|

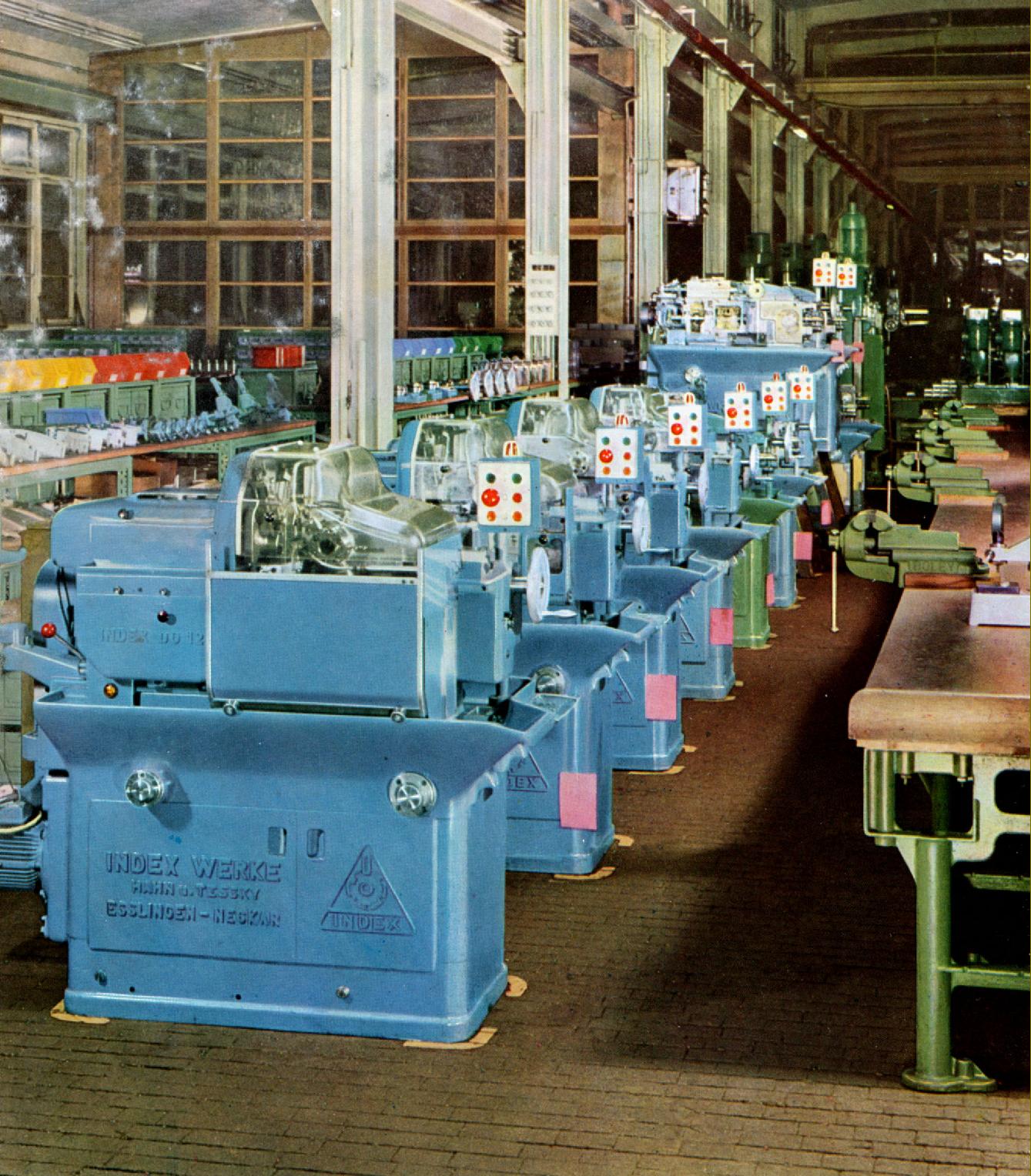

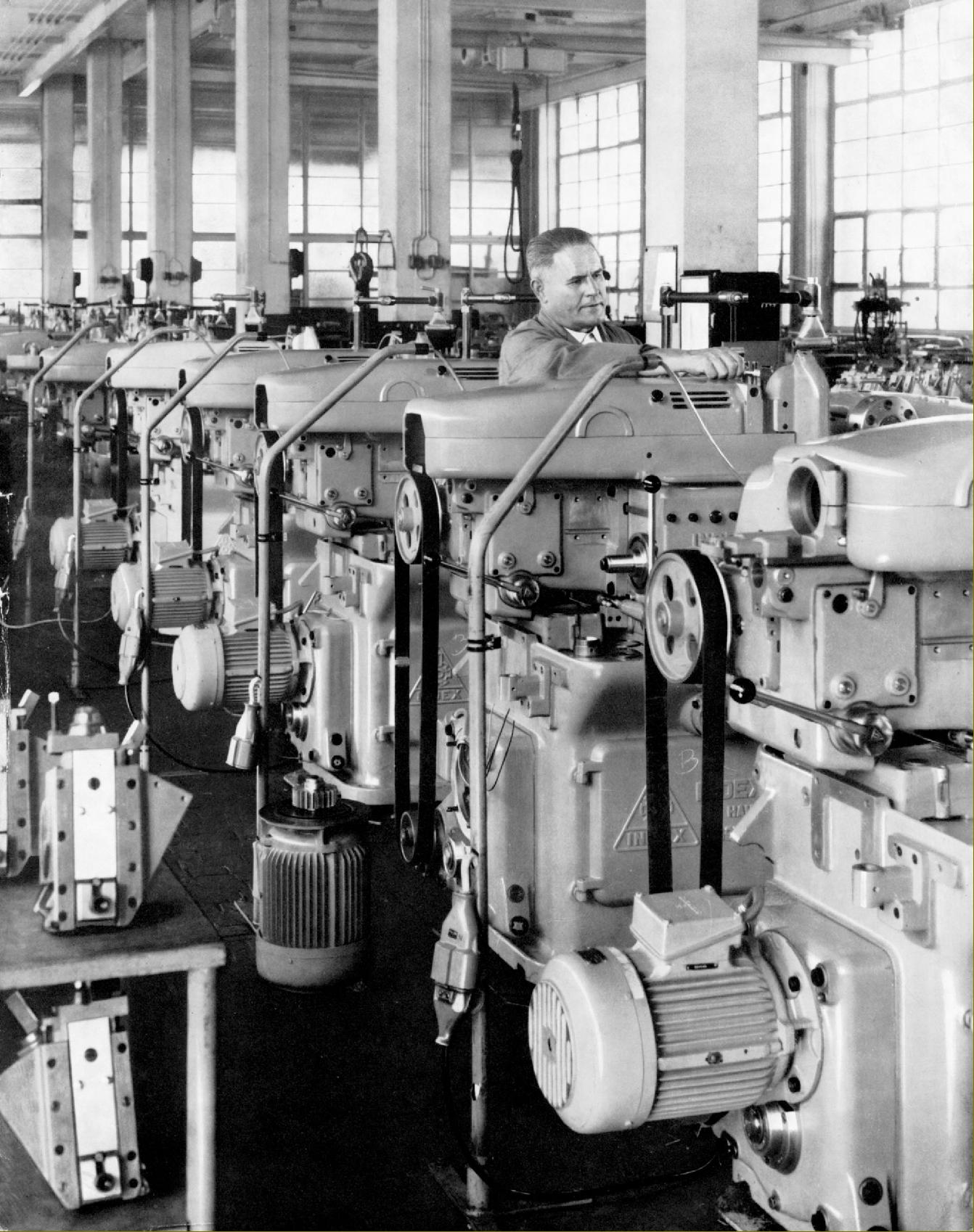

Still in business as Index-Traub, the INDEX Company is based in Esslingen, Baden-Wüurttemburg, Germany with a network of plants world-wide. Beginning as INDEX, Hahn & Kolb in 1914 and then, in 1934, Index-Werke KG Hahn & Tessky, it was to produced over many decades, a range of single-spindle automatic, mechanical (cam-operated) lathes of a type that, prior to the introduction of computer control, formed the largest single class of machine dedicated to the mass-production of high-precision small parts. Even today, during the early decades of the 21st century, such mechanical lathes still find a use where a simple, low-cost yet high-precision solution to manufacturing needs is required. Though complex mechanisms in their own right, their inherent simplicity, ease of operation and adjustment, compact dimensions and reliability over very long production runs are still hard to beat. As one experienced setter of these machines remarked: ….there is a sense of achievement and excitement when all the tools and cams are fitted and the machine timed up; and then, after a short session of adjustment, to go on and manufacture thousands of identical parts, all new and shiny. A separate section detailing how older INDEX lathes were made can be found here

The first versions of the "auto-lathe" came into use during the late 1800s with, subsequently, three distinct types evolving, all operated by cams and gearing: the common single-spindle turret type, single-spindle sliding headstock and multi-spindle machines. All versions used the principles inherent in the early models but with increasingly sophisticated controls, the development of ingenious accessories and ever-more reliable operation. So consistent were these lathes in their ability to produce accurate work that they could be left running for days at a time, it only being necessary to ensure that the bar-feed units were stocked and the finished-parts hoppers emptied.

