|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Weiler 260 Precision Plain-turning Lathes

Weiler Home Page Condor Weiler Primus Praktikant Praktikus

Weiler LZ330 Commodor Ergodor Matador 220, 250, and 280 Series

Weiler LZ280 & LZ300 Weiler 260 Series Plain Precision & Production lathes

Weiler lathes 1950s/60s: LD-220, LD220W, MD-220, LD-250, LDS-250,

LDT-250, MF-220, RDT-260, LZT-280N, LDT-250/6 & Variants

Handbooks, Parts Manuals & Catalogues are available for Weiler lathes

A Special Catalogue Data Set is available for lathes on this page

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

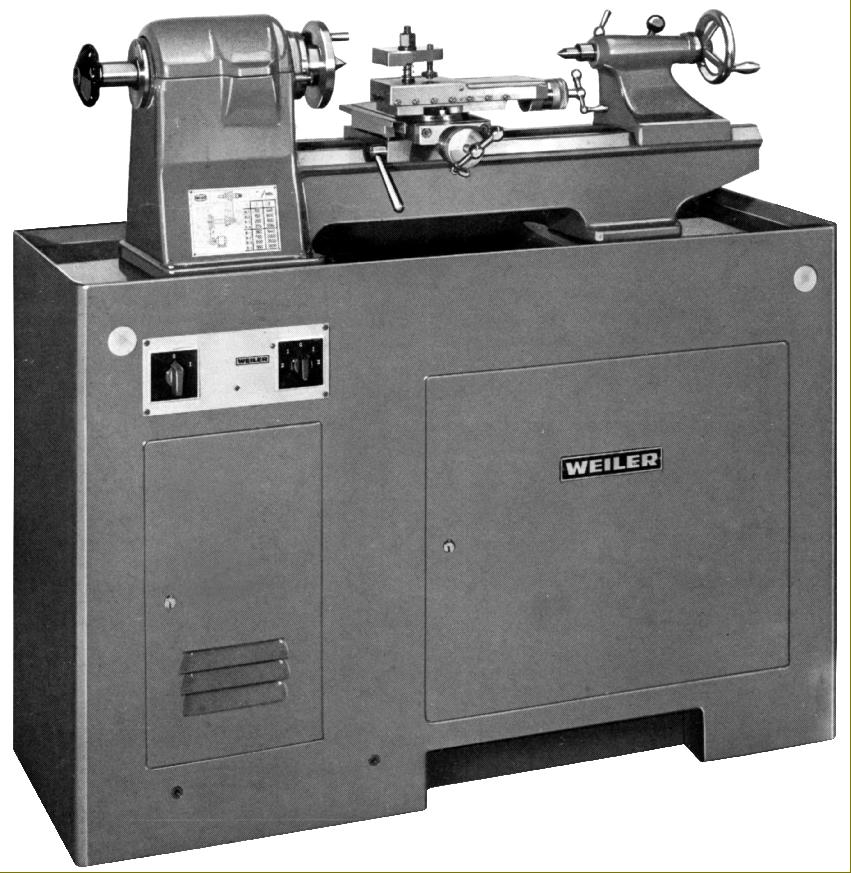

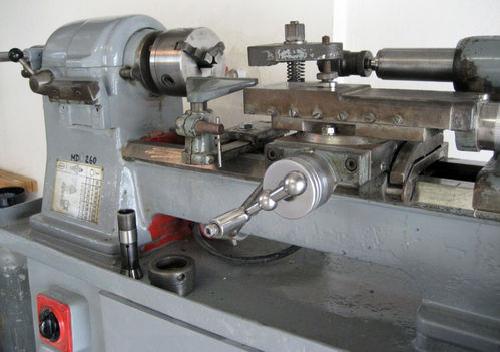

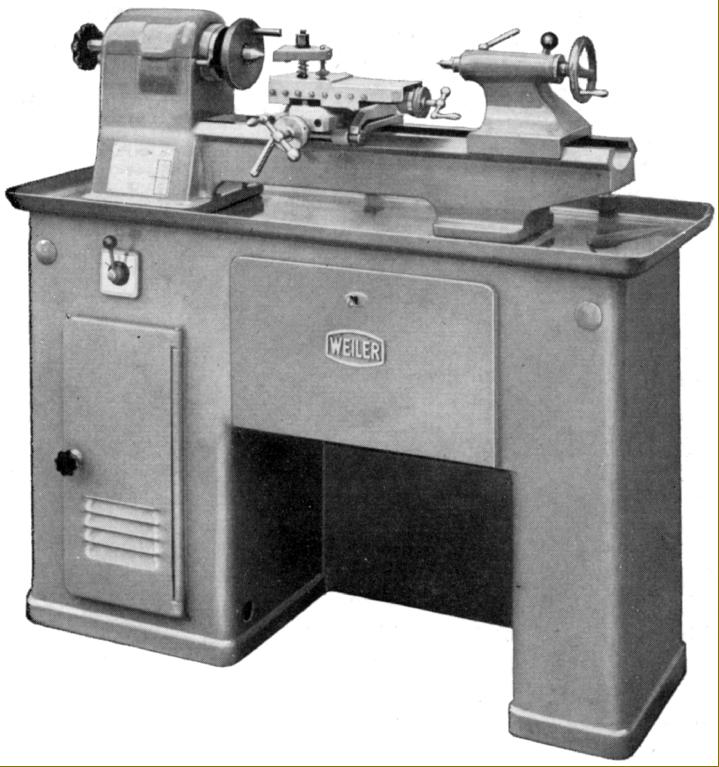

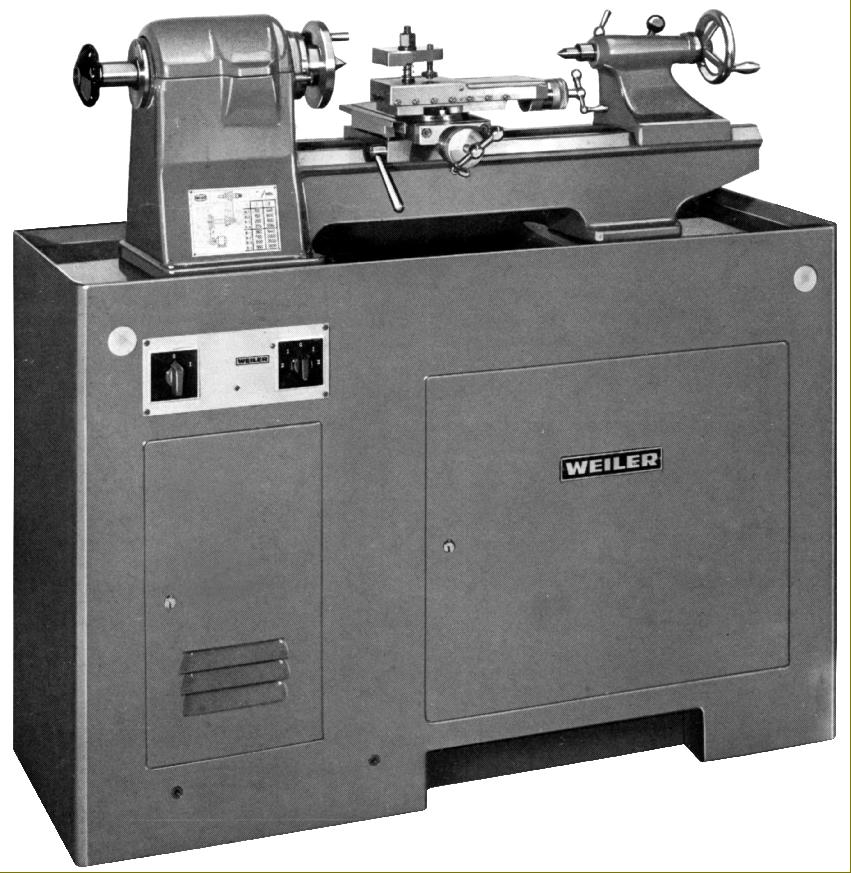

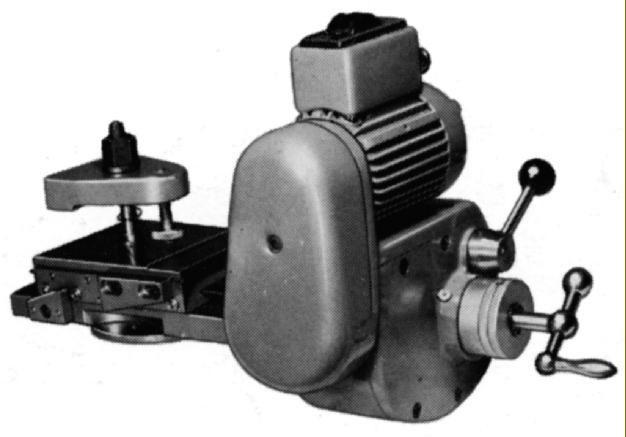

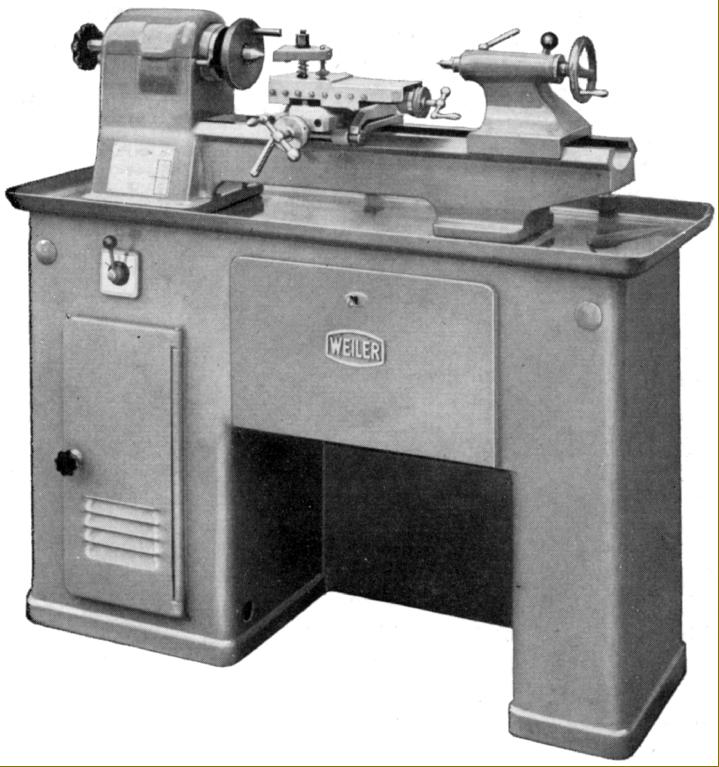

One of the last "full-size" lathes of the long-established "bench precision" type to remain in production, the Weiler 260 Series plain-turning range was introduced during the late 1940s and available until at least the late 1970s. Like the earlier examples by, for example, Stark, Schaublin, Boley, Lorch, Mikron, Wolf,Jahn, Ames, Cataract, Pratt & Whitney, Weiler continued the established tradition for the type in offering three versions, all of which were adaptable, one to another, by the use of various bed-mounted accessories. In 1976 the 260 became available as the HPF-260; fitted with hydro-pneumatic control it could be employed in automatic or semi automatic modes with its intended use being the economical finishing of automatically turned