|

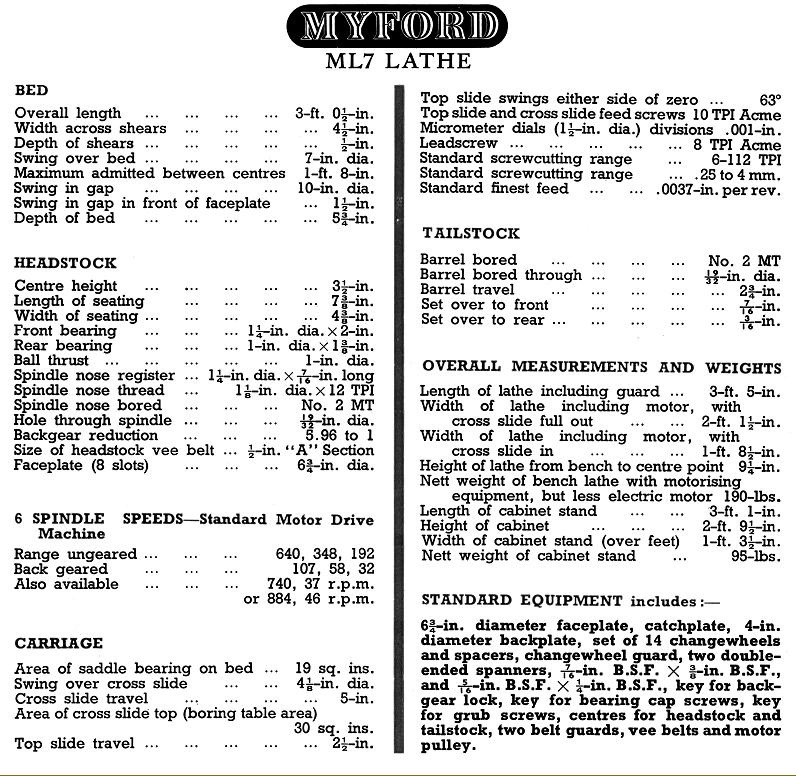

Home Machine Tool Archive Machine-tools Sale & Wanted and Catalogues, etc., are available for most Myford lathes |

