A sales and technical specification catalogue is available for the BE2 as well as other Boley Manuals and Catalogues

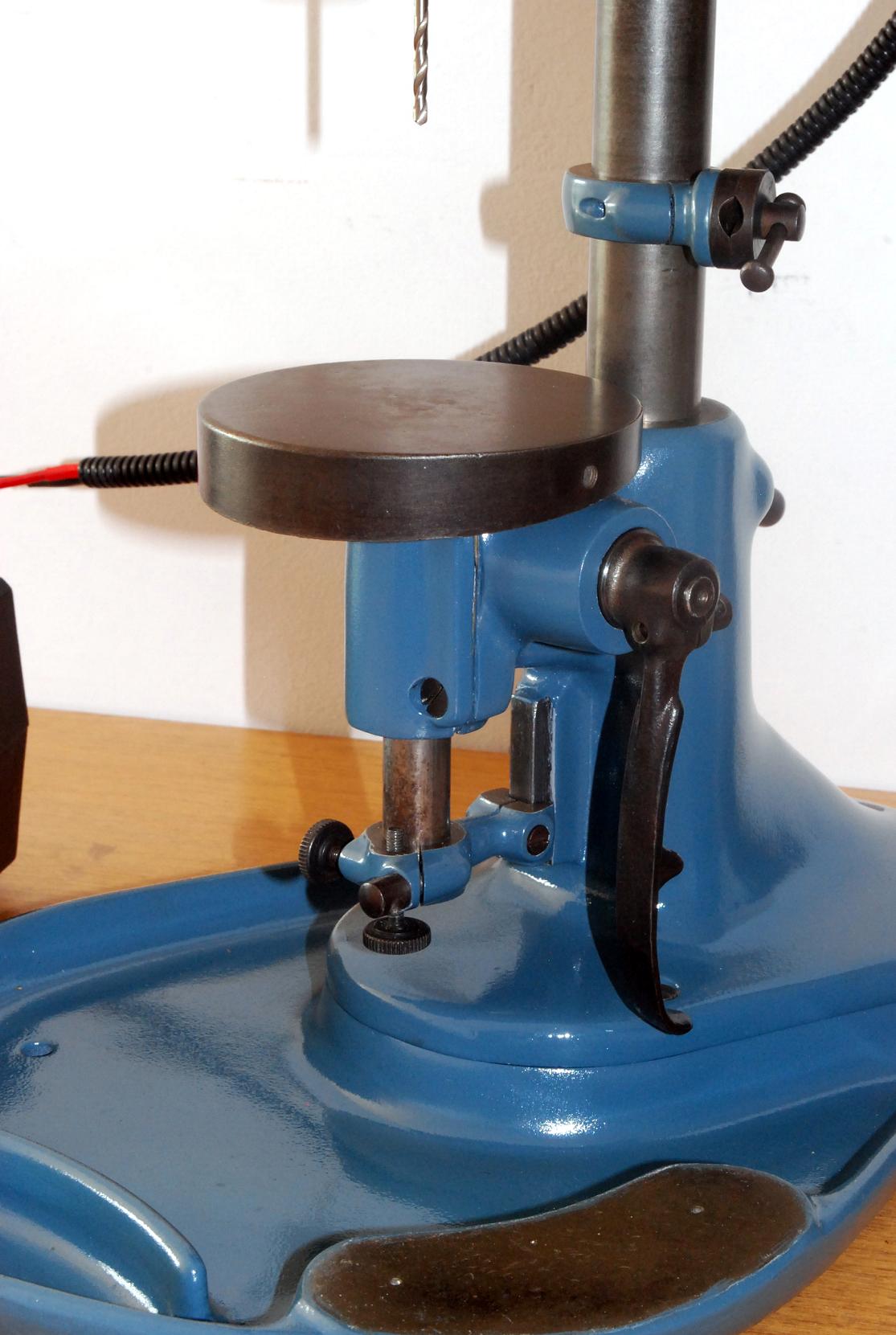

Designed for use in high-precision mechanical and optical industries, the tiny Boley BE2 was a beautifully-built drill that had a long production run (in slightly altered forms) that spanned from the 1920s until the 1980s. Of all cast-iron and steel construction and, according to the makers "vibration free", the drill was very similar in design to the much older general-purpose, "swan-neck" type, such as offered for many years by the once-well-known Denbigh Company - though the Boley was much smaller and capable of highly accurate work. Standing around 490 mm high with a baseplate 320 mm x 260 mm, the head was carried on a rigid steel column - this able to be slid into and out of the base casting through a travel of 170 mm with the setting of the column checked by an adjustable stop collar - what the makers described as an "accessory collar".