parts. Also listed was the HPR-250, a version pf the HPF equipped with a 6-station turret and functioning as a camless, fully automatic turret lathe intended for ease of use and the ability to produce high quality surface finishes (catalogue here).

In addition, two other ranges of interesting, small high-precision lathe were manufactured: the 220 Series, introduced during 1964 to compliment the 260 models and fitted as standard with variable-speed drive and offered in toolmaker and second-operation forms and a group of lathes including models listed as the types 250, 260 and 280, these being produced in several forms, precision plain turning, production, second operation, backgeared, screwcutting and with power sliding and surfacing feeds and available for bench or stand mounting.

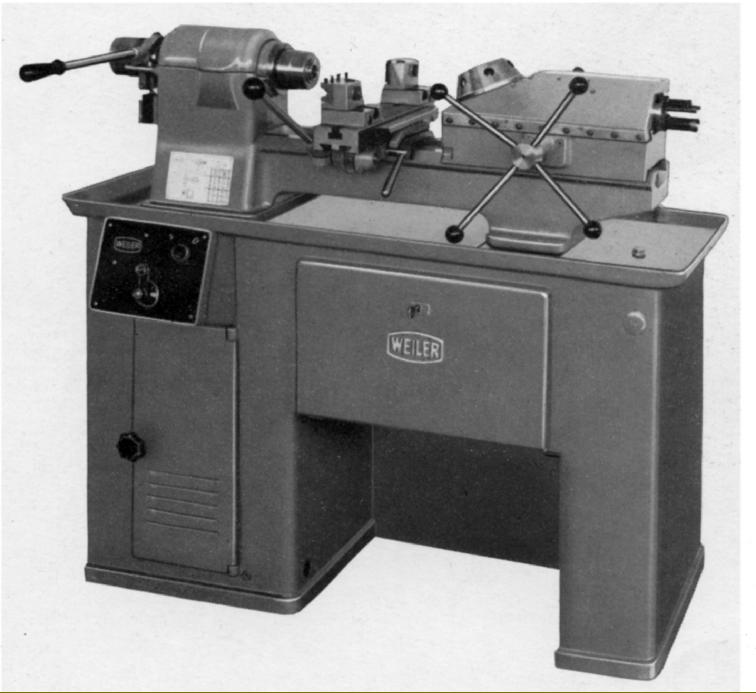

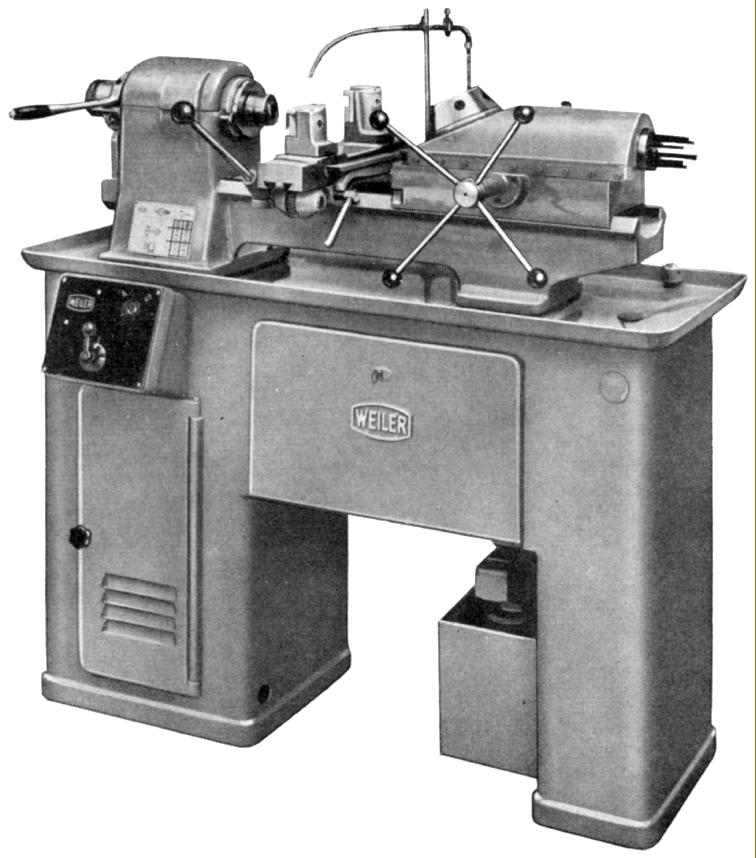

All models of the 260 had a bed with V and flat ways some 1020 mm long and 160 mm wide with a centre height of 125 mm and - where appropriate - a between-centres capacity of 500 mm. Early lathes were mounted on stands with a cast-iron plinth beneath the headstock - which held the motor and drive system - a leg beneath the tailstock and a locking storage cupboard and shelf between them. From the mid 1950s onwards, all were carried on fabricated cabinet stands with a large cut-out that allowed the operator to be seated - a great help when the work involved critical adjustments or repetitive tasks. Final models were on stands without the large cut-out, only a smaller aperture being left along the front of the base to give some useful foot room.

