|

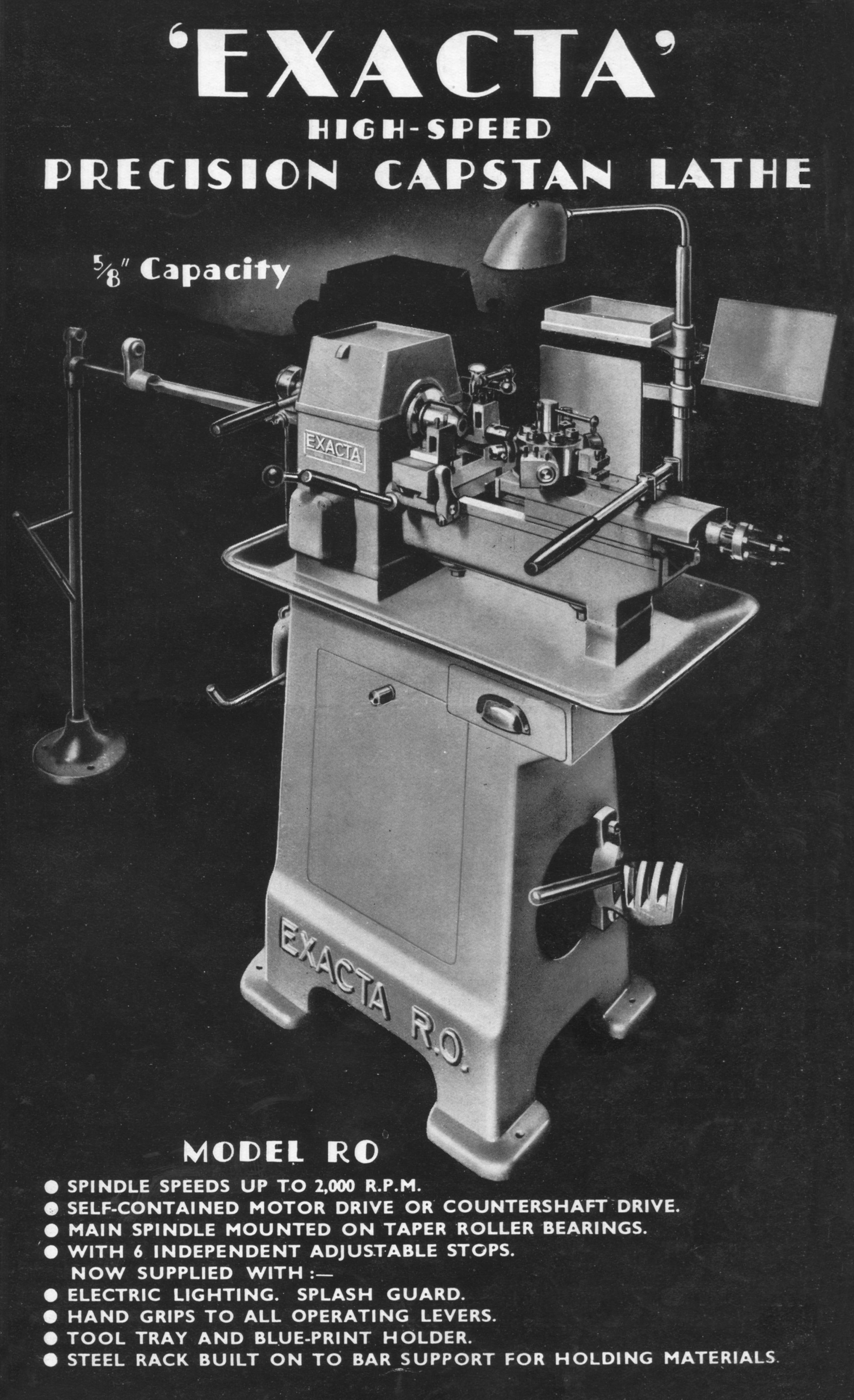

Manufactured in the UK from the mid-1930s onwards and distributed by the large Elliot group, the little 4.625" centre height Exacta Model RO capstan lathe filled the same niche in the market as the Raglan and "Atlas/Acorn" models - being intended for short production runs of smaller components.

