|

Well established by the 1920s - with the Models "1919" and "1920" in sizes 1, 2 and 3 - Aciera of Le Locle, Switzerland offered a number of high-quality miniature drilling and tapping machines intended for the homological, instrument making and similar industries. Of these, the better known are the No.6, No.10 (described below) the E.3 and E.3.T-tapper the 20,000 r.p.m. Servo 7150 and the largest of the smaller sizes, the 13 mm-capacity Type 13

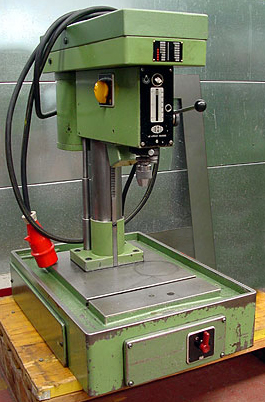

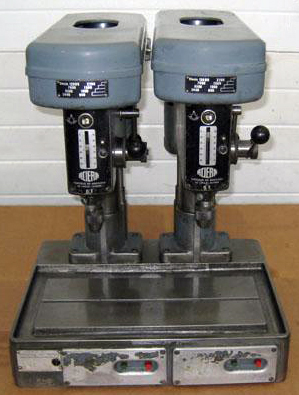

Built in both an early "rounded" style and later with particularly neat-looking more angular lines, the "miniature" Aciera drills-cum-tapping machines were offered as three models, the No. 6, No. 10 and more powerful No. 13 (this being identical, dimensionally, to the No.10) - the numbers representing the maximum drilling capacity in steel. All could be supplied as either simple drills, the 6T, 10T and 13T or, as the 6E, 10E and 13E for tapping - these having a control switch marked with an extra position - "Tapping" - and a double contactor that reversed the spindle direction automatically at an operator-set point. When tapping, the permitted revolutions were marked on the speed chart in red. In addition, an ingenious controlled-pitch tapping model was available that, with a gear housing attached to the quill and interchangeable pitch leadscrews, facilitated making high precision threads into thin or soft materials. A further development was a special model with a form of pneumatic-hydraulic control for use in batch manufacturing or long runs.