Intended for high-precision, one-off jobs, the basic model was the MDU 260 "Toolmaker", this being fitted with a screw-feed compound slide-rest assembly, screw-feed tailstock spindle and draw-tube collet retention.

For "Second-operation" work the MFU version (sometimes called a "finishing lathe") was equipped with quick-action levers to all the controls - cross and top slide, tailstock and collet closer - the latter type, when fitted to any model in the range, was interlinked with an electrically-operated spindle brake, this time-saving mechanism automatically brought the spindle to stop when the collet lever was set to open - and immediately restarted it upon setting to closed.

Earlier versions of the 260 had been offered in a more complete series, with the third model configured as a proper production machine with a bed-mounted capstan - an example being the RDU-260. However, the option was dropped at some point during the early 1960s and replaced by the Model FDU - a lathe offered as an alternative to the MFU for high-speed finishing operations and light production. Using quick-action levers for all the controls, the MFU also had a special headstock fitted for chase screwcutting and could be ordered to take either the draw-in 22 or 26 mm collets - or the heavier-duty dead-length, 26 mm type. Normally configured as a high-speed lathe with a 2-speed motor, in addition the MFU could be adapted to bar work (with a bar-feeder system) and also supplied, if required, with a clutch and brake equipped drive. When first available, the capstan RDU was listed with the option of two drive systems: a simple, all-V-belt multi-speed countershaft or a much more ambitious expanding-and-contracting, mechanical variable-speed type with 6, 8, 12 or 16 speeds powered by either a single or dual-speed motor and spanning a number of ranges, the most restricted of which ran from 220 to 1800 and the widest from 110 to 3600 r.p.m

Toolmaker's 260 Series Type MDU

Designed to be as adaptable as possible, five late versions of 125 mm x 500 mm toolmaker's 260 (the MDU) were listed, the differences between them concerning the drive system and headstock spindle - the latter, on the standard production models, having either a 28 mm bore designed to take draw-in, type W28 collets with a maximum through capacity of 22 mm, or a 38 mm bore to take W31.75 collets with a maximum bore of 26 mm.

Fitted with screw-driven feeds - the screws fitted with "balanced" handles and passing through bronze nuts fitted with backlash adjustment - the compound slide rest assembly had cross and top slides that shared the same 120 mm of travel, the top slide able to be swivelled through 90° each side of central and carry tools up to 12 mm square beneath its simple, standard-fit, triangular clamp toolpost. Micrometer dials were of a good size, dull chrome plated and beautifully engraved. Locking of the unit to the bed was not by the old-fashioned method of a through bolt to a clamp plate, but from the very first example manufactured, but by a much more convenient and neatly-engineered lever-operated eccentric.

As a further option available for all models, Weiler offered a heavy-duty tailstock with a capstan-handle that drove the spindle through rack-and-pinion gearing - this unit having a 40 mm diameter spindle and 200 mm of travel against a single, adjustable stop, All tailstocks had a main casting of the typical "bench precision" type - a one-piece affair with no facility to be set over for the turning of slight tapers - and all spindles are believed to have been engraved with ruler divisions at 1 mm intervals or their imperial equivalent.

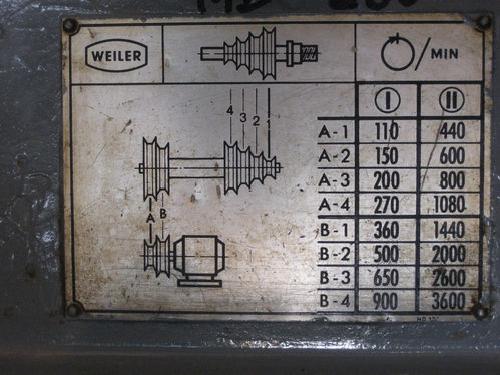

MDU 260-28: Spindle 28 mm bore, draw-in W28 collets maximum through capacity of 22 mm. 0.75 h.p. motor with V-belt drive to the spindle that gave 8 speeds from 220 to 1800 r.p.m.

MDU 260-28P: Spindle 28 mm bore, draw-in W28 collets maximum through capacity of 22 mm. 2-speed, 0.5/1.2 h.p. motor with V-belt drive 16 speeds from 110 to 3600 r.p.m.

MDU 260-28W: Spindle 28 mm bore, draw-in W28 collets maximum through capacity of 22 mm. 2-speed, 1.0/2.0 h.p. motor together with infinitely-variable speed drive 158 to 2000 r.p.m.

MDU 260-38P: Spindle 38 mm bore W31.75 draw-in collets maximum through capacity 26 mm. 2-speed, 0.5/1.2 h.p. motor and V-belt drive to give 12 speeds from 125 to 2000 r.p.m.

MDU 260-38W: Spindle 38 mm bore W31.75 draw-in collets maximum through capacity 26 mm. 2-speed, 1.0/2.0 h.p. motor and infinitely variable speed drive from 158 to 2000 r.p.m.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

