|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools for Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts Books Accessories

Hendey Factory Tour 1943

Page 2 Page 3 Page 4 Page 5

During 1943, in the middle of the Second World War, Hendey commissioned a well-known photographer, Robert Yarnall Richie, to produce a picture essay of their production processes. Richie's consummate skill is amply demonstrated in the following pages with the beautifully composed pictures made the more dramatic by low-angle lighting. The complete set is a masterly piece of work and must rank as the most artistic study ever to be published of a machine-tool manufacturing company.

Interestingly, for a machine-tool plant, the illustrations portray a manner of production that relied upon quite ordinary lathes (though operated by highly-skilled employees) with, from the pictures, little evidence that help was afforded by the use of mass-production capstan or other specialist equipment.

Robert Richie may also have been responsible for a similar commission undertaken for the makers of Monarch lathes, a 1938 publication titled "Features of Monarch Lathes".

Other interesting factory tours are those for the German companies Koepfer, VDF, Maho, Schiess (100 years), Index and the English Dean, Smith & Grace and Archdale - together other material from the Fellows 50th Anniversary, Moore Jig Borers the first 50 years, Pfauter Gear Hobbers 60th Anniversary, TOS Machine Tools History and with some inside views of lathe makers Herbert, Wadkin, Colchester and Lang..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fair-weather cumulus clouds over the factory, summer 1943

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The General Sales Manager, Mr. F.J.McCarty and his assistant, Mr. H.V.Rebillard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Board Room: Mr David Ayr, President and General Manager, consults with the Vice President and Assistant General Manager Mr. Edgar G. Seybold.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

