|

Home Machine Tool Archive Machine-tools for Sale & Wanted Precision Toolmakers' Lathes - and Types LL, LLG, LLP & LLPF - More information about Lorch Lathes is contained in various Manuals, Parts Lists and well-illustrated Sales & Technical Specification Brochures and can be purchased on-line here |

||

|

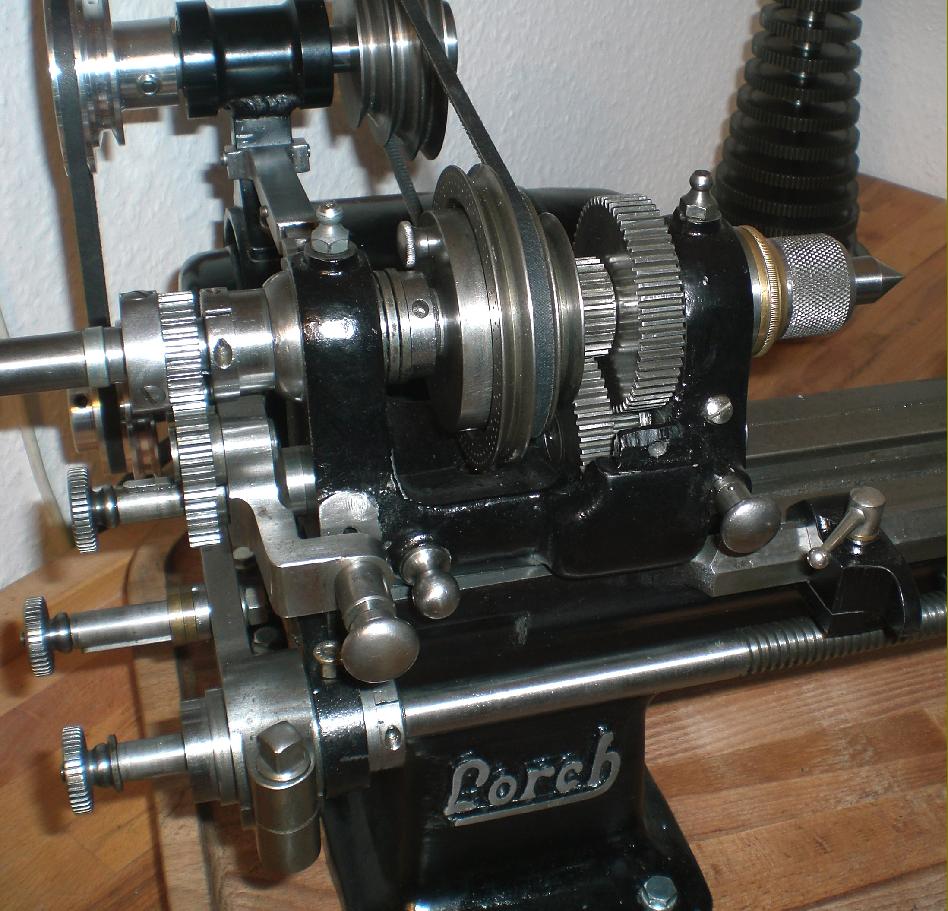

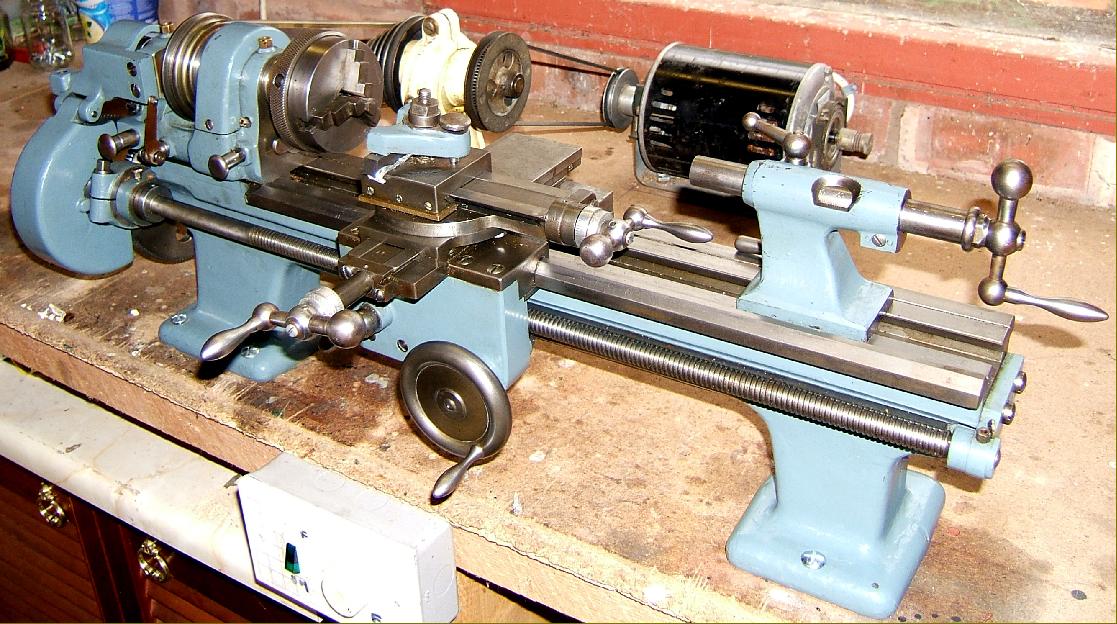

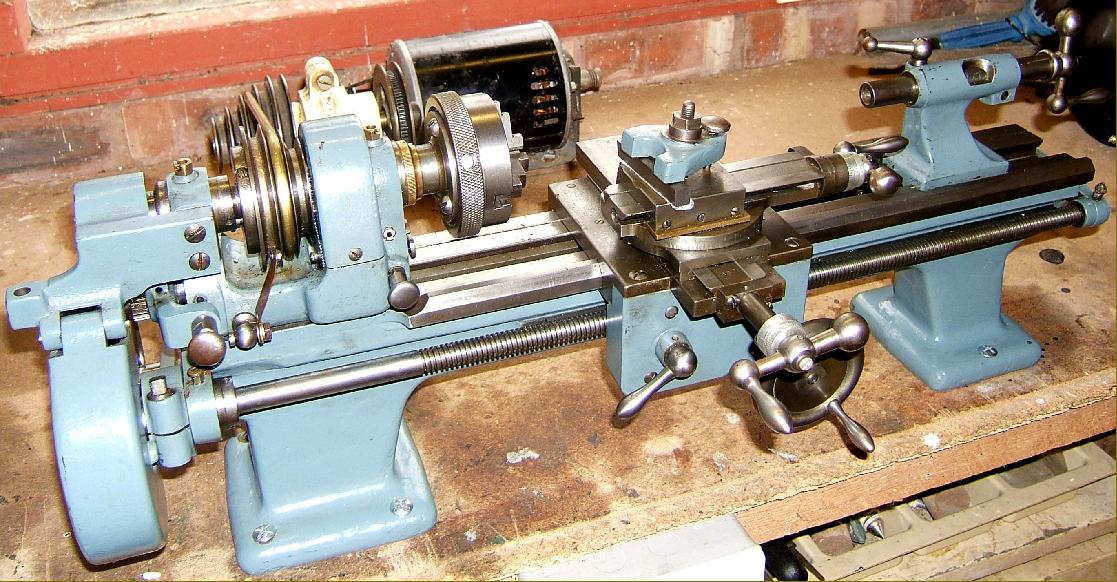

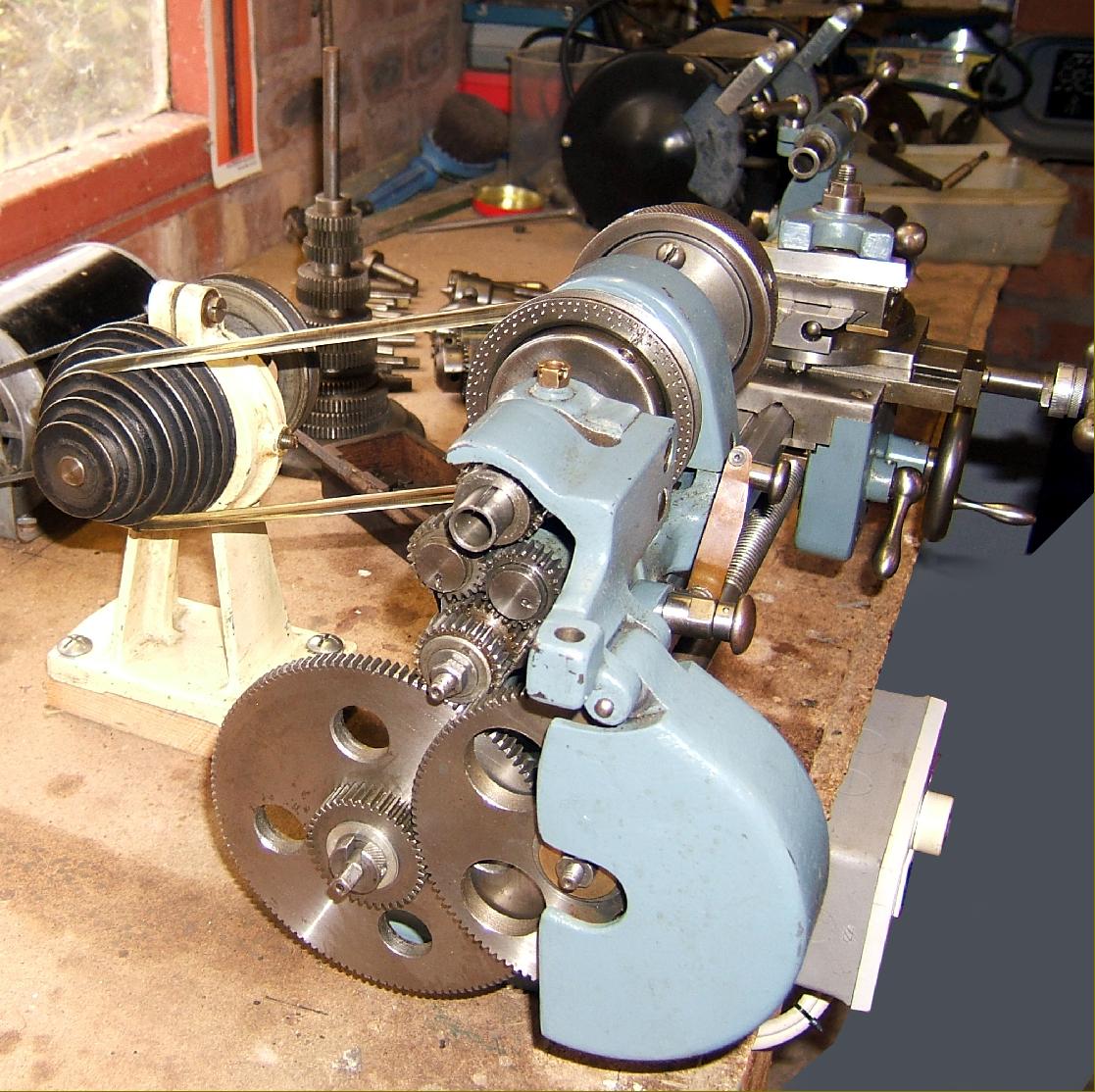

Starting life in the early 1900s, the Lorch LL range of lathes was developed steadily over many years and even continued, with various suffixes (LLV, LLS, etc.) into the 1950s. Superbly made, to the