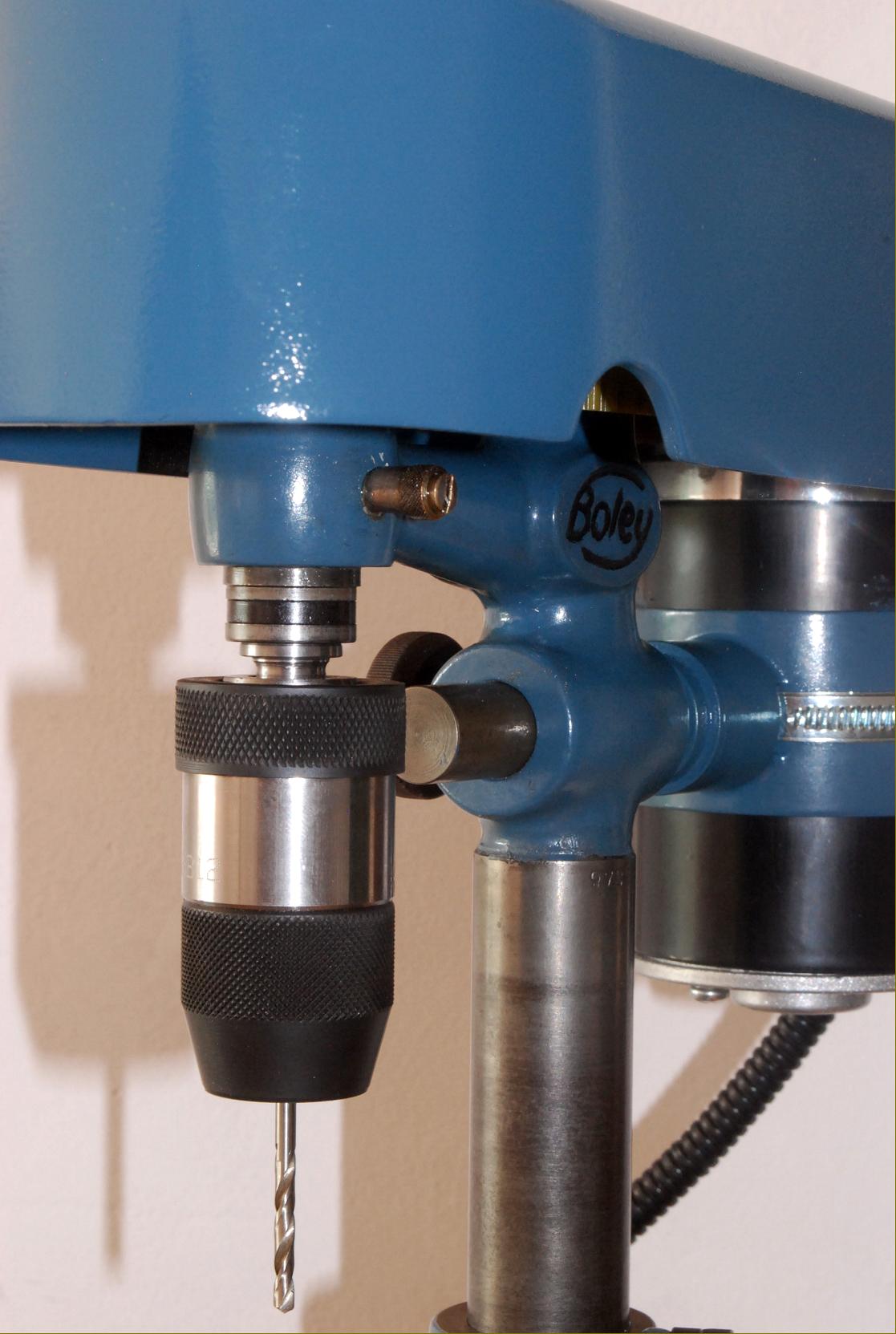

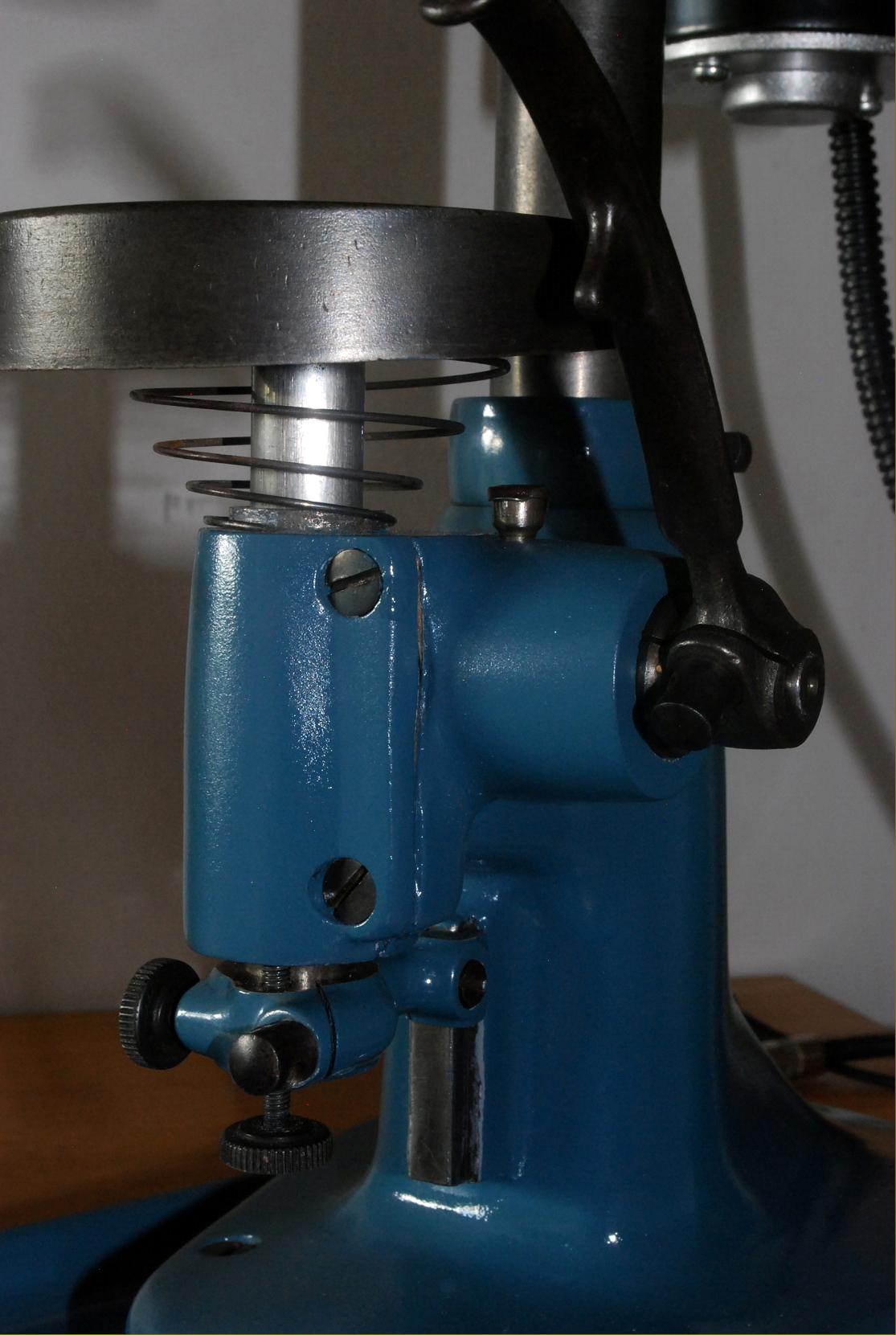

100 mm in diameter, the worktable could be elevated by a hand lever through some 30 mm, the arrangement using an adjustable, square-section guide (of a registered design) and a return spring. Fitted with a standard B12 chuck-mount nose, the spindle and bearings were of the watch-lathe type, both being in hardened, ground and lapped nitrided steel, the assembly carried inside a 28 mm diameter quill. End thrust was absorbed by a hardened conical thrust washer, the arrangement incorporating a "soft-washer" oil seal. Quill and spindle dimensions changed over the years and several differences have been found that are at variance with the catalogue specification.

