|

Home Machine Tool Archive Machine-tools Sale & Wanted & Milling Machine Headstocks Not as common as one might expect - especially given its compact dimensions and the transformation it can make to a lathe or millers capabilities - the compact epicyclic (or planetary) slow-speed mechanism often built into their main-spindle drive pulley, has been fitted to machines as diverse as very expensive the Swiss Mikron and various bargain-priced American Craftsman models. Once installed this clever arrangement gives a range of slow speeds that allows screwcutting, the facing of large diameters or heavy milling work to be undertaken with a greater chance of success. Consisting of three main elements the mechanism comprised: a small "sun" gear attached permanently to the drive pulley, a "carrier" with three planet pinions and a large "annulus" gear. The pulley, together with its "sun" gear, was not attached to but free to rotate on the headstock spindle. On the outside was a large "annulus" gear, cut into the inside surface of a short cylinder, this being either part of the headstock pulley or a separate housing, so that its teeth faced inwards; this assembly was also free to rotate on the spindle. The "sun" gear on the 3-step pulley engaged simultaneously with the three "planet" gears (called pinions because they meshed with a larger gear) mounted on studs attached to a carrier plate that was both keyed (permanently) to the spindle and locked (temporarily, by a sliding block or pin of some sort) to the annulus gear. Because the carrier was both keyed to the shaft and locked to the annulus gear, non of the gears could rotate and turning the pulley caused the spindle to rotate - so giving a direct drive. However, depending upon the design, sometimes other gears were locked to make the system operate, for in any of the arrangements, one of the three gears sets has to be held stationary so that one of the other sets can act independently as an input - and the third set independently as the output. In the case of the Craftsman 109 lathe it was the annulus gear that was prevented from rotating by a 2-position indented pin passing through the front face of the headstock into its face. The carrier had either one - or, more conveniently on some version--six slots cut in its periphery into any one of which a block - sliding in a slot cut in the face of the annulus gear - could be engaged and so lock them together. The block was clamped in place by a bolt and slackening this let the block slide out of engagement and so allowed the carrier and its planet pinions to rotate. With this new arrangement turning the pulley caused the "sun" drive gear to rotate the "planet" pinions these meshing with the large annulus gear and so reducing the drive ratio. When you see the mechanism in action, its function is obvious - though tortuous to explain. |

|

|

||

|

The whole of the epicyclic gear assembly from the Craftsman. On the left the annulus gear, free to rotate on the spindle: in the middle the carrier plate keyed to the spindle with its 3 "planet" pinions: on the right, and also free to spin on the headstock spindle, the 3-step pulley with its attached "sun" gear. |

|

The carrier plate with 6 slots in its periphery to accept the sliding block that locked it to the annulus gear |

|

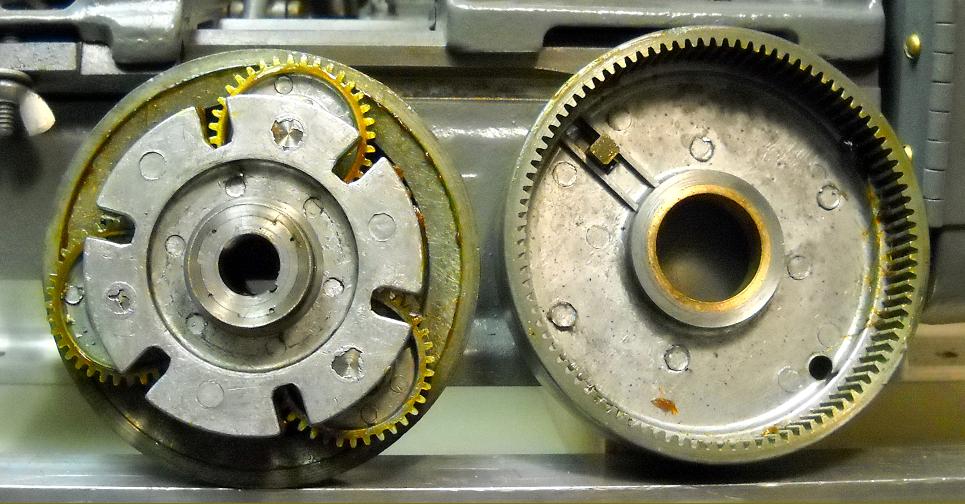

On the right the annulus gear showing the internal gear teeth and, at 10 o'clock, the sliding block that locked into the carrier planetary gear. On the left, the carrier plate fitted into the V-belt pulley assembly |

|

|

||

|

Two-position indent pin on the face of the headstock used to lock the annulus gear |

|

|

||

|

|

||

|

Swiss Lesto (Cintra, Scintilla, Blasi and INCA) lathe had an ingenious and compact epicyclic speed-reduction unit fitted to the shaft of the electric motor. The large black plastic knob was pushed and pulled to engaged and disengage the slow-speed setting |

|

|

|

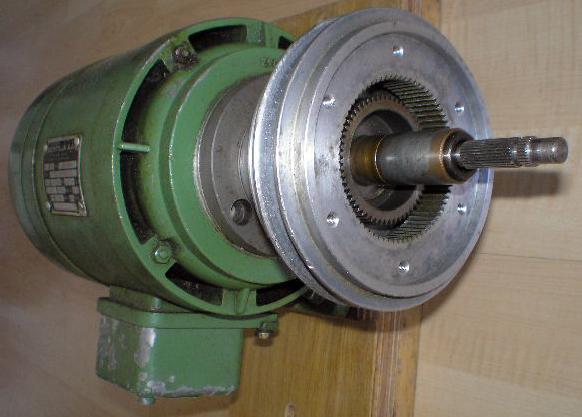

Mikron F75 precision milling machine with an epicyclic gear built into the spindle pulley. Not for Mikron a simple push-in-and-out pin to secure the annulus gear, the pin was moved by rack-and-pinion gearing, the control knob being the small knurled-edged boss protruding from the front face of the headstock. Home Machine Tool Archive Machine-tools Sale & Wanted & Milling Machine Headstocks |

||