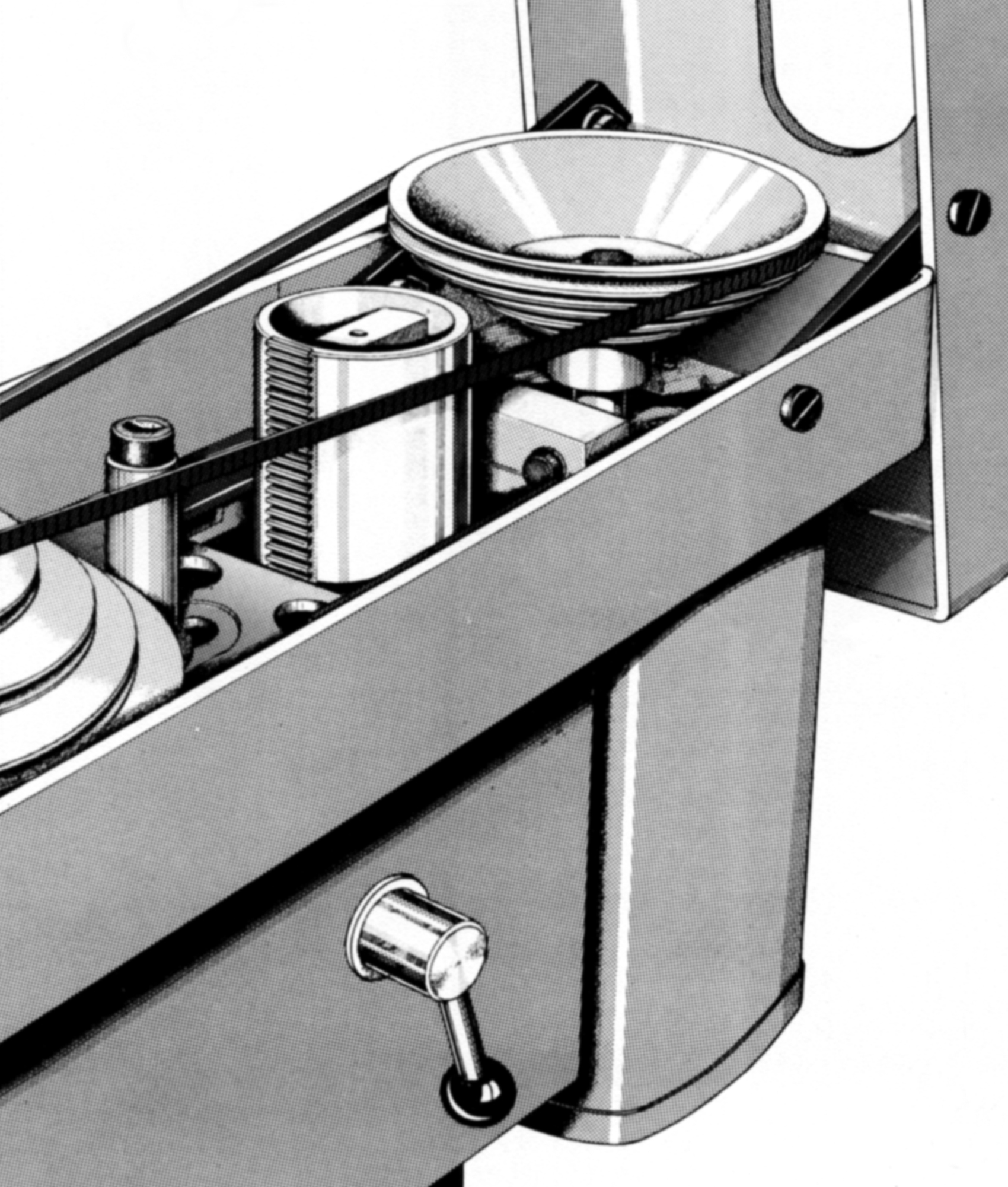

Arranged in a conventional way, with an electric motor at the back driving, by a narrow V-belt, a multi-groove pulley at the front with 8-steps on the No. 6 and six on the No. 10, a particularly wide choice of speed ranges and motors was offered. Some 2-speed motor versions of the No. 6 had sixteen speeds spanning 350 to 12,000 r.p.m. - while a similarly specified No. 10 could have as many as twelve from 175 to 10,000 r.p.m.; the speed ranges and motor availability for both models are shown separately below. Early tapping machines are known to have used a different drive with a flat belt and, generally, two fewer speeds in each range.

While the upper section of the belt-drive guard was arranged to hinge open for the changing of speeds, it did not, unfortunately, automatically release and tension the belt; instead, the lower section had to be manually unlocked by releasing a bolt. Once slackened, the assembly could be slid forwards, the speeds changed, and then pushed back to tension the drive and the bolt retightened.

Rotating in high-class, adjustable ball races, the spindle was held in a hardened and ground quill that ran in a honed bore in the cast-iron body. Quill movement - the No. 6 had a travel of 50 mm, the No. 10 twice as much at 100 mm - was by rack-and-pinion gearing under the control of a single lever, adjustable for length by being slid through its mounting - and also for its initial setting by te use of castellated faces on the inner and outer sections of the mounting boss outboard of the graduated depth-control drum. Drilling depth was controlled by a vertical shaft whose end finished in a knob positioned to the left of the chuck; the shaft was locked by a through bolt and the travel shown on a scale, graduated with both inch and mm ruler marks, on the head's front face. No.6 Drilling machines had a spindle nose with a taper to DIN 238-B12A fitted with a precision chuck while built-in 24-volt light unit - neatly integrated into the head behind the drill chuck - was a standard and useful fitting. The No.10 model could, as an option, have a spindle fitted with a No. 1 Morse taper - in which case the quill was machined with a knock-out slot.

As the drill was intended to be as accurate and as rigid as possible, there was no rise-and-fall table; instead, for a coarse setting, the whole of the drill head was arranged to travel (for 200 mm on the No. 6 and 300 mm on the No. 10) up and down a large-diameter, steel column, machined with a rack into its front face. Adjustment of the head's position was by a crank handle inserted into a square socket on the front face, a clamping lever being positioned to the right, at the rear. The crank did not engage the rack directly but instead - to prevent the head falling under its own weight - through worm-and-wheel gearing with it's usual "self-locking" properties. The rather unusual positioning of the head-lift control on the front face may have been to allow easier access when the drills were mounted in gangs of up to six at a timer on a common base - these versions being known as the K Type.

All versions of the drill were available for mounting on the customer's own bench with a plain table (Types 6T1s and 10T1s) or with a coolant trough (Types 6T1 and 10T1) - the final digit indicating one machine on its own base. When fitted to the maker's sheet-metal stand the type designation changed to 6K and 10K and, if ganged up in a line on a common cast-iron base, the suffix was changed to match fitted e.g. four in line for bench mounting with a coolant trough would been the Model 6T4 and on the maker's stand 6K4 - the same system being used for the Model 10.

Tapping versions required care in set-up and operation - and before using one reference to the operating manual is highly recommended.

Other makers of miniature drilling machines included, over many decades: Worner, Jones and Shipman, Pollard, Meddings (MB10), Servo, G.Boley, Bergeon, Leinen, Oldak and Apex, Derbyshire, Micromecchanica, Flott (TB6), Sloan & Chace, IME, Hauser, Dixi, Cataract, Nora and Precise..

The writer seeks high resolution photographs of all small Aciera drilling and tapping machines. Can you help? If so, do please email

|

|