|

Gearboxes and Screwcutting: |

||

|

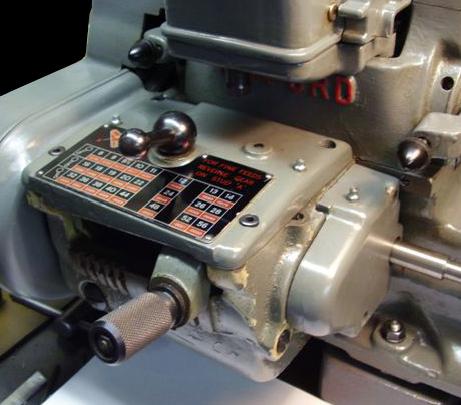

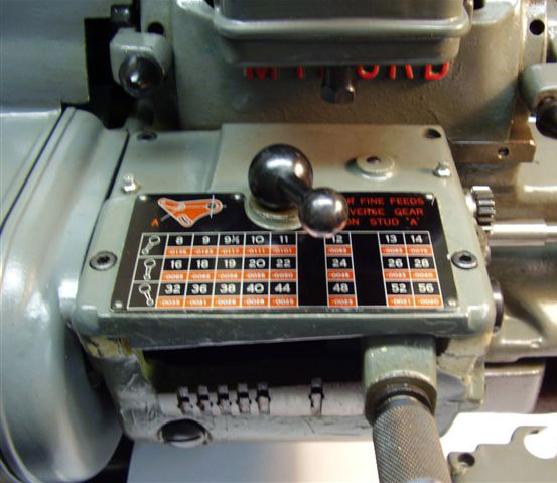

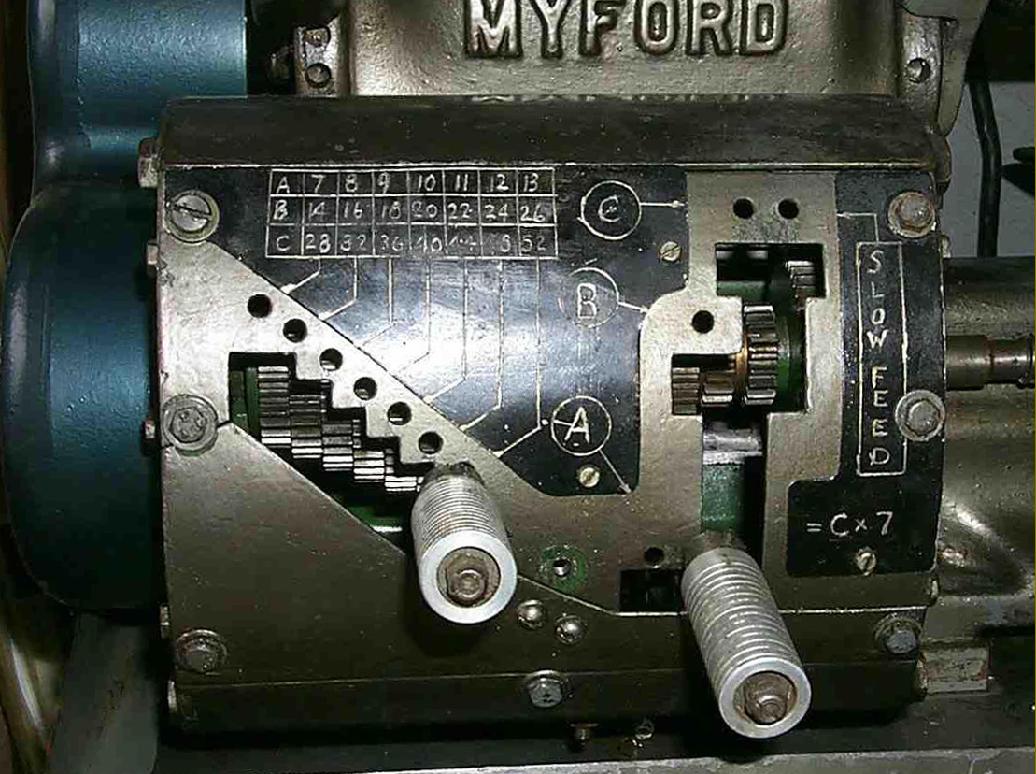

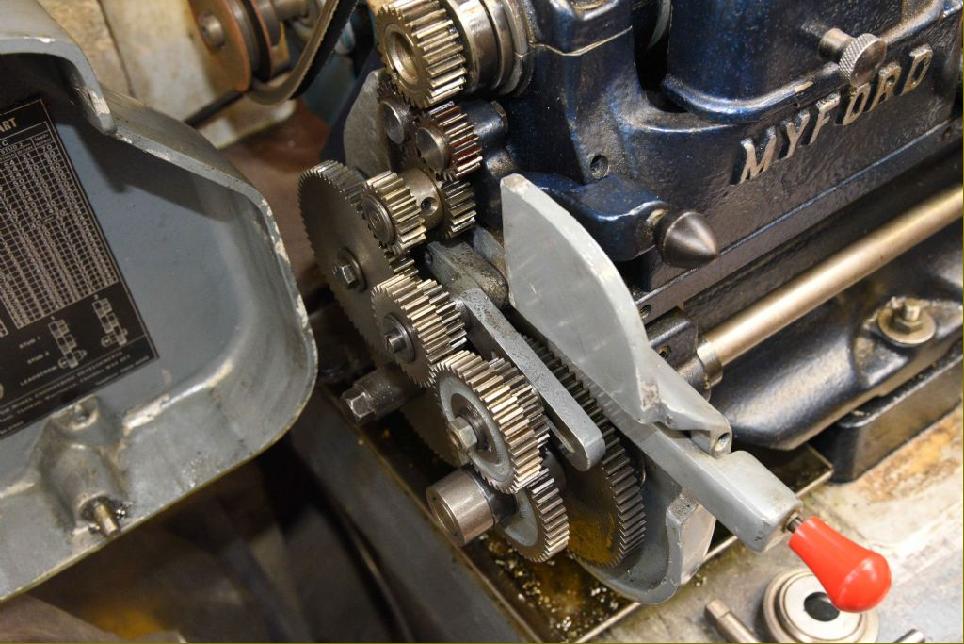

Although a kit-form gearbox had been designed and marketed in kit form during the late 1940s by L. H. Sparey (author of "The Amateur's lathe"), it was not until 1953 that Myford's first effort appeared. Lubricated by an oil-bath it was designed along long-established "Norton Quick-change" lines with a single-tumbler and a reversible gear on its left-hand face that allowed a rapid change between fine feeds and threads. The early boxes (as shown here) were fitted with unhardened gears and (hidden under a rounded, aluminium cover) a pair of external gears on the right-hand face (from which the leadscrew drive was taken) (later boxes had all the gears inside) |

