|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-Mail Tony@lathes.co.uk

Home Machine Tool Archive Machine Tools For Sale & Wanted

Manuals Machine Tool Catalogues Belts Accessories Books

South Bend 9-inch Clones

The 9-inch and 11-inch Moody Lathe

A suitable handbook is available for these lathes

For South Bend Spares click here

Other South Bend 9-inch Clones

Ace Blomqvist Boxford Hercus Joinville Moody Purcell

Sanches Blanes Sheraton Smart & Brown Storebro UFP

Boffelli & Finazzi Demco NSTC Select (Lin Huan) Parkanson

South Bend 9-inch Home Page South Bend Home Page 9-inch Lathe Accessories

An Unused 9-inch South Bend 9-inch Clones In the Factory

Original 1934 9-inch Model 5 World War 2 Export Papers Taper-turning Unit

South Bend 9-inch Catalogs

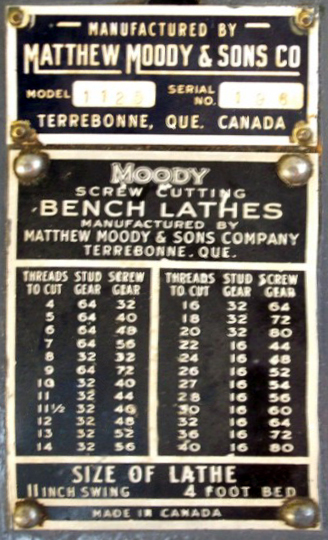

Founded by one Matthew Moody, an Irish émigré who moved to what was then Lower Canada (now Quebec), by 1833 he had established a blacksmith shop in Terrebonne, about 40km North of Montreal. By 1845, and obviously prospering with an established family, a new enterprise was underway, Matthew Moody & Sons a maker of agricultural equipment. During the 20th century, they appear to have made a range of metal and woodworking machinery including metal lathes and wood planers, eventually increasing their range by badge engineering a range of American machines.