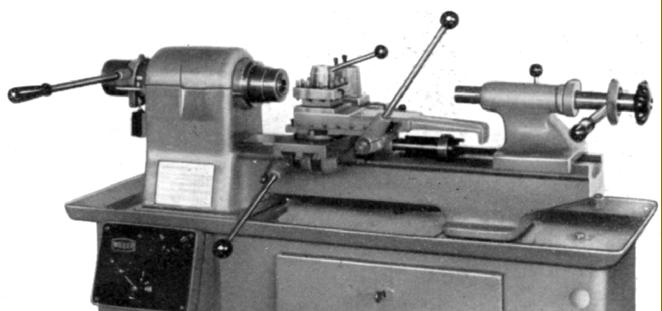

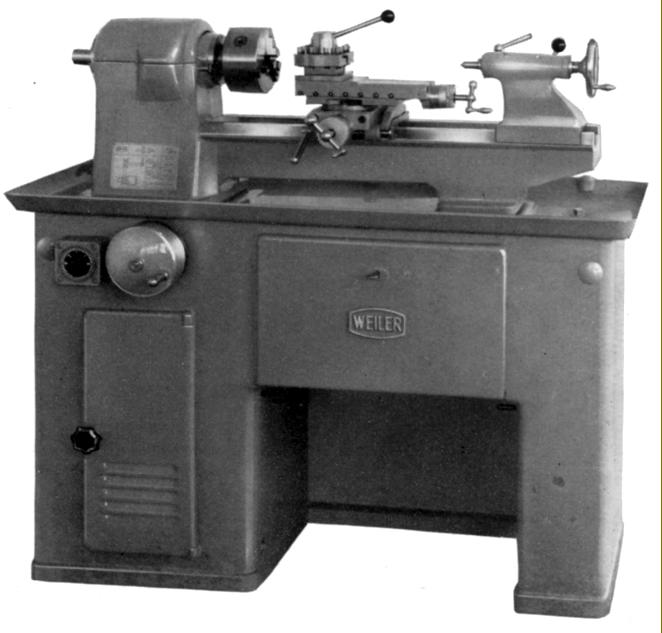

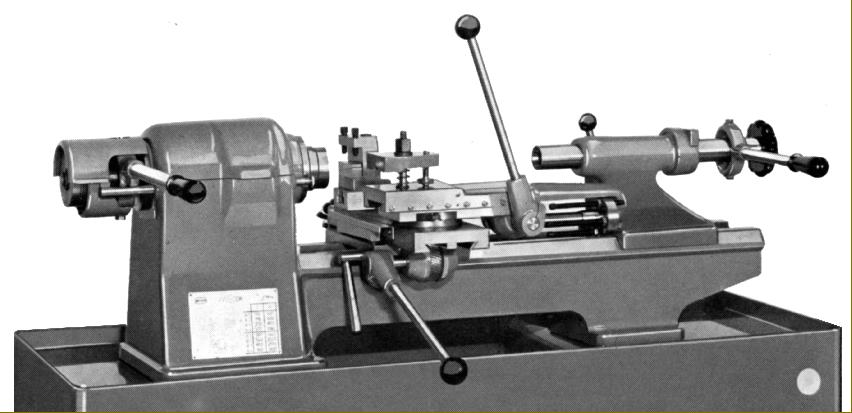

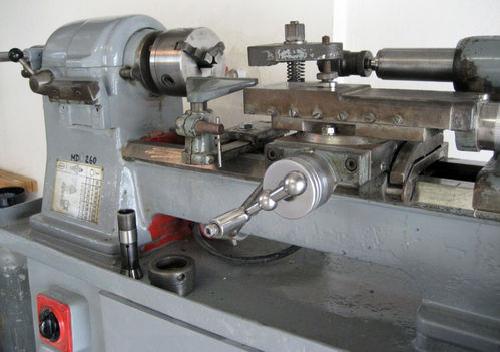

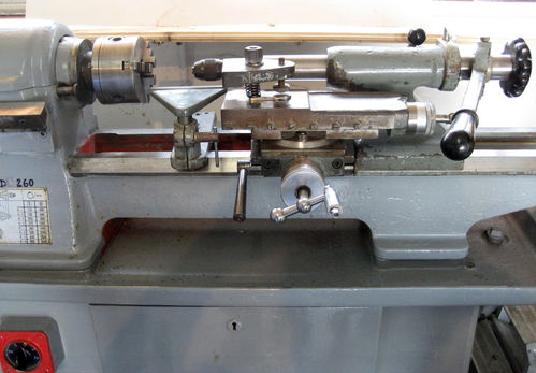

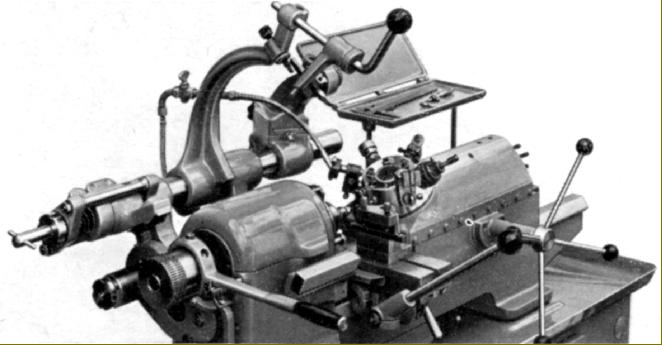

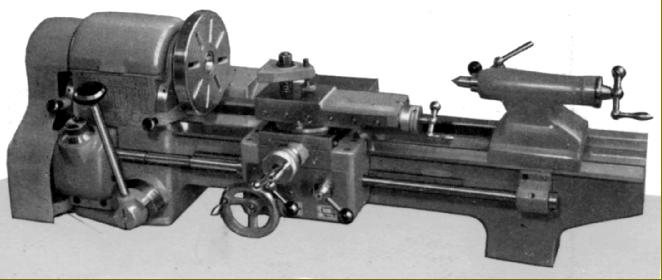

An early MD-260 - a high-class, robustly constructed Weiler plain-turning lathe as made from the late 1940s. This particular example is set up as a toolmaker's lathe with a screw-feed compound slide rest assembly--though it also has a lever-action tailstock and collet closer fitted. The now rather dated looking underdrive stand was considered a great step forward at the time - the cast-iron plinth beneath the headstock holding, typically, a safely enclosed all-V-belt drive system that gave 110 to 3600 r.p.m.

|

|

|

|

|

|

|

|

|

Continued:

