|

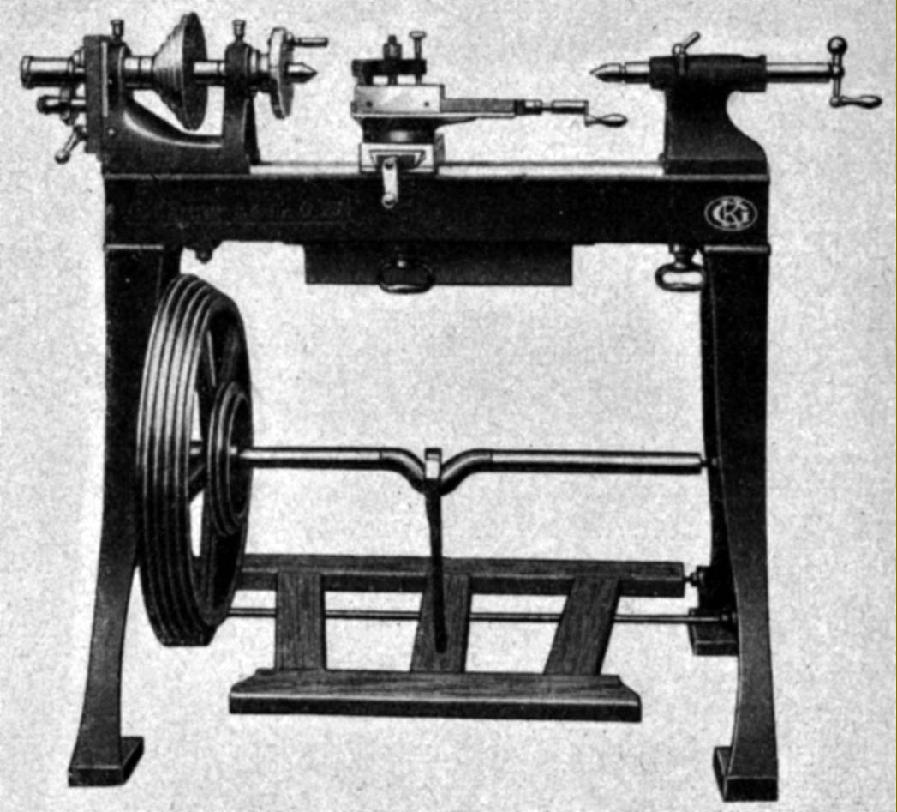

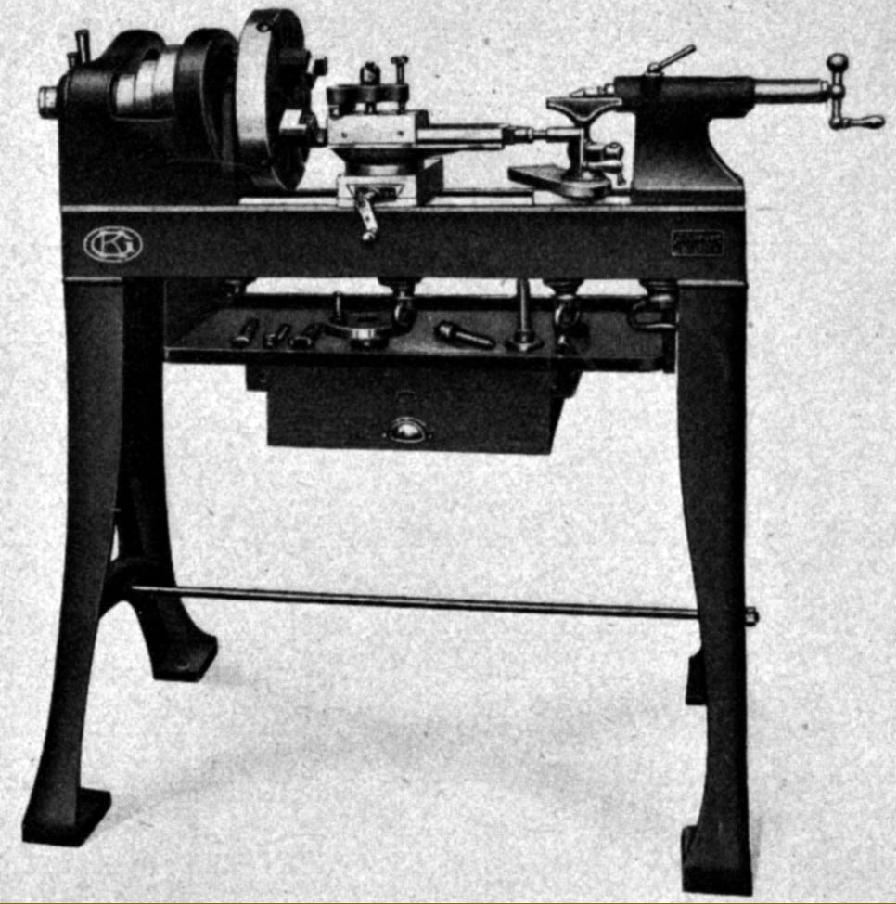

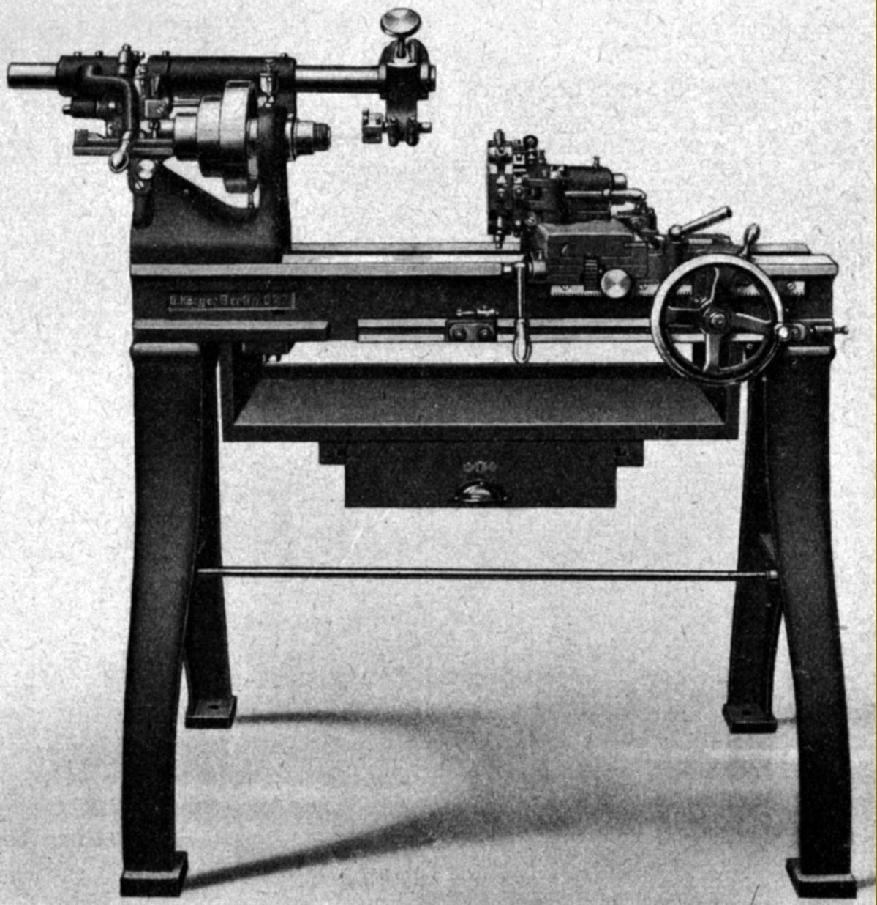

G. Kärger of Kraut-Strasse 52, Berlin 0.27 were makers from the late 1800s of high quality machine tools including millers and a range of precision plain-turning and screwcutting lathes designed for use in the watch, clock and instrument making trades. Models offered varied from simple bench machines to very much more complicated types for advanced work with the DP3, illustrated below, being a typical example as manufactured at the turn of the 19th and 20th centuries. Thoroughly well-made, this was a V-bed lathe and, although it closely reflected contemporary design for its type, it was a rather larger machine than those manufactured for the same purpose by makers in the USA such as Bottum, American Watch Tool Company, B.C.Ames, Bottum, Hjorth, Potter, Pratt & Whitney, Rivett, Wade, Waltham Machine Works, Wade, Pratt & Whitney, Rivett, Cataract, Hardinge, Elgin, Remington, Sloan & Chace, and Frederick Pearce. It was also very similar in style to models from Auerbach, another German machine-tool company. Notable points on the DP3 that indicate a machine of quality (and one intended to help the professional user) include the large-diameter front headstock bearing, a 5-speed headstock pulley, well braced stand legs, a built-in storage shelf and locking cupboard, a long foot-treadle bar and a forged flywheel shaft running in independently-mounted bearing housings. So well made were these types that many continue in serious use today, being ideal for work that requires delicate manipulation of the tool slides. The plain lathes, and ones based on them, remained in the Kärger catalogue until at least the early 1950s - and possibly longer - at which point they had been nationalised by the East German communists under the banner of the huge WMW machine-tool organisation.

