|

Manuals Machine Tool Catalogues Belts Accessories Books A suitable Handbook and Parts Manual is available for the Joinville lathe Ace Blomqvist Boxford Hercus Joinville Moody Purcell South Bend 9-inch Home Page South Bend Home 9-inch Lathe Accessories An Unused 9-inch South Bend 9-inch Clones In the Factory Original 1934 9-inch Model 5 World War 2 Export Papers Taper-turning Unit |

|

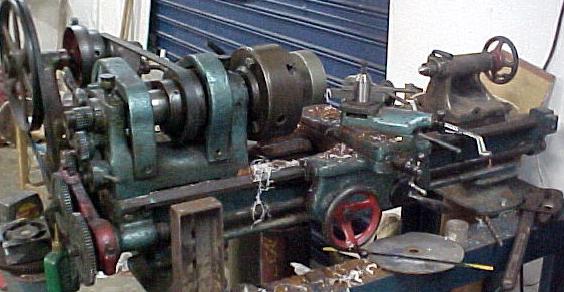

Usina Metalúgica Joinville was a Brazilian foundry and toolmaking business established in 1893 by Otto Bennack (an immigrant from Germany) and concentrated mainly on parts for the railroad industry and farming tools. The company remained in his hands until the Second World War when, because of his German connections, he was forced to sell to the Government who feared for their neutrality. At some point during the 1940s a South Bend lathe was acquired as a master pattern and production stated of a straightforward copy - the donor machine (based on the appearance of the bed feet and other details) being of 1940 vintage. The only significant modification made to the first production examples was a change from a V to a flat rear bedway - though soon afterwards a radial alteration was made when the headstock was modified to accept a larger bore spindle (0.826") running in parallel-bore, plain bronze spindle bearings held in conical housings by serrated screwed rings with adjustment by compression nuts. Later changes included a full-length cross slide carrying a single length-wise T-slot, extra-wide bed feet and an entirely different and simpler design of apron with a single vertical lever to select and engage power cross feed. Although driven by a key riding in a slotted leadscrew, as on the South Bend original, on the Joinville the apron mechanism was not used to provide a geared-down sliding feed along the bed - this being left to the screwcutting gearbox and leadscrew. |

|

Brazil was a country that used both inch and metric measurements in engineering and the screwcutting box on the Joinville was arranged for English-pitch threads. The screwcutting plate on the changewheel cover was engraved with metric conversion charts and lists of associated transposing gears. |

||

|

|

|

Comprehensive screwcutting chart on the changewheel cover. Like the South Bend original this could not be locked shut nor did it have an inner safety guard. |

||

|

The top slide is held to the cross slide using the standard arrangement of pins pushing screwed in from each side but it was not T slotted for a toolholder - instead the present owner has fitted a solid post to carry a single toolholder split through one face and so easily adjustable by its clamp bolt. This arrangement, used on the Drummond and Myford M Type lathes, is known in Britain as a "Norman Patent" toolholder. |

|

|

|

One slight difference was the provision of angled oilers on the front face of the headstock. These, as on the South Bend, filled sumps beneath the bearings from which oil was lifted through wicks. |

|

The earliest-known Joinville appears, apart from the flat rear bedway, to have been a straightforward copy of a 1940 South bend "Workshop" lathe |

||

|

|

|

The Joinville headstock spindle bearing |

||

|

|

|

|

|

The completely-different apron of the Joinville. Instead of power being taken to both longitudinal and cross travel this clone had it restricted to the cross feed only - with the clasp nuts providing both the screwcutting and sliding feeds. Although this was a perfectly satisfactory arrangement the original South Bend mechanism was superior in that it gave a geared-down and hence slower rate of sliding feed than could be obtained by use of changewheels and leadscrew. |

||

|

|

||

|

Ace Blomqvist Boxford Hercus Joinville Moody Purcell South Bend 9-inch Home Page South Bend Home 9-inch Lathe Accessories An Unused 9-inch South Bend 9-inch Clones In the Factory Original 1934 9-inch Model 5 Taper-turning Unit the Joinville lathe Manuals Machine Tool Catalogues Belts Accessories Books |

||