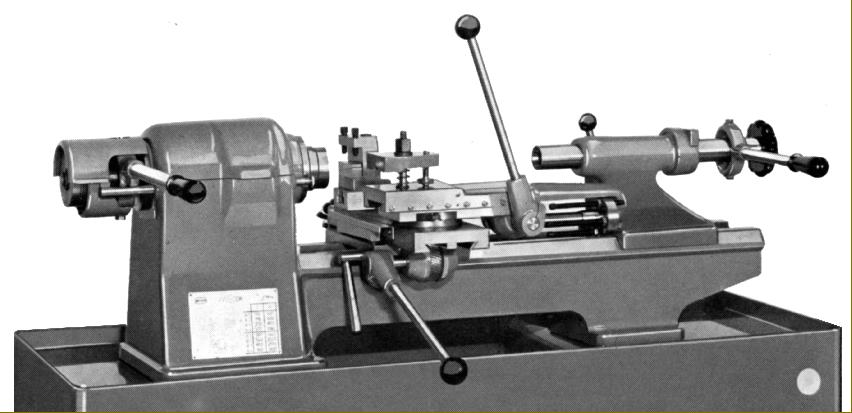

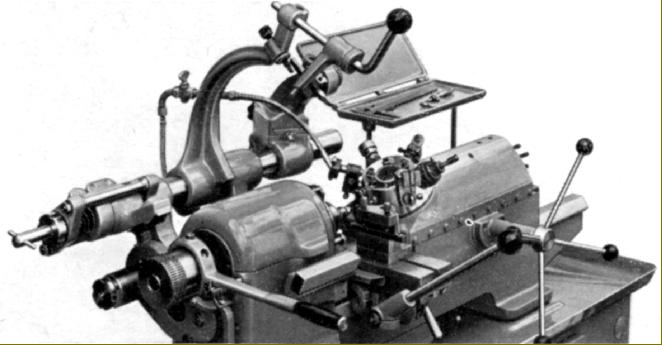

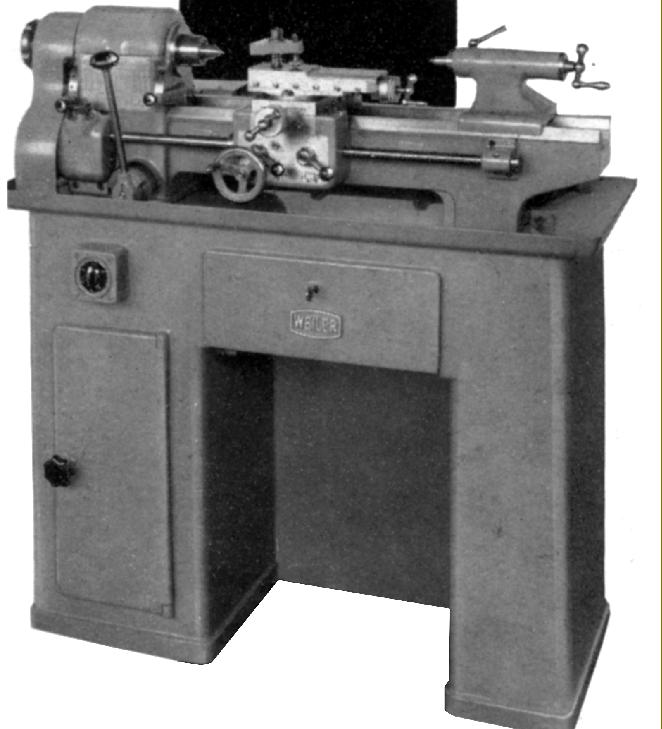

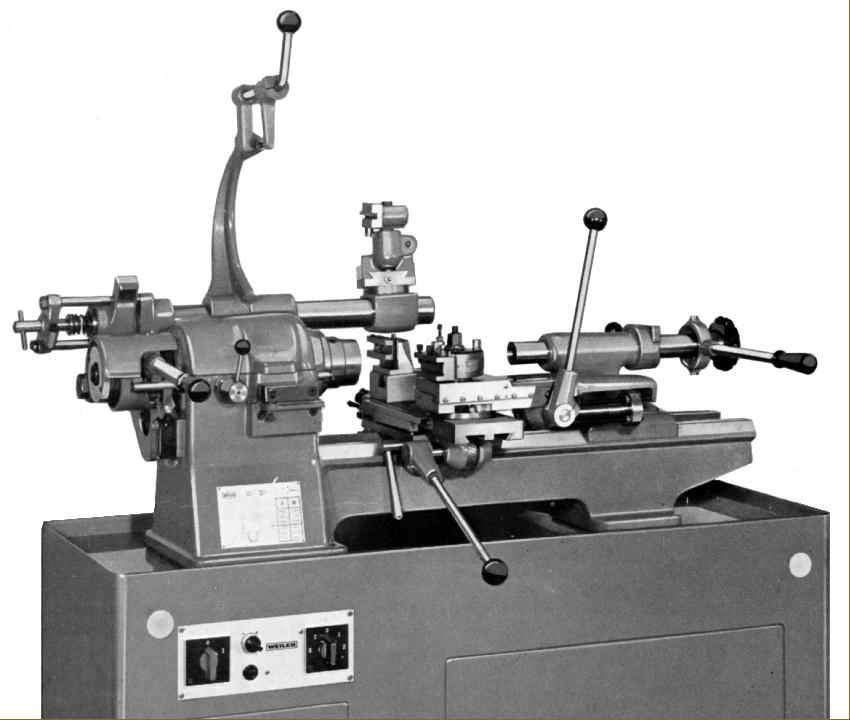

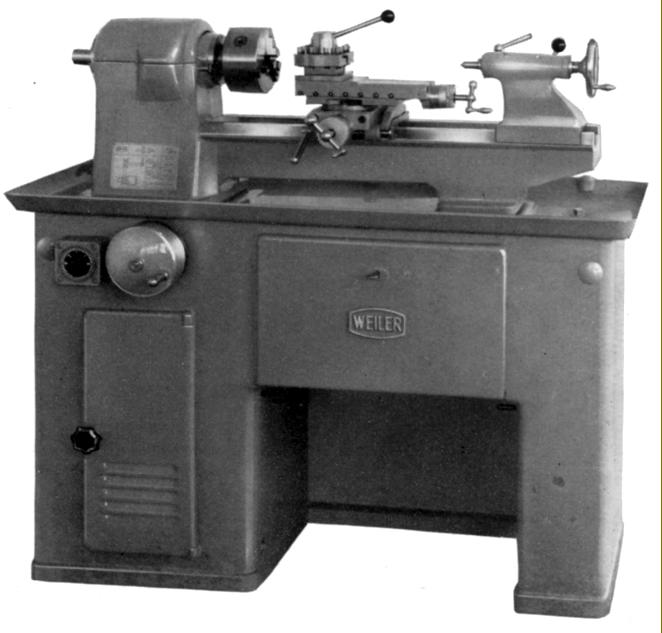

Operation Type MFU 260

Employing the same stand, bed and headstock as the toolmaker's MDU, the late-model "second-operation" Type MFU was available as either a "28" or "38" model, with W28 and W31.75 collets respectively, both equipped with a lever-action closure that was interlinked with an electrically-operated spindle brake. All mechanical controls were by quick-action levers, the compound slide rest assembly being arranged with a cut-off/forming cross slide with 95 mm of travel and a rear toolpost together with a 100 mm travel top slide - four-position, rotating adjustable stops being fitted to each axis.

A Choice of four drive systems was offered, these being designed to suit the most common types of usage likely to encountered. The standard installation was a 2-speed, 0.5/1.2 h.p. motor that gave 12 speeds by V-belt from 110 to 3600 r.p.m. for the Model 260-28 and 125 to 2800 r.p.m. when fitted to the larger work capacity 260-38. Where especially fast operating times were required, with frequent stopping and starting, a disc-brake equipped version was available, this being powered by a 2-speed, 0.65/2 h.p. motor that gave 18 speeds from 140 to 3550 r.p.m. by V-belt. When greater flexibility of the speed range was needed, a more expensive variable-speed drive could be specified, this giving 158 to 2000 r.p.m. driven by a 2-speed, 1.0/2.0 h.p. motor. As an alternative, a pre-selector gearbox version was also available, this being more suited to batch production that involved frequent speed changes, the 18 speeds being powered by a 2-speed, 0.65/2.0 h.p. motor. However, the standard machines offered by the maker consisted of the following four - with changes to their specification, mechanical and electrical, available to special order:

MFU 260-28: Spindle 28 mm bore, draw-in W28 collets maximum through capacity of 22 mm. 0.75 h.p. motor 8 speeds by V-belt from 220 to 1900 r.p.m.

MFU 260-28P: Spindle 28 mm bore, draw-in W28 collets maximum through capacity of 22 mm. 2-speed, 0.5/1.2 h.p. motor 12 speeds by V-belt from 110 to 3600 r.p.m.

MFU 260-38P: Spindle 38 mm bore W31.75 draw-in collets maximum through capacity 26 mm. 2-speed, 0.5/1.2 h.p. motor 12 speeds by V-belt from 125 to 2800 r.p.m.