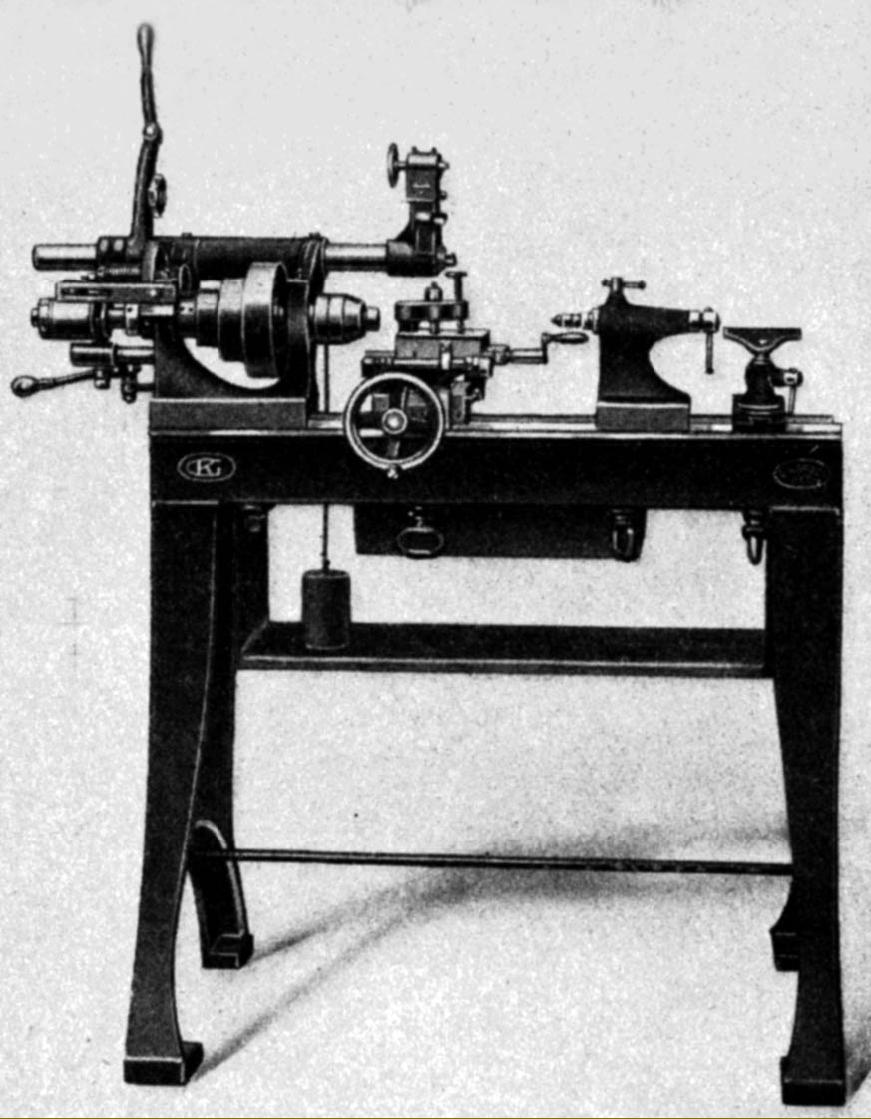

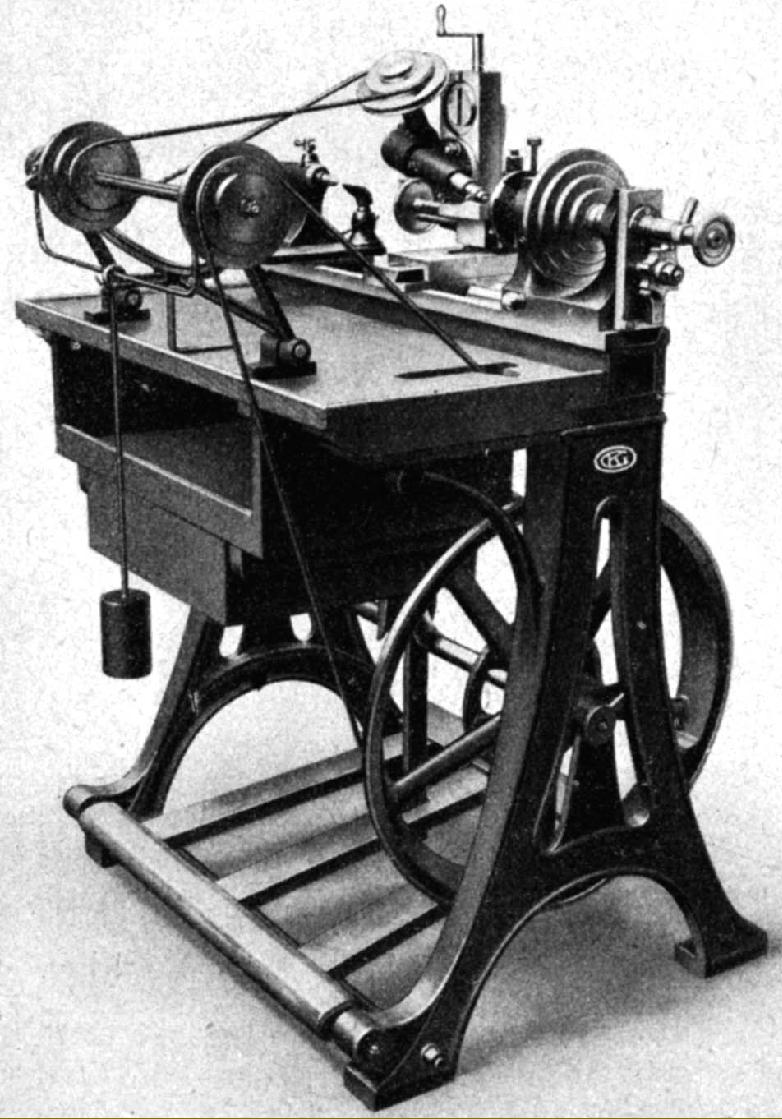

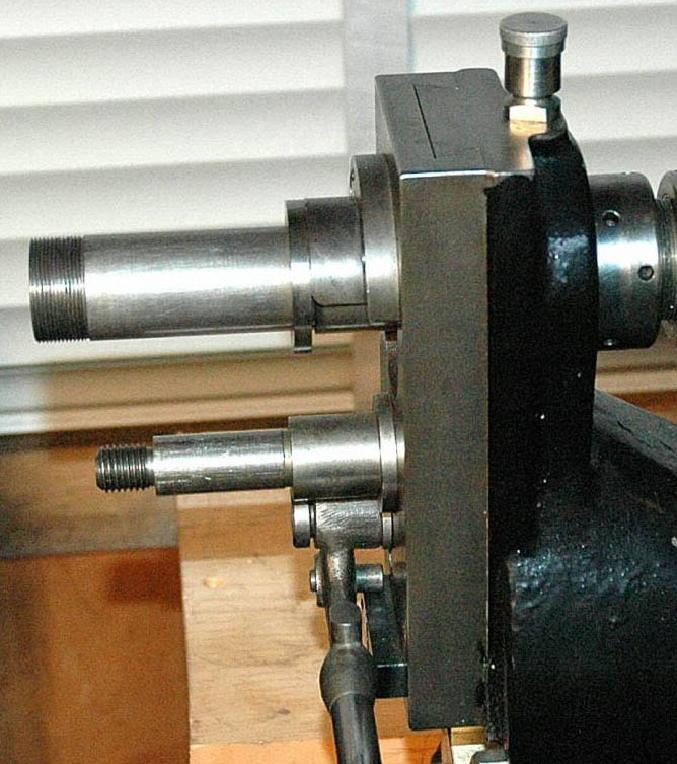

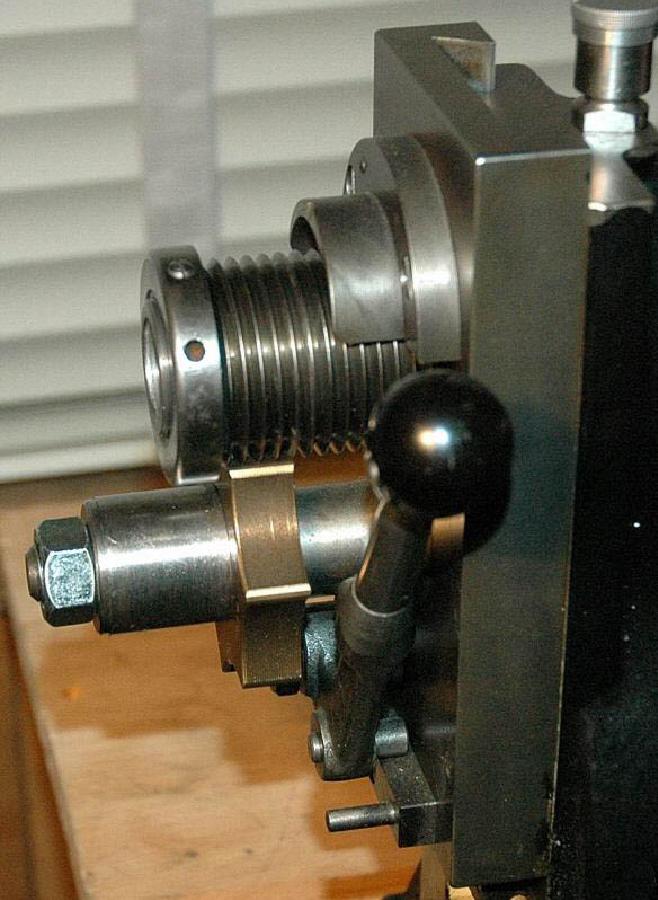

One important development for the company was the introduction, in 1892, of their first "precision leadscrew" models, the long-lasting DL Series. This came about as the result of Dr. Loewenherz, the director of the Physikalisch-Technischen-Reichsanstalt in Berlin (the P.T.R., an organisation similar to National Physical Laboratory in the UK) introducing a metric thread system (flank angle 53°8`), for use in precision trades such as watch making and political production. Needing a suitable lathe on which to turn micrometer screws, female micrometer screws and taps and other items needed to launch the new thread-system the P.T.R. turned to Kärger. For threading purpose the DL1 had a special spring-loaded and lever-operated support, to prevent the work from bending. There was also a simple - but ingenious - eccentric-operated slide system that permitted a quick retraction of the turning-tool as the end of the job was reached. The Loewenherz thread-system was quickly supplanted, in 1888, by the present metric (SI) thread-system with a flank angle of 60°.

During the middle years of the 20th century Karger's range developed to include more modern versions of the DL series, high-speed geared-head and production types and a range of unusual toolroom lathes with separate spindle-drive gearboxes in the base of their headstock-end plinths. The company exported their products world-wide both voluntarily, by normal commercial means, and after WW2 "involuntarily" when it is known that many, because of their high quality and durability, were seized as war reparations. For example, in the just-post-war years at the Standard Telephones & Cables Company's radio workshops at New Southgate, England, there were 5 Kärger lathes of about 6-inch centre height that had been brought over from Germany in this way.

If any reader can provide more information about the Kärger company and its products the writer would be very interested to hear from you..

|

|