|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||

|

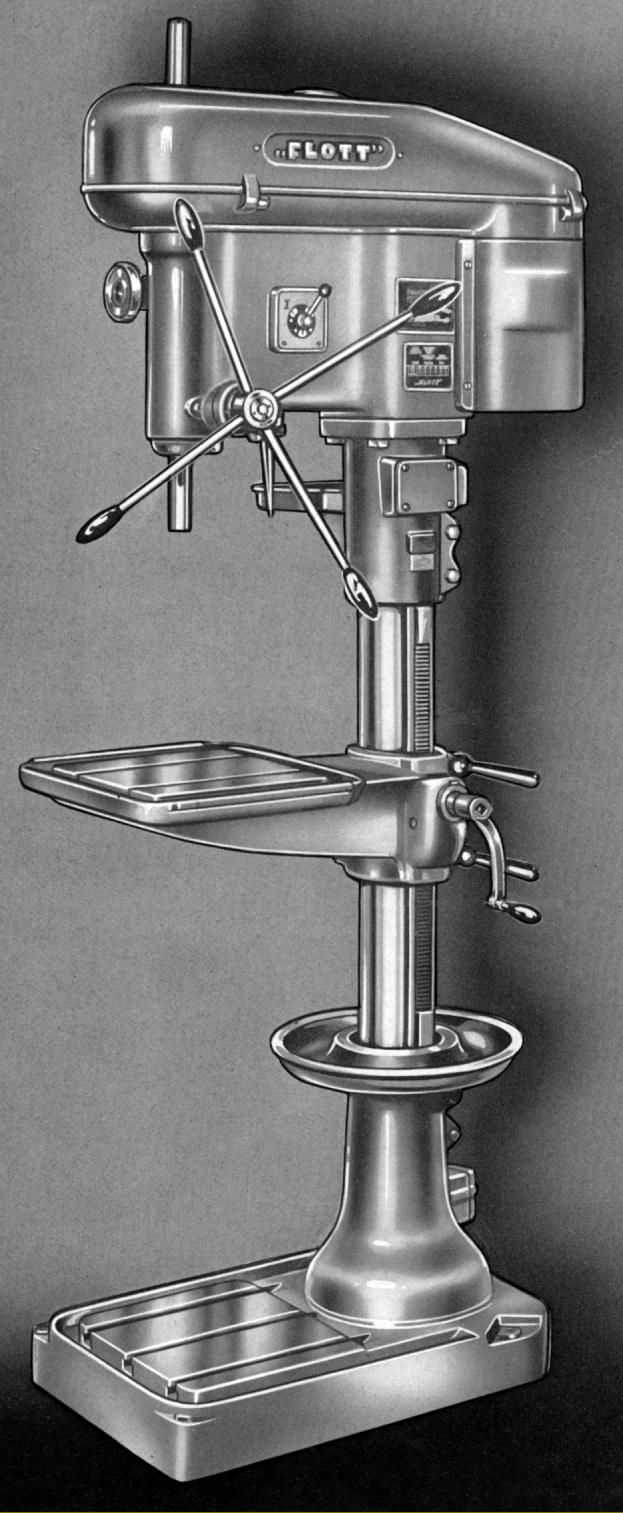

Founded in 1854 - and now the oldest maker of drilling machines in the world - Friedr. Aug. Arnz Flott GmbH + Co. is based in Remscheid, North Rhine-Westphalia, Germany, a town once well known for its expertise in engineering and high-class toolmaking. Today Flott still thrive, export world-wide and offer an especially wide variety of drills as well as band sanders, double-ended grinders, metal saws and special machines. During the 1950s a range of bench and pillar drills was offered, amongst which the more popular appear to have been the small, bench-mounted high-speed Type TB-6 and two floor-standing pillar models: the ordinary V-belt drive SB-23 and the variable-speed SB-23-ST (SB is the Flott abbreviation for a floor drill). |

