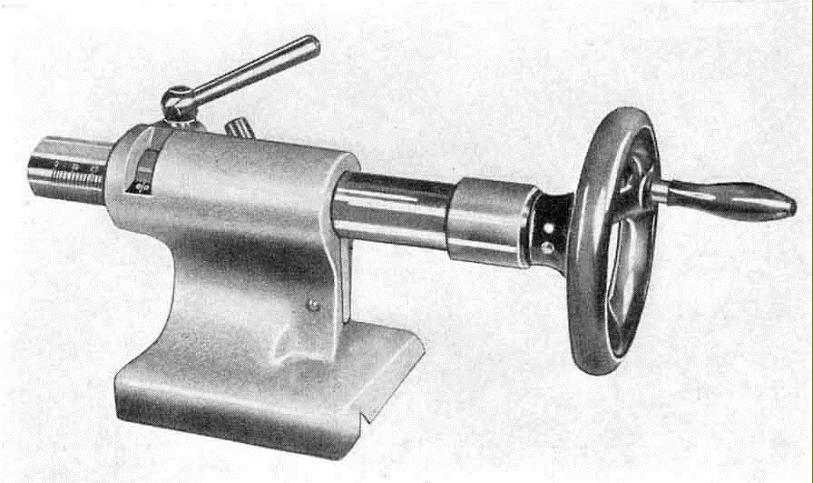

Three designs of tailstock were listed: one with an ordinary screw feed, one lever-(both with their barrel fully supported at any point in its travel in traditional precision-lathe style) and the other a special 4-position "turret "model with a drawbar collet assembly that also accepted collets from 1 to 4 mm in steps of 0.5 mm. The barrel could also be had as a simple hand-pushed type designed to assist in the drilling of very small holes.

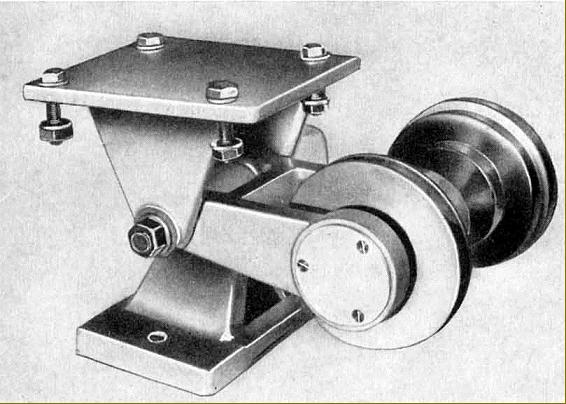

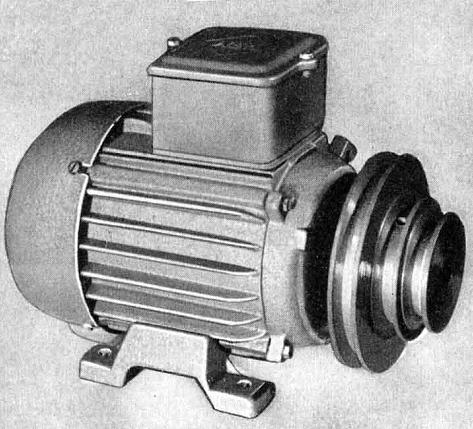

Heavily-built, the countershaft was a self-contained unit that bolted to the bench behind the lathe and drove with standard V-belts. 3-step pulleys, fitted to the motor spindle and at both ends of the countershaft gave, in conjunction with the standard 0.4 kW 1400 rpm motor, 9 speeds of: 560, 710, 900, 1120, 1400, 1800, 2240, 2800 and 3550 rpm.

Offered as a complete machine, ready assembled, or as a kit of parts that could be arranged as desired by the customer; the basic unit consisted of the bed, headstock, countershaft unit together with a 3-phase motor for a total of £262 (at 1970's prices); to this could be added a choice of components, of which the following are typical examples (all at early 1970s prices): screw-operated compound slide rest £104; lever-operated compound slide £104,; lever-operated tailstock £65; screw-operated tailstock £65; special Drilling Tailstock £114; lever-operated cut-off slide £54; lever-operated vertical cut-ff slide £42; hand support £9.50; quick-action collet attachment; collet set 1 mm to 12 mm in 0.5 mm steps £60.; chuck backplate, safety collar and a 3-jaw chuck £27. Thus, a basic lathe ready to run with a countershaft and motor, bed, headstock, tailstock, screw-feed compound slide rest and a set of collets together with a holder would have been approximately £570; a figure put into context by the £194 asked for a Myford Super 7 in 1972. Interestingly, the Myford almost tripled in price during that inflation-racked (socialist-governed) decade to become £578 by 1978.

Finished in that typical East German shade of "vita" hammer-texture green, with motor, countershaft, compound slide rest and tailstock approximately the lathe weighed approximately 74 Kg.

The writer would be interested to hear from any reader with a fine-condition, early Saupe - or experience of using any version..

|

|