highest standards, it was the smallest of the company's plain-turning precision toolmakers' models to have a version fitted with backgear and screwcutting (by leadscrew) and a tumble reverse unit. By retaining the usual long-travel top slide it was able to maintain the advantages of the ordinary "bench precision" (fine turning by hand) type whilst being a much more practical and adaptable machine. First listed as the Model LA it was to become, when fitted with better guarding of the gears and other small changes, the LAN. Retaining the same 65 mm centre height as the plain-tuning lathes in the series, the LA/LAN shared a number of headstock and tailstock components - but there the resemblance ended. Clustered together at the right-hand end of the spindle, the backgears were set beneath the spindle line, producing a neat, compact arrangement (as also used on the post-WW2 Myford 7 Series). With a 1 : 6 reduction, the backgears combined with a 3-speed headstock pulley and a 2800 rpm motor carrying a 2-step pulley to provide 12 spindle speeds starting at a rather high 75 and extending through 105, 150, 210, 300, 415, 450, 630, 900, 1250, 1800 to a maximum of 2500 rpm. Of 3 mm pitch, the leadscrew (accurate to 0.02 mm in a length of 200 mm) was driven by changewheels through a tumble reverse mechanism; the full set of gears consisting of: 18, 20, 22, 25, 26, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90 and 100t. Whilst changewheel guarding on the LN was non existent, the LAN was fitted with a very heavy cast-iron cover that shielded just the front section of the gear train. |

|

|

||

|

|

||

|

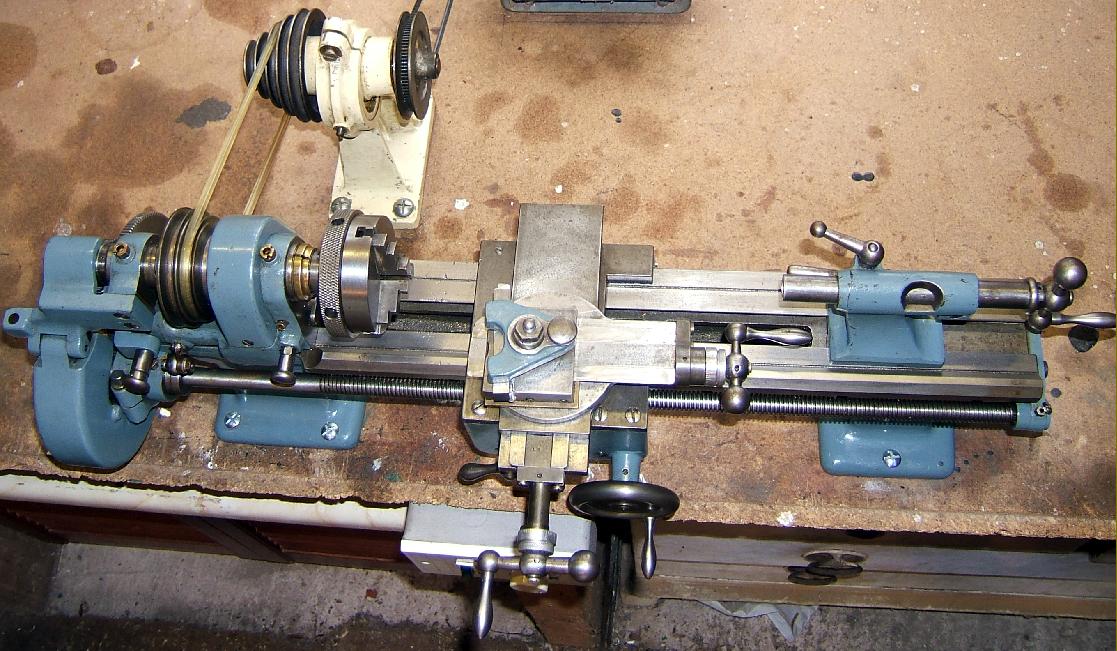

Lorch LLPN with the headstock arranged for "chase screwcutting" where the entire spindle was induced to move backwards and forwards under the influence of a Master Thread - or hob - held on an extension to its left-hand end. This restricted the machine to short - but very accurate threads - and was intended for use in the optical and instrument industries. |