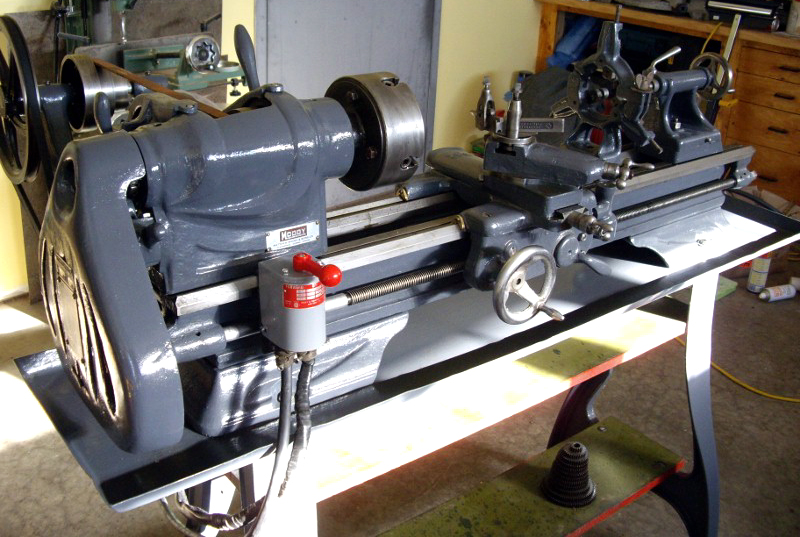

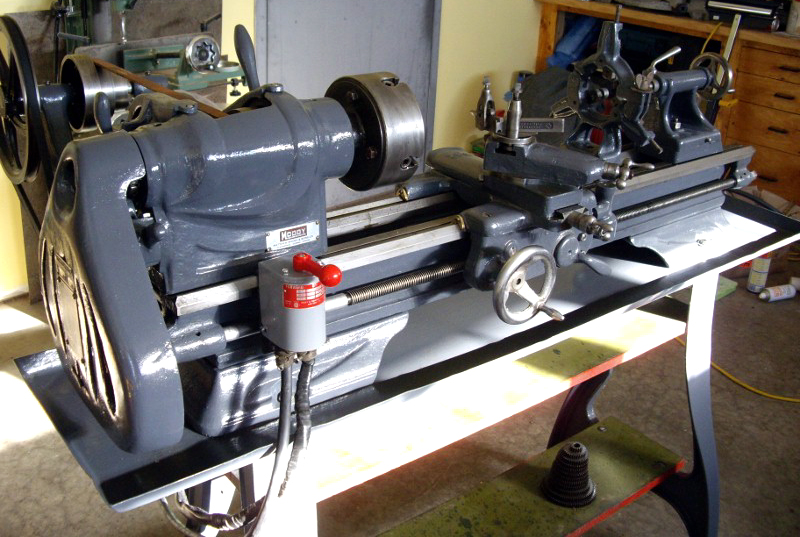

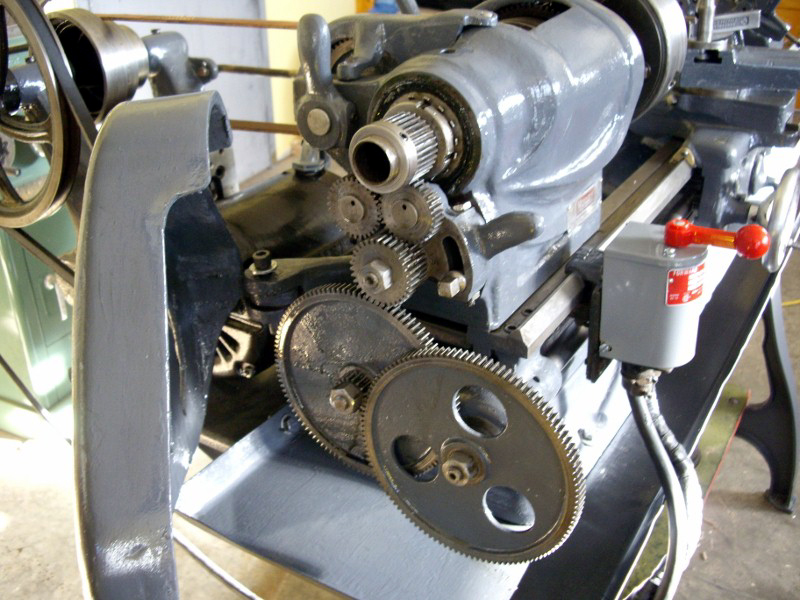

A copy of the South Bend 9-inch, the Moody must have begun life as a 9-inch machine - the swing eventually being increased to a more useful 11 inches (5.5-inch centre height). In comparison with the South bend, a distinctly different headstock assembly was fitted, this having its front face fully enclosed (and so stiffened) with the large-bore spindle running in roller races. While the headstock (like that on the English Boxford) was a marked improvement on that used by the original South Bend, the remainder of the design, apart from those changes necessary to compensate for the increased centre height and weight, looks to have been very much left alone. On later 11-inch model the saddle, cross slide and top slide castings were increased in thickness - necessary to raise the cutting tool to the correct height - and the idler and leadscrew gears in the changewheel train both had to be increased in diameter, a change that had the benefit of allowing a finer rate of carriage feed to be set up. The tailstock and carriage handwheels had a rather delicate appearance and seem to have been pressure cast in ZAMAK - but are reported to have been in cast iron, though with (apparently) very little machining required to clean them up; perhaps the reality is that both types were used.