The main use of early automatics was the manufacture, in great volume, of simple items such as screws, threaded studs, pins and bushes - with the smallest models able to make even the tiny fastenings used in watches. As the size, weight and rigidity of models increased, so did their ability to handle much greater sizes of bar, together with the ability to machine ever-more complex parts.

Now adapted to computer control (having abandoned cam operation), these machines and their close cousins the "Swiss Auto" are, unsurprisingly, still being built by numerous makers world-wide.

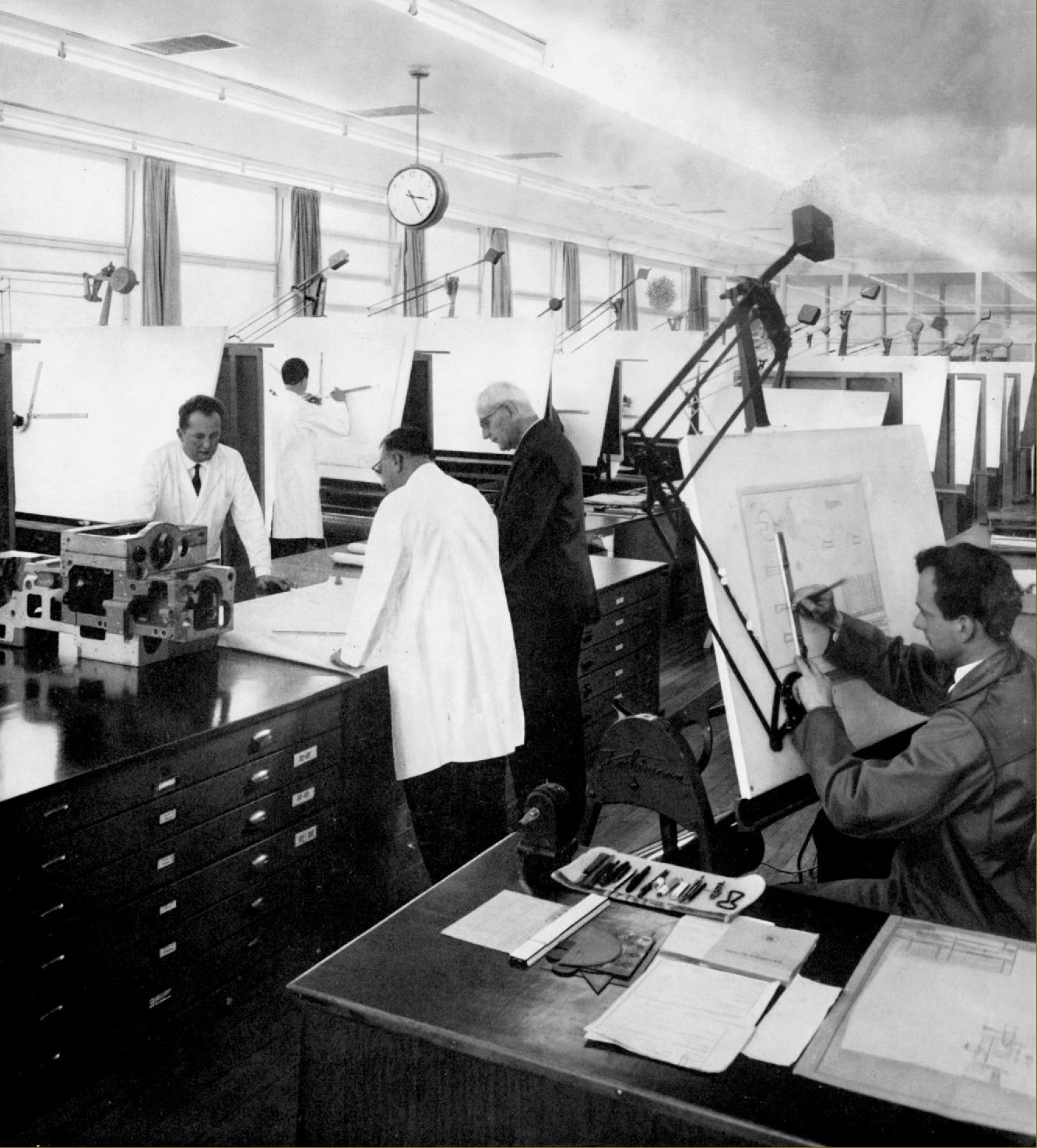

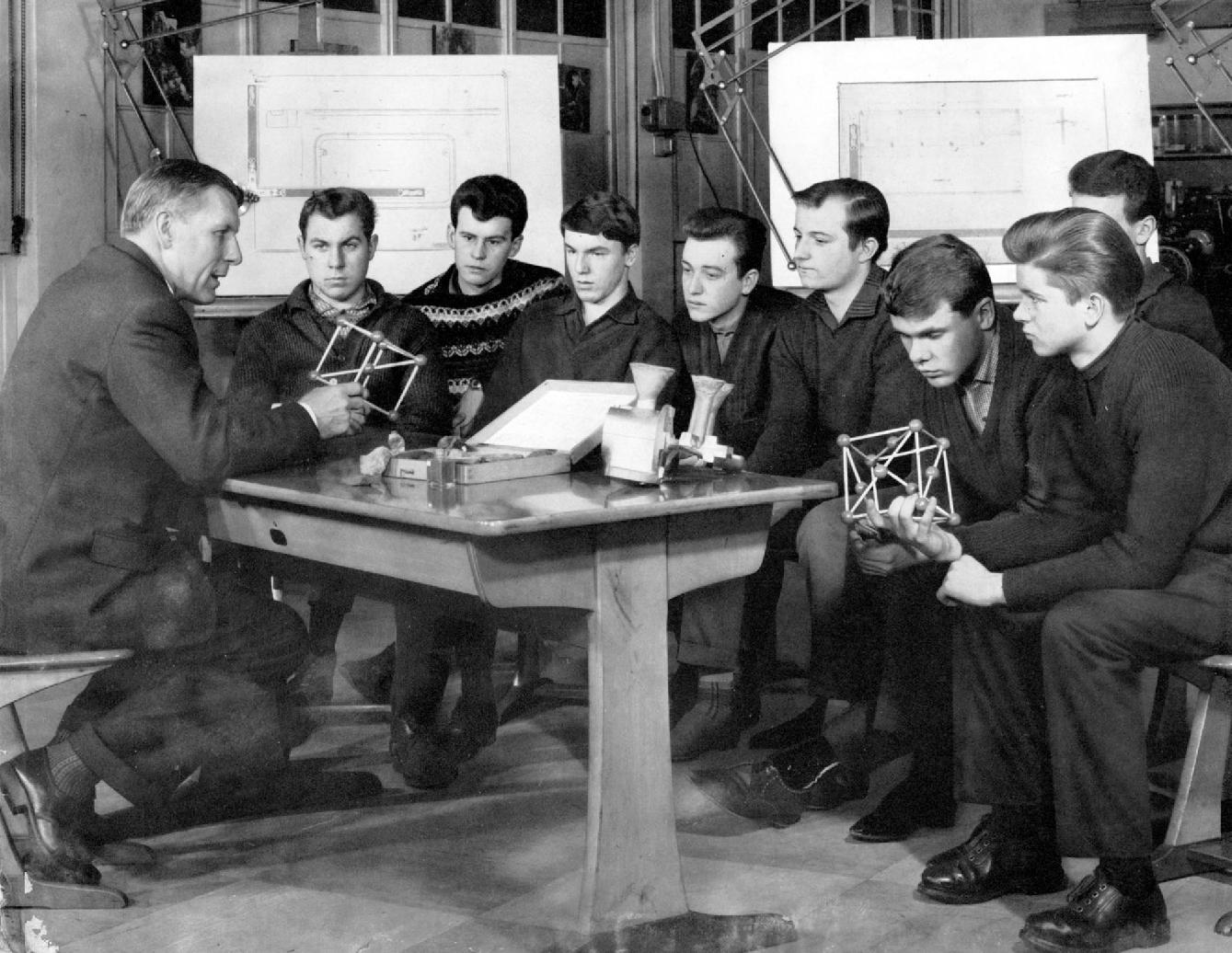

In 1964 INDEX celebrated their 50th anniversary and produced an interesting "factory-tour" book , pages from which are reproduced here. Although not as artistic as the similar publication issued by the American Hendey lathe company during the 1940s, it still gives a useful impression of 1960s working practices and machine-tool technology. On this page are pictures of the factory and personnel, assembly and testing rooms while this page, and this page, have details of machine tools and production methods employed by the company. In its jubilee year the factory was employing 1450 staff, had a manufacturing floor space of around 334,000 square feet with 830 machine tools and produced around 120 finished autos per month.