||

|

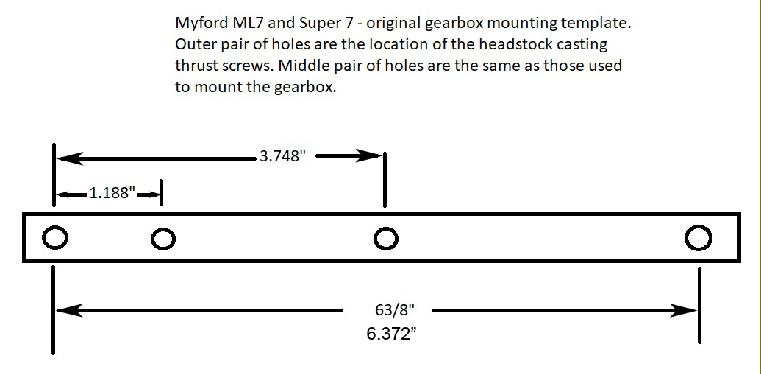

If an owner bought a gearbox kit for an early lathe a template was provided (Part No. 232) to help mark out the position of the holes that had to be drilled and tapped - on later beds these were already provided. The plate was secured to the tapped holes that held the screws used to push the headstock back against its alignment flange and holes drilled through the two centre holes such that they could be tapped 1/4" BSF. The maximum holes depth was 0.625" (though the right-hand hole may break through at that setting), the tapped length 0.500" and drill specified a 0.0204" (i.e. a No.6) |

|

|

||

|

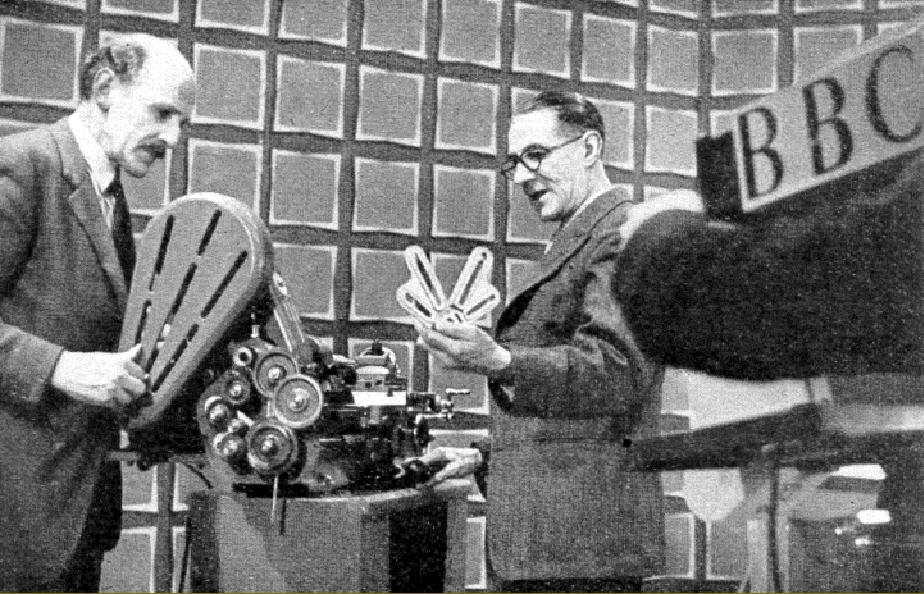

Designed in the late 1940s by L.H.Sparey, author of the indispensable book "The Amateur's Lathe" and a prolific writer on model engineering and model aero engines this screwcutting and feeds gearbox was produced in advance of Myford's own in 1953 - with a surprisingly large number appearing to have been constructed by enthusiastic owners. The box economised by using standard Myford changewheels. Later, the box was somewhat modified by David Machin with a cast aluminium casing and the introduction of a fine-feed assembly--though the latter has been found on some of the Sparey boxes. The magazine "The Model Mechanic" carried, in its March and April 1950 editions, articles about the construction of the box. |

|

Featured on the BBC "Inventor's Club" programme during 1949. Sparey, right, demonstrates to Geoffrey Baumfrey one of the modifications to his ML7 lathe |