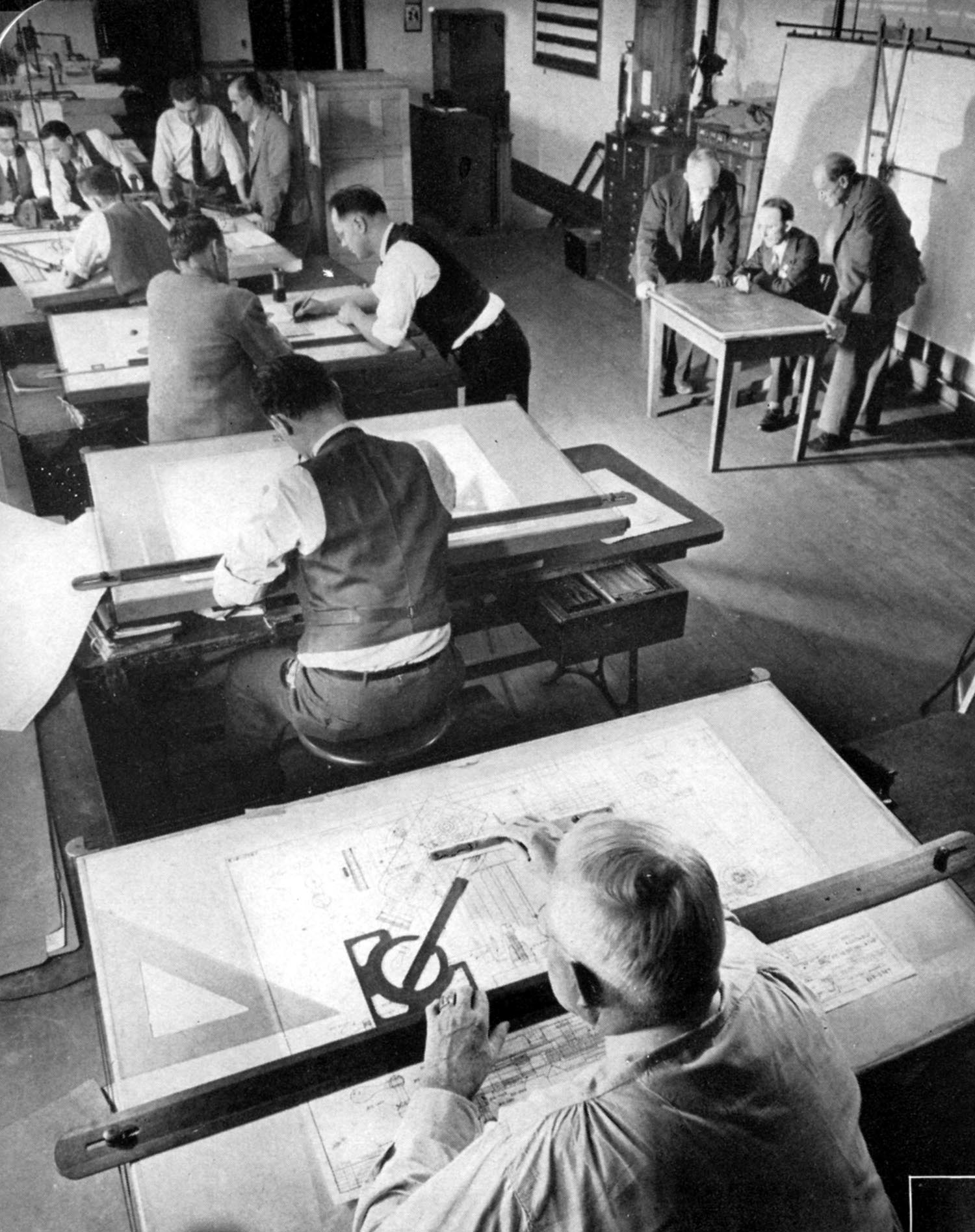

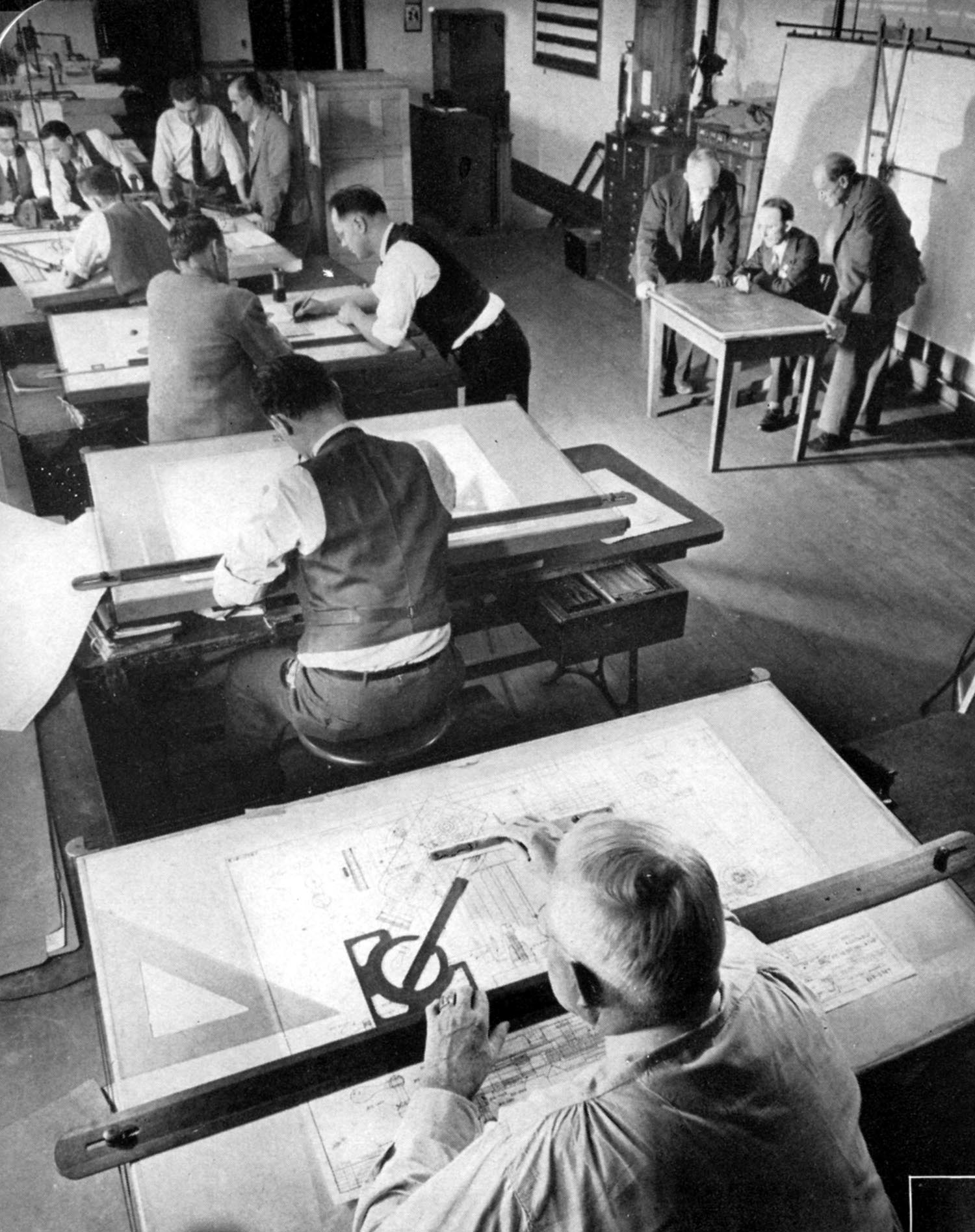

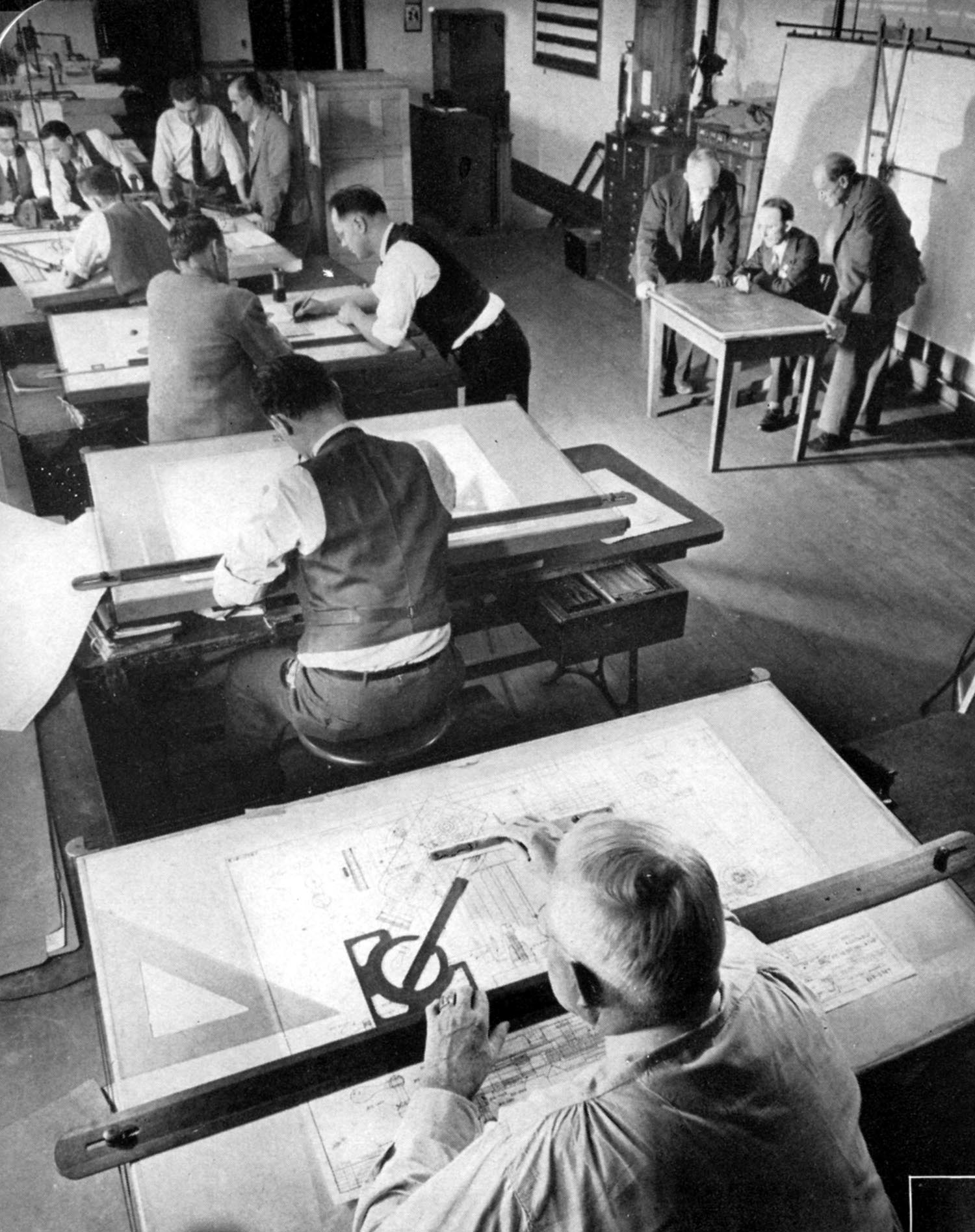

Engineering and Drawing Office

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

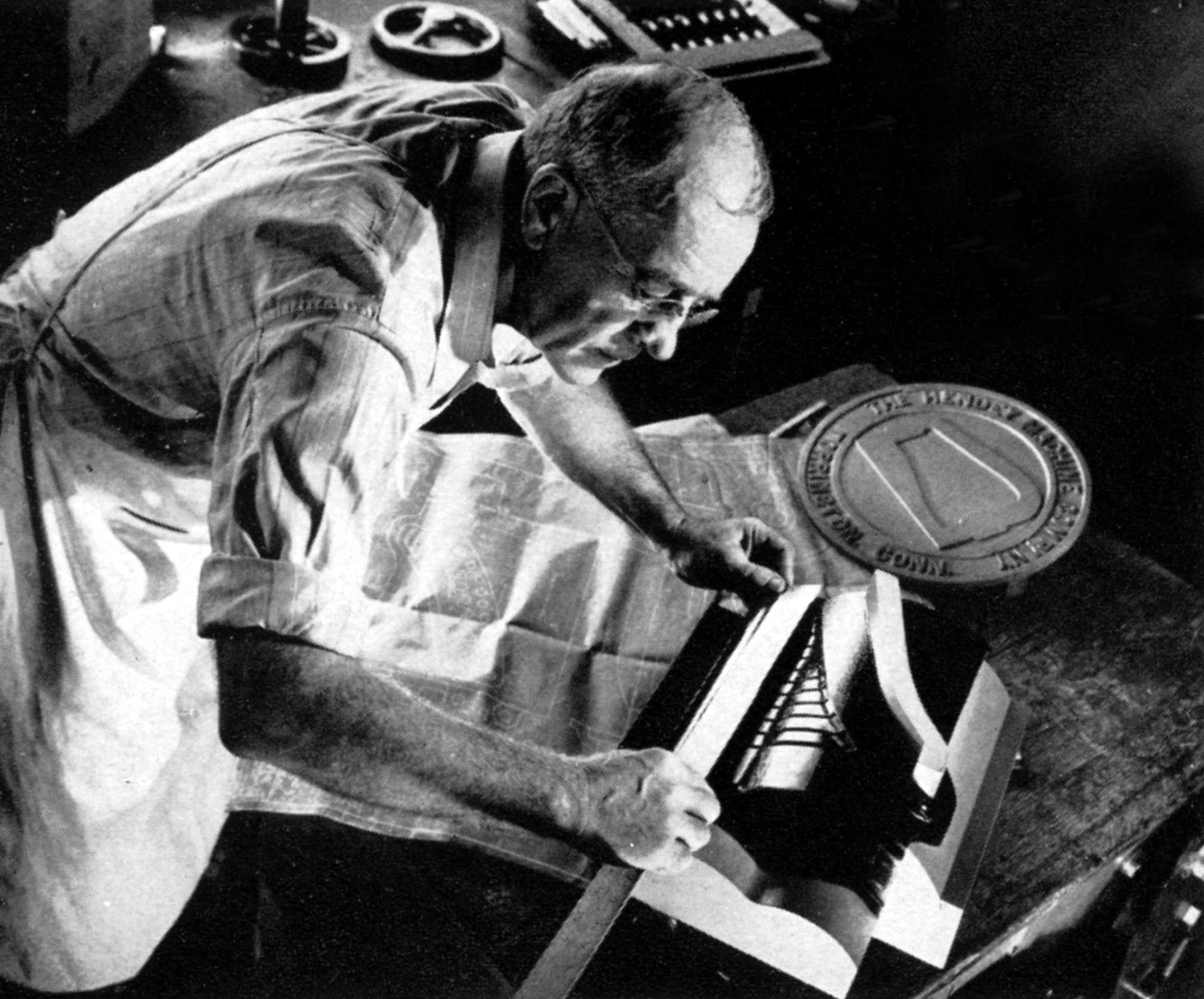

A quieter room than many in the factory the pattern shop worked to the principle that: "precision begins in the pattern".

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

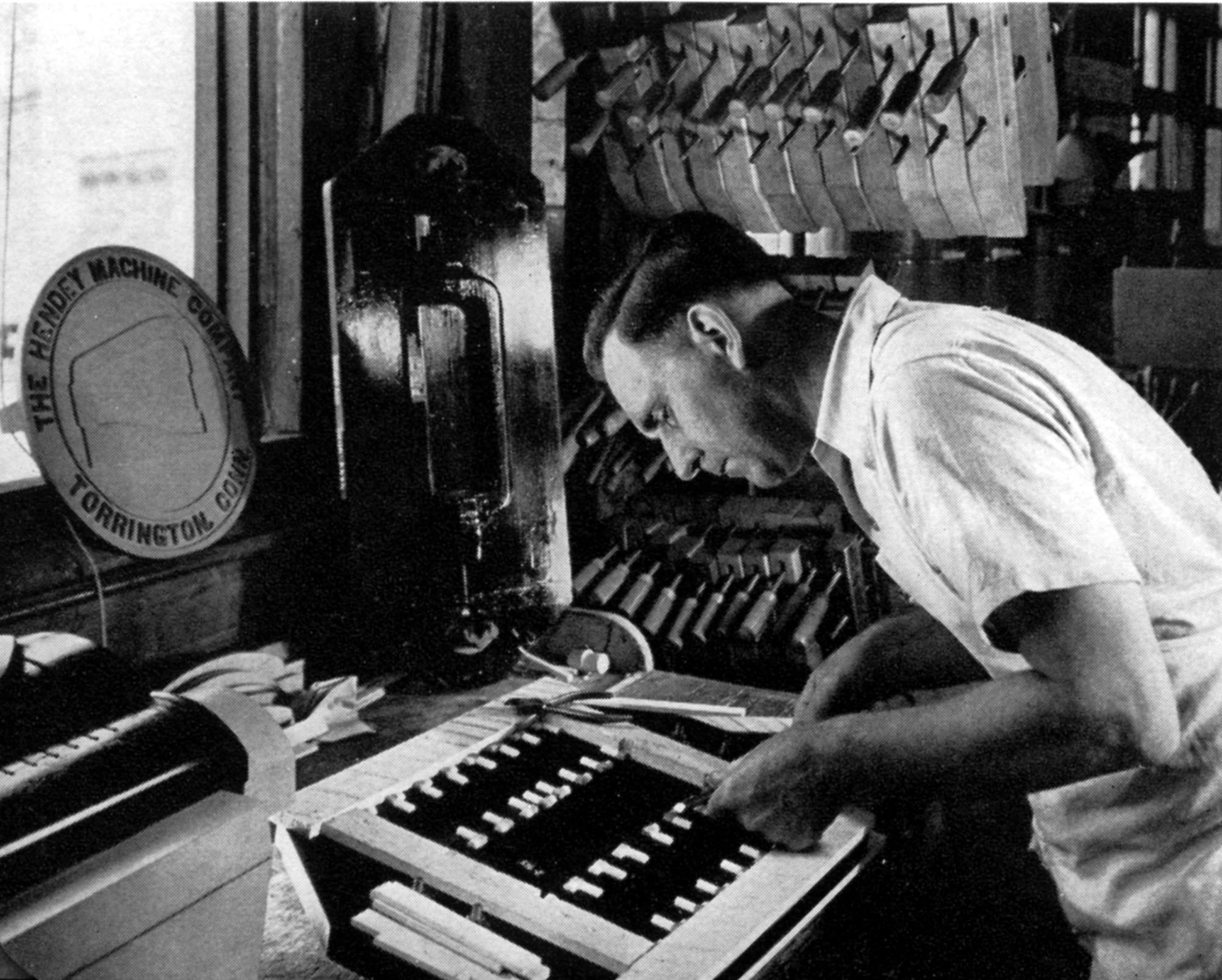

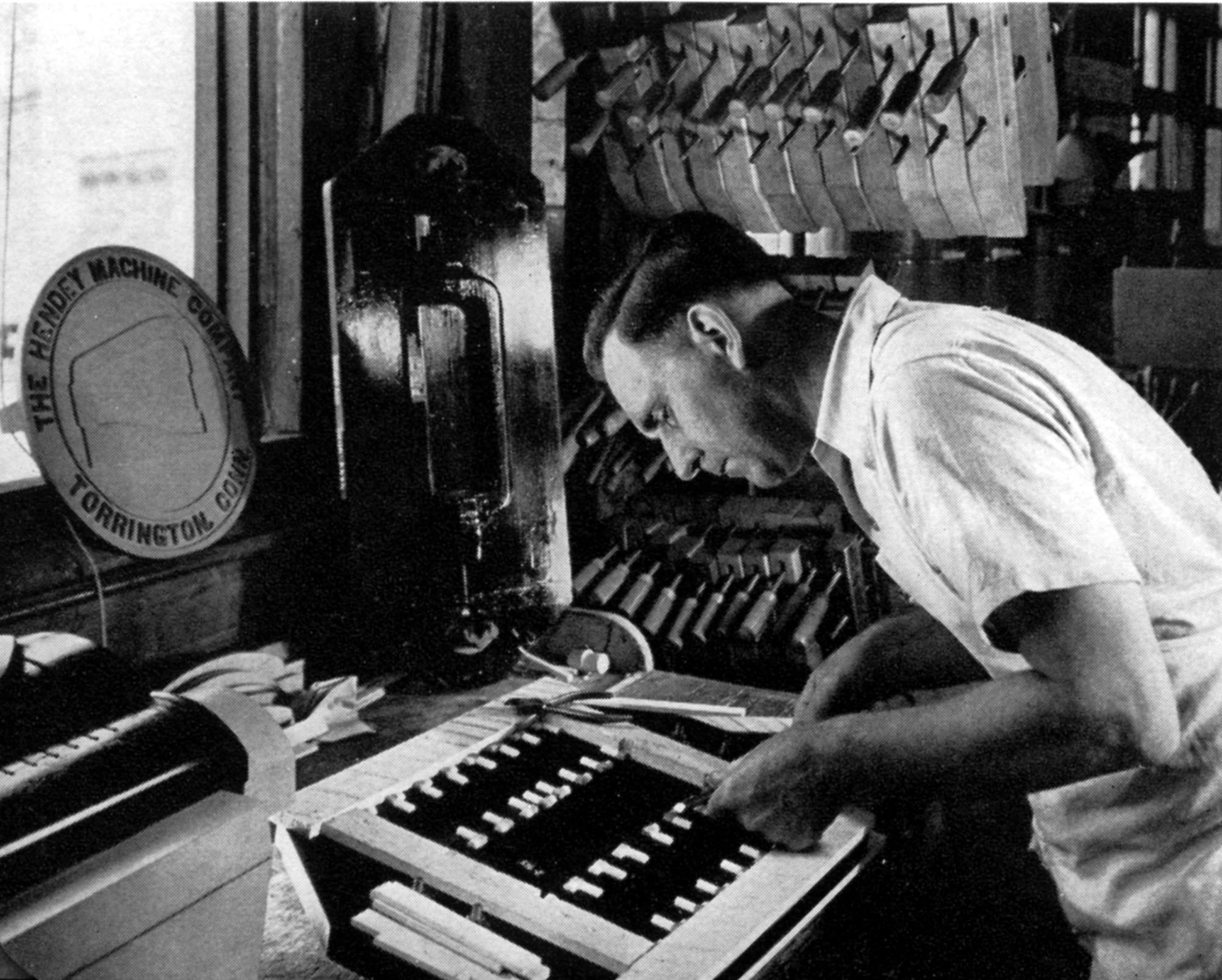

Multiple small patterns being arranged on a board prior to forming the "gating" that allowed molten metal to flow through the box.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