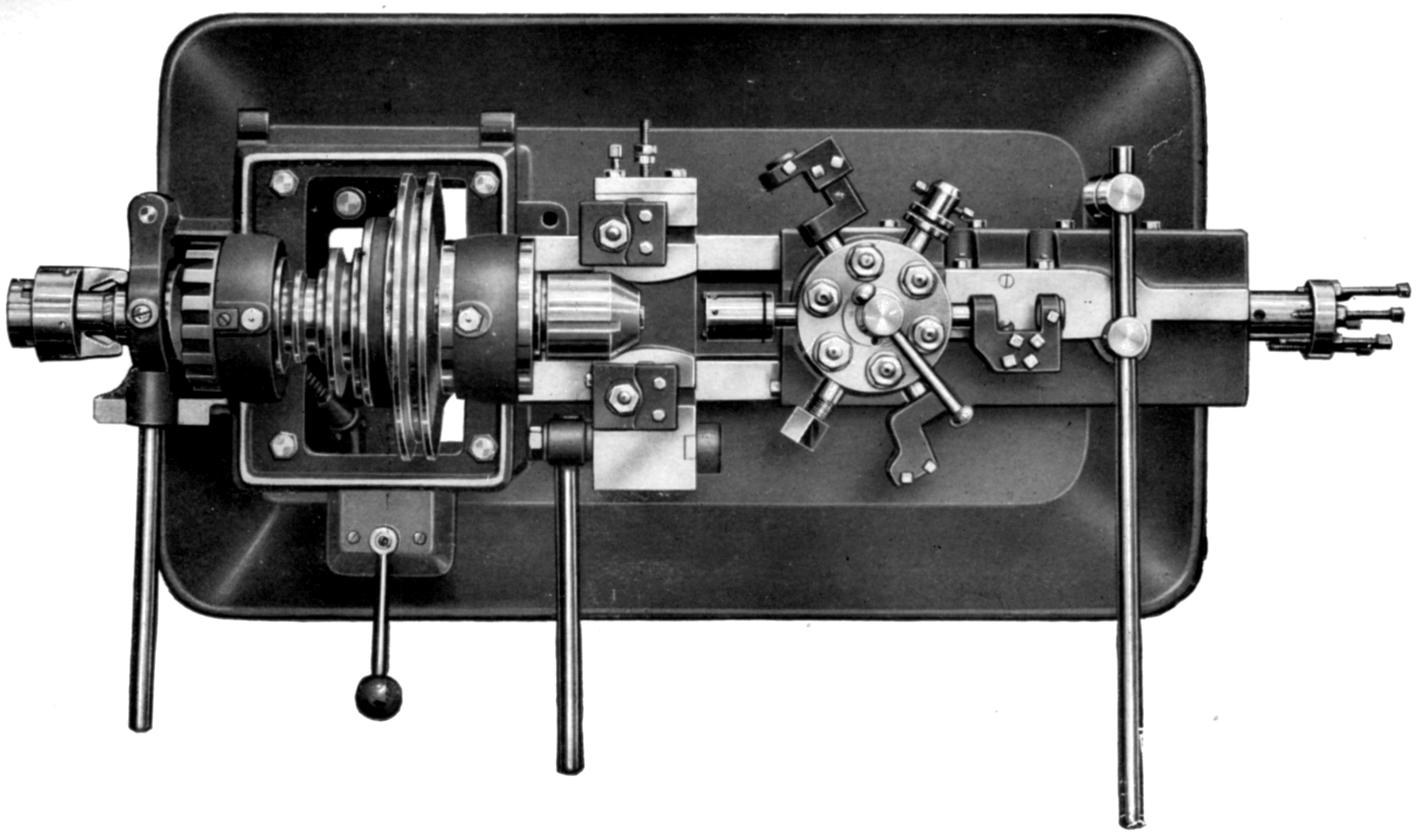

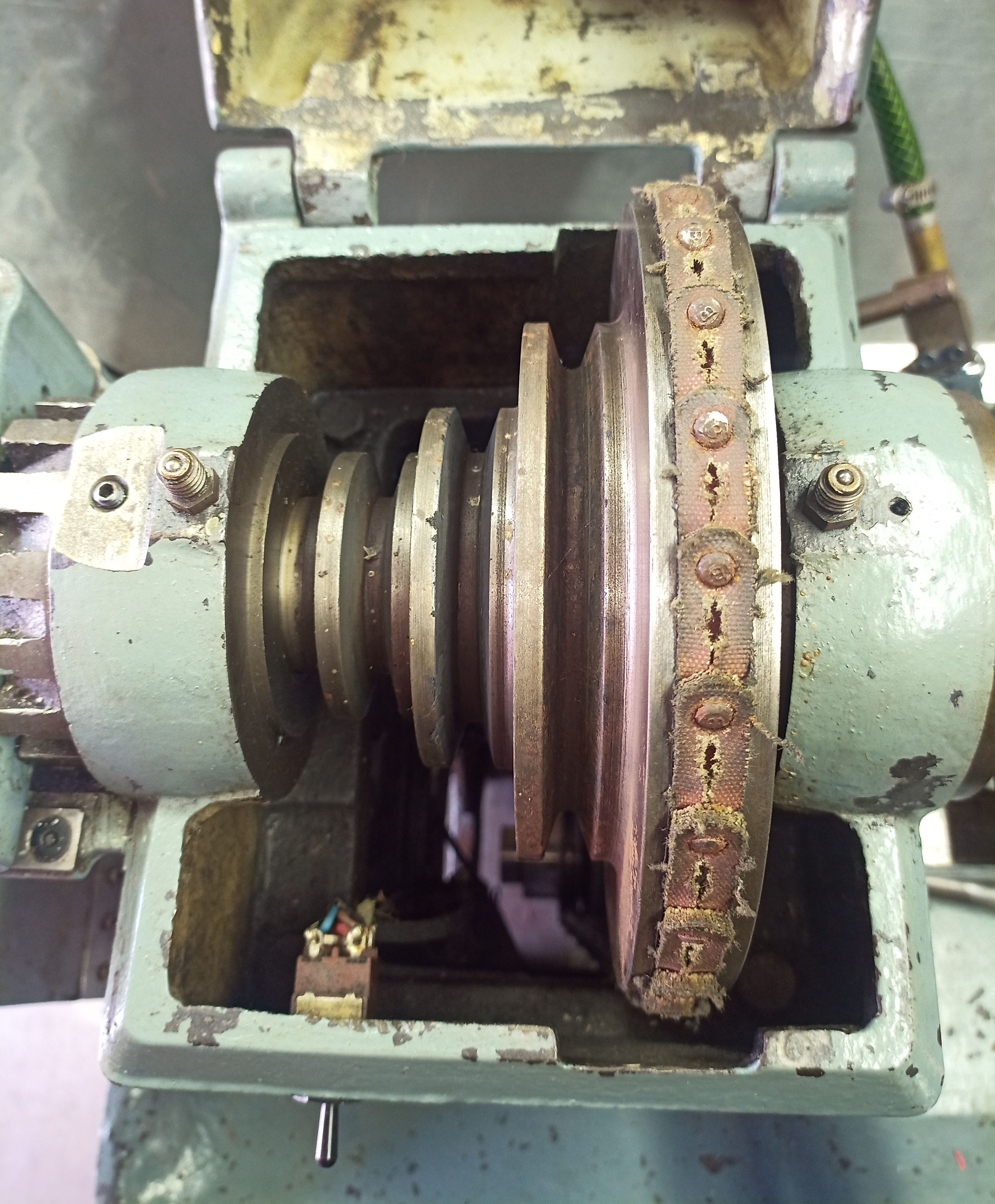

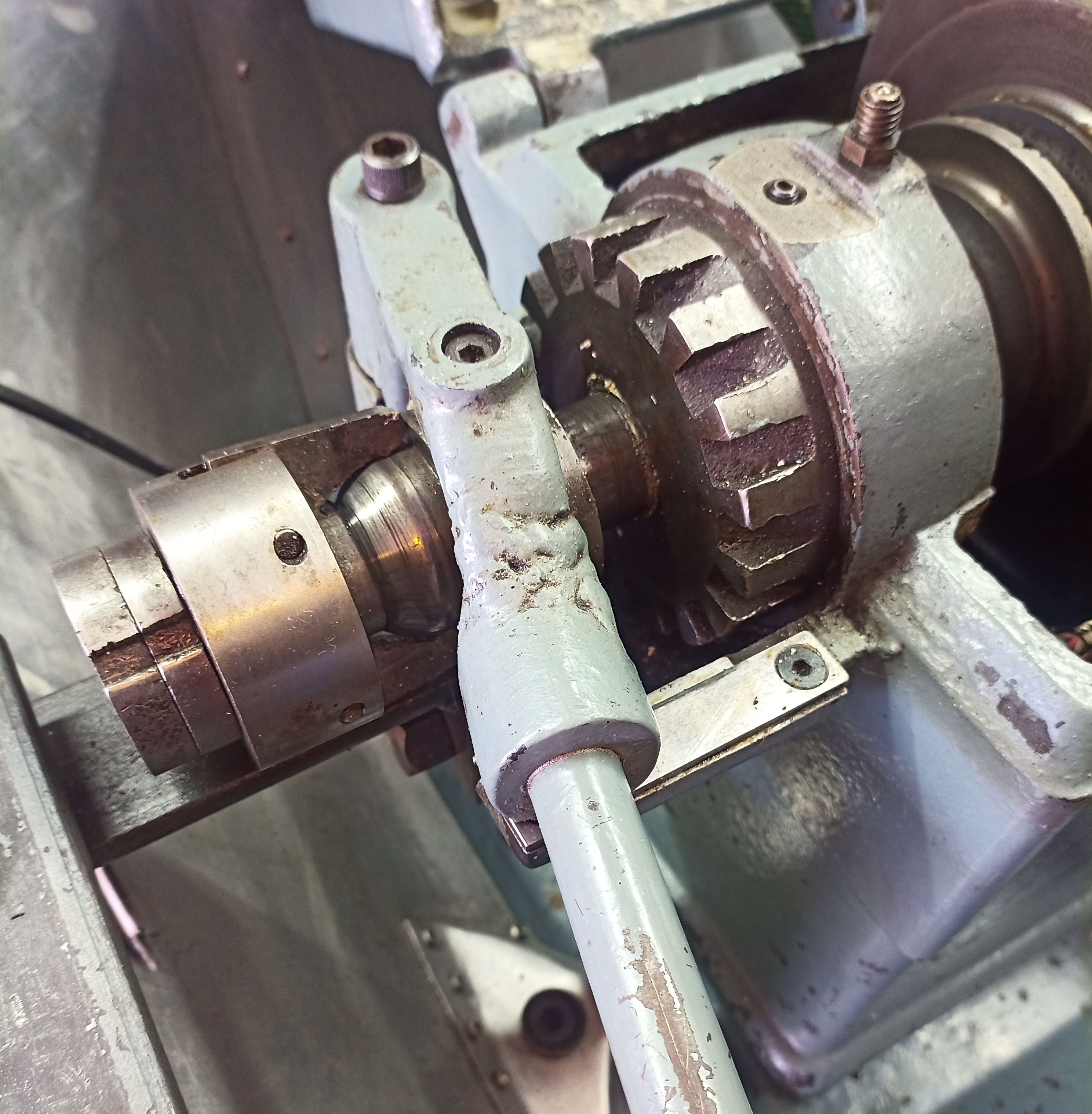

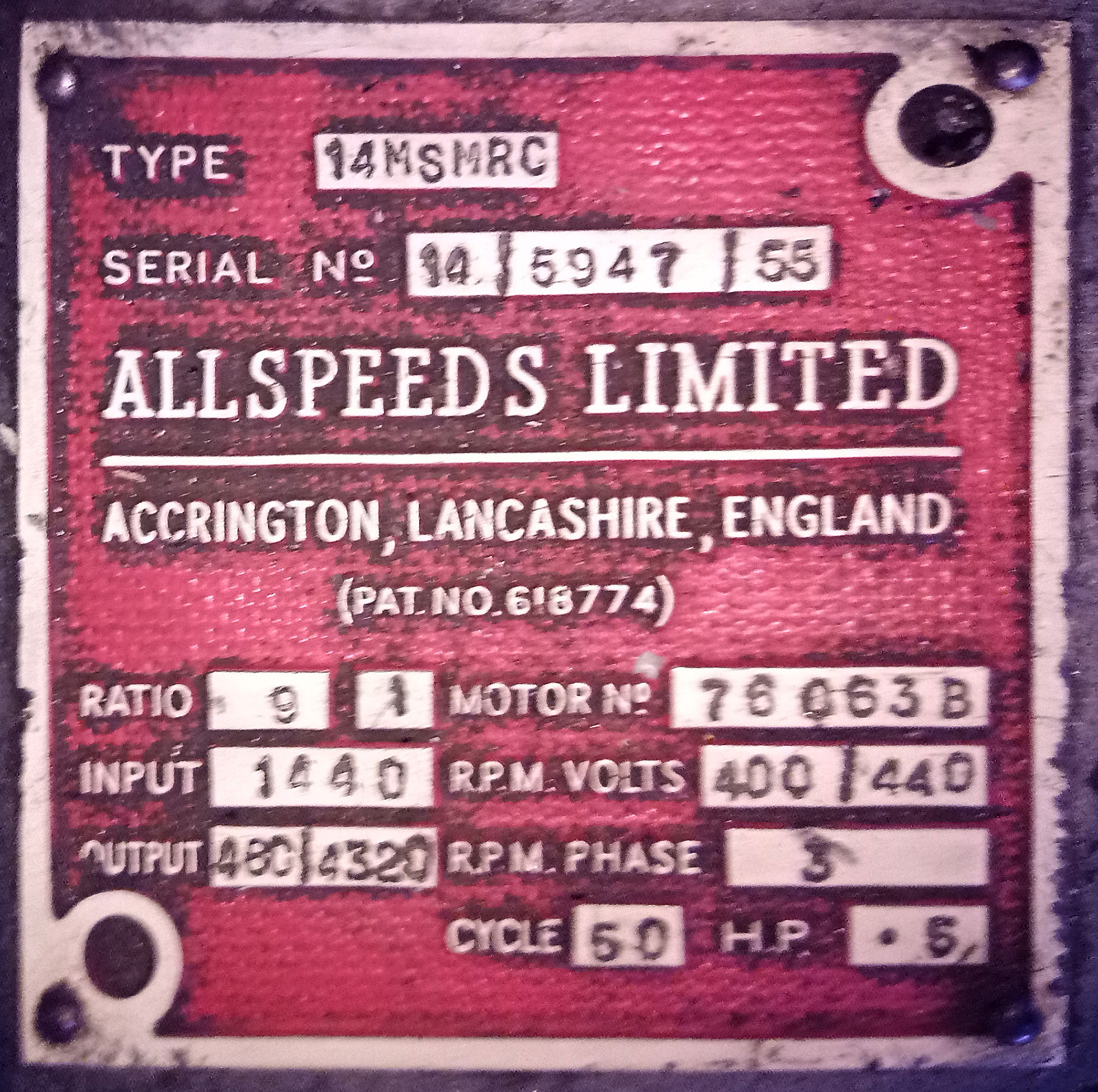

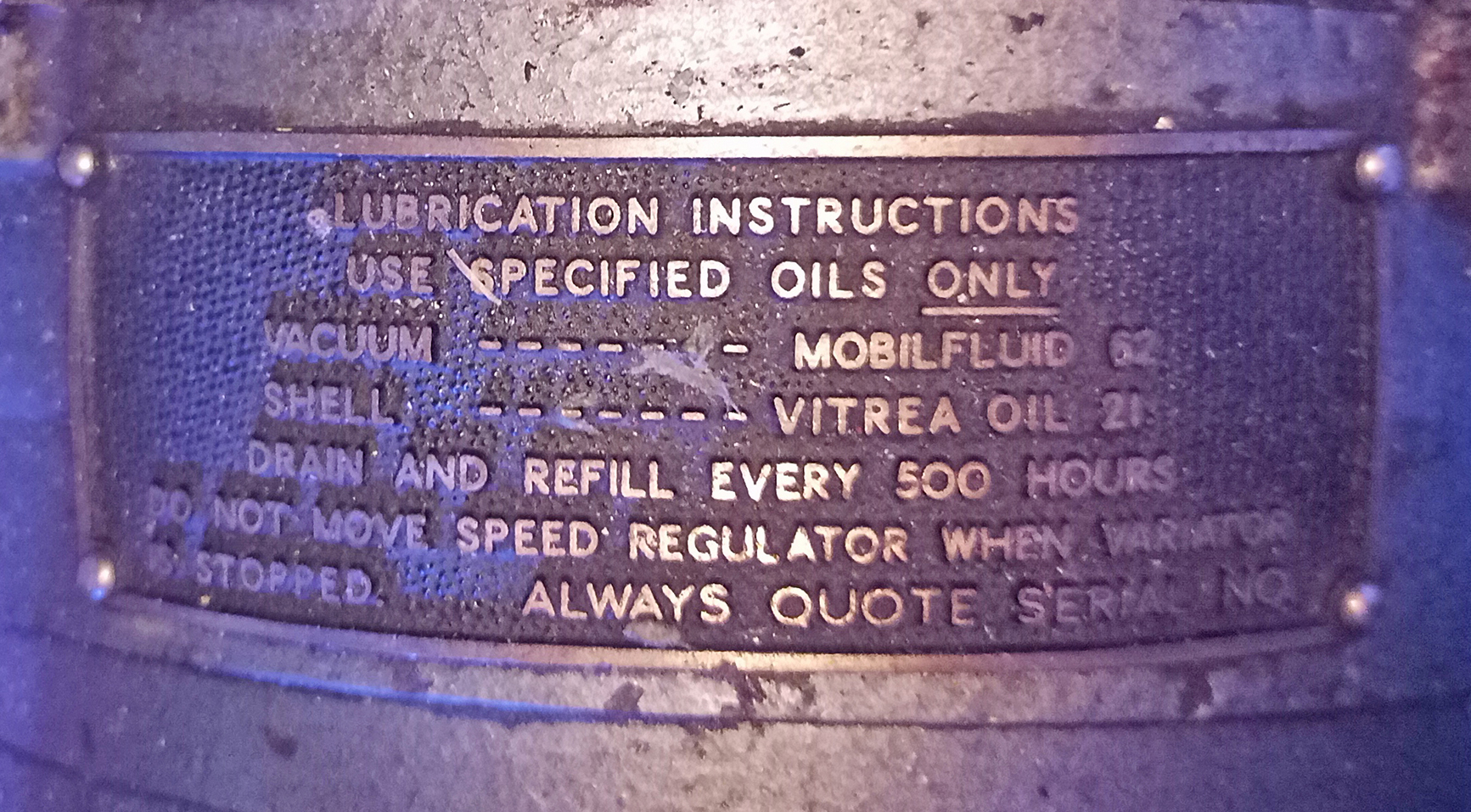

Also built in Australia as the somewhat cosmetically restyled Milro, the Exacta was available for drive from a remote countershaft or fitted to an all-cast-iron underdrive stand with an integral chip