Founded on the 2nd of January, 1914, by Hermann Hahn (already an established machine-tool maker and proprietor of Hahn & Kolb in Stuttgart) Index began in rented premises with a separate firm, "Werkzeugmaschinesfabrik INDEX, Hahn & Kolb", established with eighteen workmen, four office staff and two apprentices. At the end of the first year (and just into the start of World War 1) the first automatics of the INDEX Type 1 and Type 2 were being delivered to customers. By 1917 the number of employees had grown to 150 and by now, convinced of their success, the company bought the land on which their works stood. In 1919 Hermann Hahn took on his brother, Oskar, as a partner and by 1921 had further expanded to employ two-hundred and sixty-seven workers and introduced the INDEX 0, designed under the supervision of chief engineer Adolf Mayer. In 1922 a new chief engineer, Karl Tessky, formerly of Siemens & Halske in Berlin, was appointed and the firm registered under the new name of "INDEX-Werke Hahn & Kolb". During 1924 and 1925 a modern fitting and assembly shop was erected and a proper apprentice-training school opened. In 1927 the Types 1 and 2 models were superseded by the Models 12-18, 20, 24, 30 and 36 while in the following year a retirement trust fund, for aged and infirm workers, was established with an initial capital of 60,000 Marks. In 1929, just as the world reached The Great Depression (with a serious downturn in trade) the total workforce reached 585 and Karl Tessky, in recognition of his essential services, became a full partner. Thanks to the specialised nature of their business INDEX weathered the trading difficulties well and, having had to lay off few workers, started 1932 with a new model, the long-lived and very successful Type OR high-speed turret automatic. With the world's economic crisis easing, INDEX continued to expand during the middle years of the 1930s and, in 1937, erected new buildings to accommodate the now 850-strong workforce. In 1938 Eugen Hahn, son of Hermann Hahn and working as a qualified engineer since 1934, joined the company which was henceforth known as "INDEX-Werke KG.Hahn & Tessky".

Although Hermann Hahn died in 1939, at the age of 74, this did not diminish the company's progress and by 1940 (at the beginning of WW2 and with a consequent increase in production) employee numbers rose to a record high of 1200. However, once into the war, a slight scaling back of operations was experienced with numbers falling to 950 at the war's end in 1945. By great good fortune (and poor planning by target annalists) the works were not hit by Allied air action and escaped the conflict undamaged and with all facets of production capacity intact. However, now taken over by the occupying forces and marked as a technical prize, in 1947 the plant was dismantled and (though not confirmed) it is certain that many valuable machine tools would have been removed. Despite these setbacks, a number of older machines were taken in for rebuilding and, by 1948, and assisted by the post-war Marshall reconstruction plan, work was in progress on new buildings with a fresh sales organisation, "INDEX-Verkaufs-GmbH", being established in Stutgart. Late in 1948 production of Index 12-18-25 models was underway and in the following years of the ON and OR types. By 1950 the number of employees had risen to 300 and in 1951, Karl Tessy, who received an honorary Doctorate from the Technische Hochschule in Stuttgart in 1949, retired from active participation in the company. By 1953 connections to the founding family were further loosened with the death of Frau Ida Hahn, widow of the founder, though Eugen Hahn continued to be involved in day-to-day activities. In 1954 the works area occupied by the American Army was finally released and production began of a new design of the "open-front" type, B30, B42 and B60 models, one of these being the 20,000th automatic to leave the factory. In 1956 employee numbers had risen to over 1,000 and the INDEX-Verkaufs-GmbH organisation moved to the factory site at Esslingen. In 1956 Oskar Hahn died (in his 82nd year) and Karl Mühlschlegel, commercial director since 1919, retired - his place being taken by Dr. Manfred Borst. Further development of both factory and machines now took place with the opening of a new building to replace the old material store and the introduction, at the 6th European Machine Tool Exhibition in Paris, of the C19 and C29 turret automatics. At the following exhibition, held during 1961 in Brussels, the INDEX DG12 was announced and went into production during that year. New buildings were added in 1962 for the machining of major components and Dr. Tessky - who had so much to do with the success of the company - died in Stuttgart at the age of 78.

Other interesting factory tours are those for the German companies Koepfer, VDF, and Maho, the English Dean, Smith & Grace and Archdale - together with some inside views of Herbert, Wadkin, Colchester and Lang - and from American the superb factory tour of the Hendey works by the renowned industrial photographed Robert Yarnall Richie. A rather different approach was taken by the American Monarch Company who also employed Richie to display some of the manufacturing techniques used in their factory together with the special features of their high-quality lathes ..

|

|