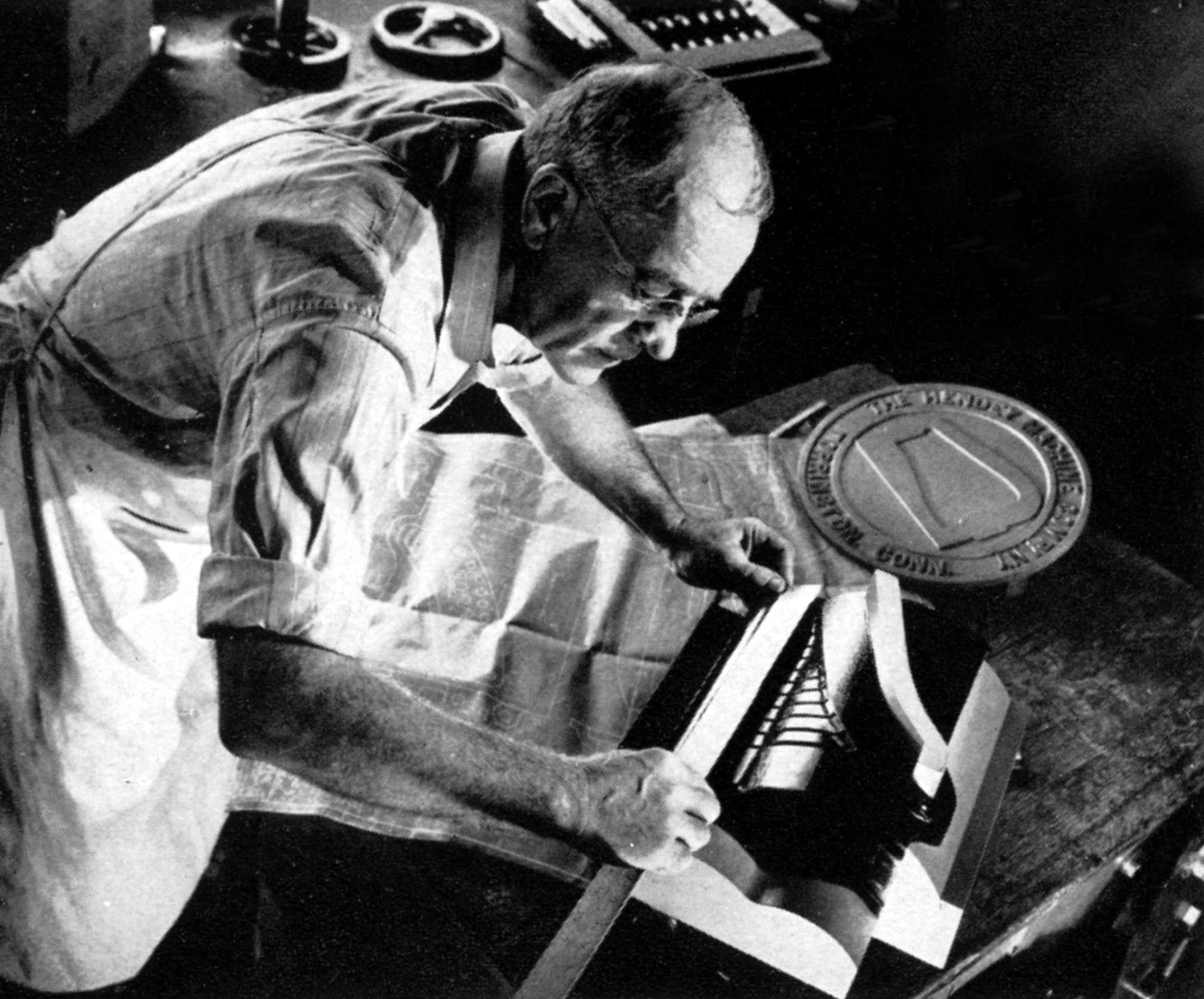

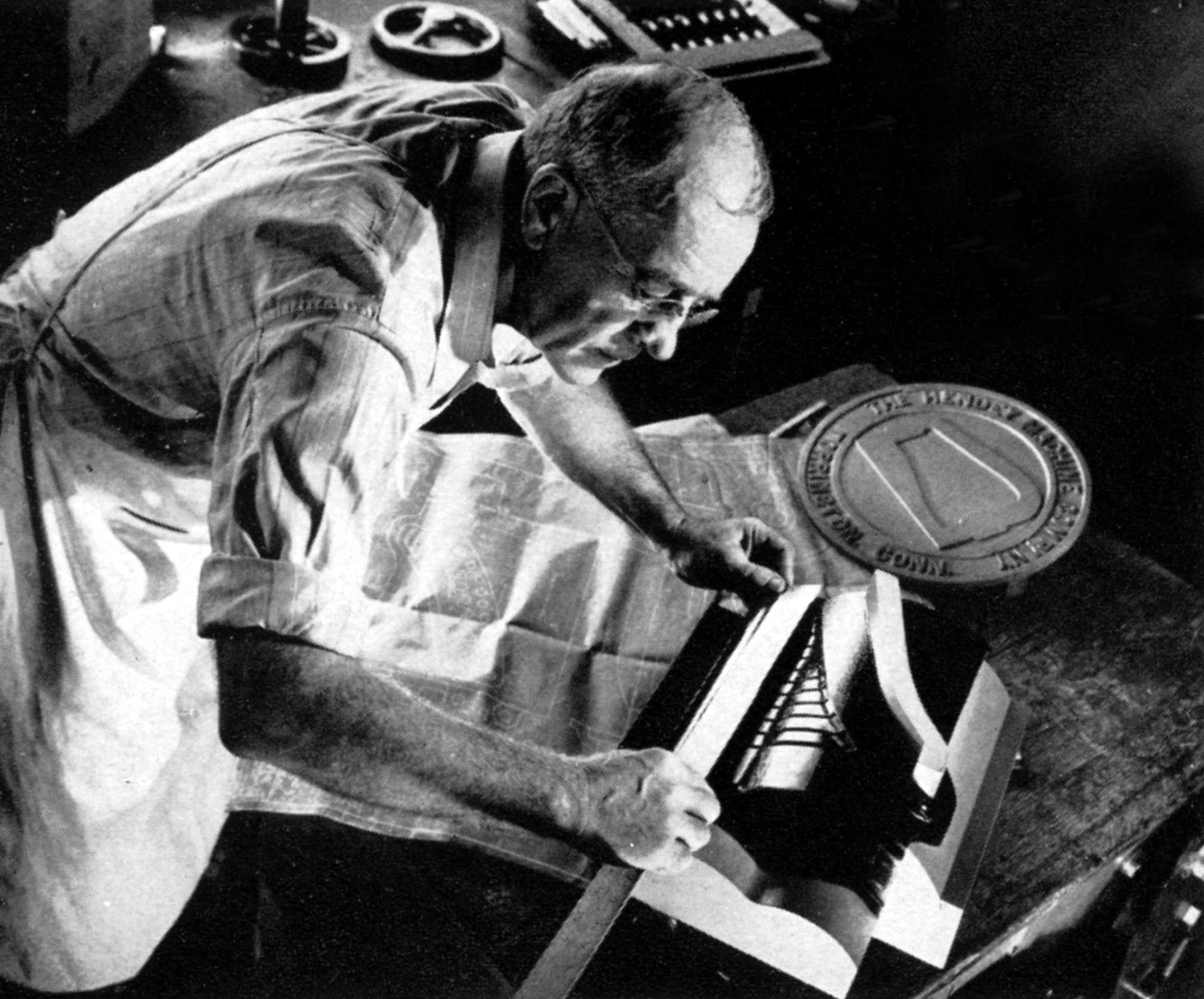

Measuring a gearbox pattern with a "shrink" rule - calibrated to allow for the shrinkage that occurs as metal cools in a mould.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