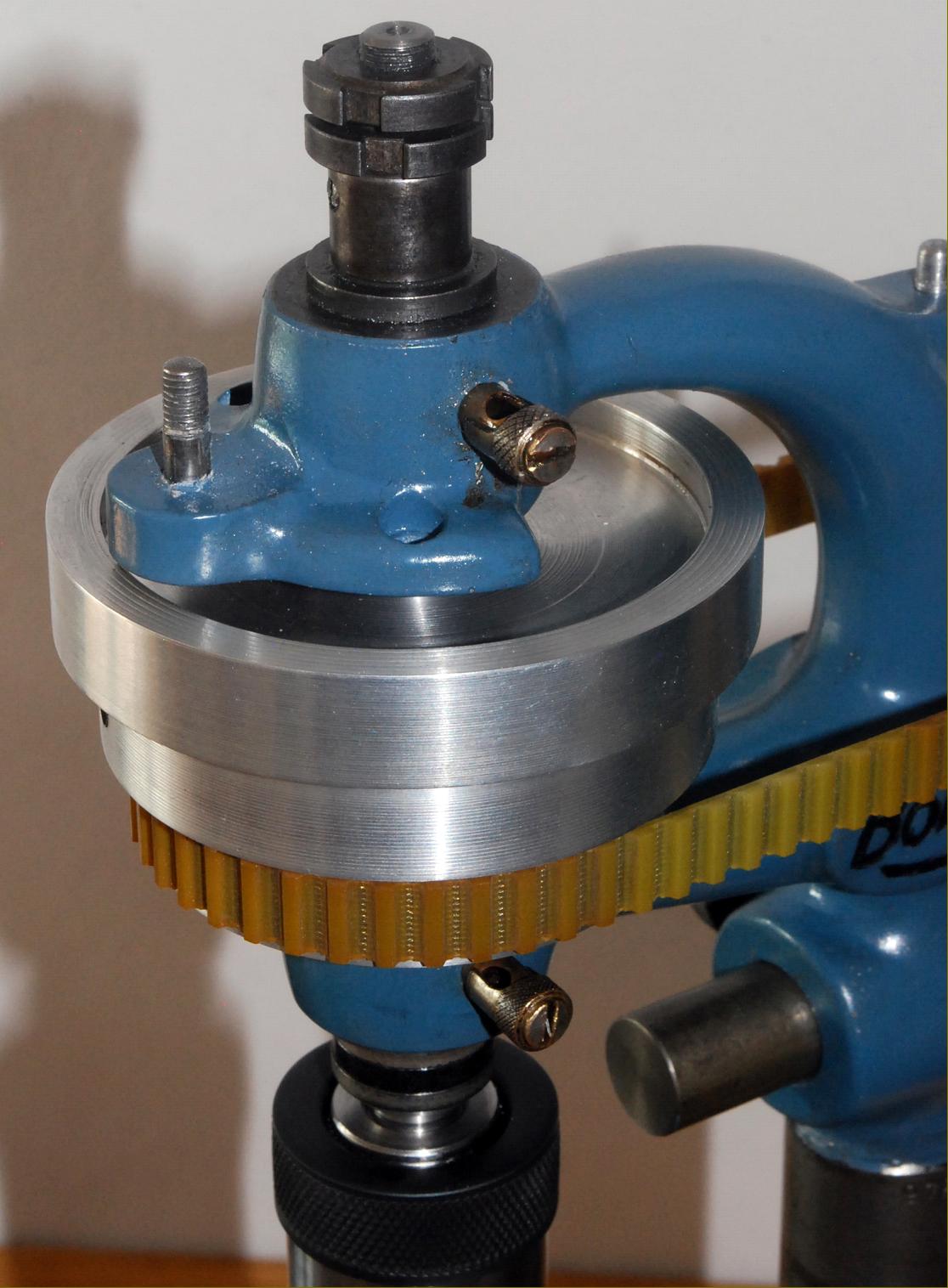

Heavy for its size at approximately 16 kilo, the drill carried, as standard, a small 3-phase, 0.06 kW, 2800 r.p.m. motor that drove by a flat belt through heavy, dynamically balanced 3-step steel pulleys designed to impart a flywheel effect. Four sets of pulleys were listed, Range 1 giving 1880, 2500 and 3700 r.p.m.; Range 2 giving 2200, 3000 and 4200 r.p.m., Range 3 giving 3600, 4700 and 6200 r.p.m. and Range 4 allowing 5600, 7100 and 9000 r.p.m.. However, with a variable-speed, DC motor fitted, the makers advised that up to 12,000 r.p.m. could be achieved - the belt used in all cases being an endless type woven in silk (modern replacements are available). Interestingly, the pulley on the motor was not keyed on nor locked by a screw, but pressed on the achieve "absolute accuracy".

Drilling capacity in steel was 2.5 mm (0.098") and in brass 4 mm (0.147"). Although the original standard colour is not known, the makers did offer to provide "special colours" - presumably at extra cost and to any shade desired by the buyer..