||

|

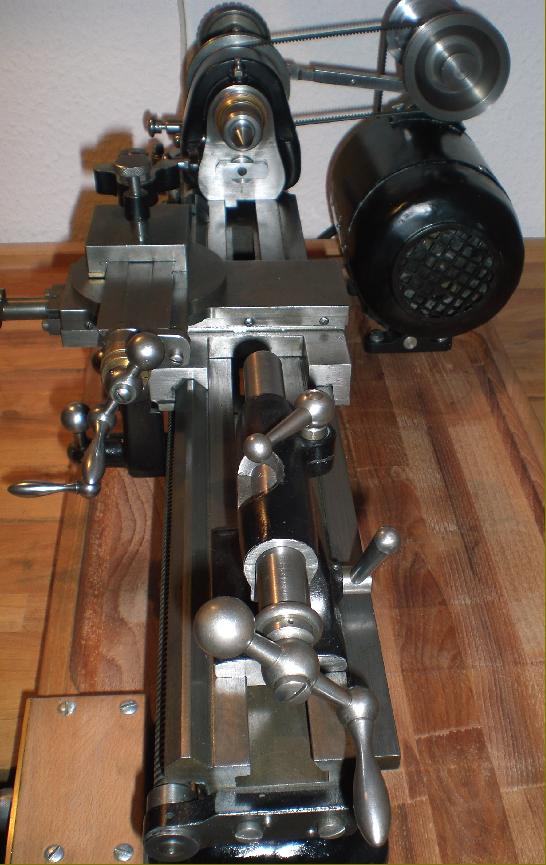

The Lorch Model LAN fitted to the wooden bench top No. 38 and driven by the table countershaft unit No. 43a. |