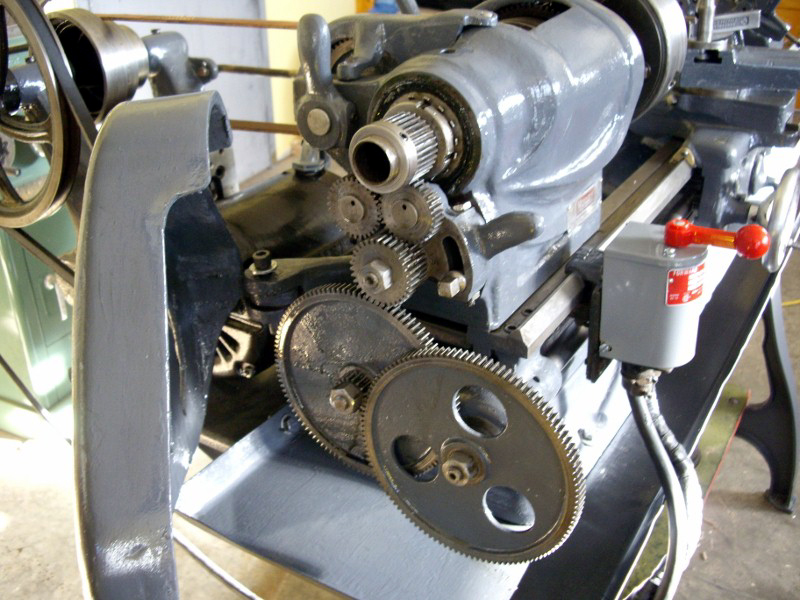

One small but significant improvement was the use of a clevis end on the changewheel guard support arm, a modification that would have prevented the recurring tendency of the original to flop down as the metal packing around its mounting pin compacted. Unfortunately, even the frustratingly small micrometer dials of the original compound slide rest were retained - with other unmodified parts including the hardened square-headed nut for the saddle clamp, the exact shape of the leadscrew clasp-nut lever and the tumble-reverse lever with its inconvenient bolt instead of spring-indexed location. One interesting modification by Moody was the scrapping of the very short bed feet used by South Bend and their replacement by much longer items along the lines of those long-used used on the ubiquitous American 10-inch Atlas.

The Moody Countershaft was almost identical to the South Bend but used a V-belt pulley on both the motor and countershaft with final drive by a flat belt.. On the South Bend an unusual though very effective arrangement was used, a narrow flat pulley on the countershaft and a V-pulley on the motor - this relying upon the great wrap-around of the V-belt to provide sufficient friction.