tray. While the Australian version was built in at least two versions, a Mk. 1 and a developed Mk. 2, it is not known if the Exacta followed suit. Running in opposed, pre-loaded Timken taper roller bearings, the spindle was driven by a V-belt running over a 4-groove pulley connected directly to a 3/4 h.p. 1425 r.p.m. 3-phase motor. The arrangement (in its standard form, though others are likely to have been available) gave speeds of 600, 1000, 1500 and 2000 r.p.m. but, instead of a 4-step pulley on the motor, it had just one, the assembly being arranged to lift (to allow the belt to be shifted on the headstock pulley) and slide so that the motor lined up correctly. The lifting and sliding movements were controlled by a handle (at the right-hand side of the stand) that dropped into one of four slots cut in a heavy cast-iron bracket - each indentation being of such a depth as to automatically give the correct belt tension for the selected speed. When specially ordered for drive by a remote countershaft an entirely different and not so versatile system was fitted - a flat belt running over a 2-speed pulley. However, machines have been discovered with a number differences including one with an Allspeeds KOP infinitely-variable swash-plate unit. The output setting of the KOP was changed by an electrical control, a small DC motor fixed to the output end of the drive controlled by a Centre Off |Up Faster|Down Slower toggle switch. Fitted with this system, the range of speeds available (including the 4-step headstock pulley) spanned 430 r.p.m. and 4800 r.p.m. a most useful range of speeds for a small capstan lathe.