|

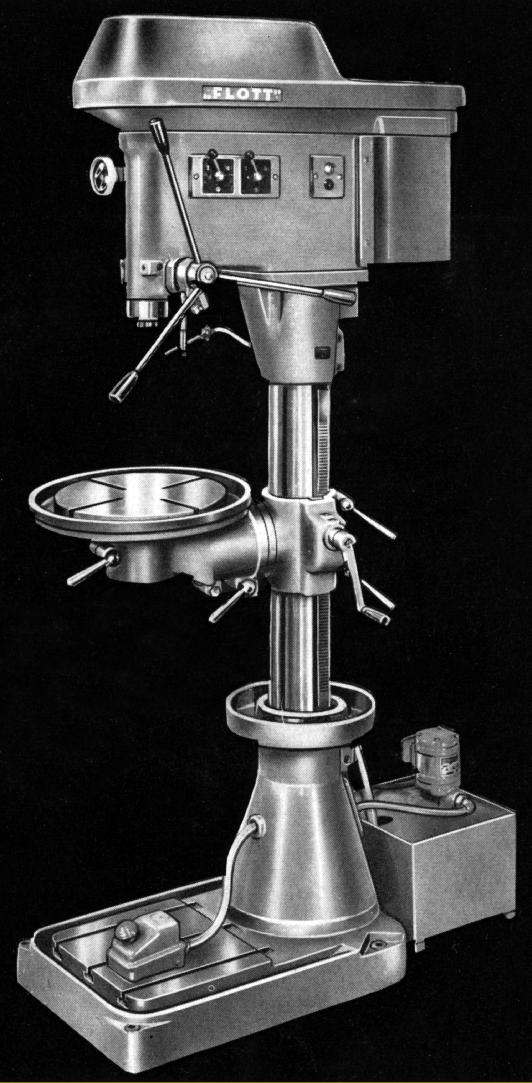

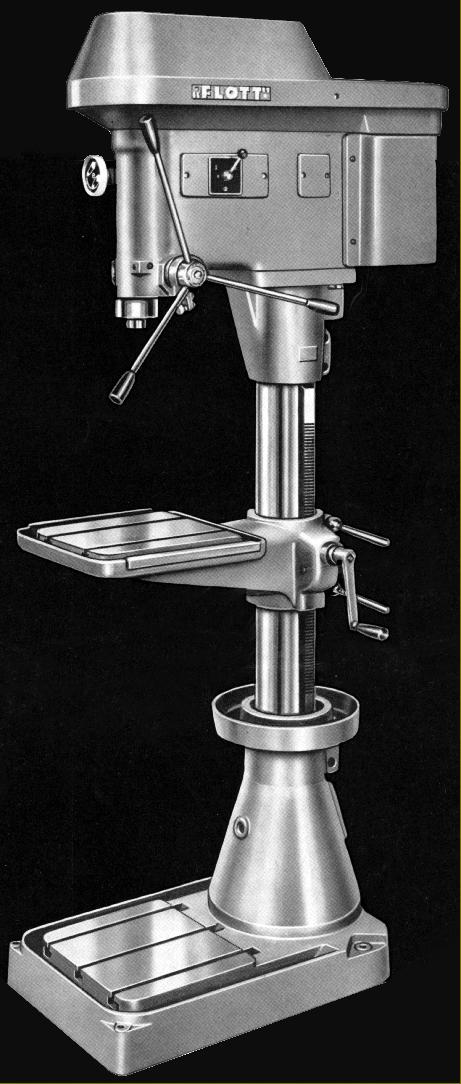

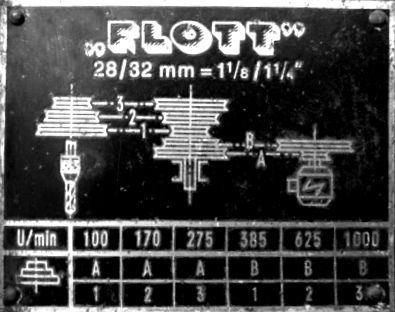

round table and coolant equipment This type of Flott drill used a Poly-V drive, generally with a 2-step pulley on the motor driving forwards to an intermediate shaft with a matching pulley and, above it, a 3-step pulley to drive the spindle. The result, powered by a 1.1 kW 1400 r.p.m. motor, was a range of 6 speeds panning a range from 100 to 1000 r.p.m. As an option, for heavy-duty work, a 1.5 kW 700 r.p.m. motor could be supplied that resulted in speeds half as fast. |

