|

Founded by Francis Moseleyvn in Pasadena, California, during 1964, the first product of the Servo Company was a very successful power-feed attachment to drive the table of a milling machines - of which over 300,000 have been sold world-wide.

Today, Servo designs and manufactures a range of traditional manual machine tools and accessories including power-feed attachments, milling machines, high-precision drill presses and power drawbars. Products are marketed worldwide through a distribution network of over 500 dealers.

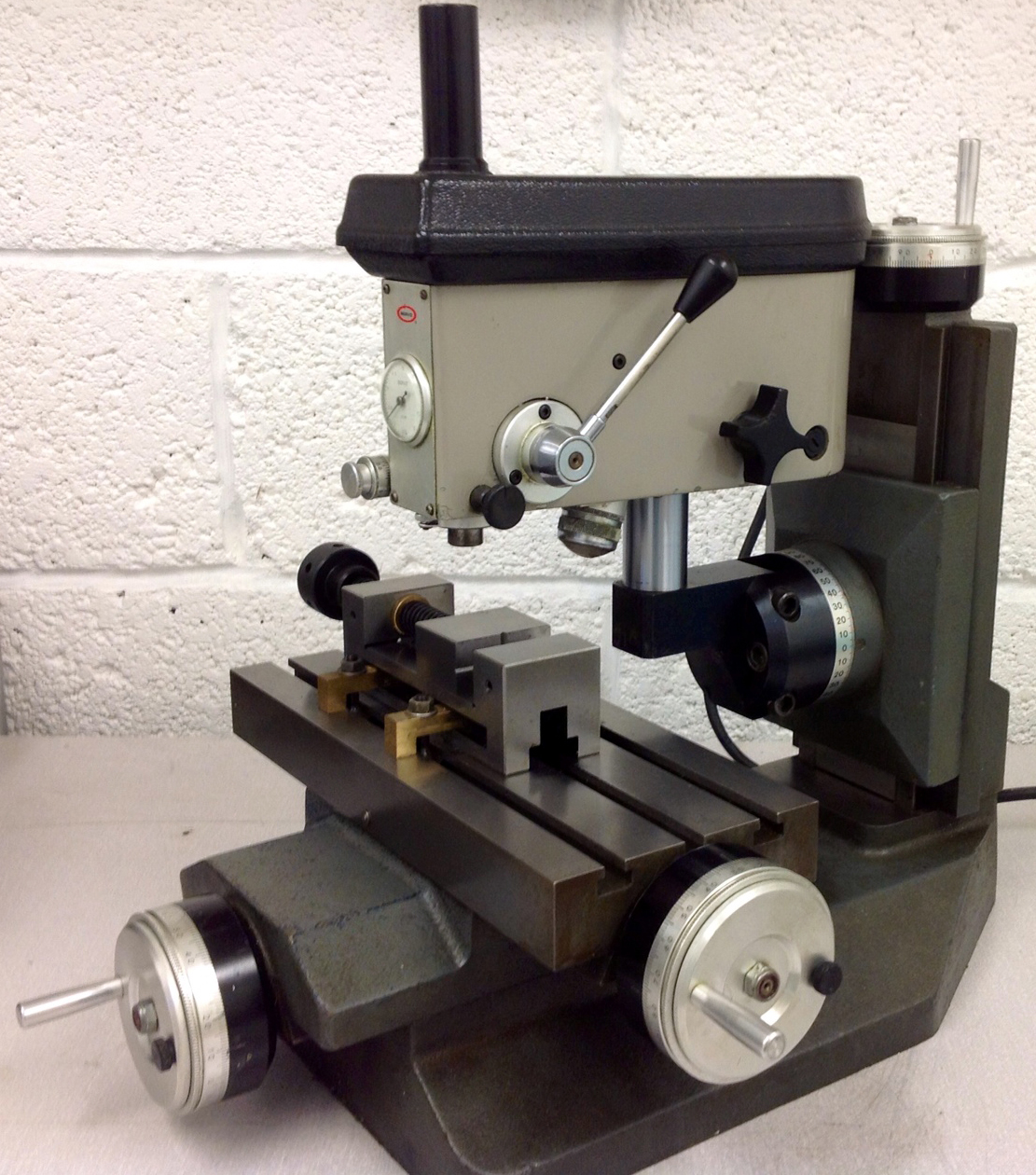

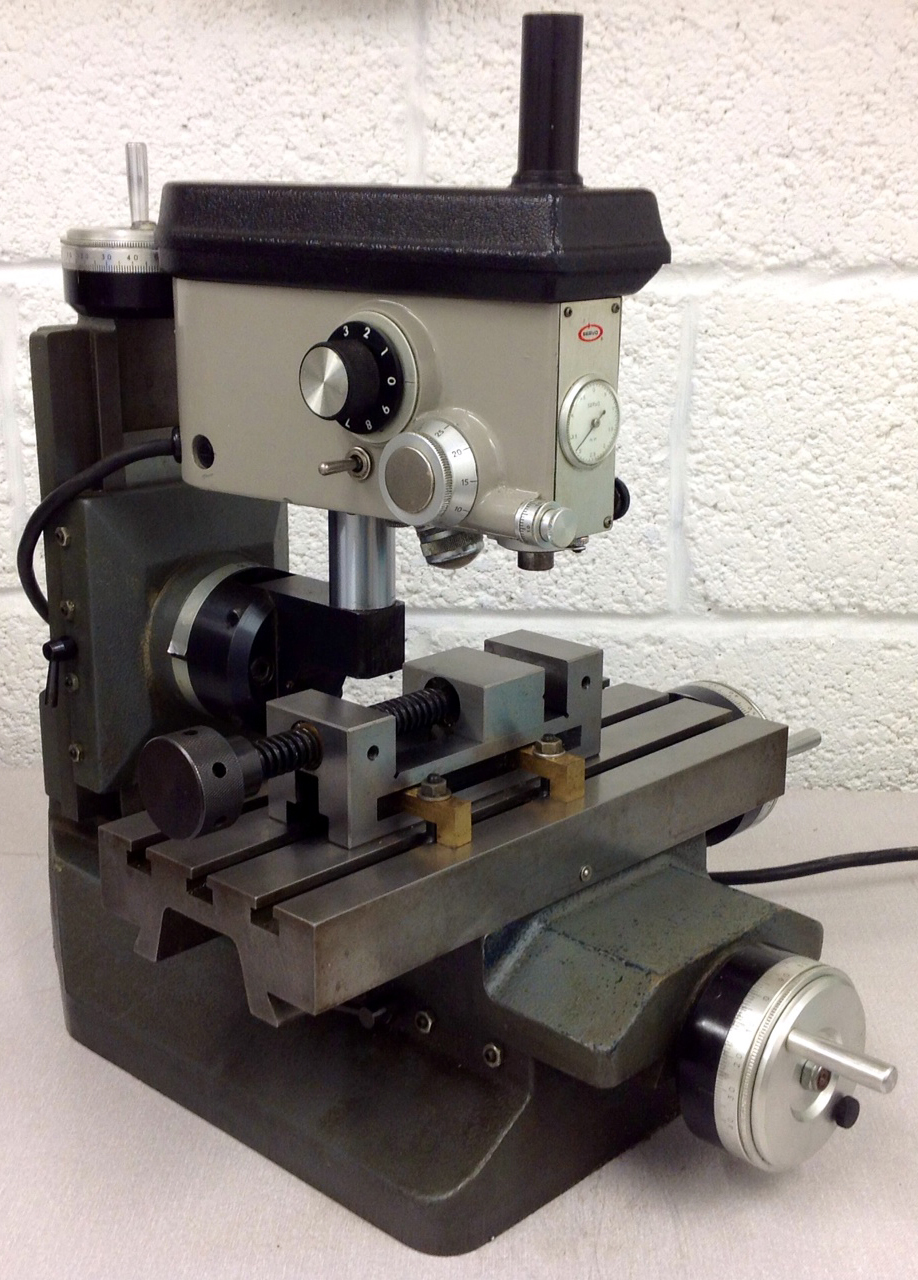

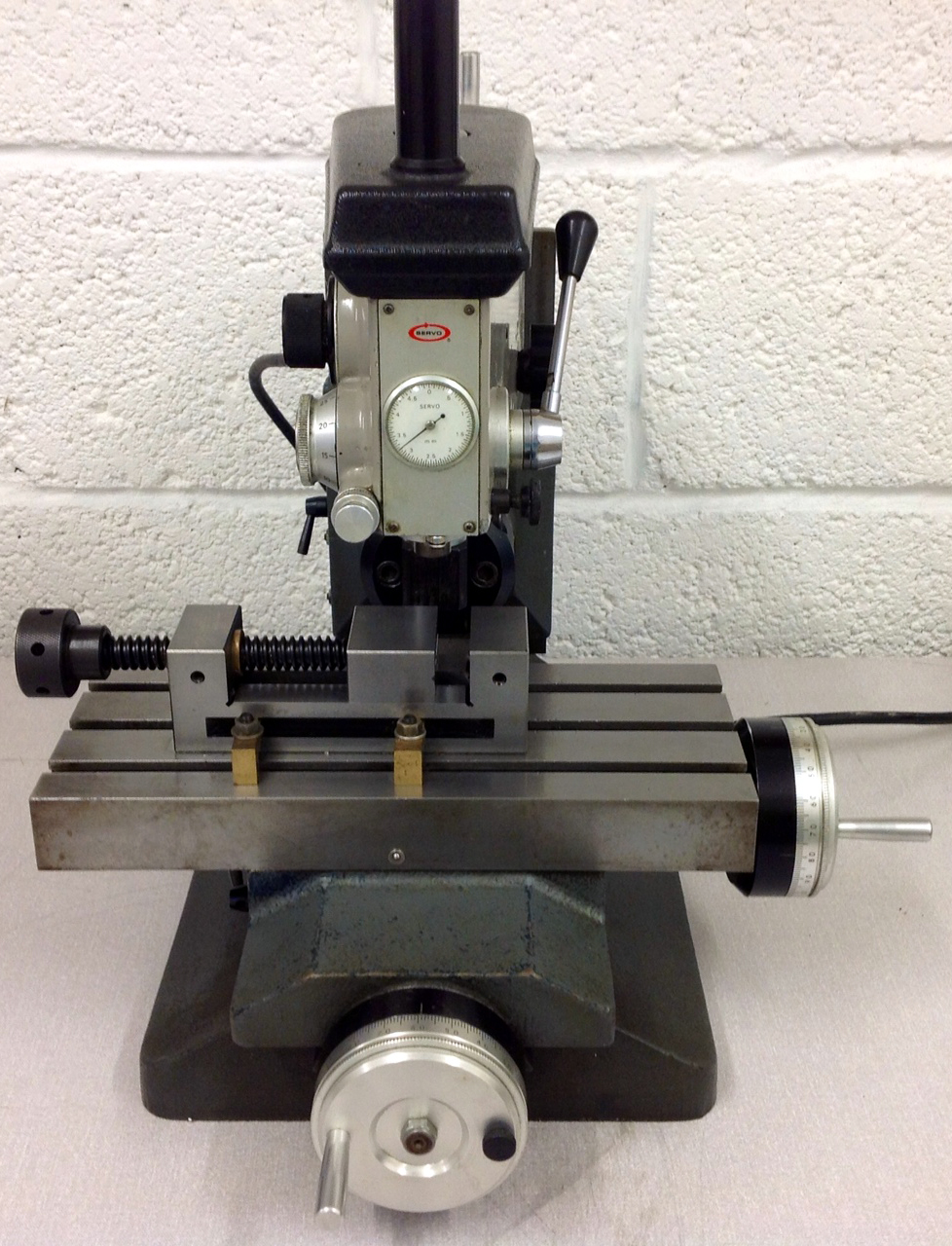

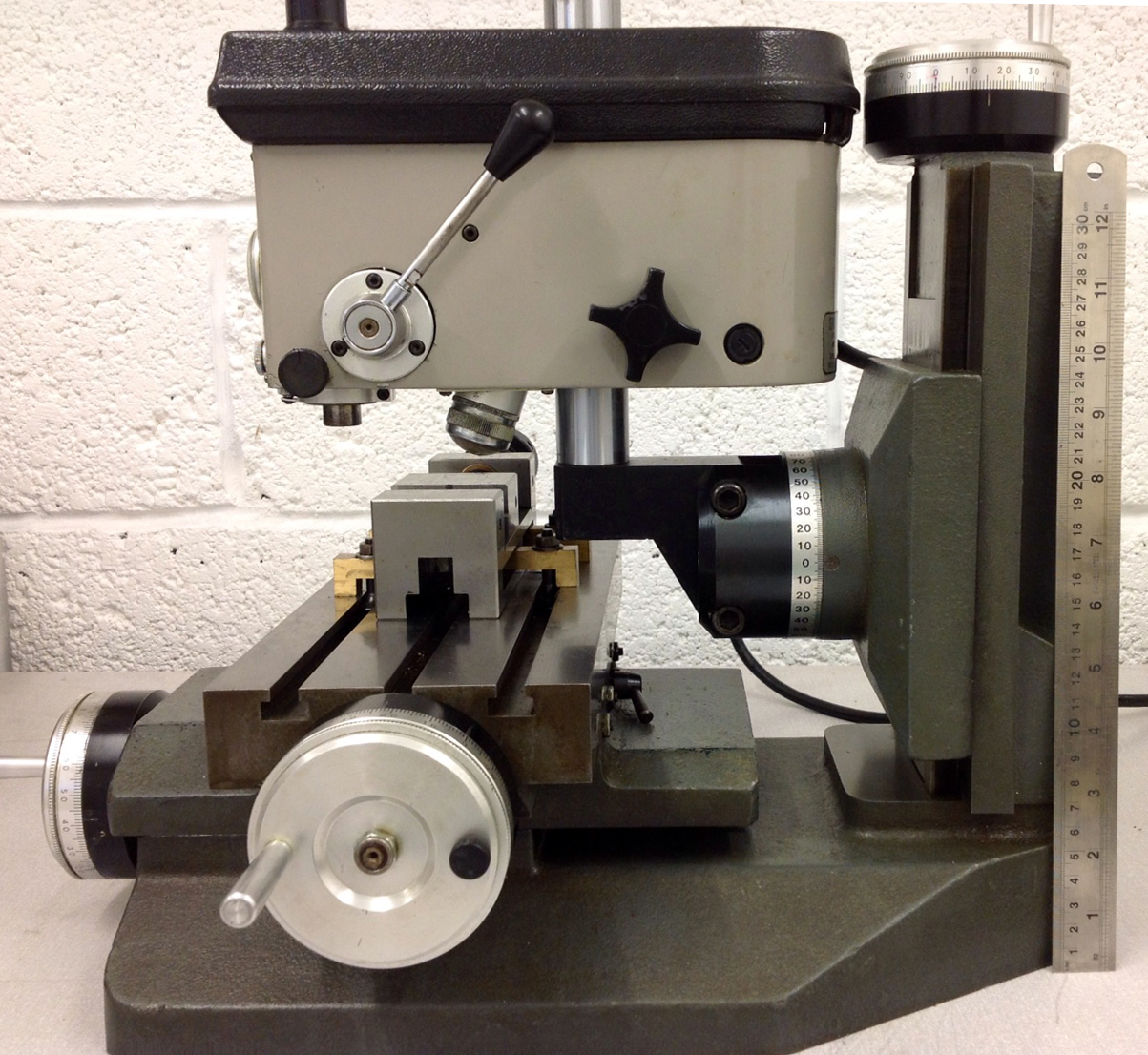

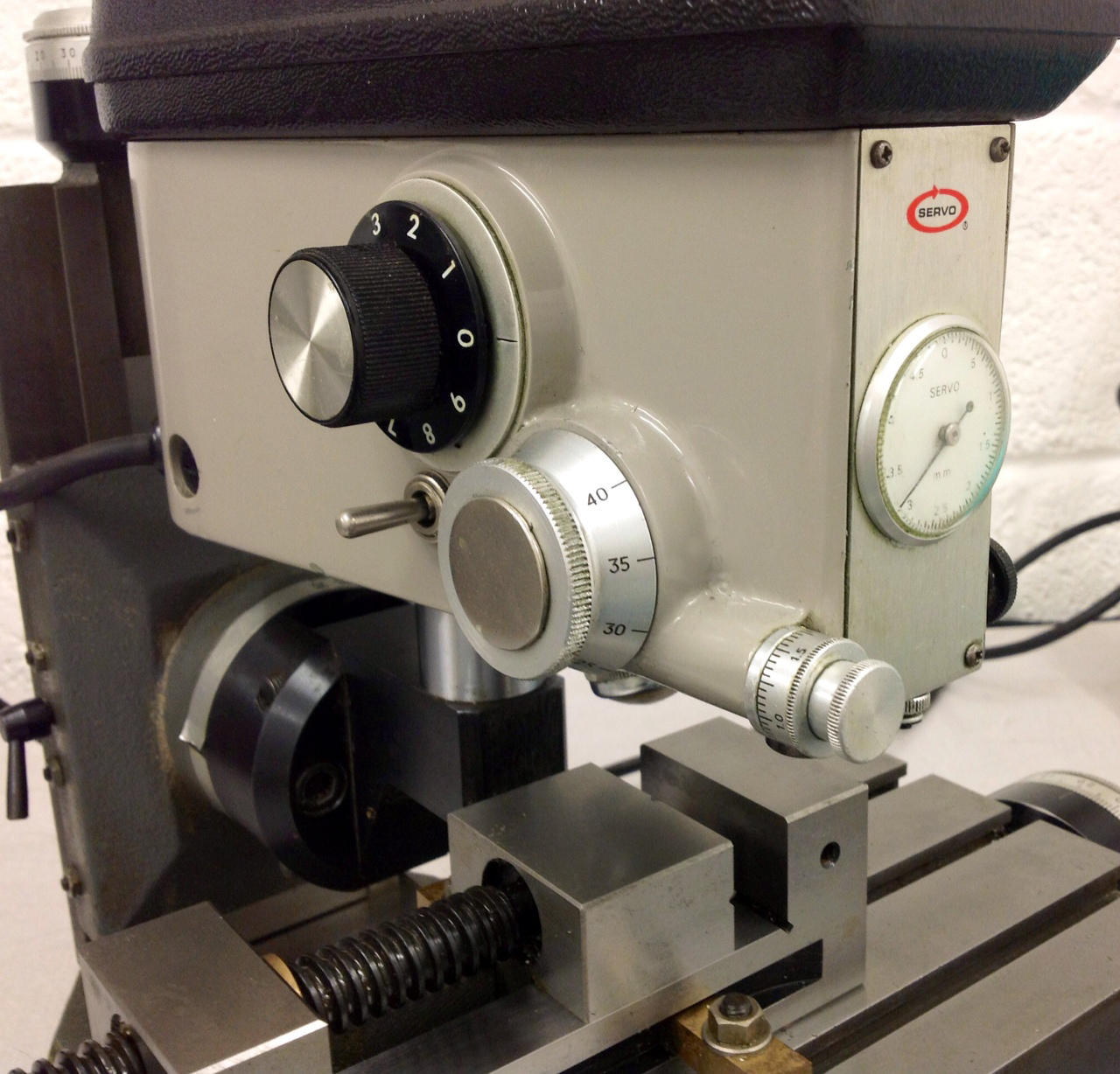

Beautifully made, in recent years the range of micro-drilling machines appears to have been trimmed down with previous models, such as the superb co-ordinate model shown here, no longer available. However, although only conventional drill presses are now listed, the range is extensive with numerous options available to satisfy a variety of specialist needs.

Unlike the more conventional precision drills such as those by Derbyshire, Levin, and Bergeon, the first Servo model below was being arranged along the lines of a miniature jig borer with a compound table driven by fine-feed screws with large zeroing (metric scale) micrometer dials locked by non-upsetting face screws. Superbly constructed, the machine is of a rare type with few similar ever being offered - though probably the very first, by Wolf Jahn, was a handy high-precision drill/mill that was to be steadily developed through the Leinen BFL and subsequent copies by Ultra, Excel, Sigma and BCA; more recent models of the genre including the Leinen Micro Mill and possibly the American Precise.