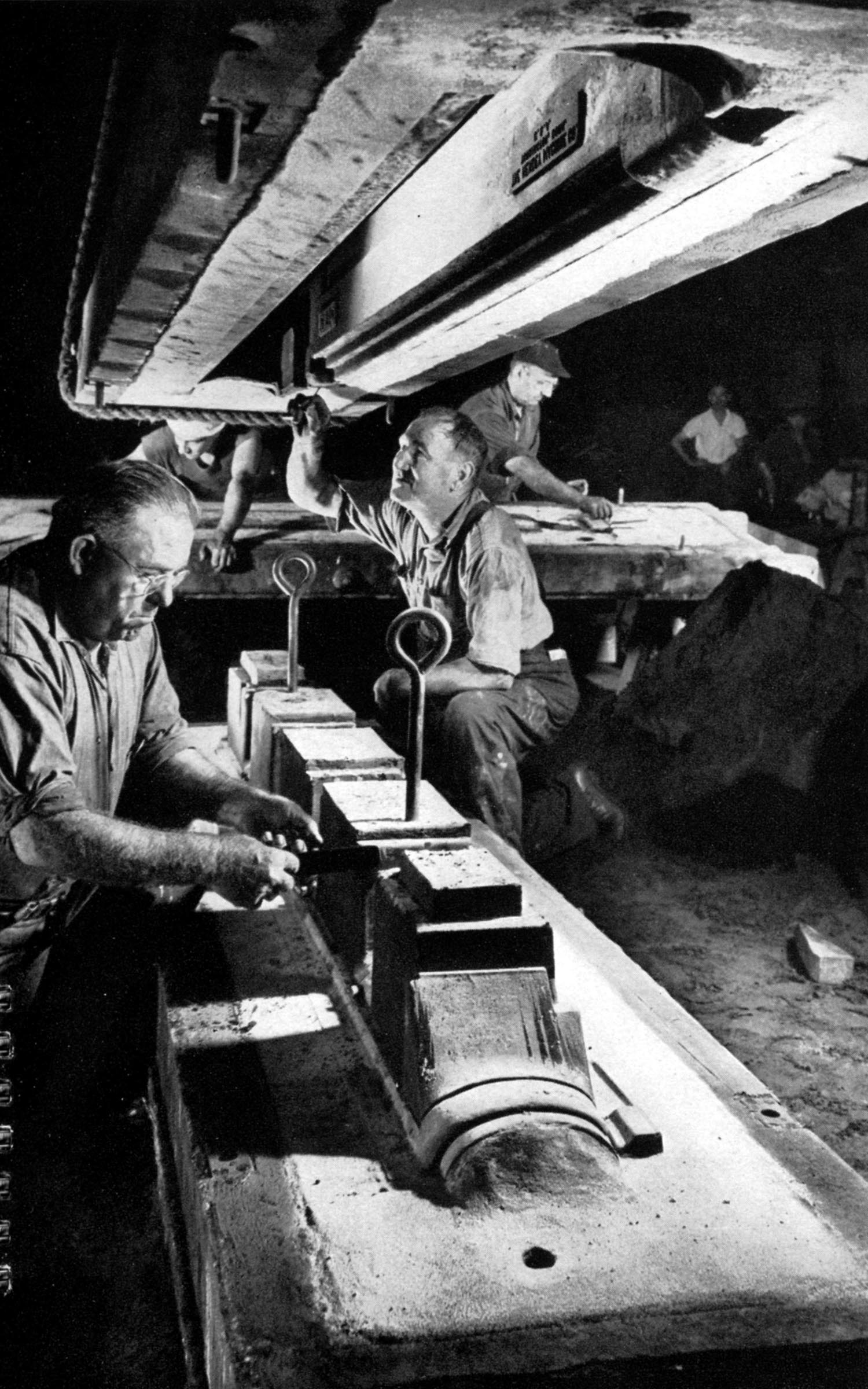

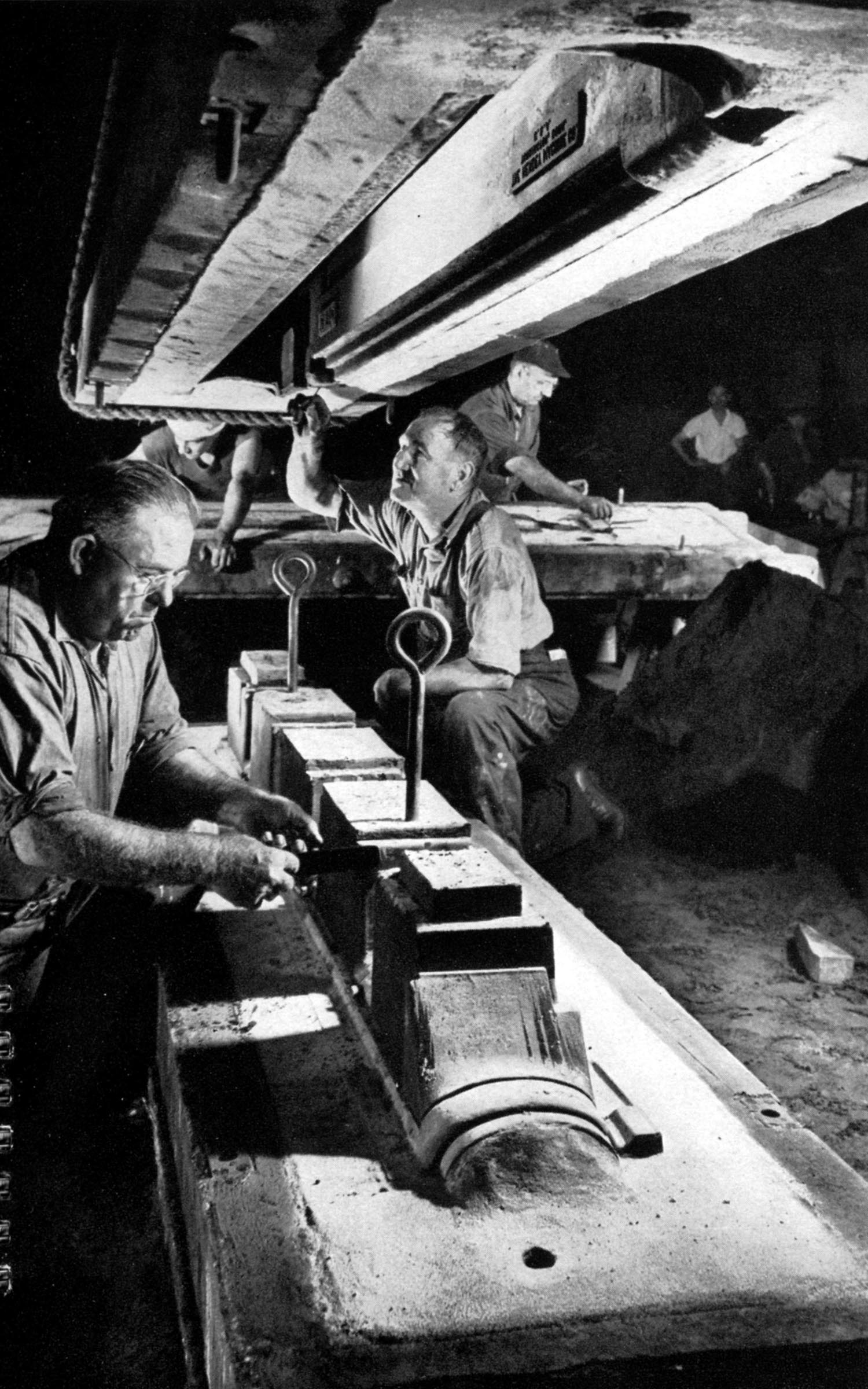

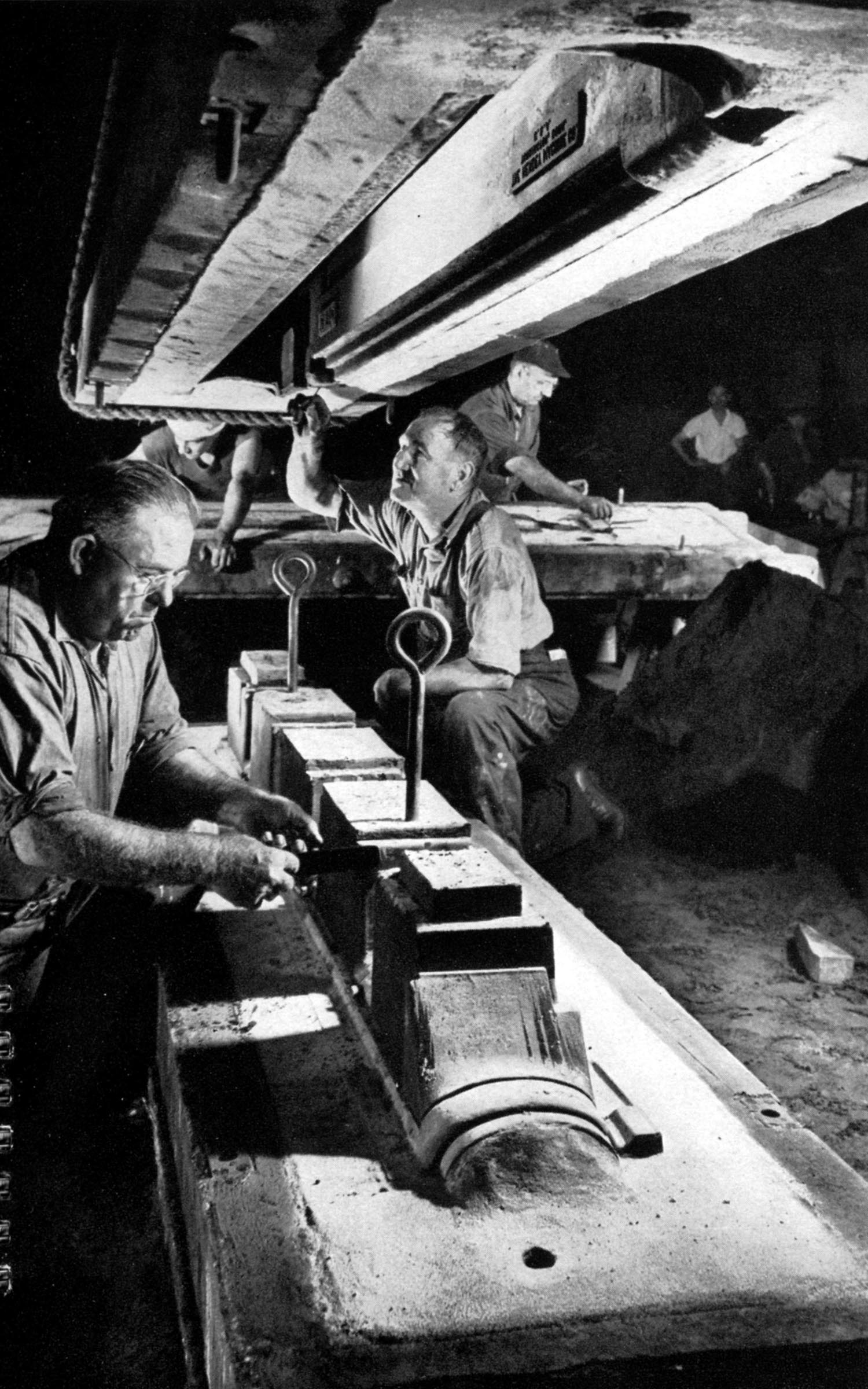

"Experienced workers put the finishing touches to the core and mould of a 3-part flask"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cores being readied for baking in of several large ovens