|

|

|

Speed chart Mk. 2 SB-23 with standard-fit 1400 r.p.m. motor |

||

|

|

|

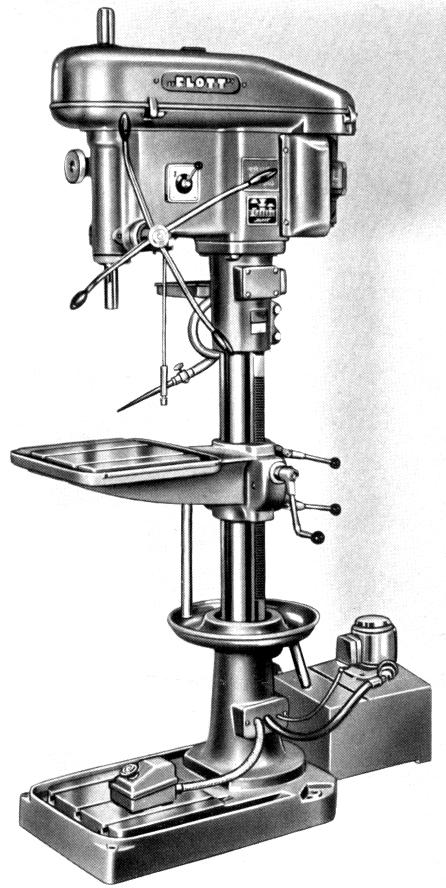

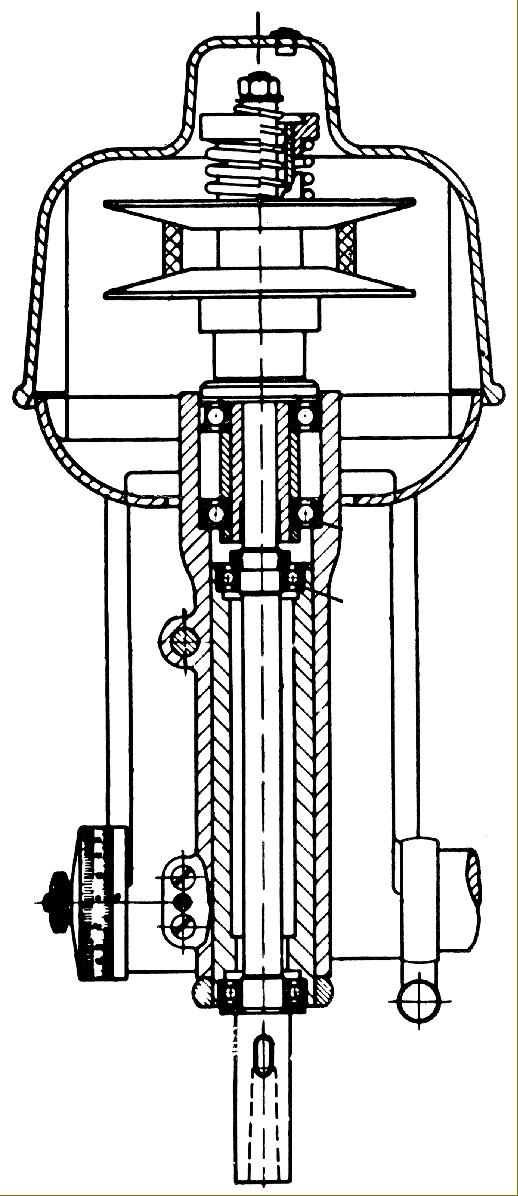

Equipped with a 1.3 kW motor running at 1680 r.p.m. the all-mechanical drive system of the Mk. 1 SB-23-ST consisted of two reduction stages. each using expanding and contracting pulleys. The result was a usefully deep speed range, quoted by the makers as being from 240 to 2400 r.p.m. - though it also appears that a choice of two other motors may have been available, these giving speed ranges of 100 to 1000 and 200 to 2000 r.p.m. As the drive system was all-belt, drilling holes at the machine's maximum capacity of 25 mm (1-inch) in steel would almost certainly have been less effective than if equipped with a combination of belt and reduction gearing - as used by many other makers. However, with a 5-inch diameter column supported on a 24" x 12" foot with three T-slots, an 11" x 163/8" table with two T-slots, a quill travel of 6 inches, a throat of 12 inches, an all-up weight of 772 lbs and a choice of either a No. 2 or No. 3 Morse taper spindle (the latter with the slower set of speeds), the SB-23-ST would certainly have been capable of heavy work. |