||

|

|

||

|

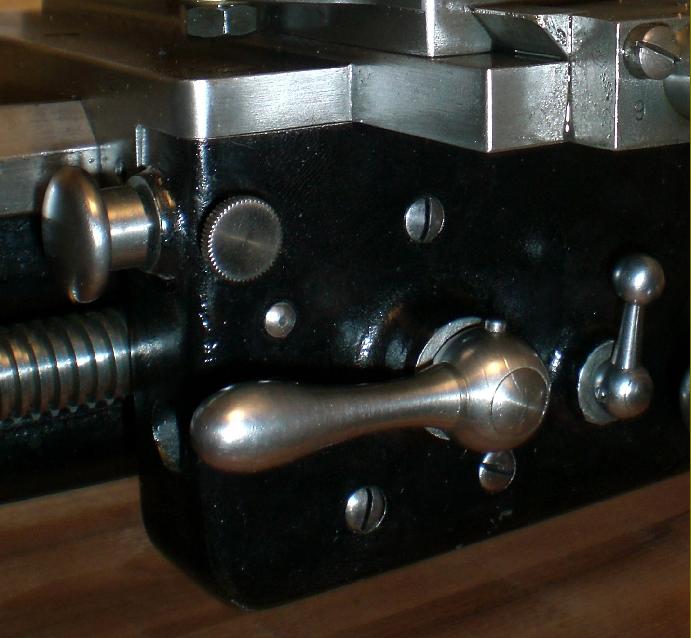

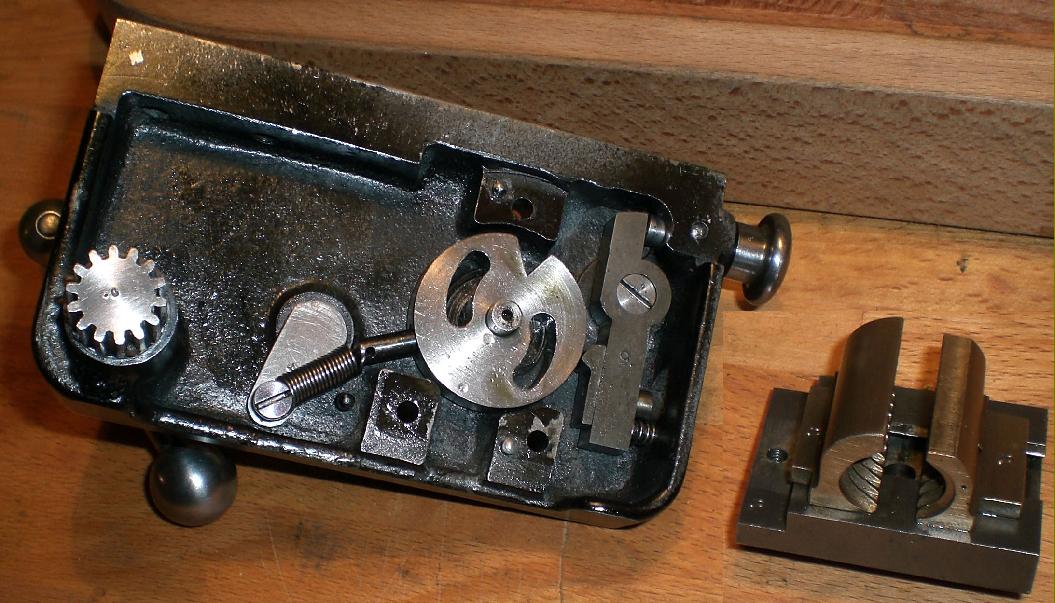

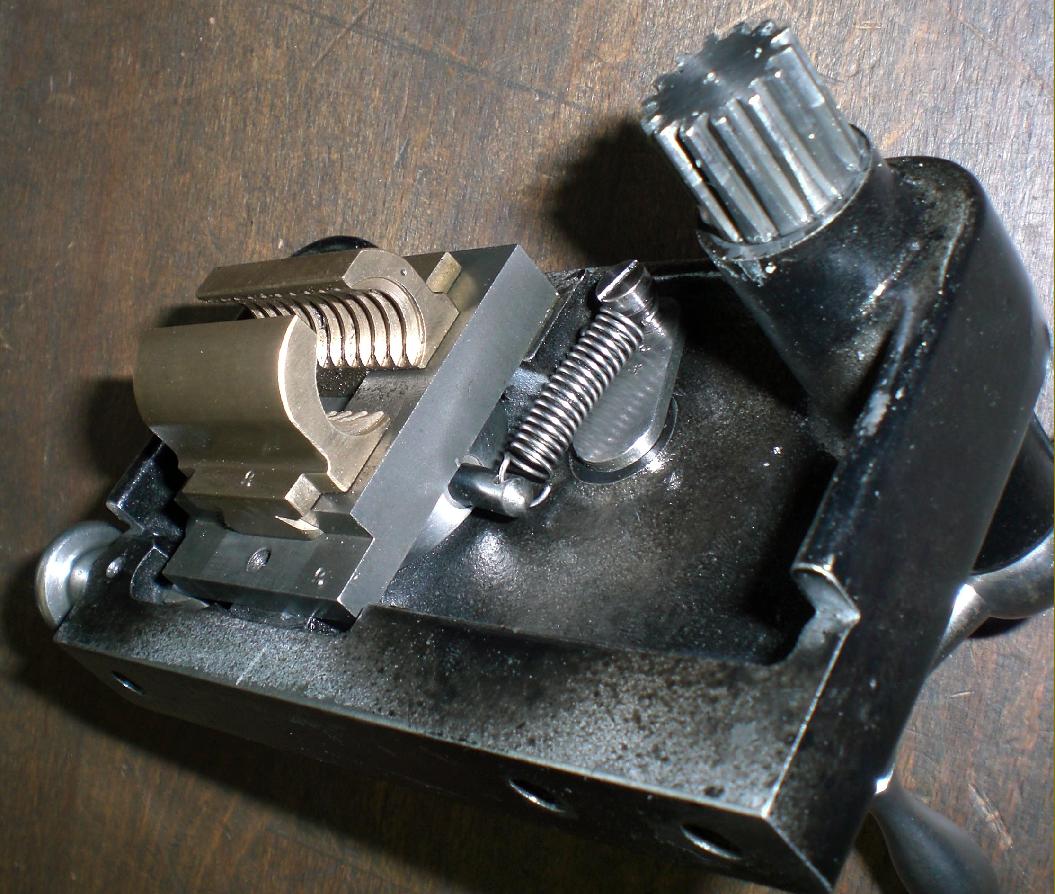

that pressed against the clasp-nut closing cam and, separately, the bolt-on carrier for the bronze clasp nuts. |