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

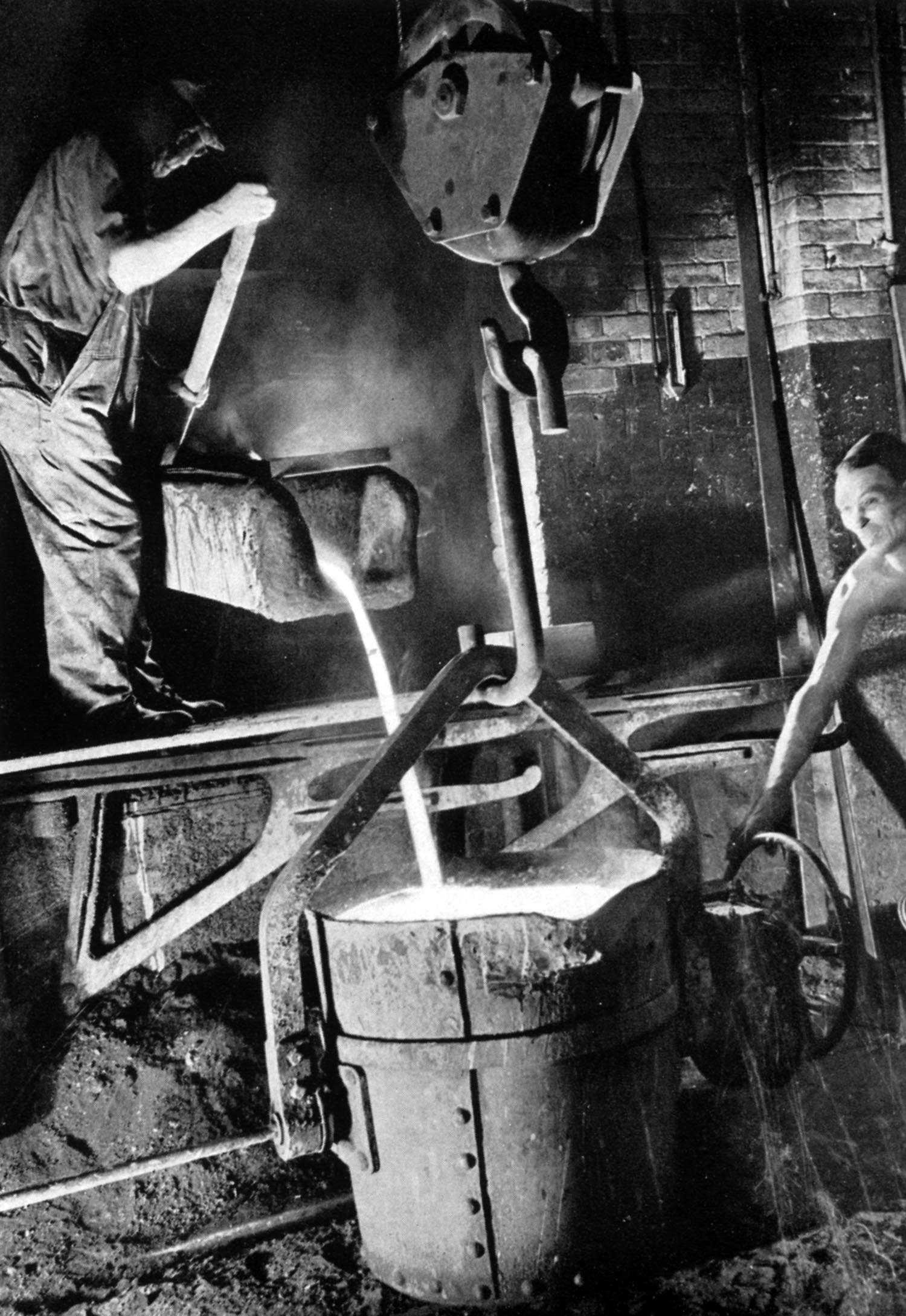

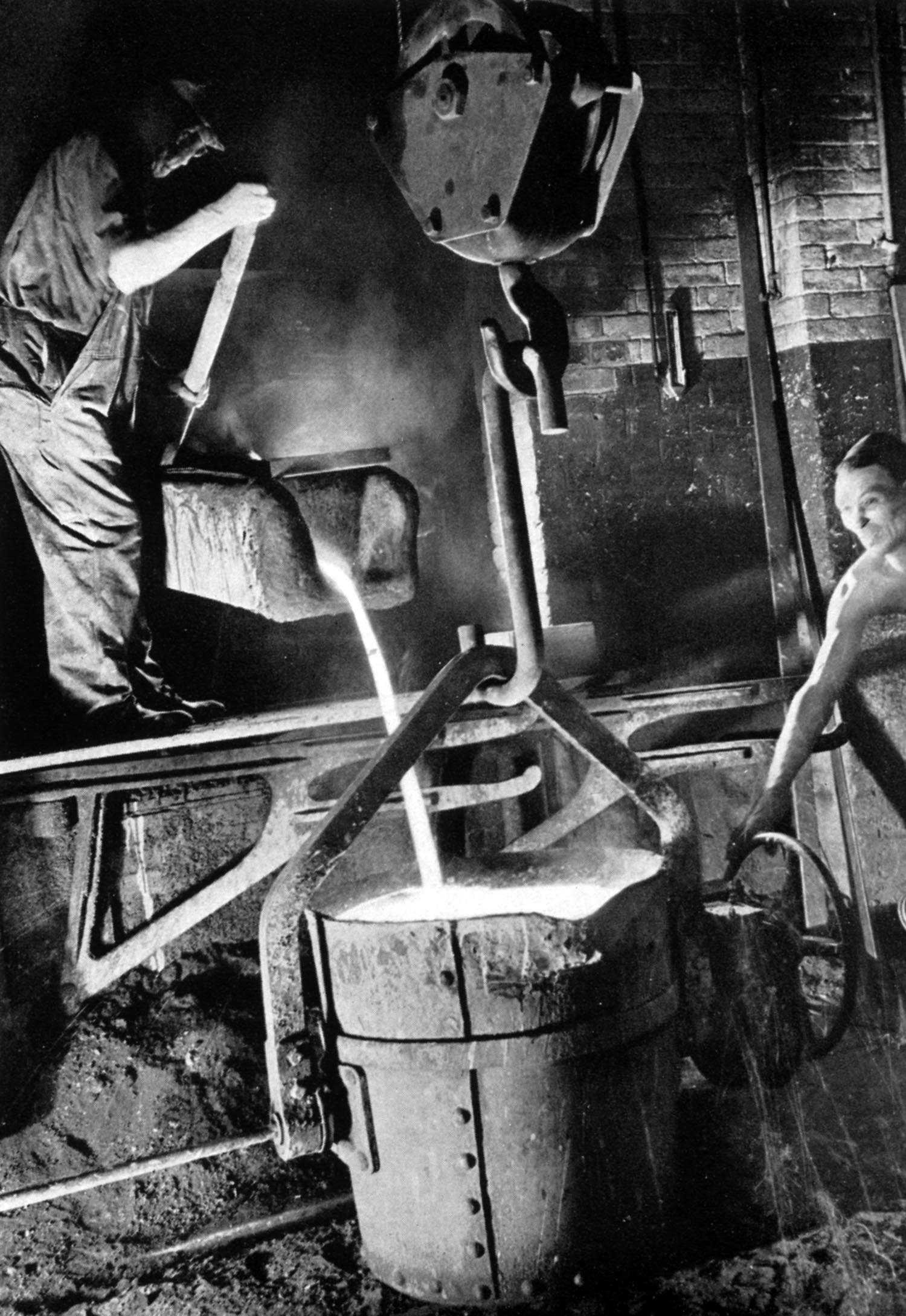

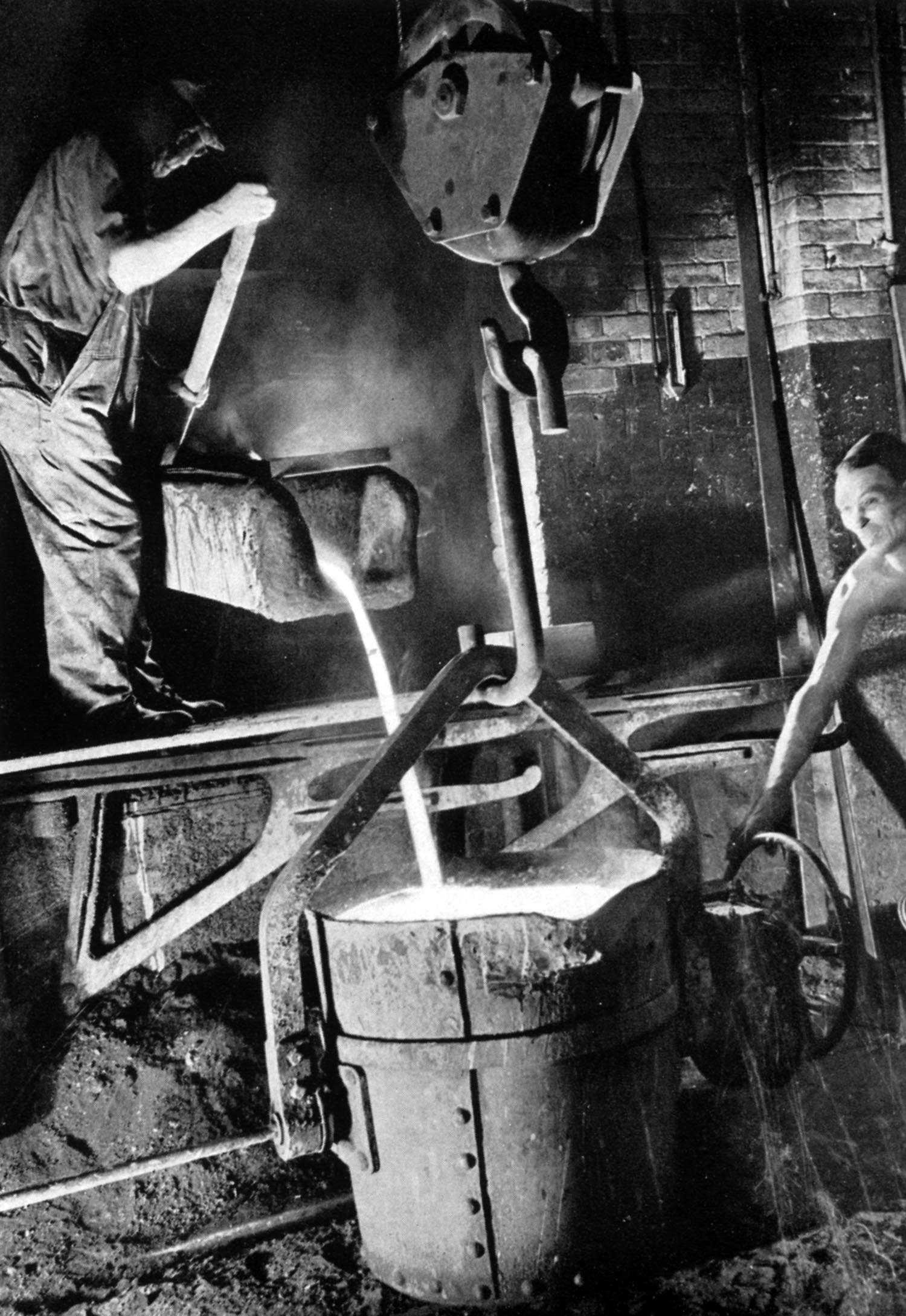

Running Molten metal from the cupola into a bull ladle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

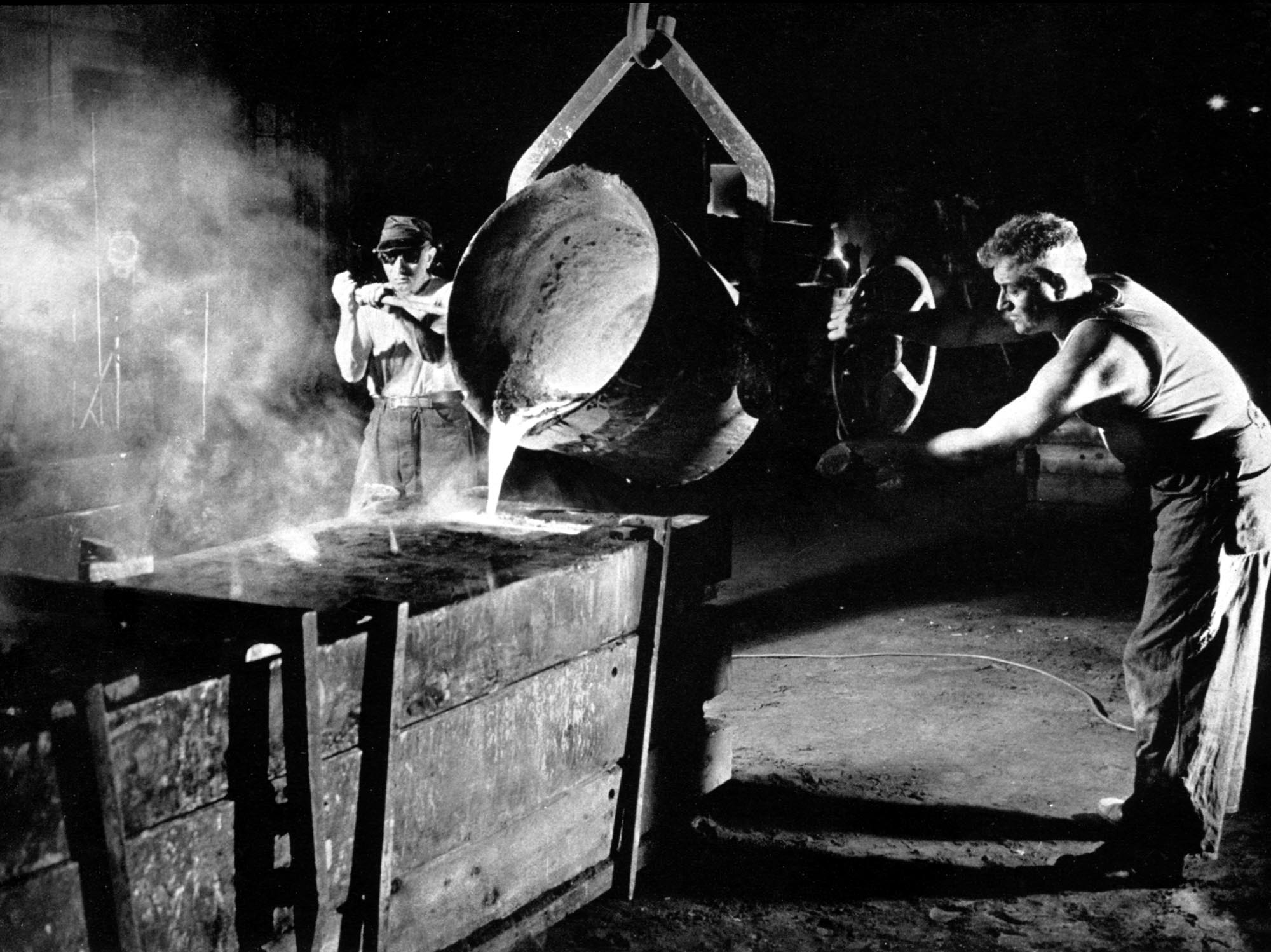

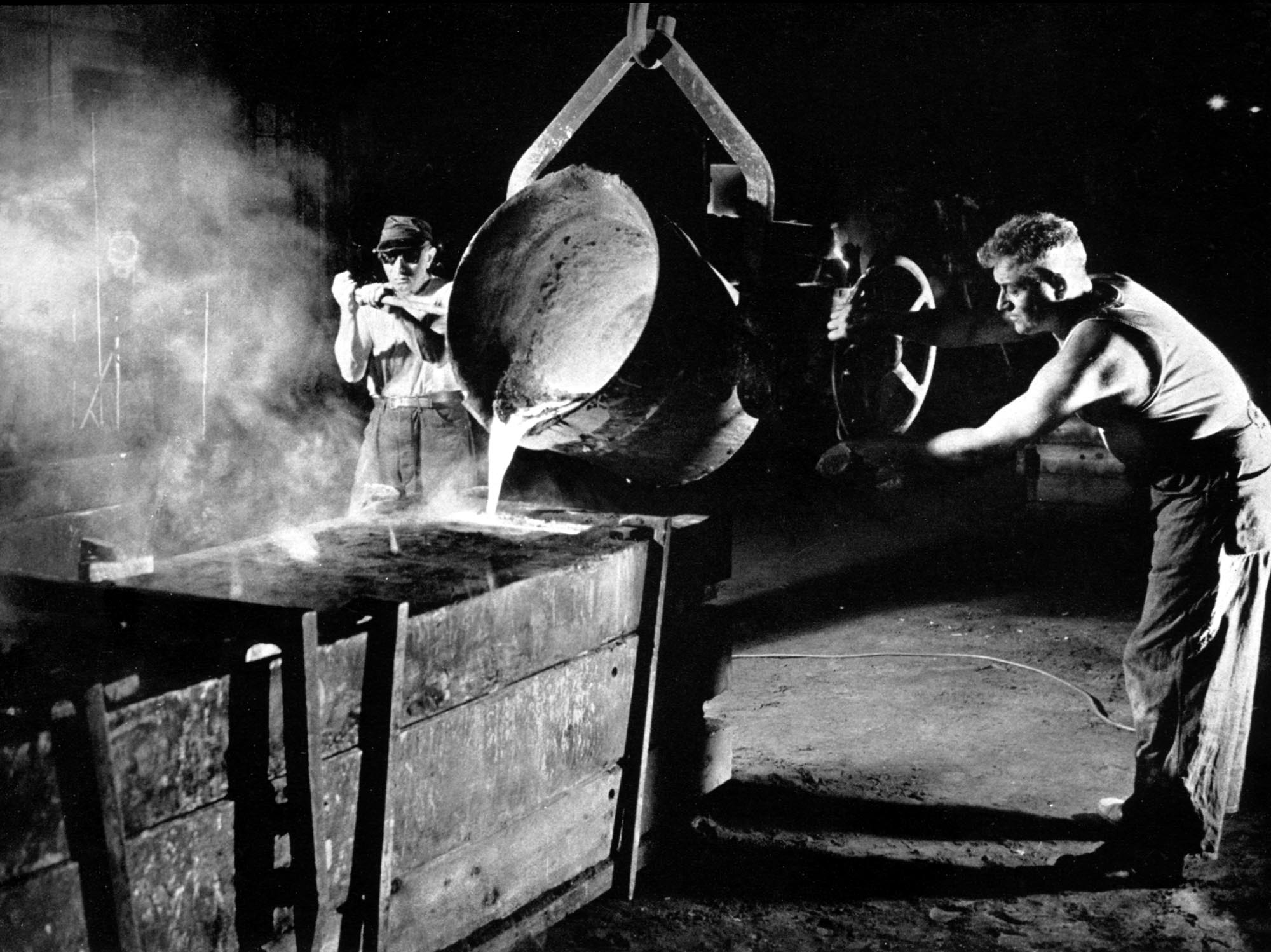

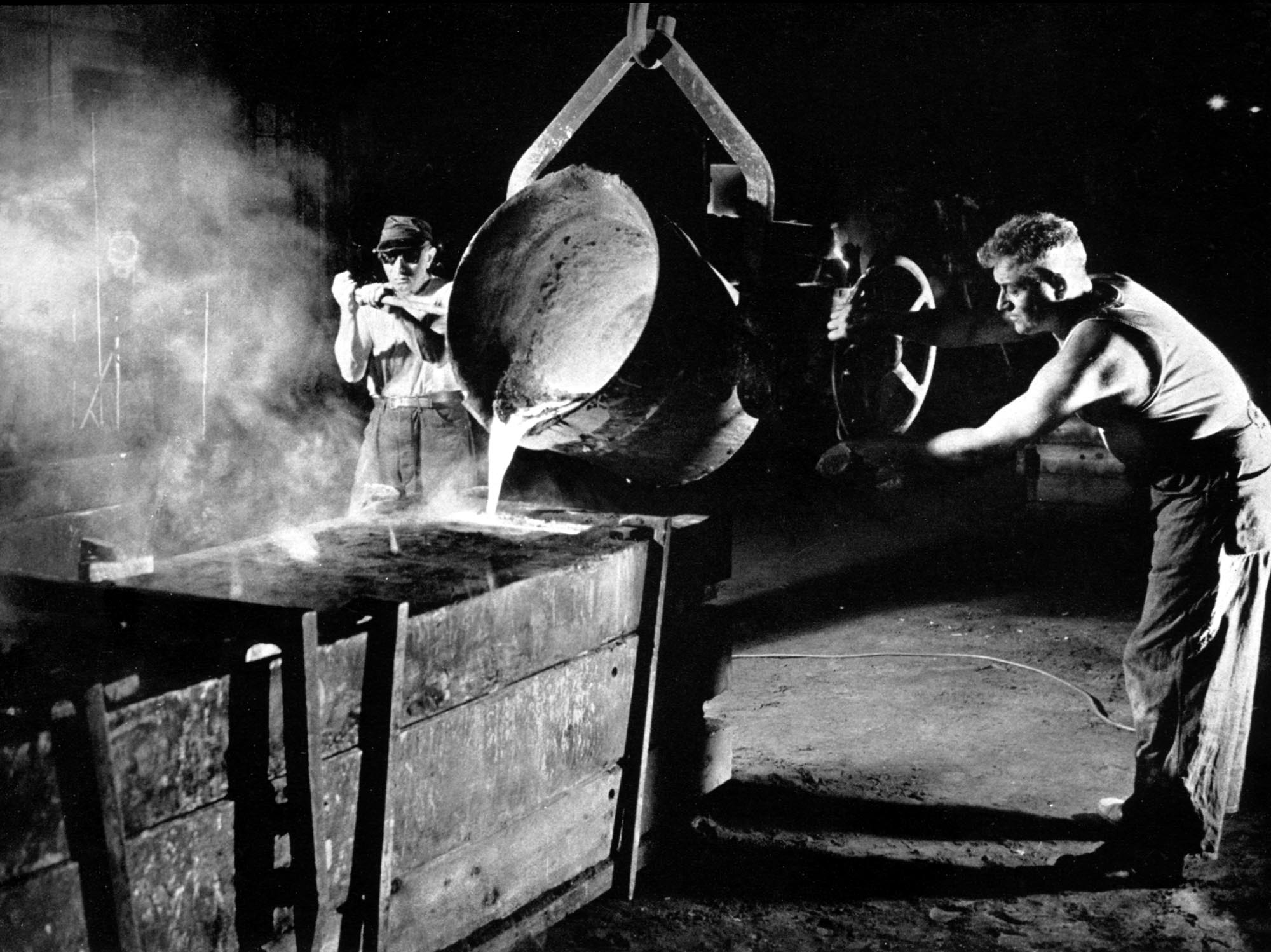

Above: the bull ladle almost filled and ready for pouring into the large bed moulds