|

|

||

|

Section through the spindle of the variable-speed Flott Type SB-23-ST |

||

|

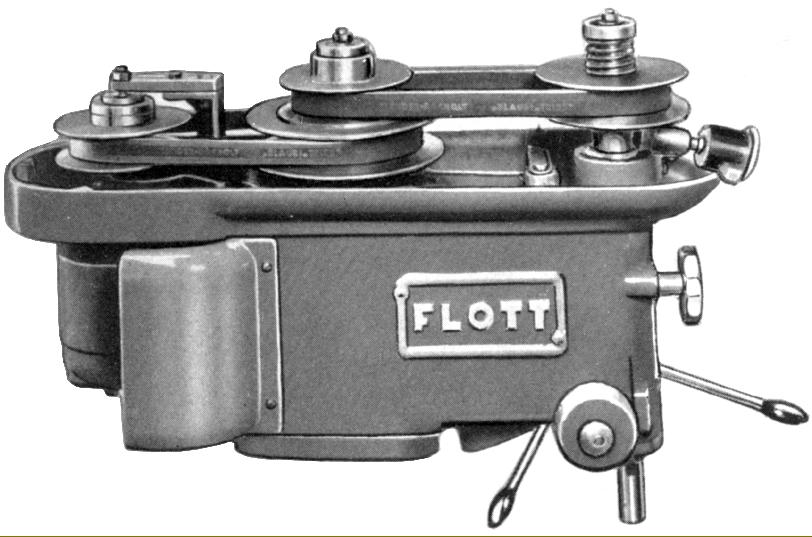

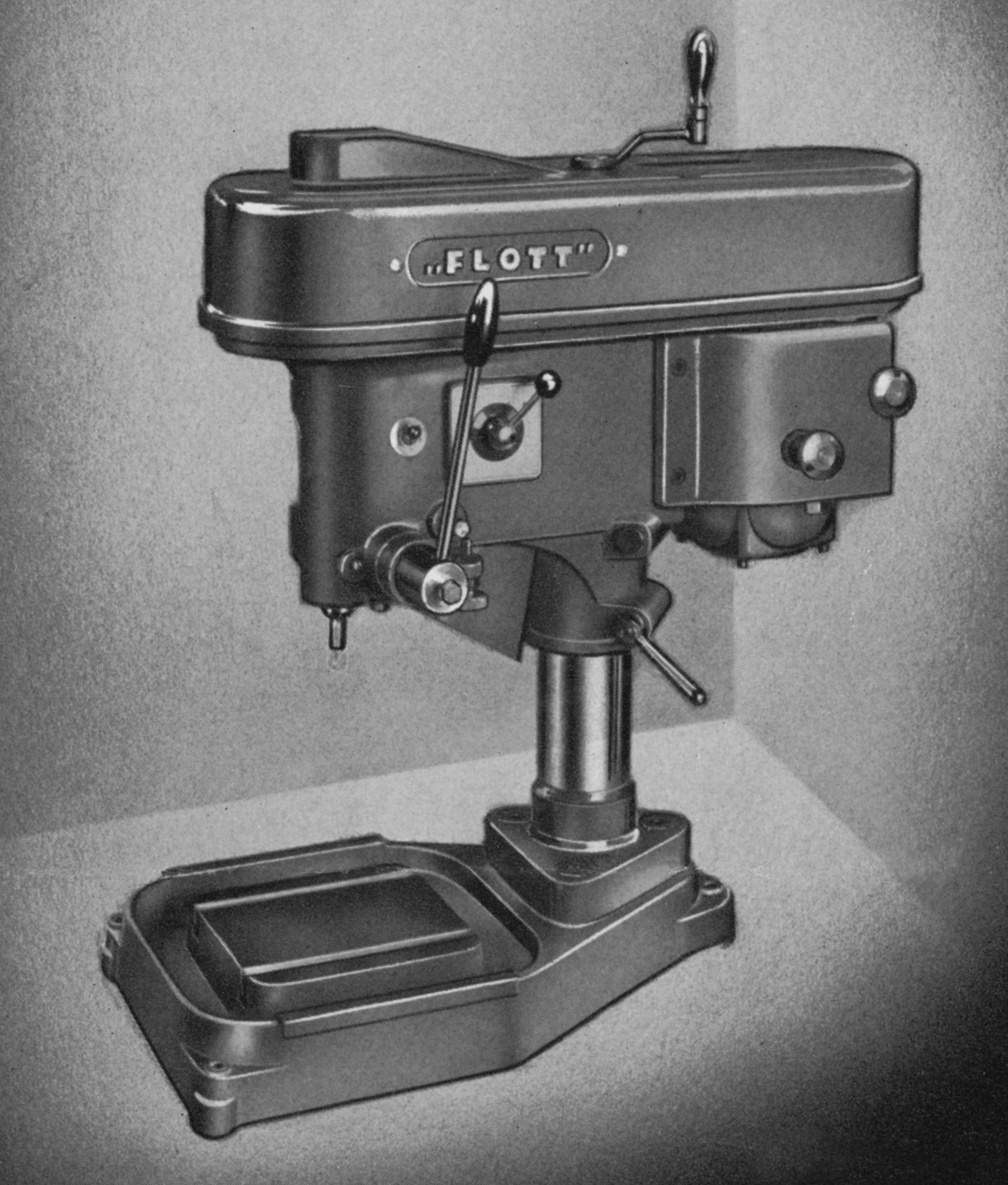

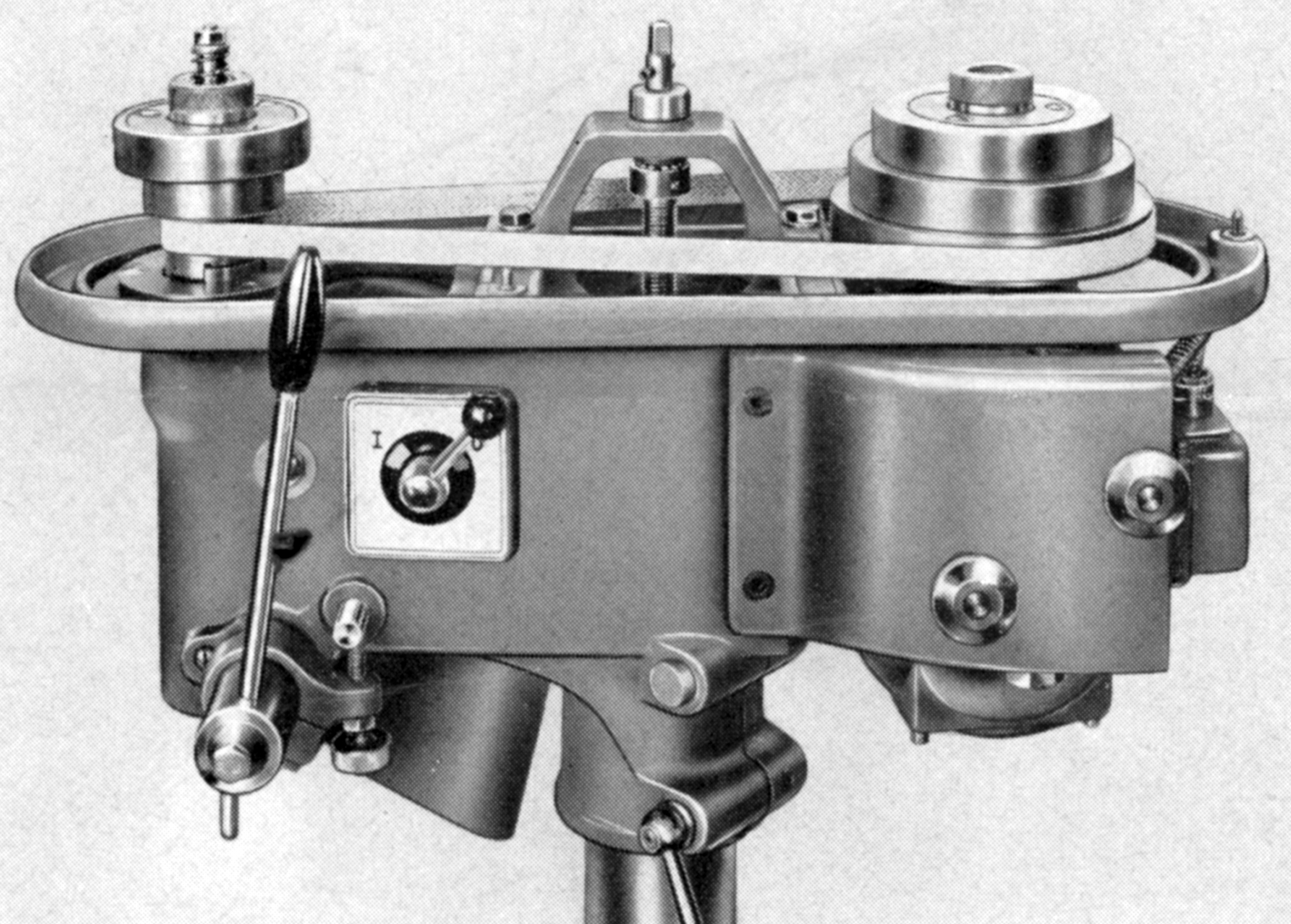

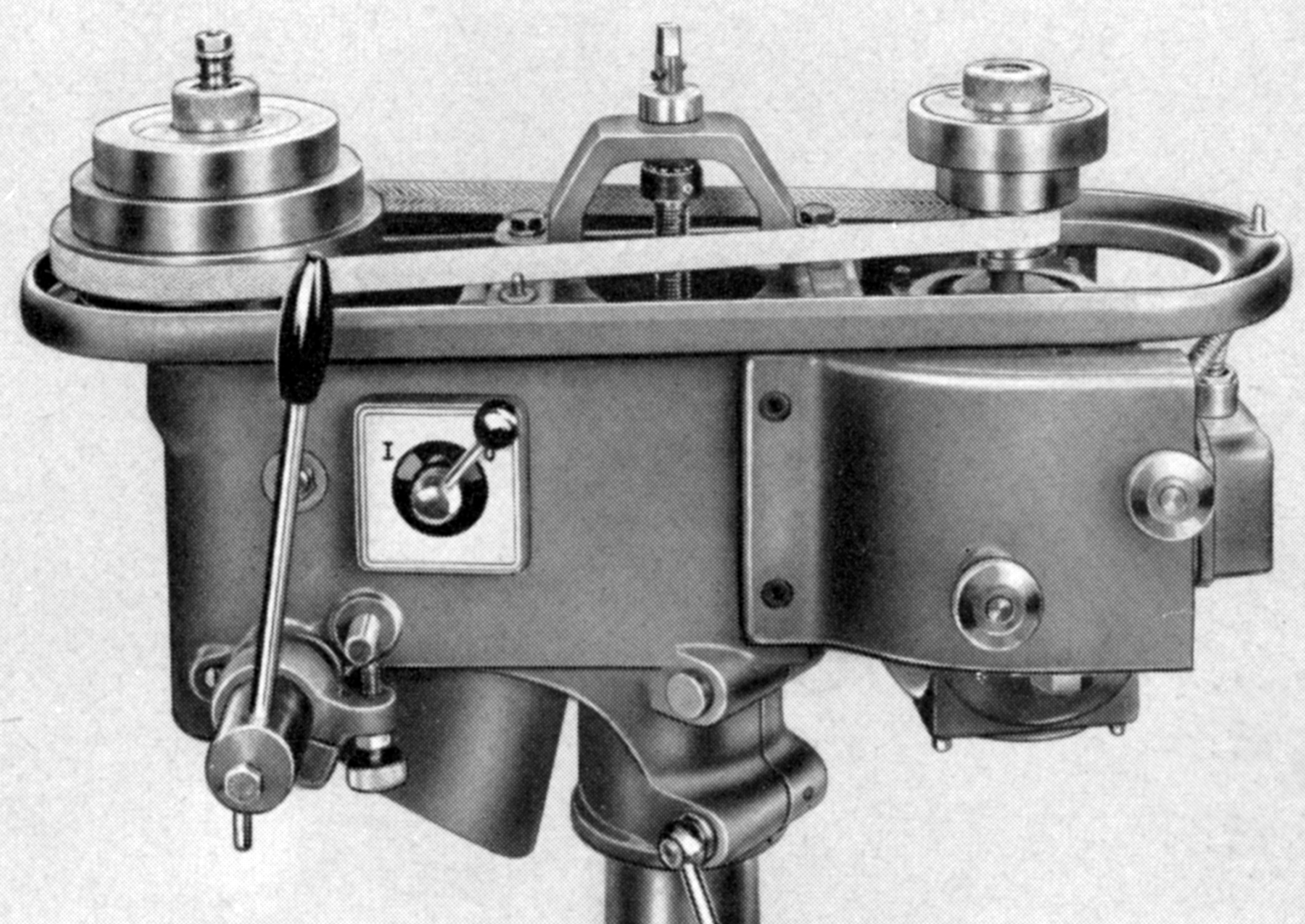

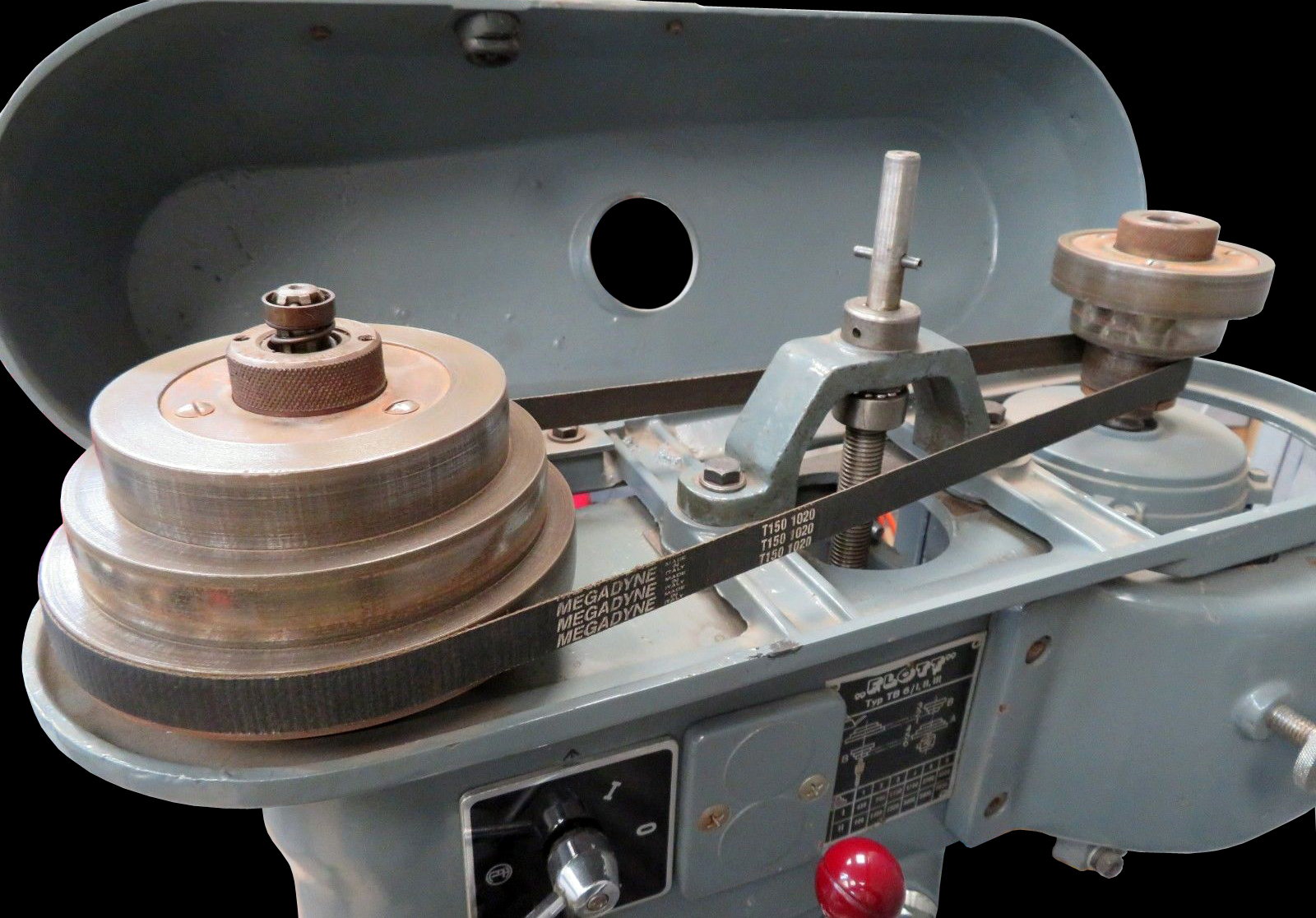

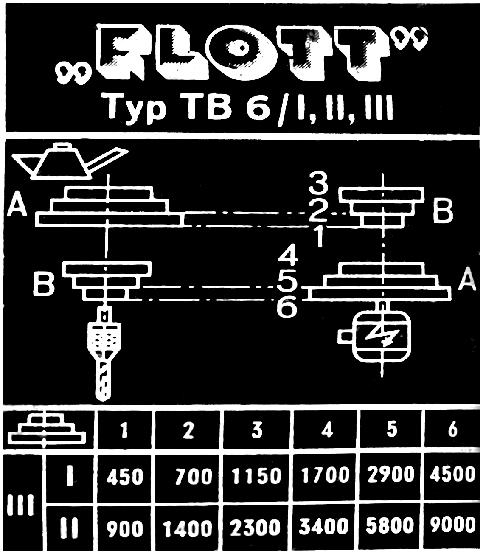

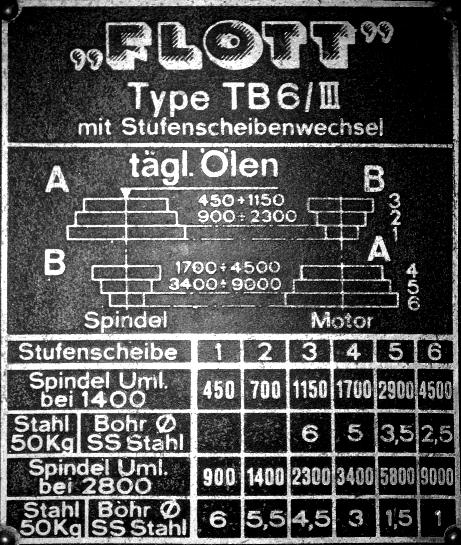

