|

Constructed in the style of the already established and very successful 7.5-inch centre height Triumph 2000 and 8.5-inch Mascot 1600 models, the 6.5-inch (165 mm) centre height Student 1800 (together with its close cousin the Master 2500), continued Colchester's traditional use of two names that had been synonymous with lathes of an almost perfect design and capacity. Especially suitable for both training and professional workshop use, the lathe was copied--rather well - in Taiwan and sold as the Liberty 1300 and Dashin 1440.

As with older Student and Master Models, the two lathes shared the vast majority of their components and had only small but nevertheless significant differences in their specifications - all of which, in the case of the newer machines, centred on the headstock and drive system. The model number of each lathe referred to its top speed that, in the case of the "Student 1800", was reached with a 2.2 kW (3 h.p.) motor and a direct drive by twin V belts into an all-geared, splash-lubricated headstock.

Induction hardened and ground-finished as standard, the 9.5-inch (230 mm) wide bed was of the usual Colchester V-and-flat type with separate pairs of ways for the carriage and tailstock. It was available in two lengths that gave either 25 or 40 inches (635 mm and 1000 mm) between centres and both could be had both with and without a detachable gap piece that allowed material up to 19-inches (480 mm) in diameter and 4.5 inch (115 mm) thick to be swung on the (optional-extra) 12 or 18-inch diameter faceplates.

Able to be adjusted laterally on the bed (although before altering the settings the owner was strongly cautioned to consult the owner's manual) the headstock was lubricated by splash with the same oil fed, unfiltered, to the "Gamet Super Precision", pre-loaded and self-adjusting taper roller bearings. The 1.625" (40 mm) bore, 4-in D1 Cam Lock nose spindle was especially rigid and had been designed in conjunction with the British Machine Tool Industry Research Association. When new these lathes were supplied as standard with high-quality chucks made by Burnerd in the UK. Because of the high speeds available it is essential to avoid cheap, unbranded imports, the stresses encountered on top speed when holding large job are considerable. Instead, you are welcome to email for details of quality replacements that we can recommend.

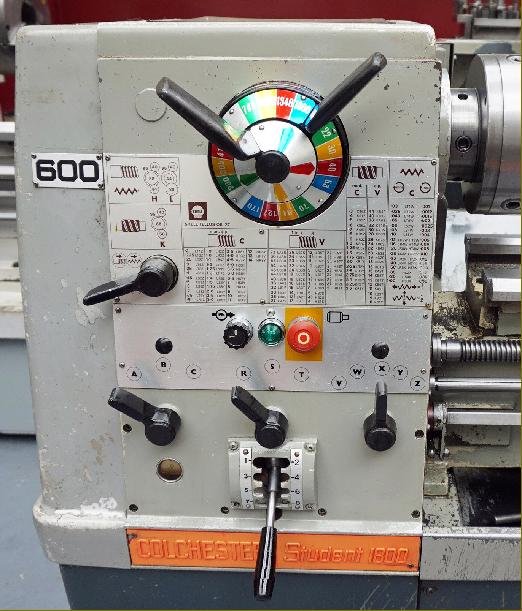

Not all the gears in the headstock were hardened, only those under the greatest strain, but all were ground finished on Reishauer machines. 16 speeds were available that spanned 30 to 1800 r.p.m. with selection by a pair of concentrically mounted paddle levers that worked through an ingenious and compact mechanism, with (for a machine tool) an almost foolproof system of colour coding to indicate the settings. Once the motor had been switched on by the headstock-mounted push-button starter the spindle control was by a single lever pivoted from the right-hand apron wall and working through a 'third shaft' parallel and below the feed shaft and leadscrew and connected by links to a cross shaft that passed through the bed just in front of the headstock . Moving the lever up and down simply switched the motor to forward, reverse and off. With the lathe capable of rotating heavy jobs at high speed a powerful and easily-operated spindle brake was essential and Colchester took the opportunity to reposition its control (formerly combined with a stop/start lever of limited leverage on the headstock front face) to a full-length foot-operated brake bar, interconnected with the motor switchgear, and hinged between the stand's plinths. The lathe was also fitted with a headstock-mounted emergency stop button that operated through the obligatory "no-volt" release (to prevent the motor restarting after a power cut) and a motor-run warning light to alert the hard-of-hearing, or those working in a noisy environment, that things were "active" and the controls not to be played with casually..

Continued below:

|

|