Below: pouring molten metal from the bull ladle into a flask.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

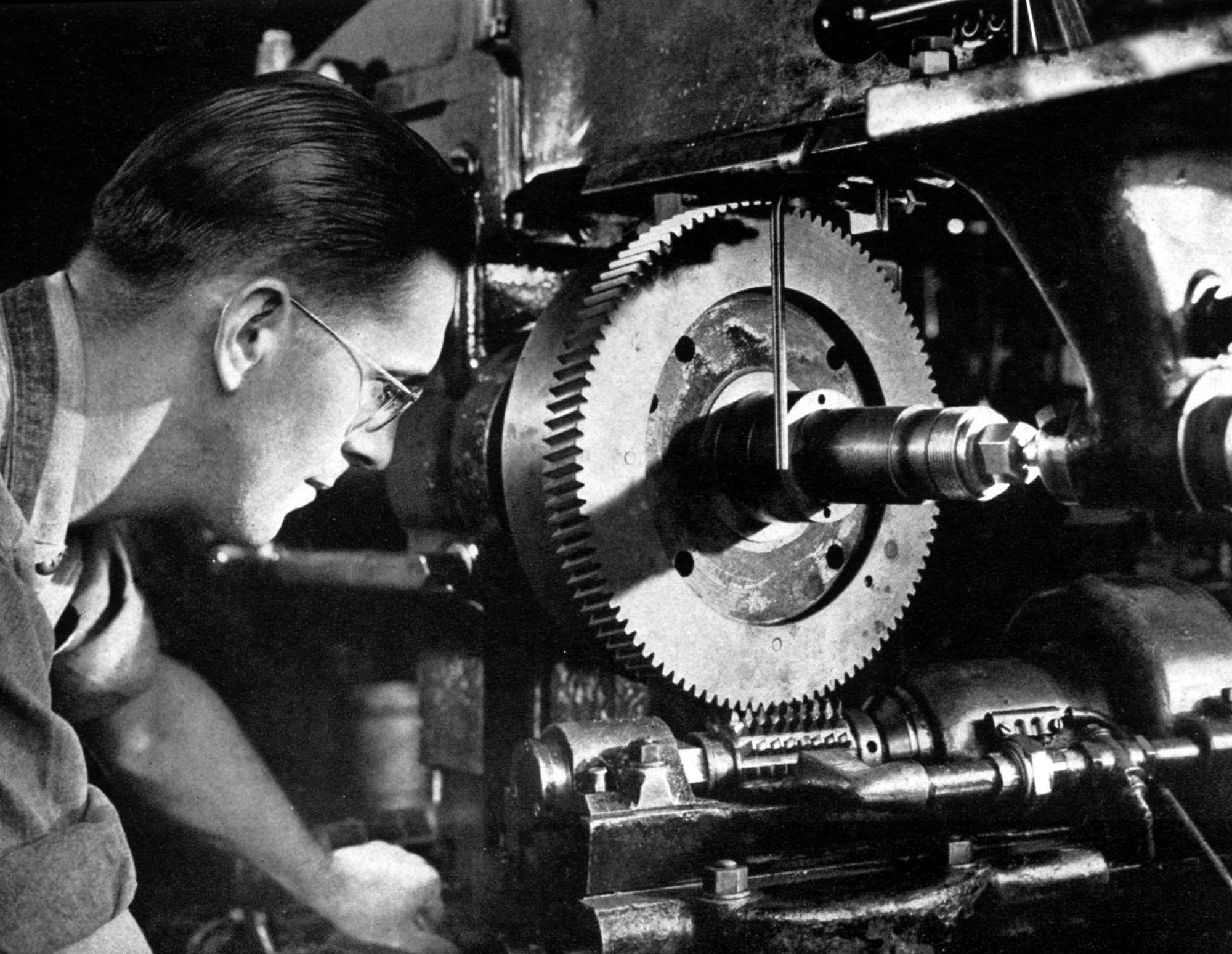

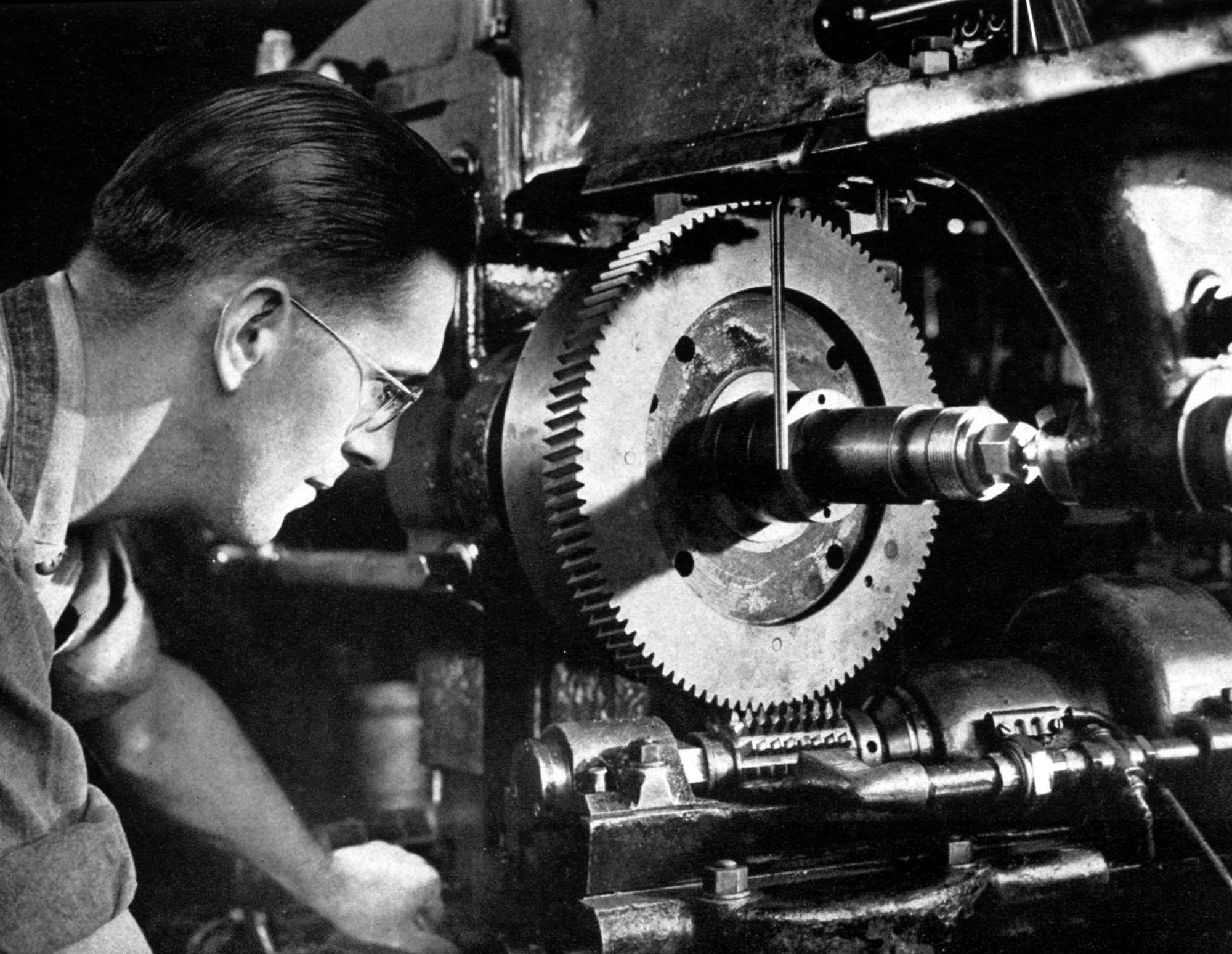

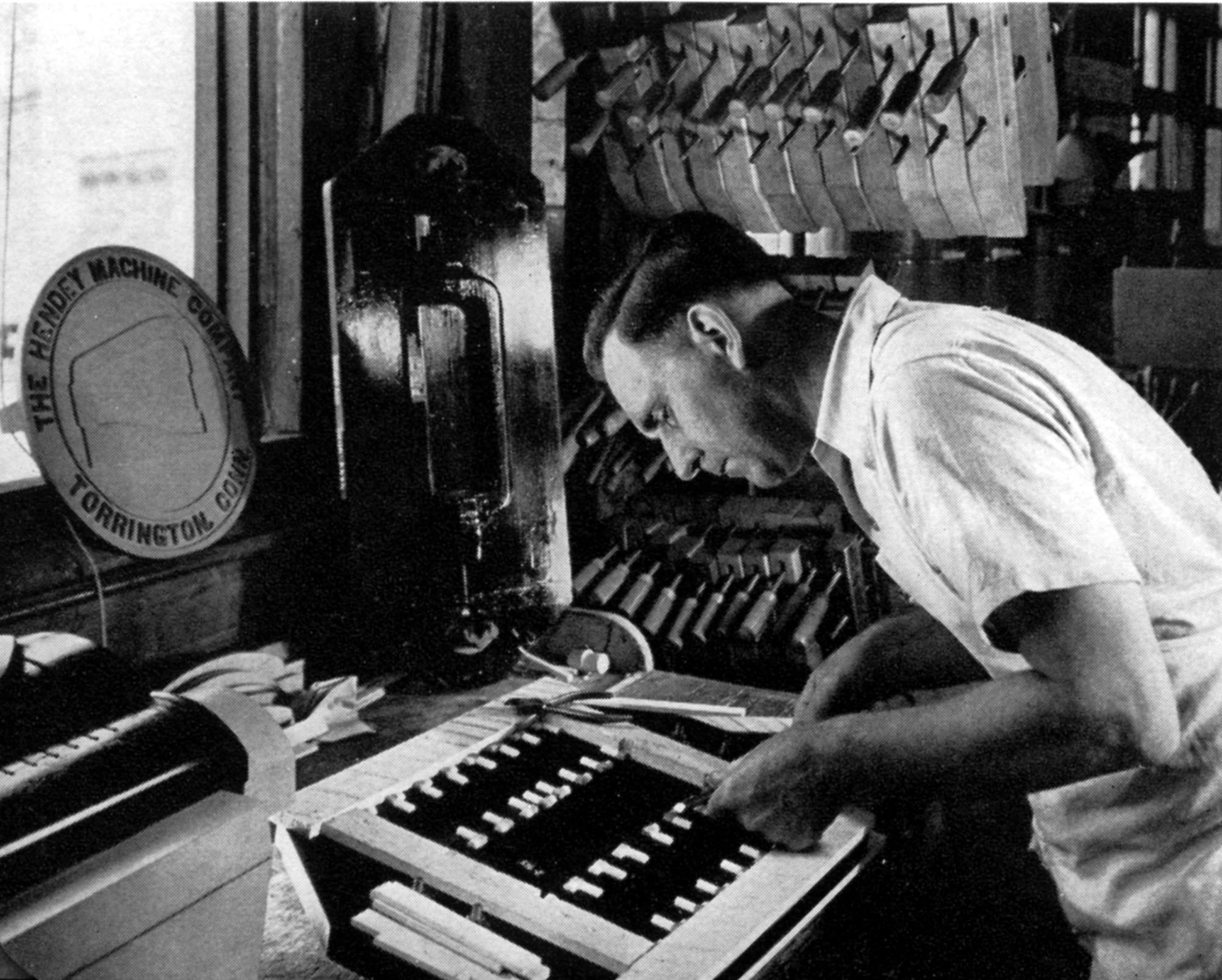

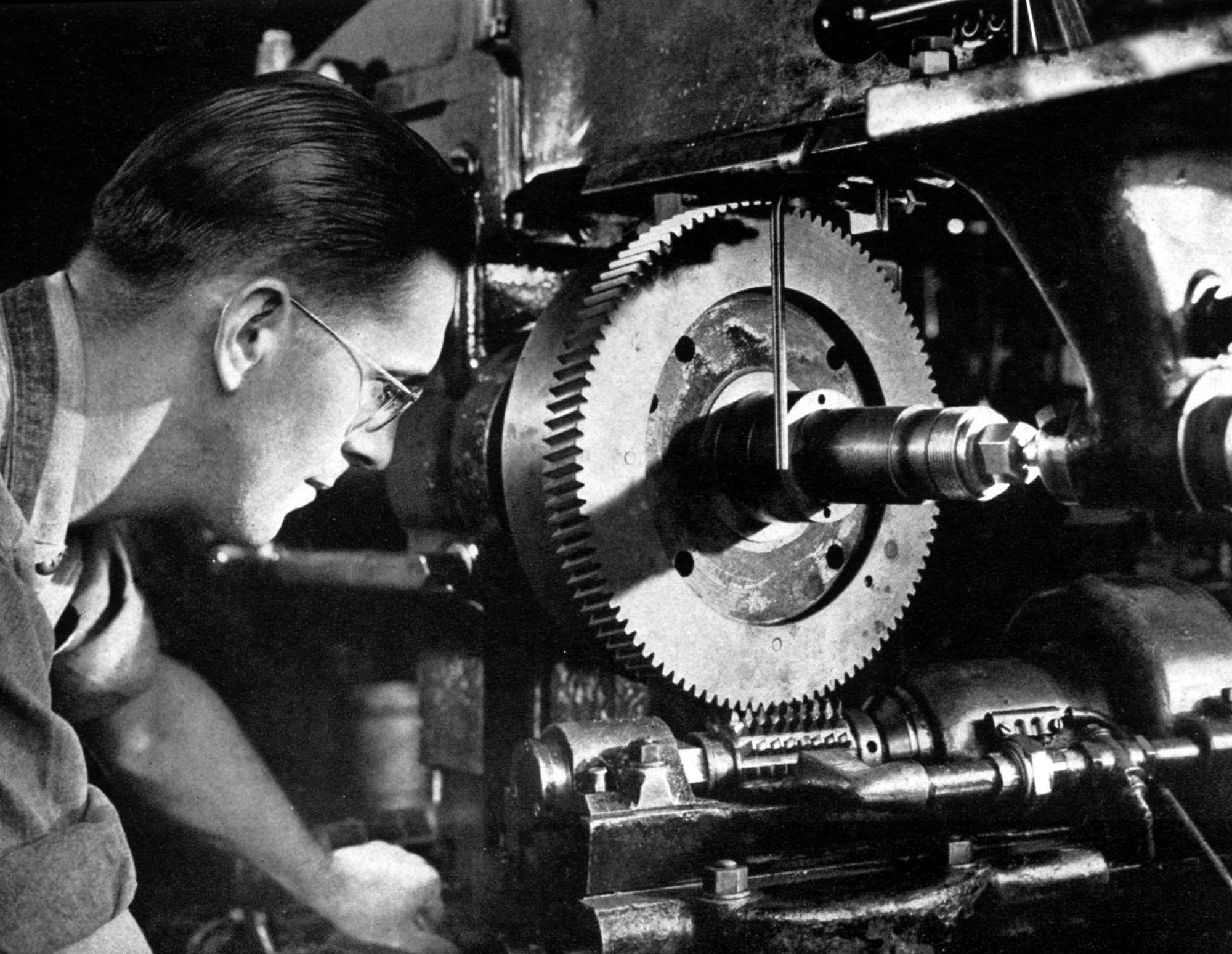