If you have a Moody lathe of any kind the writer would be pleased to hear from you..ess of the confusion surrounding the literature, the Burgeon has always had a particularly pleasing cosmetic finish with the main components painted in beige enamel and other surfaces nickel plated.

If you have a Moody lathe of any kind the writer would be pleased to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

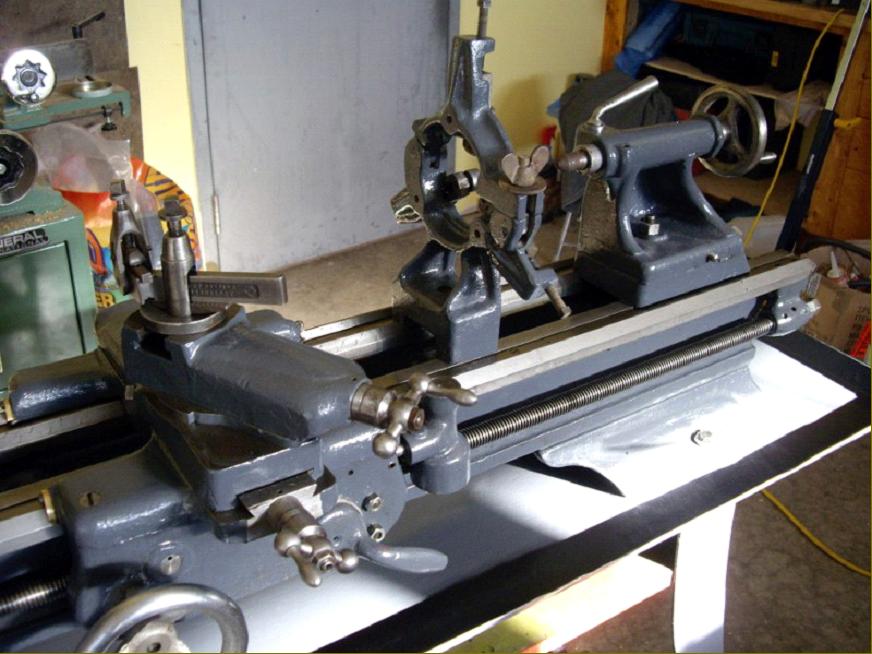

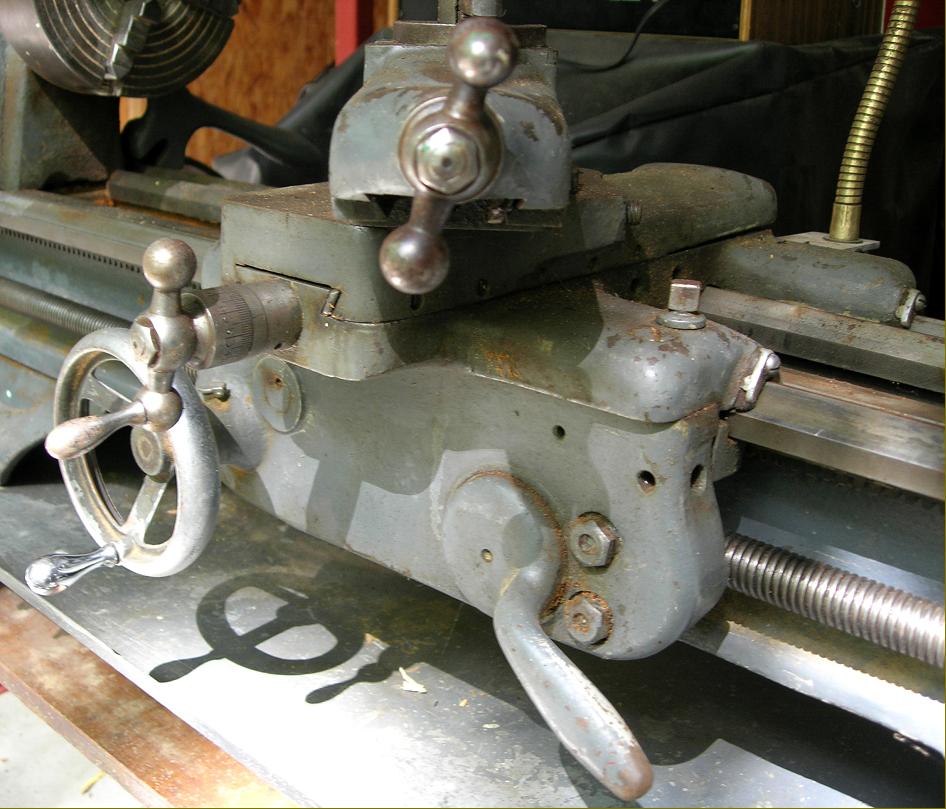

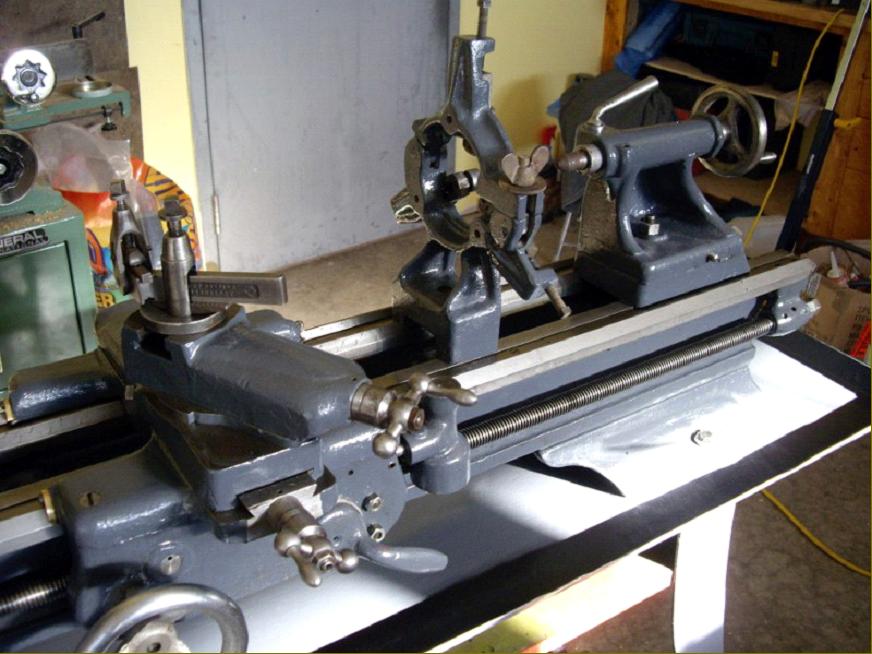

While the whole lathe is largely traditional 9-inch South Bend in appearance, the design of the bed feet looks to have been borrowed from the American 10-inch Atlas

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Moody Countershaft - almost identical to the South Bend but a V-belt pulleys on both the motor spindle and the driven spindle on the countershaft. On the South Bend the makers used a narrow flat pulley on the countershaft and a V-pulley on the motor - this relying (effectively) upon the great wrap-around of the V-belt to provide sufficient friction.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