||

|

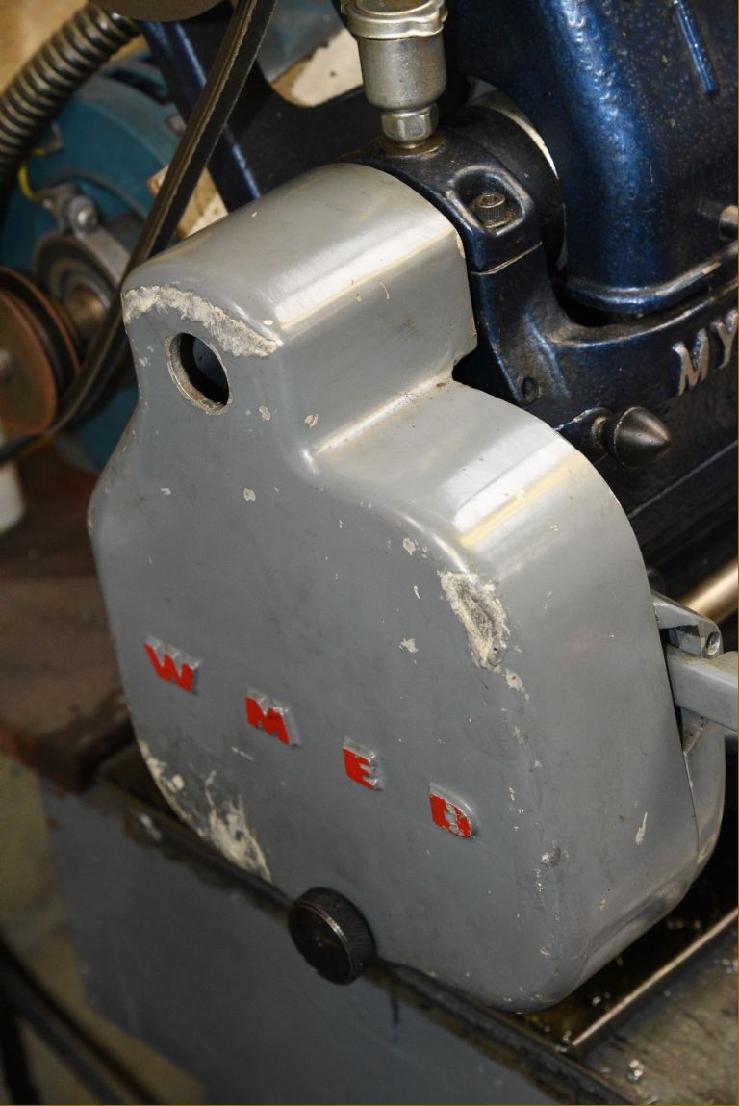

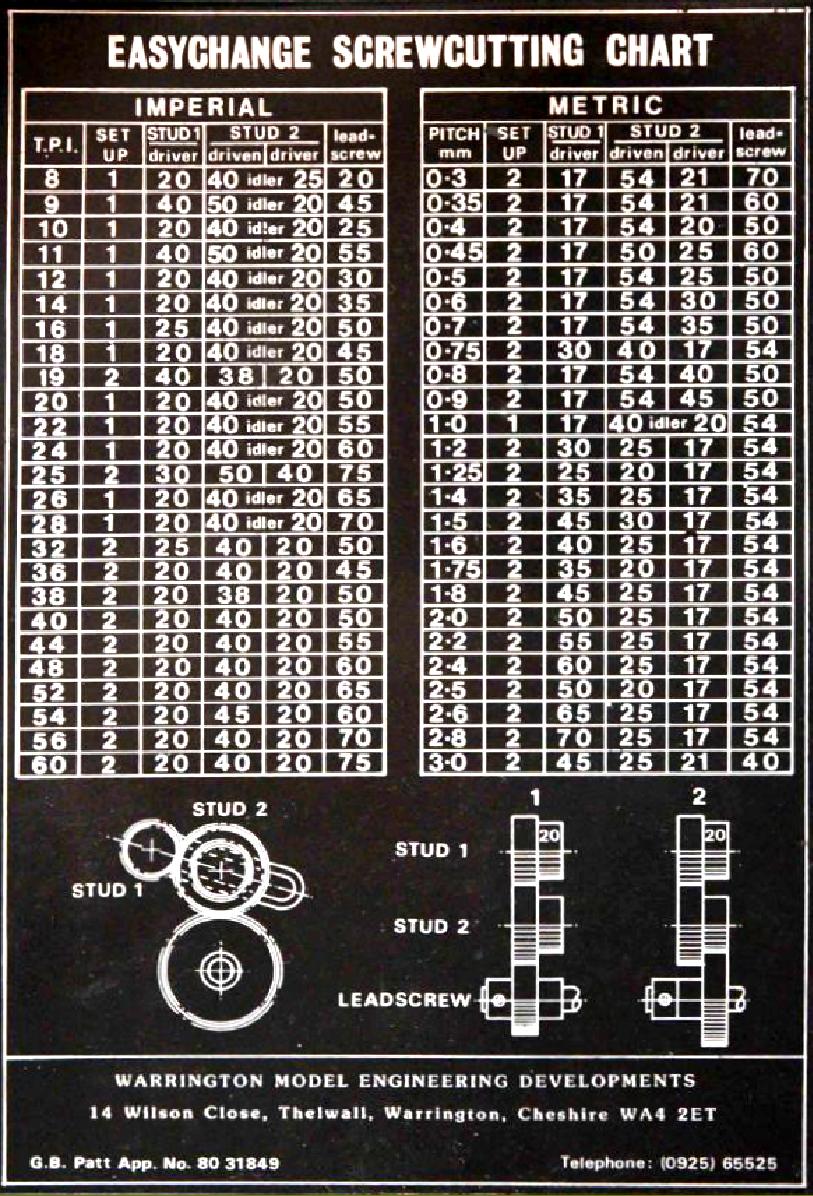

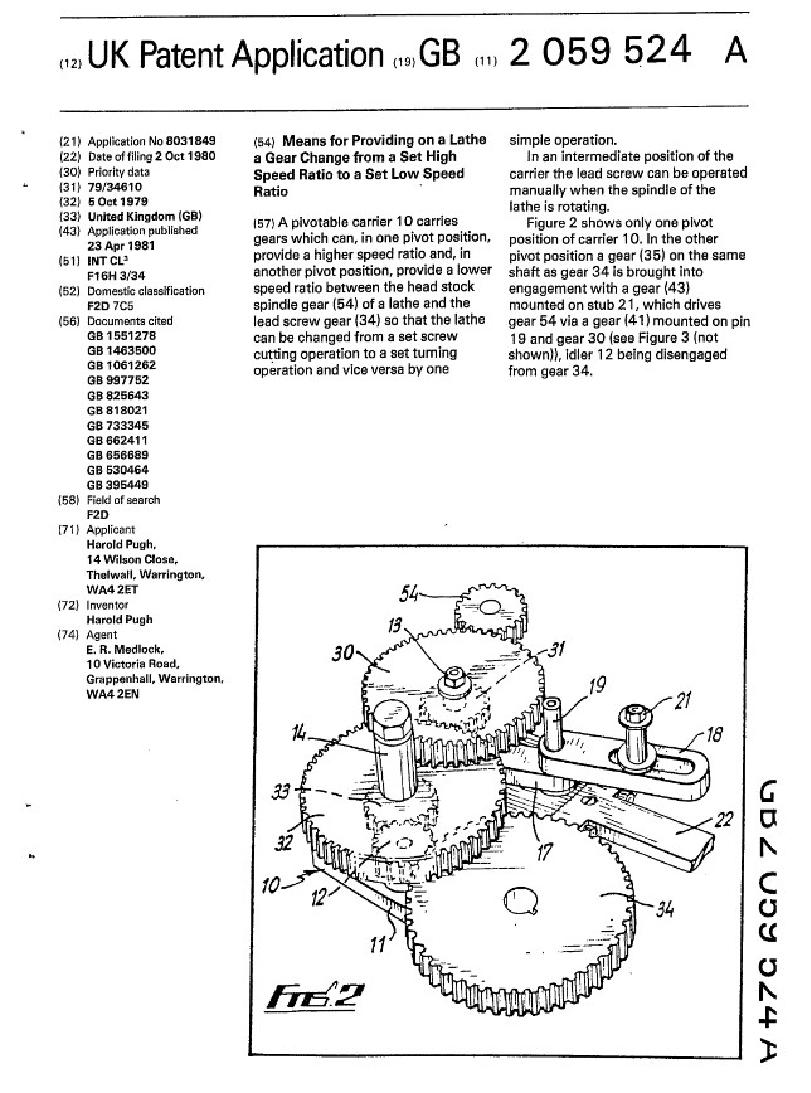

One very interesting screwcutting accessory for the Myford was that invented and patented by Mr. Harold Pugh whose company, Warrington Model Engineering Developments, also manufactured a power cross feed attachment. |

||

|

The Easychange screwcutting chart differed from the Myford original, with the relative complexity of the unit limiting the combinations of changewheels that could be mounted. |

|

- Mk.1, Mk. 2 and various third-party kit-built types - Myford Home Page |

||