|

|

|

|

|

|

|

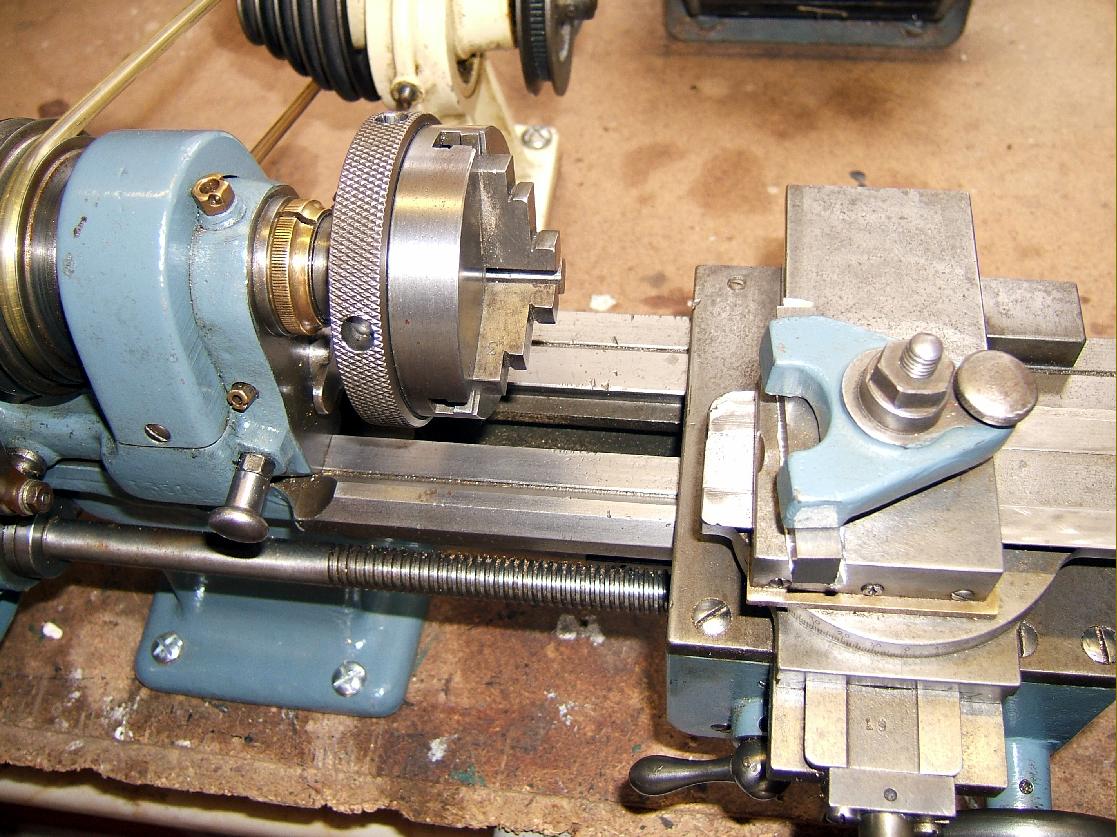

Although the carriage was guided by a conventional V and flat way on this model Lorch used a special form of guidance to retain the headstock and tailstock that consisted of a vertical face together with an angled way cut into the underneath of the slot that ran down the centre of the bed. The arrangement can be seen above. Note the 3 circles of division holes in the outer face of the largest headstock pulley. |

|

The location method of headstock and tailstock can also be clearly seen in this photograph. Note the full-length cross slide. |

||

|

|

|

|

|

|

||

|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories Precision Toolmakers' Lathes - and Types LL, LLG, LLP & LLPF - and well-illustrated Sales & Technical Specification Brochures and can be purchased on-line here |

||