Hobbing the crank gear for a Hendey 12-inch Crank Shaper on a Barber Coleman gear hobber

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

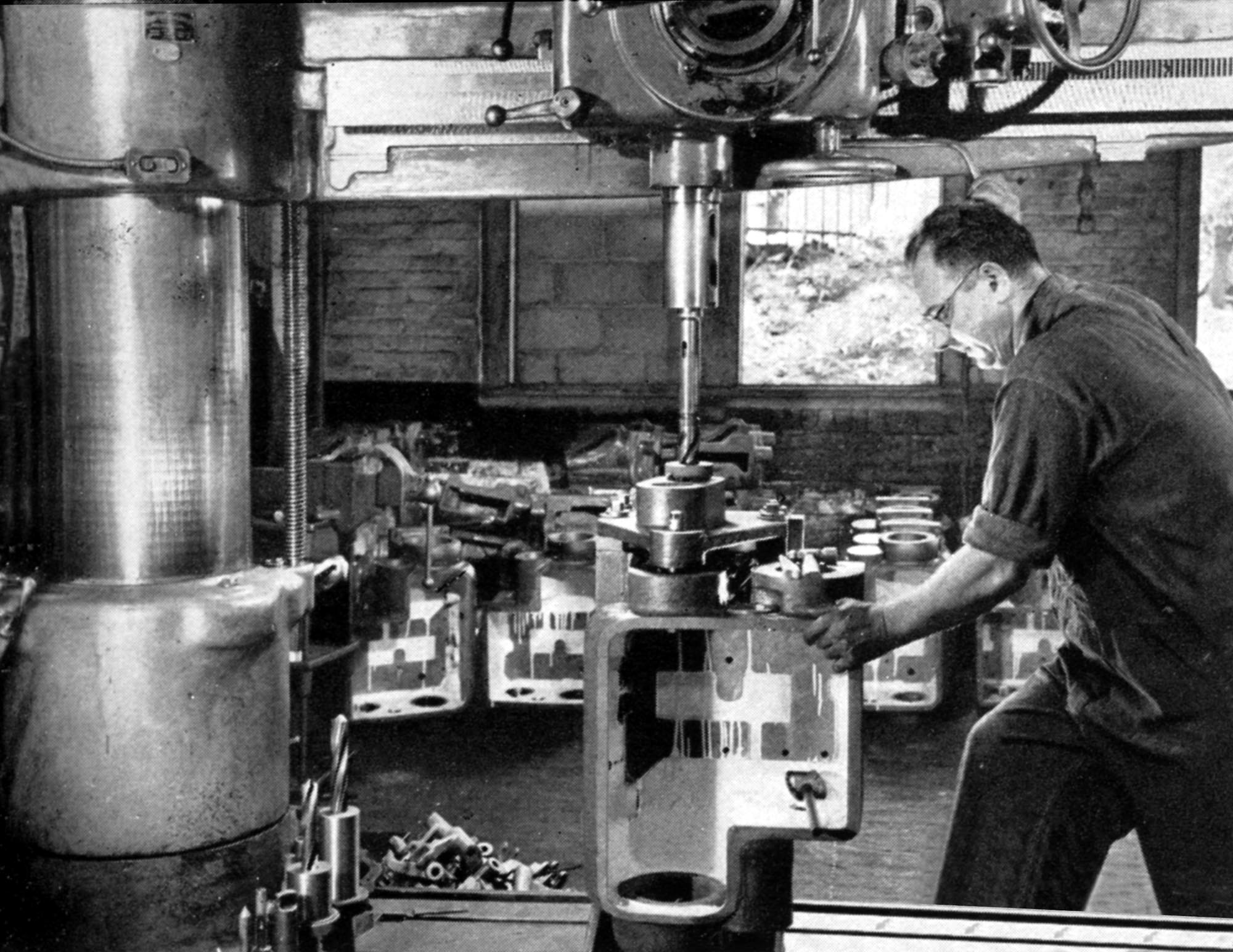

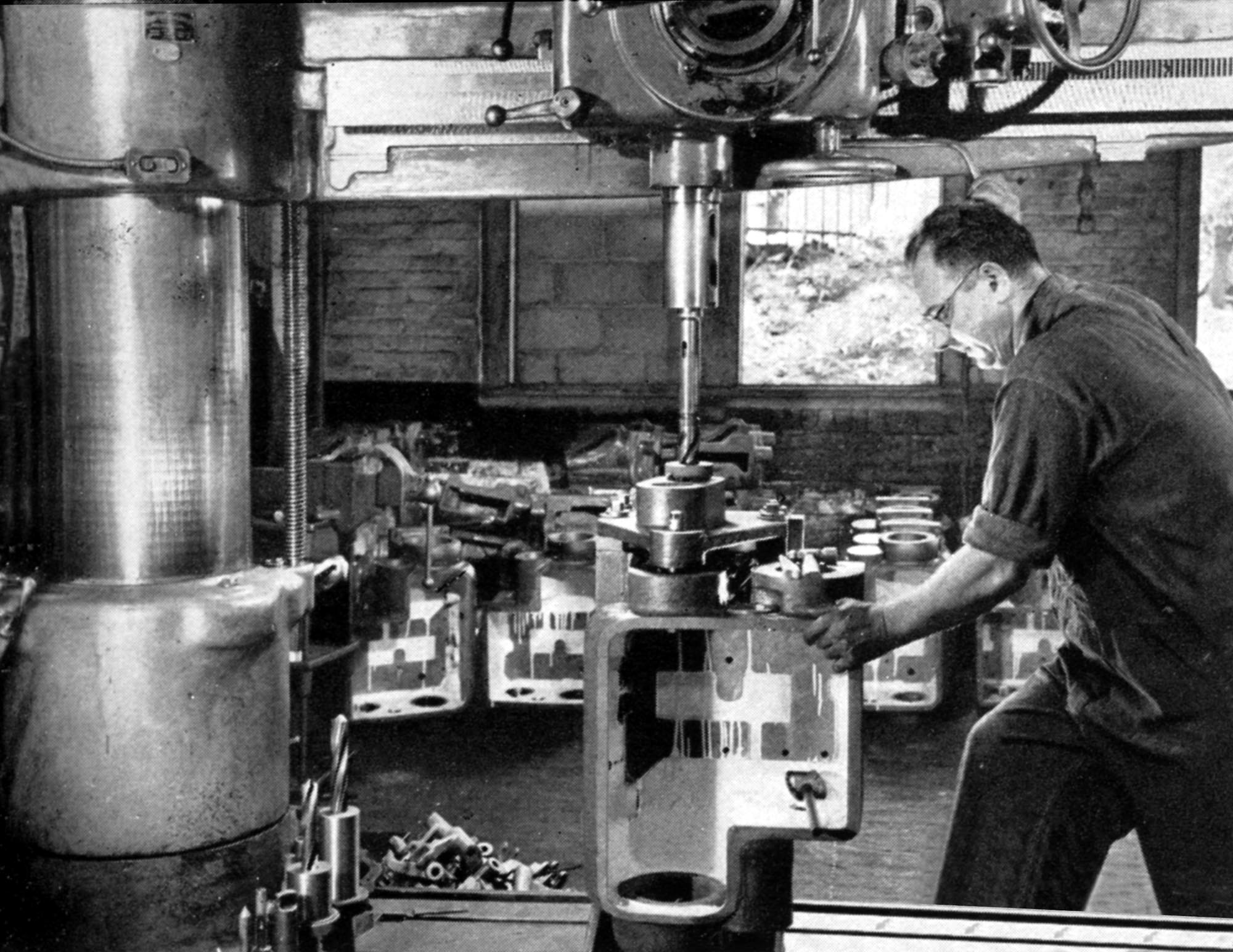

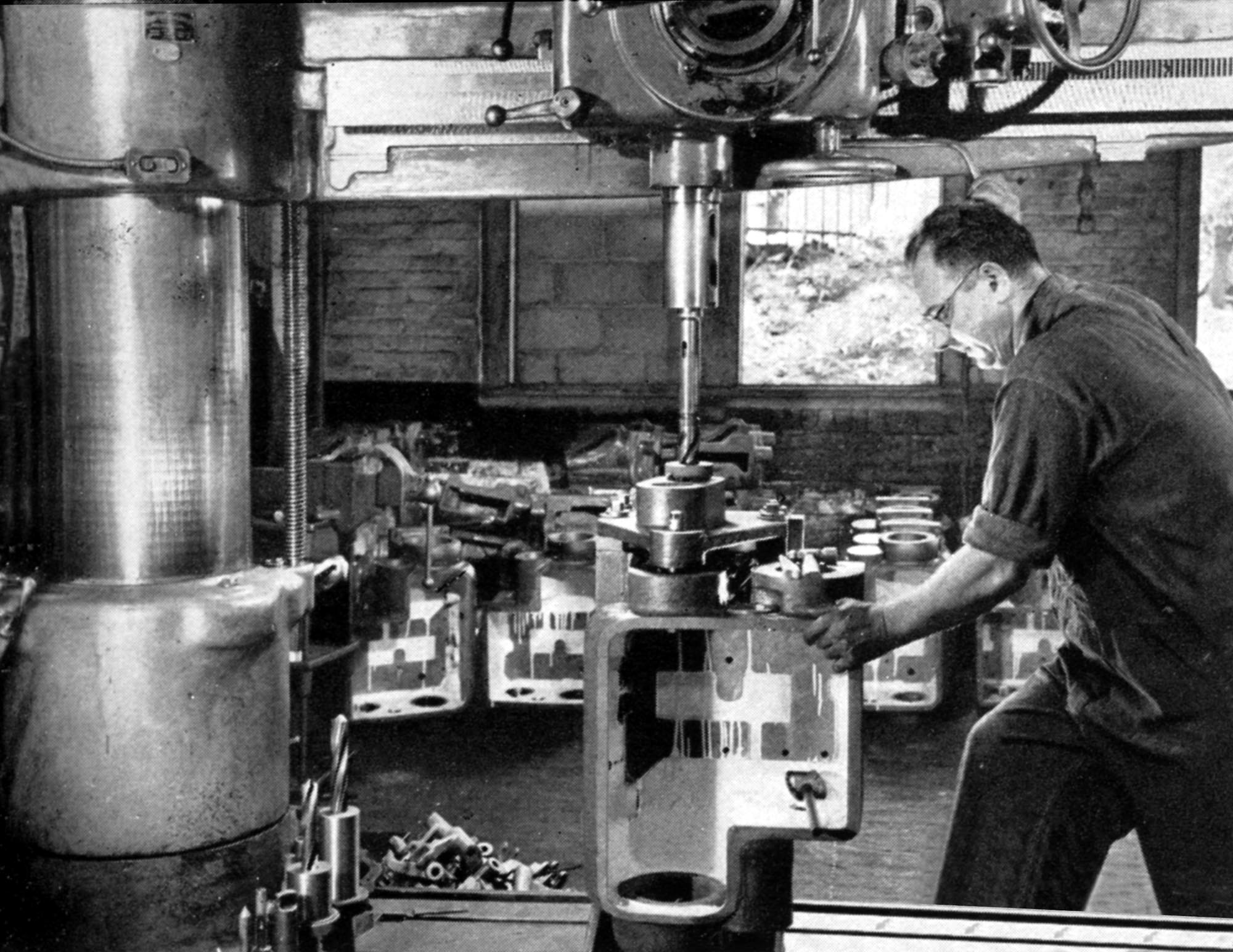

Secondary holes in the headstock casting were jig-drilled on a large radial-arm drill