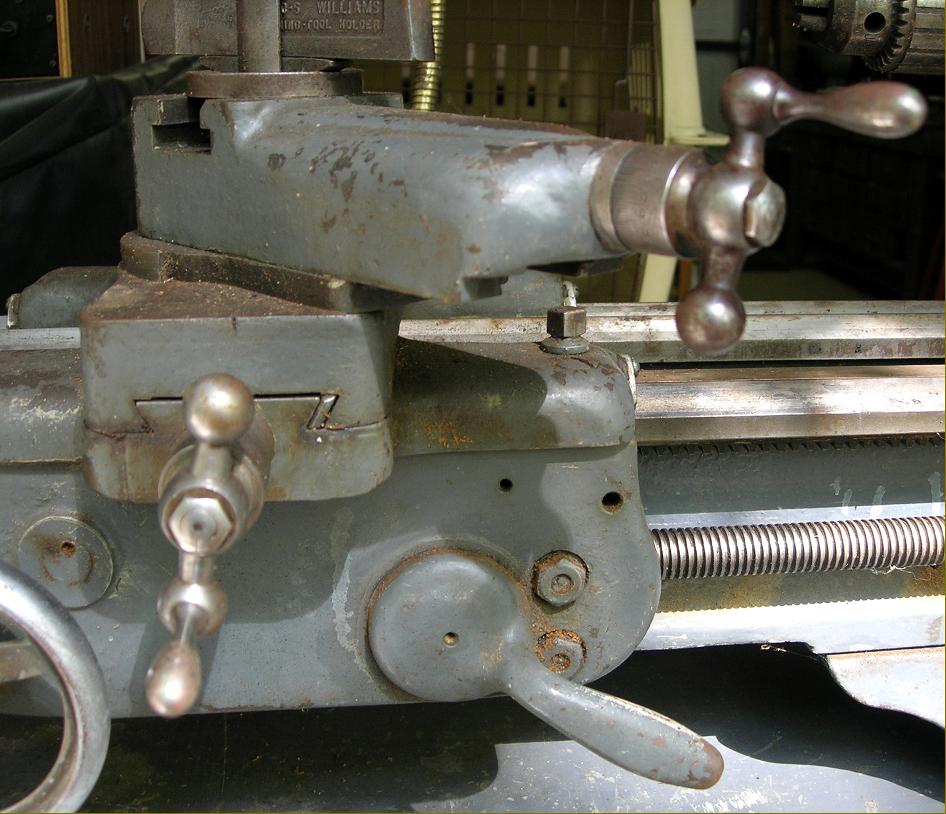

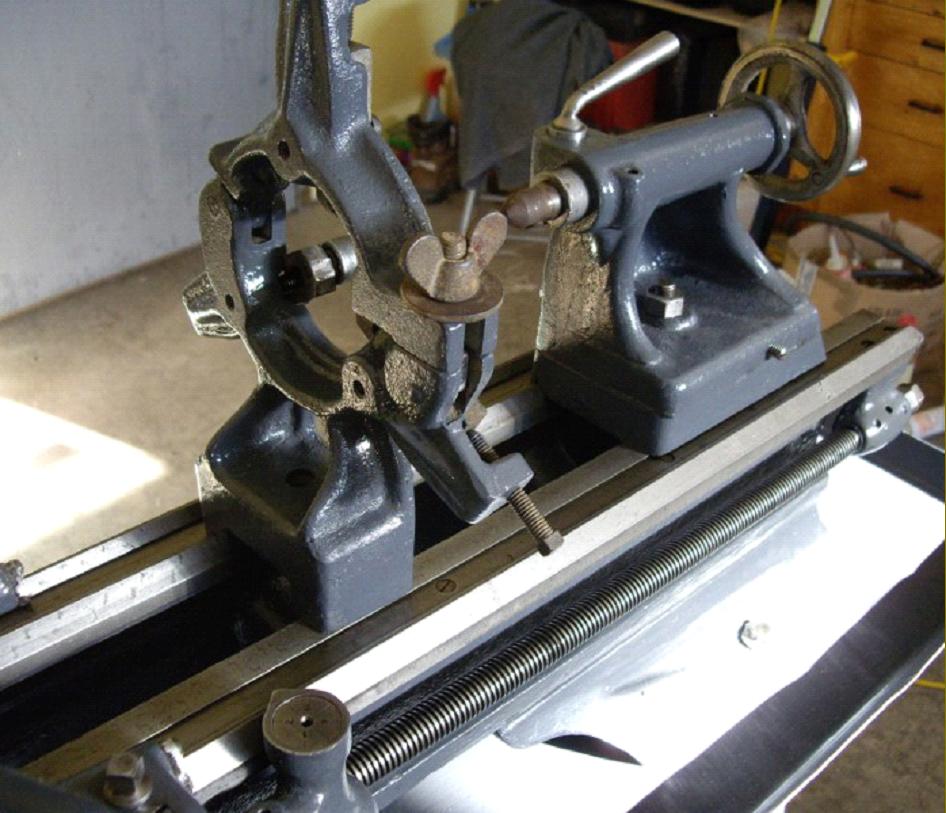

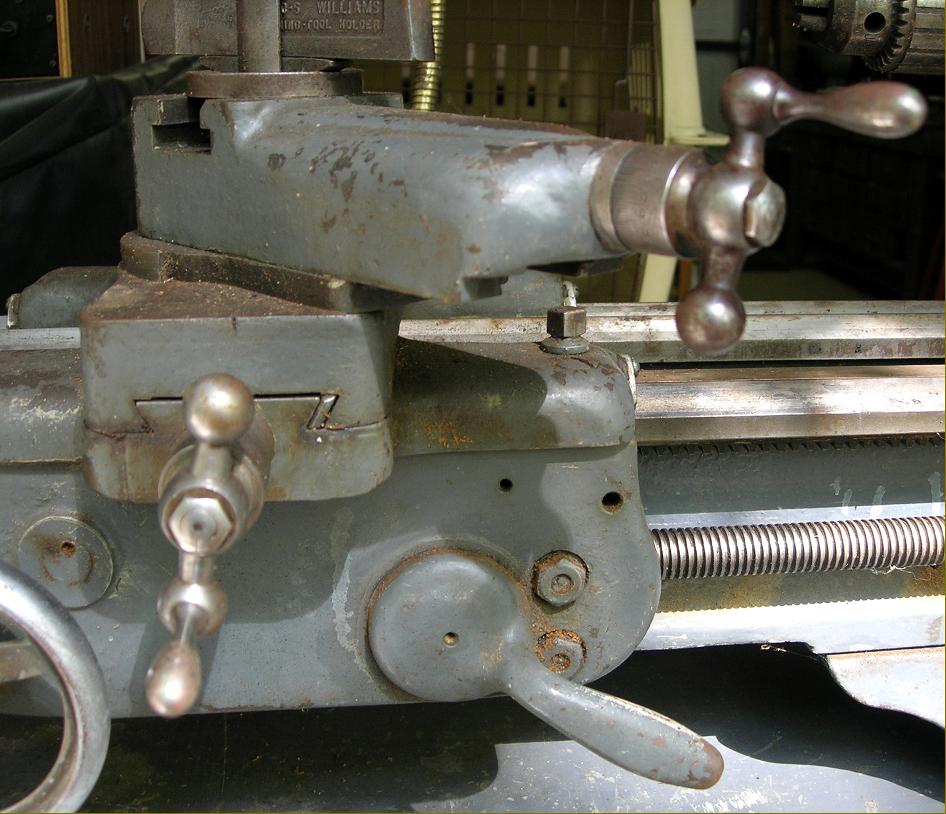

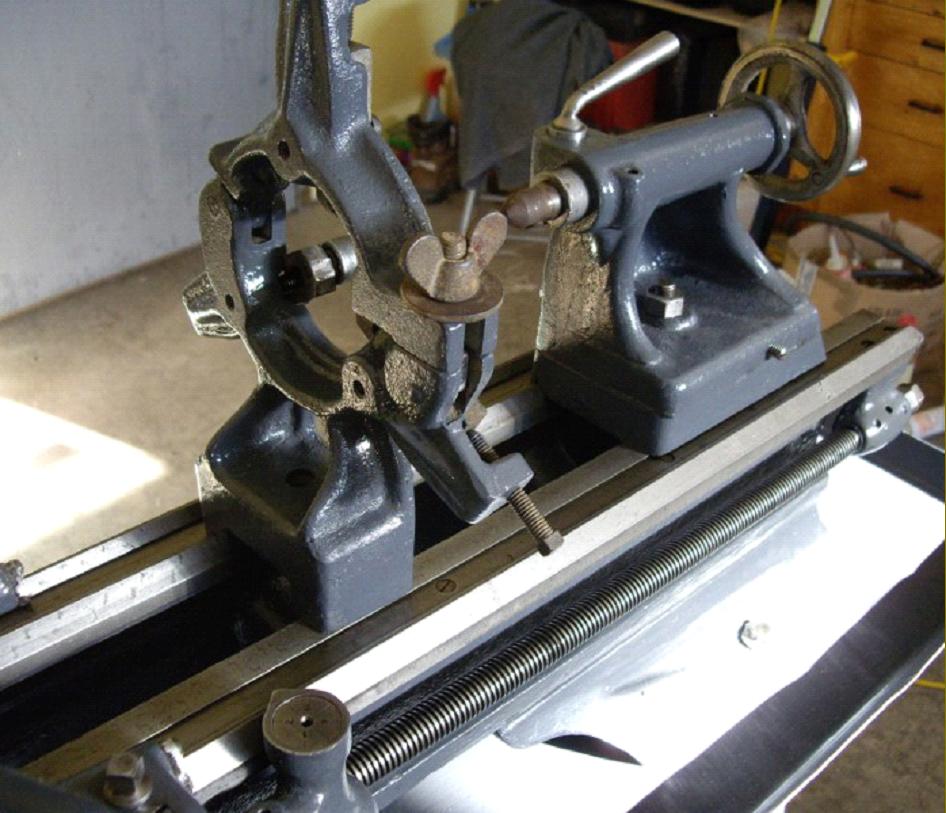

The tumble-reverse lever, with its inconvenient bolt instead of spring-indexed location, was carried over from the South bend to the Moody. Note the clevis end on the changewheel guard support arm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

