|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories and Automatic Pinion Cutter Cataract Accessories Cataract Stands & Drives Cataract Drills & Pinion Cutter "Quick-change" Toolroom Lathe Cataract Millers Hardinge History Cataract Home Page Hardinge Elgin Lathes & Millers |

|

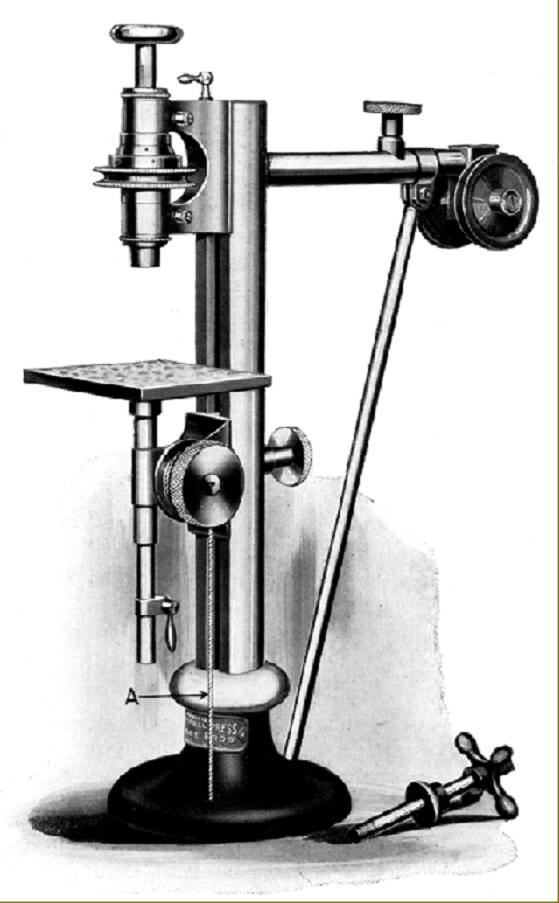

Beautifully-made, the Cataract "Sensitive Drill Press" was, in effect, a vertically-mounted watchmakers' lathe with a hardened and ground spindle running in a hardened and ground upper bearing and a cast-iron taper bearing beneath; the spindle end thrust was taken against a ball-bearings race. The spindle accepted Cataract No. 1 Draw-back collets which was able to hold drills down to a No. 80, and reamers, "dead true". As an alternative Cataract offered a "Beach Drill" 1/8" capacity chuck mounted on a solid draw-in collet. |

||

|

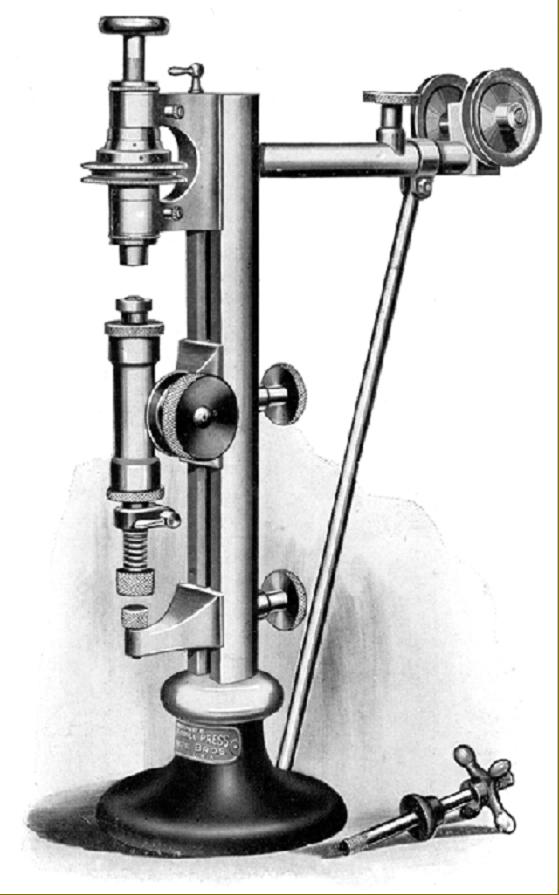

A modification of the drill above was the "Drill Press with Chucking Drill Press". |