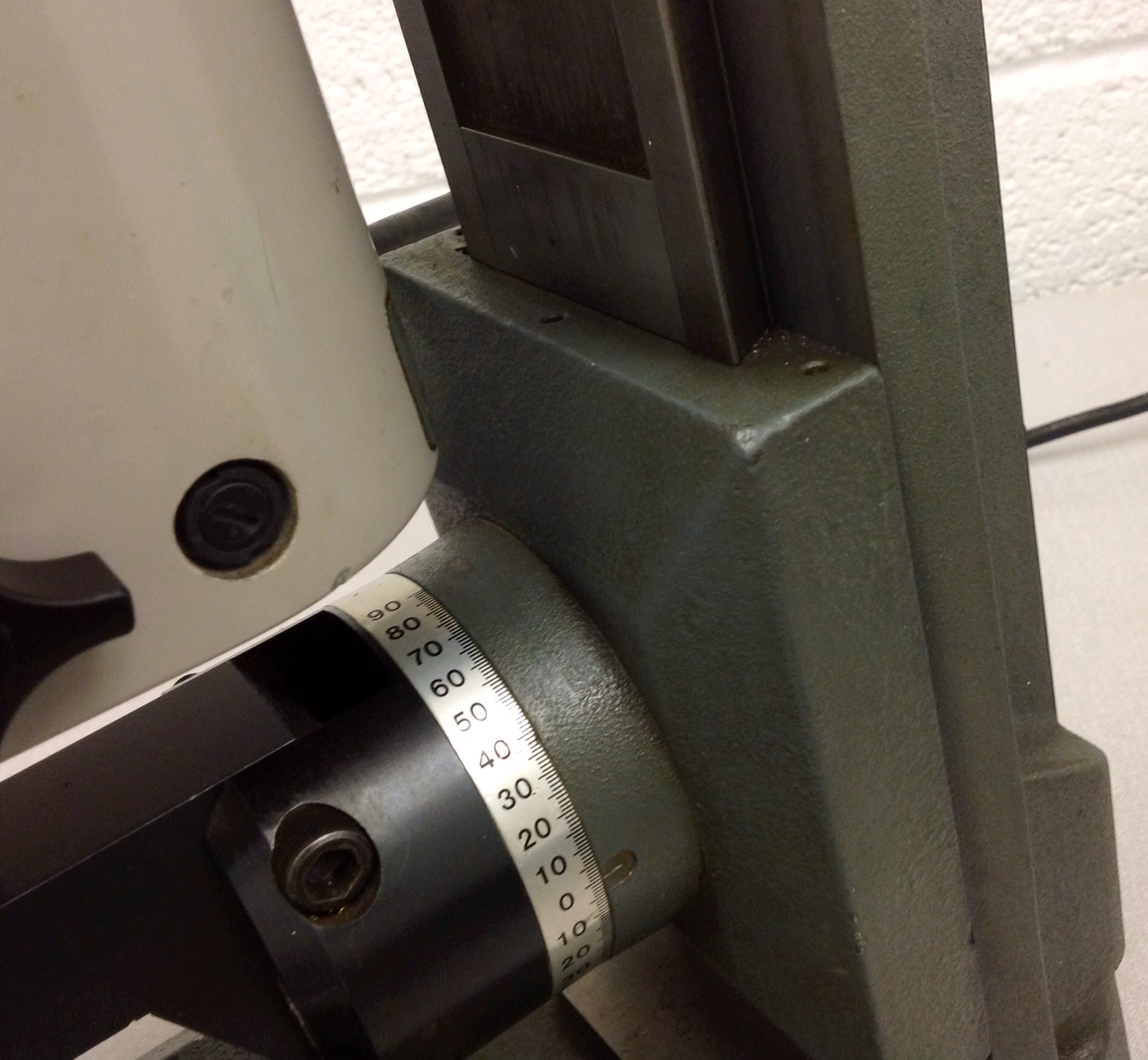

Able to be swivelled, the drilling head was carried on a solid steel bar fixed to a boss formed as part of a casting that could be moved up and down a vertical way machined into the face of the main column. Vertical travel of the whole head assembly was by screw-driven feed (with travel measurement by a large zeroing micrometer dial) while quill travel was by both a quick-feed handle and a micro-feed dial - travel of the latter being by a front-facing, built-in dial indicator. A built-in light unit illuminated the job (a common fitting on this class of machine) while the spindle took readily-available 8 mm watchmaker collets - two current Bergeon types, for example, being a direct fit. Power came from a DC variable-speed motor, with a control dial on the left-hand face of the head - a round belt transmitting the drive by equal-size pulleys to the spindle.

The final three pictures show a much simpler version, this being, in effect, a miniature version of the quite ordinary type of bench-mount drill press with the head carried on a round column and a precision-ground, plain table..

|

|