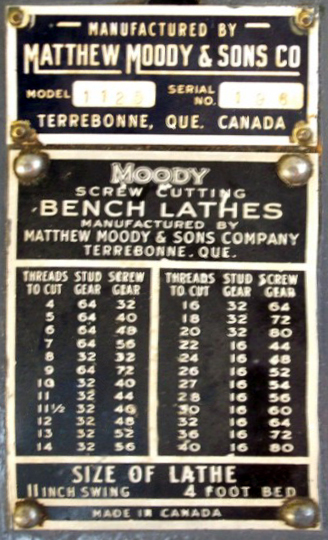

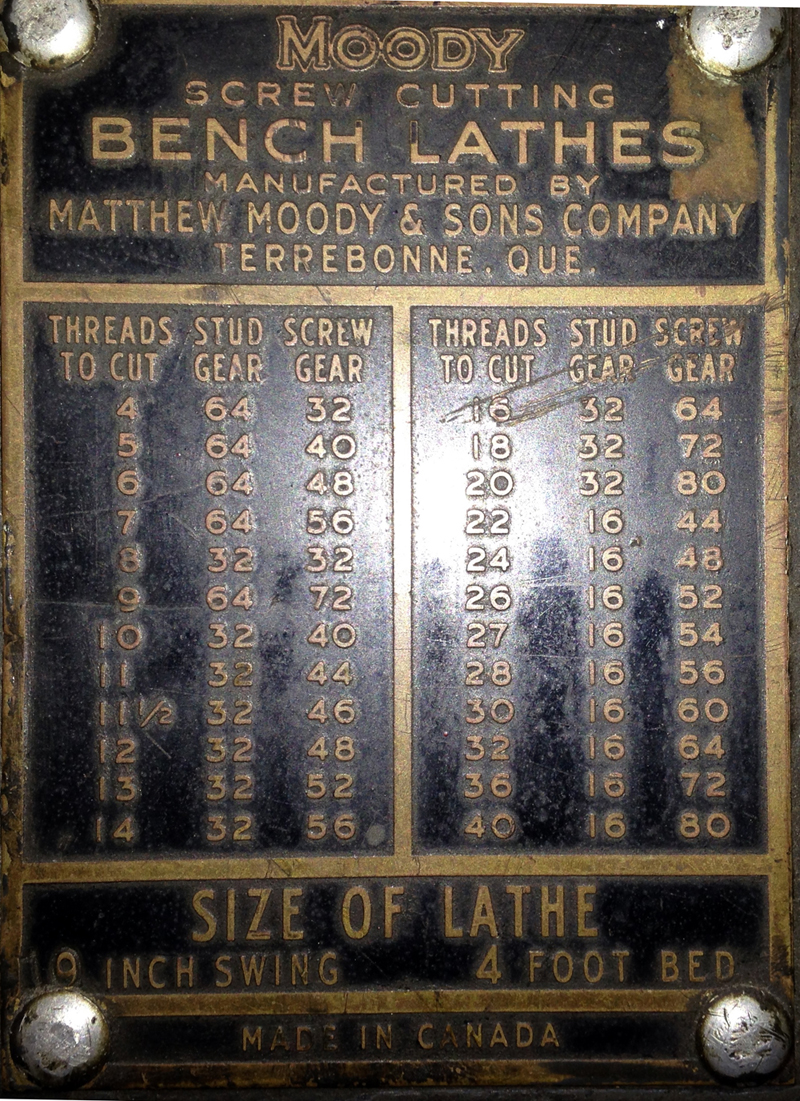

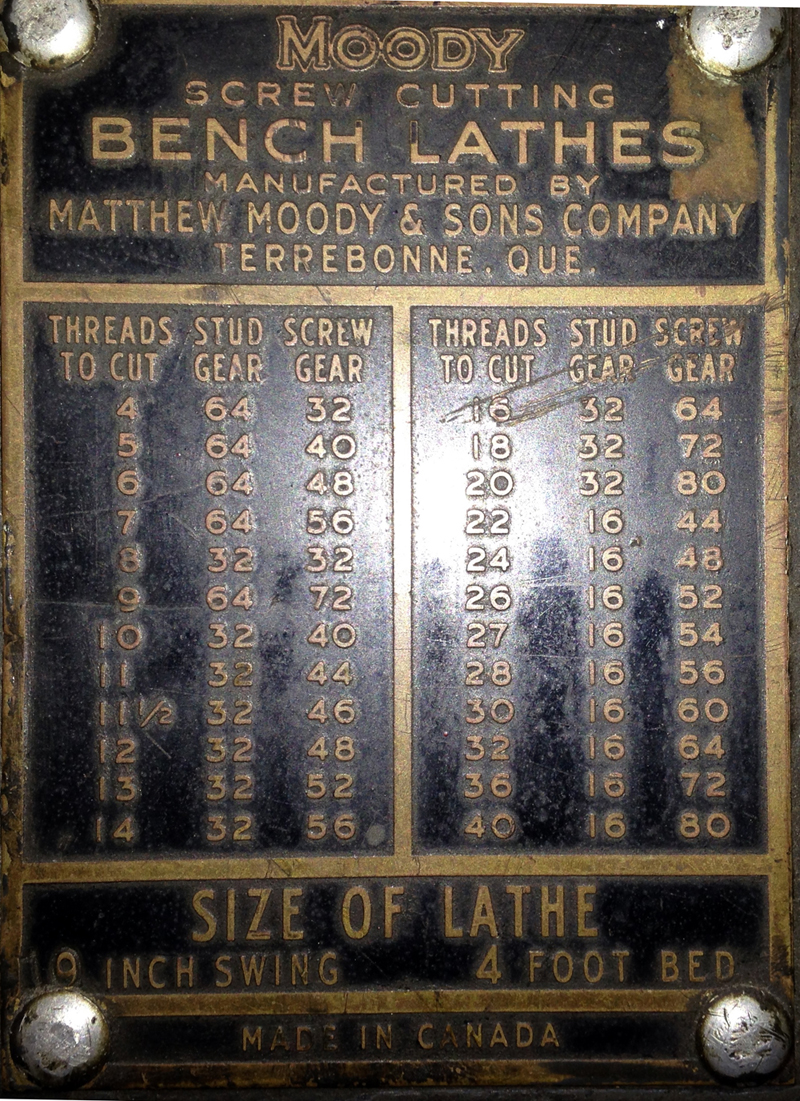

Screwcutting charts for the 11-inch Moody on the left and, on the right, the 9-inch. Both were identical