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

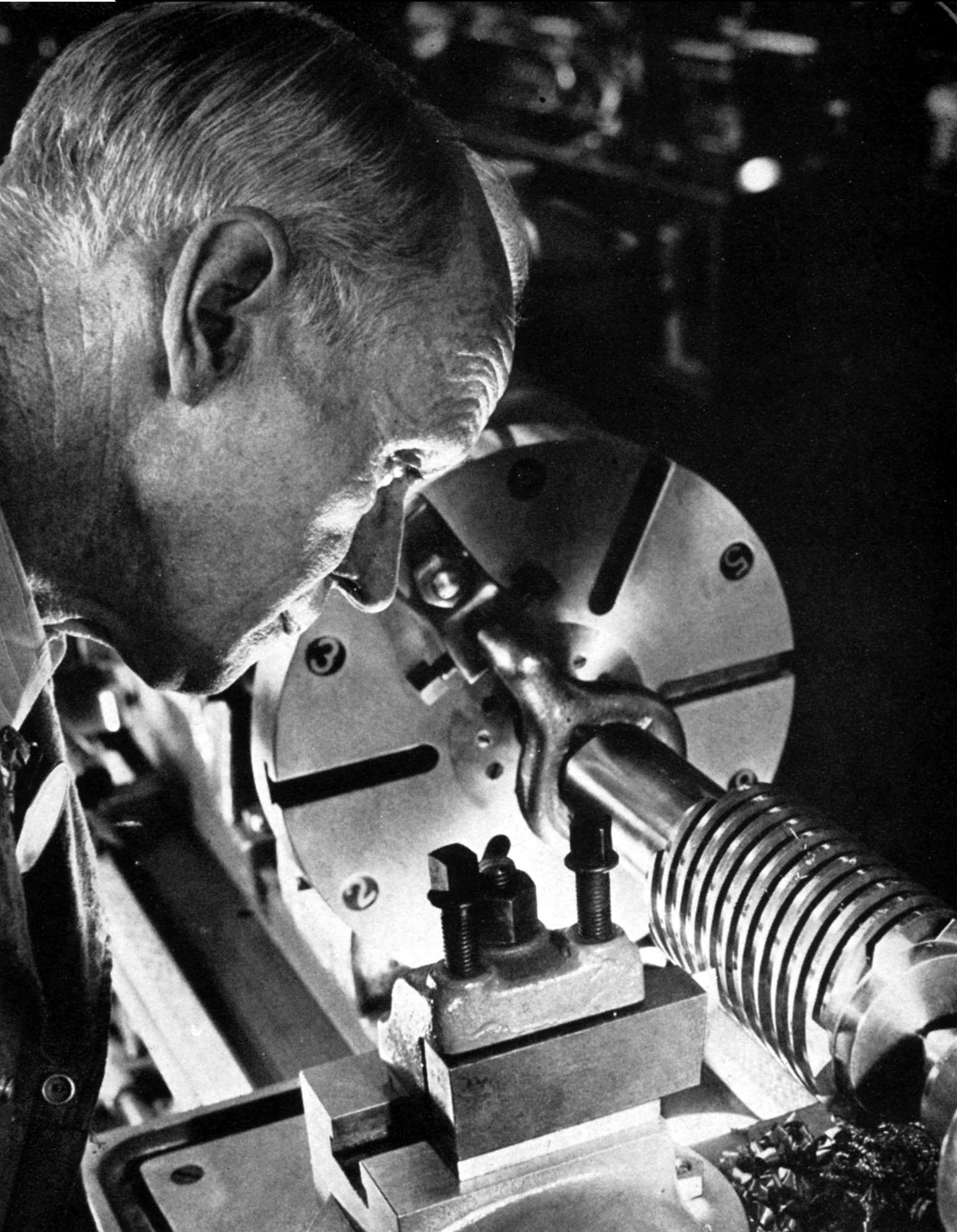

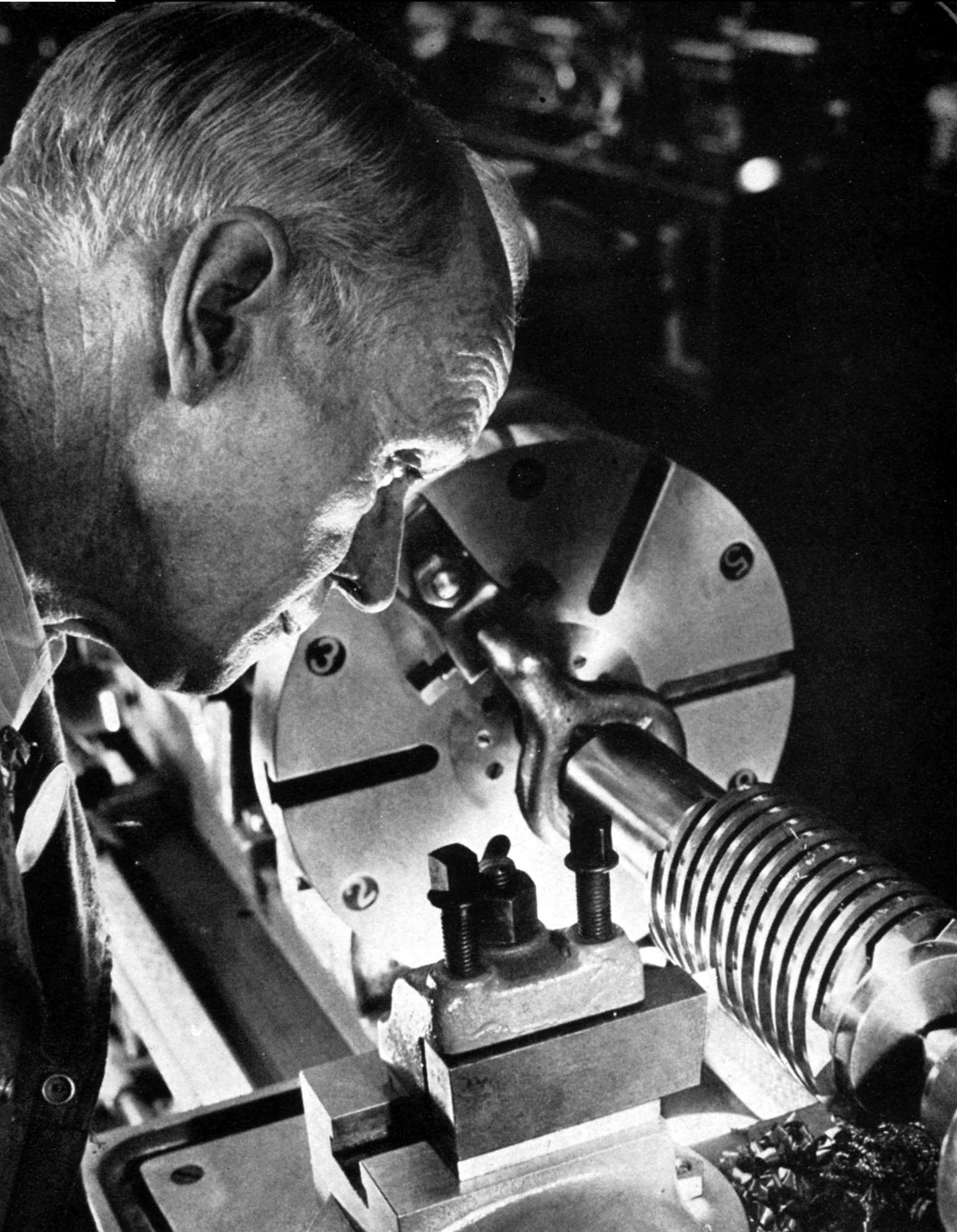

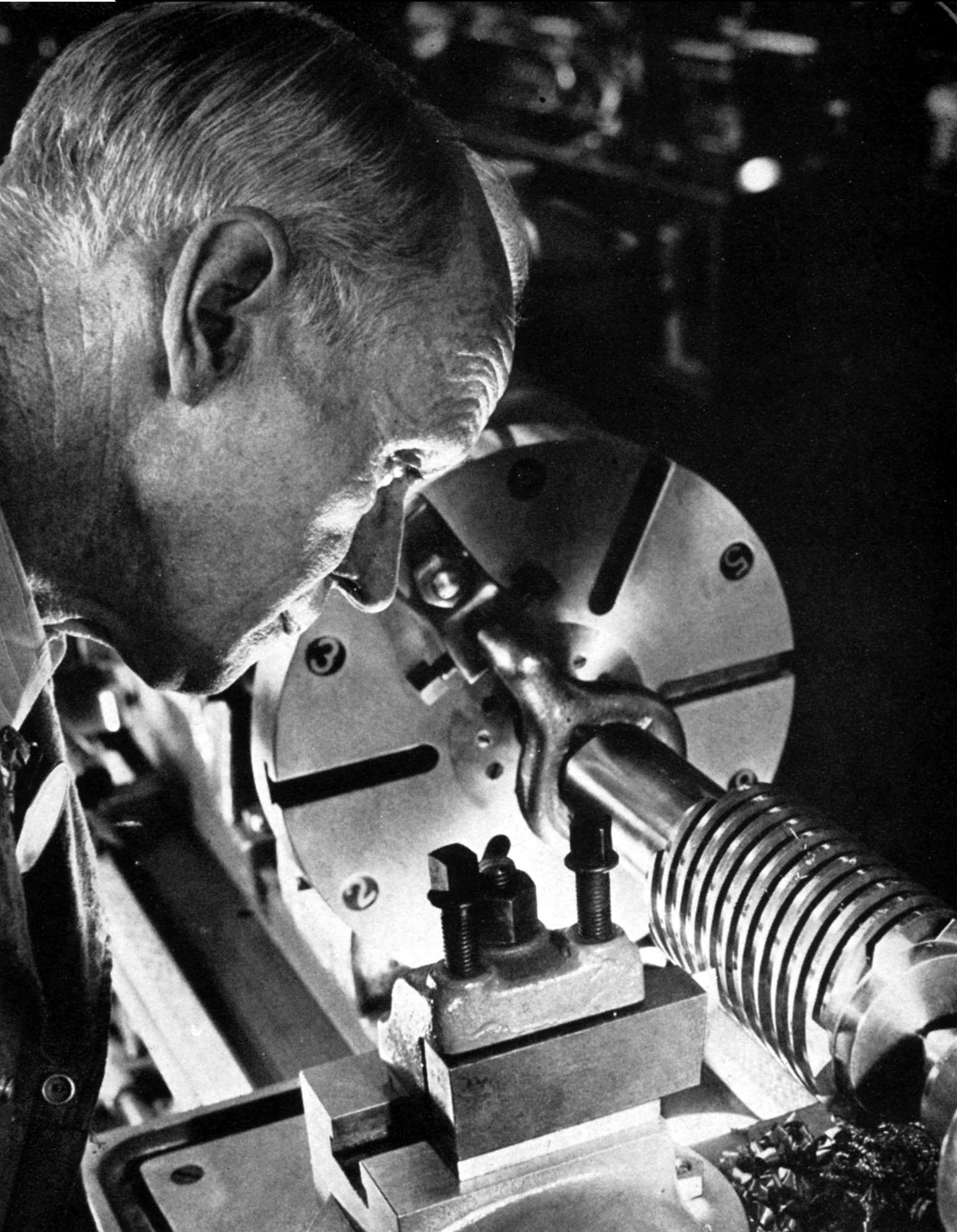

Cutting a coarse-pitch, multiple-start worm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A headstock mounted in tandem jigs, one at each end of the casting, on the table of a horizontal borer.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cutting the teeth of a bevel gear on a Gleason gear generator

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|