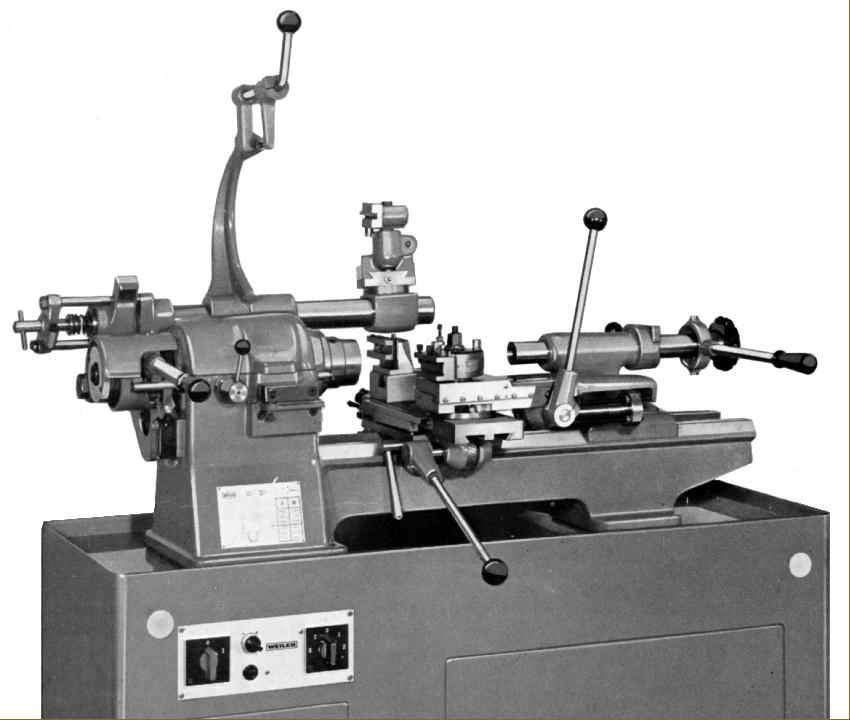

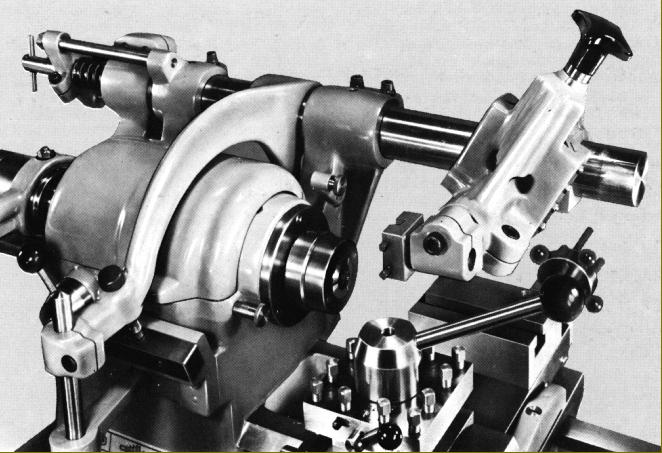

Hand-lever finishing Lathe Type FDU 260

As an alternative for high-speed finishing operations and light production, the late-model FDU was listed, early versions of which could be supplied with a 6-station capstan unit for bed mounting. However, this option was dropped at some point during the early 1960s and instead the lathe was listed as being fitted with a thread chasing attachment that required the use of a dedicated headstock casting and factory installation (it was not possible fit the chasing attachment to a standard headstock). Following a design probably invented by Joseph Nason in 1854, the thread chaser was capable of producing left and right-hand threads internally or externally and 50 mm long, the unit could generate either very fine pitches, such as those used on microscopes and telescopes or ones as coarse as 3 mm or 8 t.p.i.. A set of pick-off gears allowed ratios of 1:1, 2:1 and 4:1 to be set between the headstock spindle and "master thread" in use, each of the latter therefore able to generate three different pitches. One advantage of a thread chasing system is that jobs can be turned (or bored) and threaded in one setting, thus enhancing accuracy, especially on very fine pitches. Like the MFU, all mechanical controls were by quick-action levers, the compound slide rest assembly being arranged with a cut-off/forming cross slide with 95 mm of travel and a rear toolpost together with a 100 mm travel top slide - four-position, rotating adjustable stops being fitted to each axis. Collet closing was by lever, using either draw-in 22 mm collets or the heavier-duty dead-length, 26 mm capacity type.

The FDU was normally configured as a high-speed lathe with a 2-speed motor and could be adapted to bar work (with a bar-feeder system) and also supplied, if required with a clutch and brake equipped drive.

Three standard production versions were offered by the makers:

FDU 260-28: Spindle 28 mm bore to take W28 draw-in collets with a maximum through capacity 22 mm. Single-speed motor of 0.75 h.p. with V-belt drive to give 8 speeds from 220 to 1900 r.p.m.

FDU 260-28P: Spindle 28 mm bore to take W28 draw-in collets with a maximum through capacity 22 mm. 2-speed motor 0.5/1.2 h.p. power with V-belt drive to give 16 speeds from 110 to 3600 r.p.m.

FDU 260-38P: Spindle 38 mm bore W31.75 draw-in collets maximum through capacity 26 mm. 2-speed, 0.5/1.2 h.p. motor 12 speeds by V-belt from 125 to 2800 r.p.m.

At first a vast range of accessories was offered (though this was slimmed down considerably in later years and demand for this class of lathe slowed), these including the expected 3 and 4-jaw chucks and various collet sets; pneumatically operated chucks; expanding mandrels; a high-precision top slide of heavier build with 150 mm of travel by a non-travelling, double ball-bearing screw; a power-driven top slide with 150 mm of travel and, most unusually, an integrally-mounted motor - this arrangement giving two feed rates of 25 and 77 mm/min; a combination screw and lever compound slide rest assembly with a screw-feed cross slide and a lever-feed top slide (other combinations could be ordered as well); a lever-operated cut-off slide with a rear toolpost and adjustable travel stops; 4-way toolpost in either a simple or ratchet-indexing form; quick-set toolpost and the previously described thread-chasing attachment.

While it appears that all early versions of the 260 were finished in a standard machine-tool grey, during the 1960s and 1970s a choice was offered of two colours: grey to RAL 7031 or, optionally, green to RAL 6011. The overall length of all versions was 1200 mm, the width 500 mm and the height - depending upon the fittings - around 1200 mm.

Other examples of might be termed "late-type, professional-class compact capstan lathes" (as distinct from the smallest Ward and Herbert models) include the Italian Ceriotti, the British Accuratool, Britan and Exacta, the Spanish Elgoand the Dutch Emwee..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