Intended for precision work using high speeds and small diameter drills, the Type TB6 was a bench-mounted machine available in three versions, the Types TB-6/1, TB-6/11 and TB-6/11 (TB being the Flott abbreviation for a bench drill). Each was of identical mechanical construction with a capacity in steel of 1/4", a drilling depth of 2.375", a spindle centre to column throat of 6.25", a column 2.75" in diameter, a foot with two T-slots of 6.75" x 11" (there was no elevating table) and a maximum height, with the head fully lifted by the use of a top-mounted crank handle, of 30" and a weight of approximately 119 lbs. The difference between the models lay in the motor - that on the TB-6/1 and TB-6/11 being rated at 550 Watts and running at 1400 r.p.m. while on the TB-6/11 a 2-speed, 250/350 Watt, 1400/2800 r.p.m. unit was used. Motor and spindle were each fitted with identical and interchangeable 3-step cone pulleys, these being held on tapers and secured by knurled nuts, the turning of which, to the left, caused the taper to be broken. By shifting the flat, 17 mm wide silk belt - yes, it really was silk - from step to step and interchanging the pulleys six speeds were available, these being: TB-6/1 450, 700, 1150, 1700, 2900 and 4500 r.p.m. Somewhat faster, those on the TB-6/11 ran from 900 through 1400, 2300, 3400, 5800 to 9000 r.p.m. With a 2-speed motor, the TB-6/111 had 12 speeds: 450, 700,900, 1150, 1400, 1700, 2300,2900, 3400, 4500, 5800 and 9000 r.p.m. |

|

|

|

|

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||