||

|

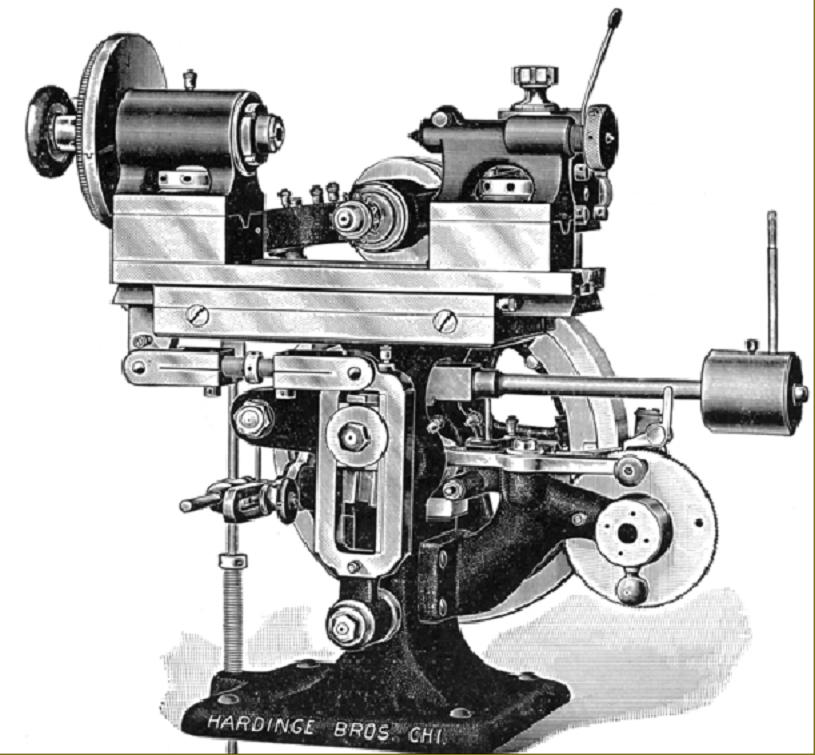

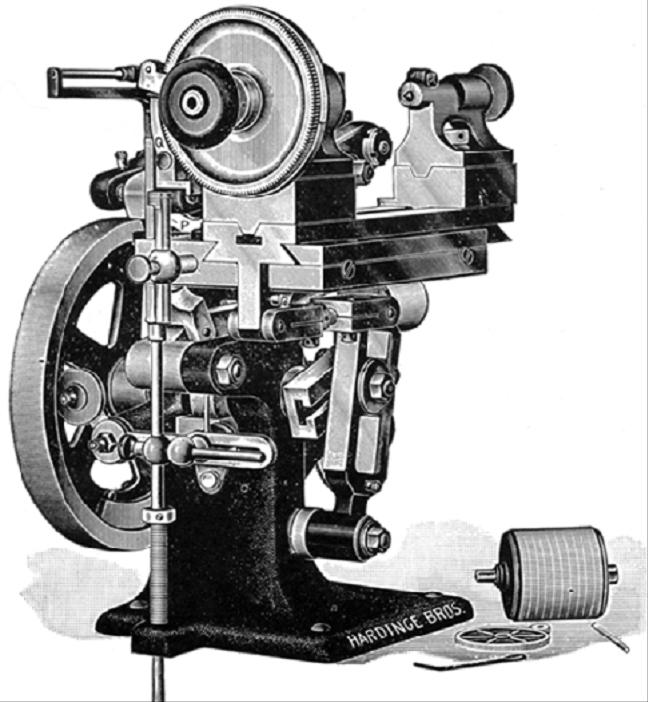

Cataract Automatic Gear and Pinion Cutter - designed for use in watch and clock factories where small "wheels" (gear) were mass produced. In addition, at a time when almost any type of measuring instrument relied upon gears and not electronics, gear and pinion cutters were an essential adjunct to instrument and toolmakers of all kinds. |

|

|

|

"Quick-change" Toolroom Lathe Cataract Millers Hardinge History Cataract Home Page Hardinge Elgin Lathes & Millers and Automatic Pinion Cutter Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories |

||