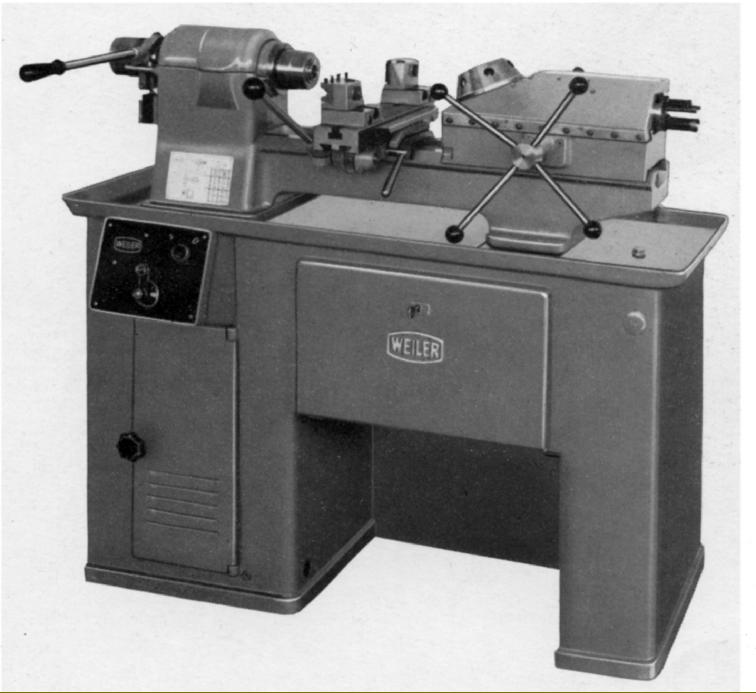

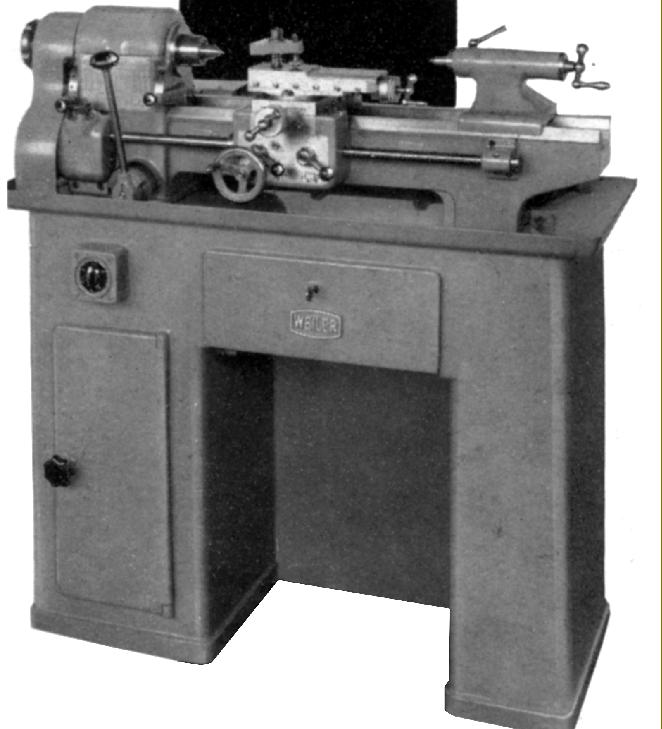

Weiler MDU-260 Toolmaker's lathe as sold during the 1970s

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

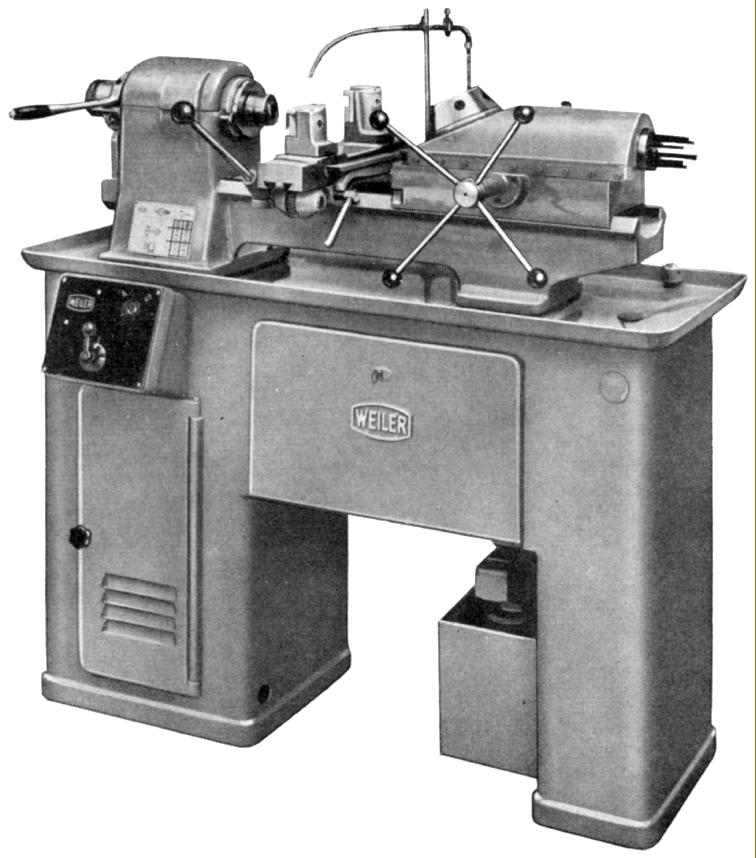

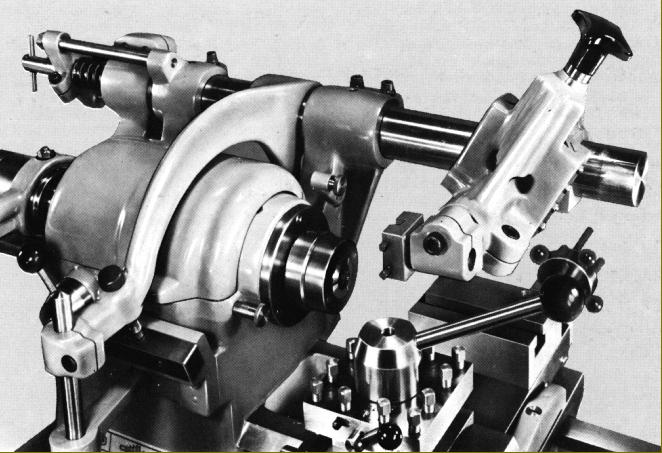

Weiler MFU-260 Second-operation lathe as sold during the 1970s

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

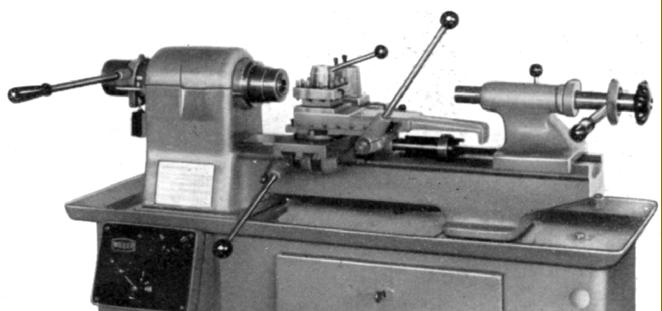

Weiler FDU-260 - the Second-operation lathe fitted with a chase-screwcutting headstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

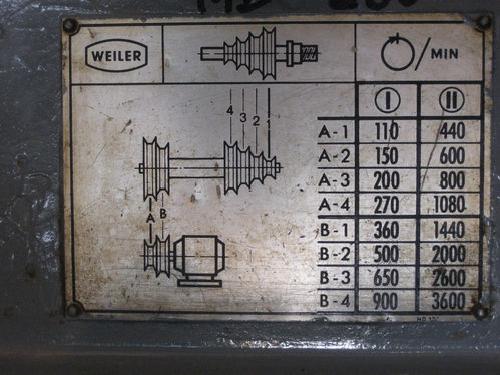

Typical Weiler plain-turning lathe speed chart showing the use of a 2-speed motor and all-V-belt drive countershaft to give a total of 16 speeds spanning 110 to 3600 r.p.m.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

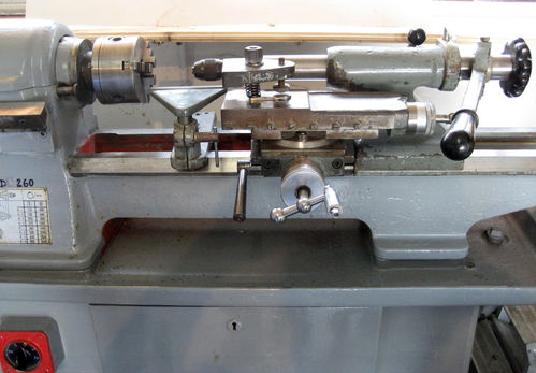

MF-260P - this was a version of the MD-260 Series set up as a second-operation and finishing lathe with lever-operated collet closer, compound slide and tailstock. The underdrive stand had an all-V-belt drive countershaft that gave 16 speeds spanning 110 to 3600 r.p.m. The through-collet capacity was listed as 7/8" (22 mm).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

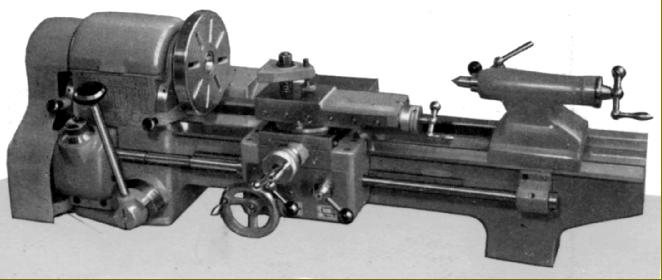

RDU-260 and RDU-260-38 capstan lathes with bed-mounted turret. a cut-off /forming slide and lever-action collet closer. The RDU-260 could be had with a 0.75 h.p. 1-speed motor that gave 8 speeds from 220 to 1800 r.p.m. or a 0.5/1/1 h.p. 2-speed that provided a more useful 16 speeds from 110 to 3600 r.p.m. The RDU-260/38 was offered with a choice of ether a 0.75 h.p. 1-speed motor that gave 6 speeds spanning 250 to 14000 r.p.m. or a 0.5/1/1 h.p. that provided 12 speeds from 125 to 2800 r.p.m. The headstock spindle could take a 1-inch (26 mm) bar and, to speed up production, was equipped with a powerful brake