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

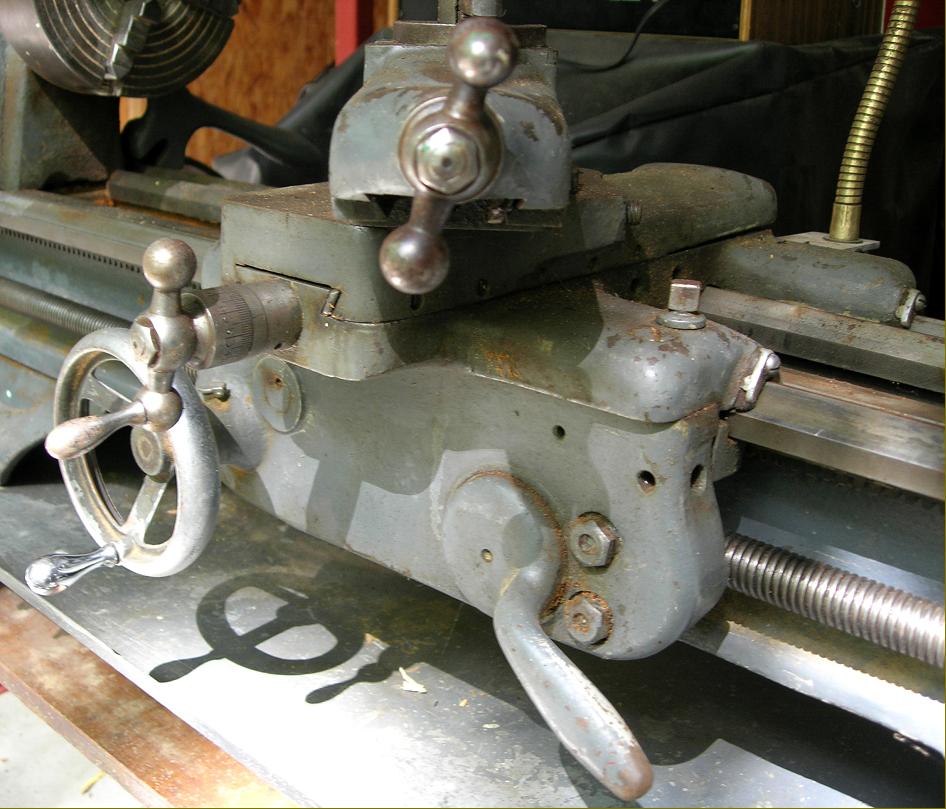

In order to lift the cutting tool to the correct 5.5-inch centre height the saddle and both cross and top slides were thicker than those on the original 9-inch model. The tiny micrometer dials of the original were retained, as were even such minor details as the square-headed nut for the saddle clamp and the exact shape of the leadscrew clasp-nut lever. Although the tailstock and carriage handwheels had every appearance of being cast in ZAMAK (with a rather delicate appearance) they are reported to be in cast - though with very little machining to clean them up. Possibly both kinds were used….

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another view of the noticeably deeper top and cross slide castings used on the Moody

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tailstock handwheel - surely, this must be a ZAMAK casting?

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The length and mass of the long bed foot is clearly evident in this picture

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

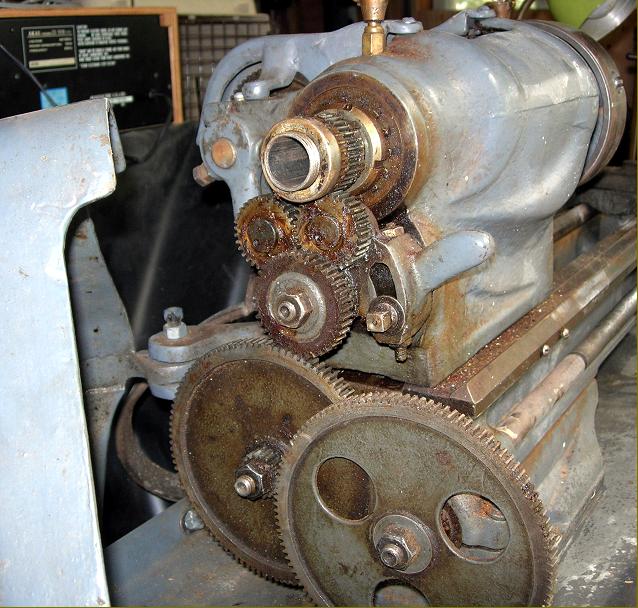

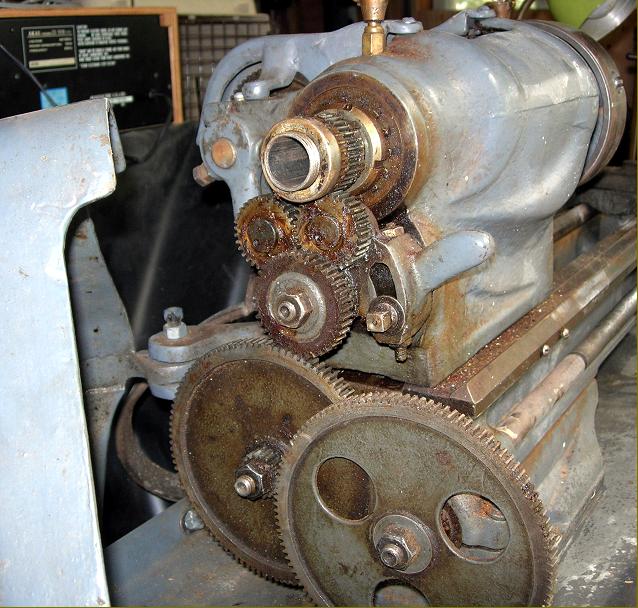

Evident in this picture is the standard South-Bend-like eccentric-spindle backgear assembly

and over-centre countershaft handle and the novel clevis end on the changewheel guard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A clear illustration of the mass of the Moody headstock with its large frontal bulges to clear the backgear and pulleys

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ornately styled changewheel guard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|