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A version of the RDU-260 as sold during the mid 1950s.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FDU-260/38. This version was arranged as a second-operation and finishing lathe. It retained the 1-inch clear bore headstock, lever-action collet closer and spindle brake as found on the RDU-260 but mounted on its bed was a lever-action compound slide assembly and tailstock. An all-V-belt drive countershaft, held within the cabinet stand, gave 12 spindle speeds from 125 to 2800 r.p.m.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All versions of the plain lathes could be fitted with a headstock equipped

for chase screwcutting This is an earlier version, from the 1950s

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The more rigid, improved chase-screwcutting attachment as it appeared from the late 1960s onwards

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

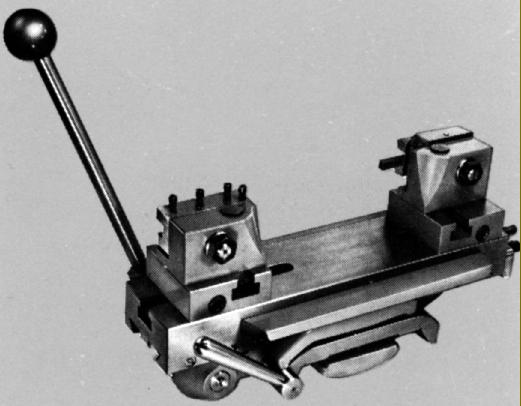

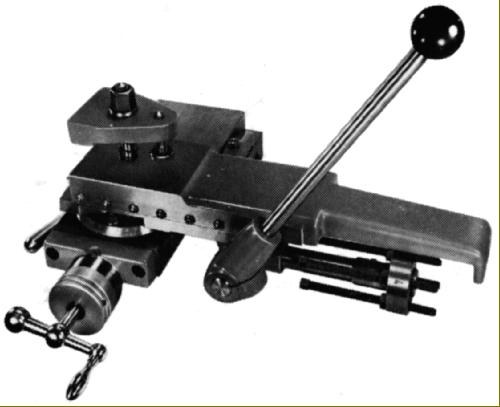

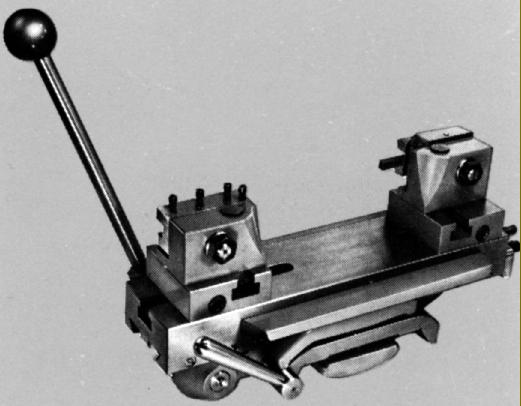

Lever-action cut-ff slide as intended for the capstan version of the 260

|

|

|

|

|

|

|

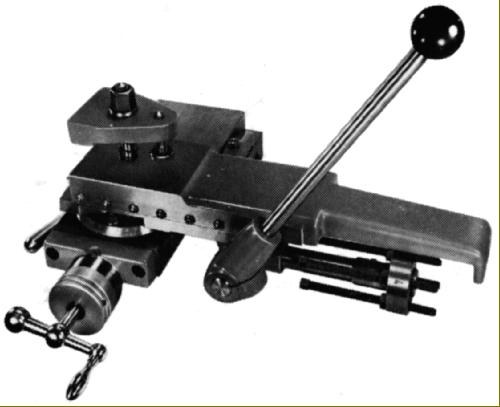

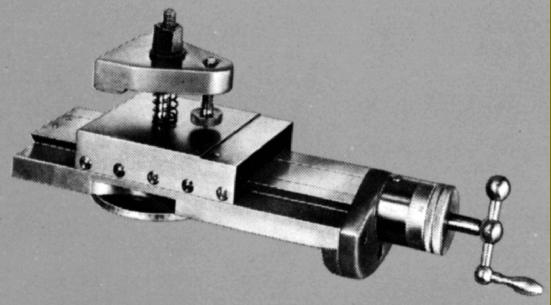

Compound slide rest assembly with screw-feed cross slide and

lever-feed top - the latter fitted with a 4-position rotating travel stop

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

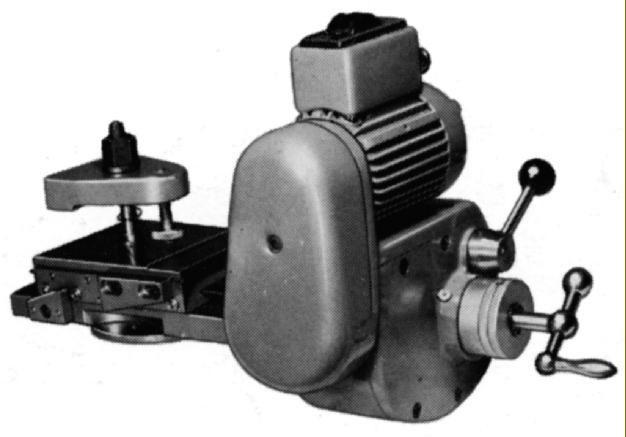

A true oddity - and possibly unique: a top slide fitted with an integral motor drive

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

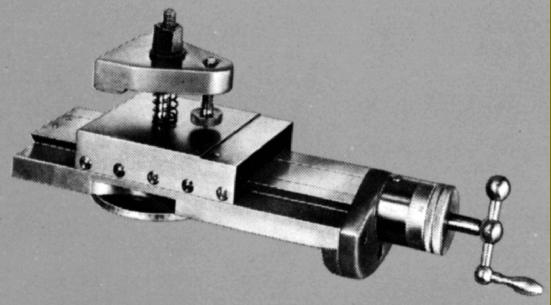

Late model extended travel, heavy-duty top slide fitted with a recirculating-ball feed screw

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weiler MDU-260/38 a precision plain-turning toolmaker's lathe equipped with a screw-feed compound slide and mounted on a steel cabinet stand with an all-V-belt countershaft unit that gave 6 speeds from 250 to 14000 r.p.m. with a single-speed 0.75 h.p. motor or 12 speeds from 125 to 2800 r.p.m. with a 2-speed 0.5/1.1 h.p. Collet capacity was 26 mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weiler MDU-260W. A more expensive precision plain-turning toolmaker's lathe mounted on a steel cabinet stand and fitted with backgear and variable-speed drive to give a range from 55 to 1800 r.p.m. (the large speed-control handwheel is on the face of the stand immediately below the 22 mm collet capacity headstock)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LD220W - variable-speed screwcutting Weiler--additional details here

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LD220W - variable=speed drive, screwcutting Weiler L-Series mounted on the maker's underdrive stand

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard MD260 arranged as a toolmakers' lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weiler Home Page Condor Weiler Primus Praktikant Praktikus

Weiler LZ330 Commodor Ergodor Matador 220, 250, and 280 Series

Weiler LZ280 & LZ300

Weiler Lathes 1950s/60s including: LD-220, MD-220/W, LD220W, LCD-220,

LZD-220, LD-250, LDS-250, LDT-250, MF-220, RDT-260, LZT-280N, LDT-250/6 & Variants

Handbooks and Parts Manuals are available for Weiler lathes

A Special Catalogue Data Set is available for lathes on this page

Weiler Precision Plain-turning Lathes

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

|

|

|

|

|

|