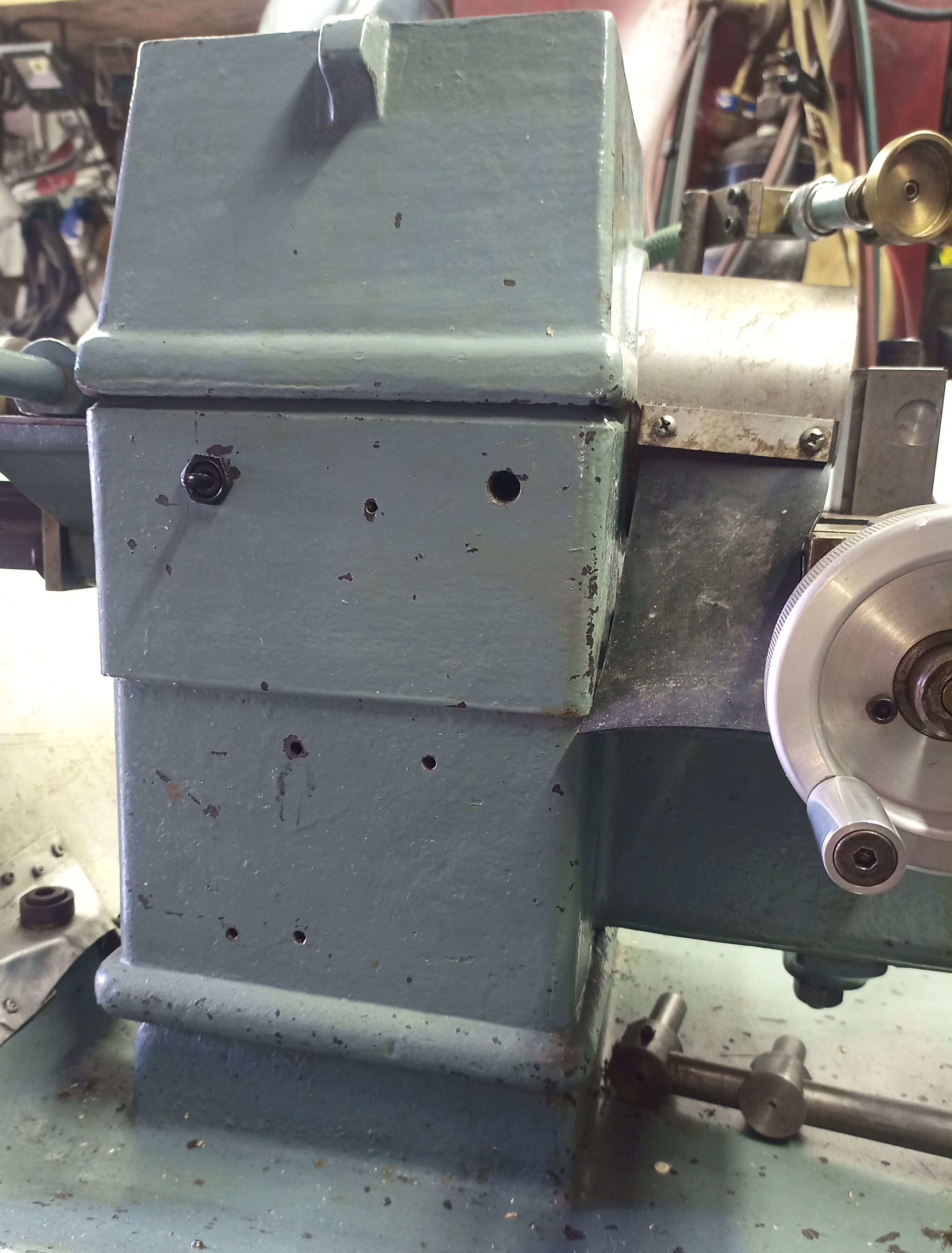

Unlike the rounded Milro, the Exacta had its angular, lift-off headstock cover formed so that the top provided a handy lipped storage for odd and ends.

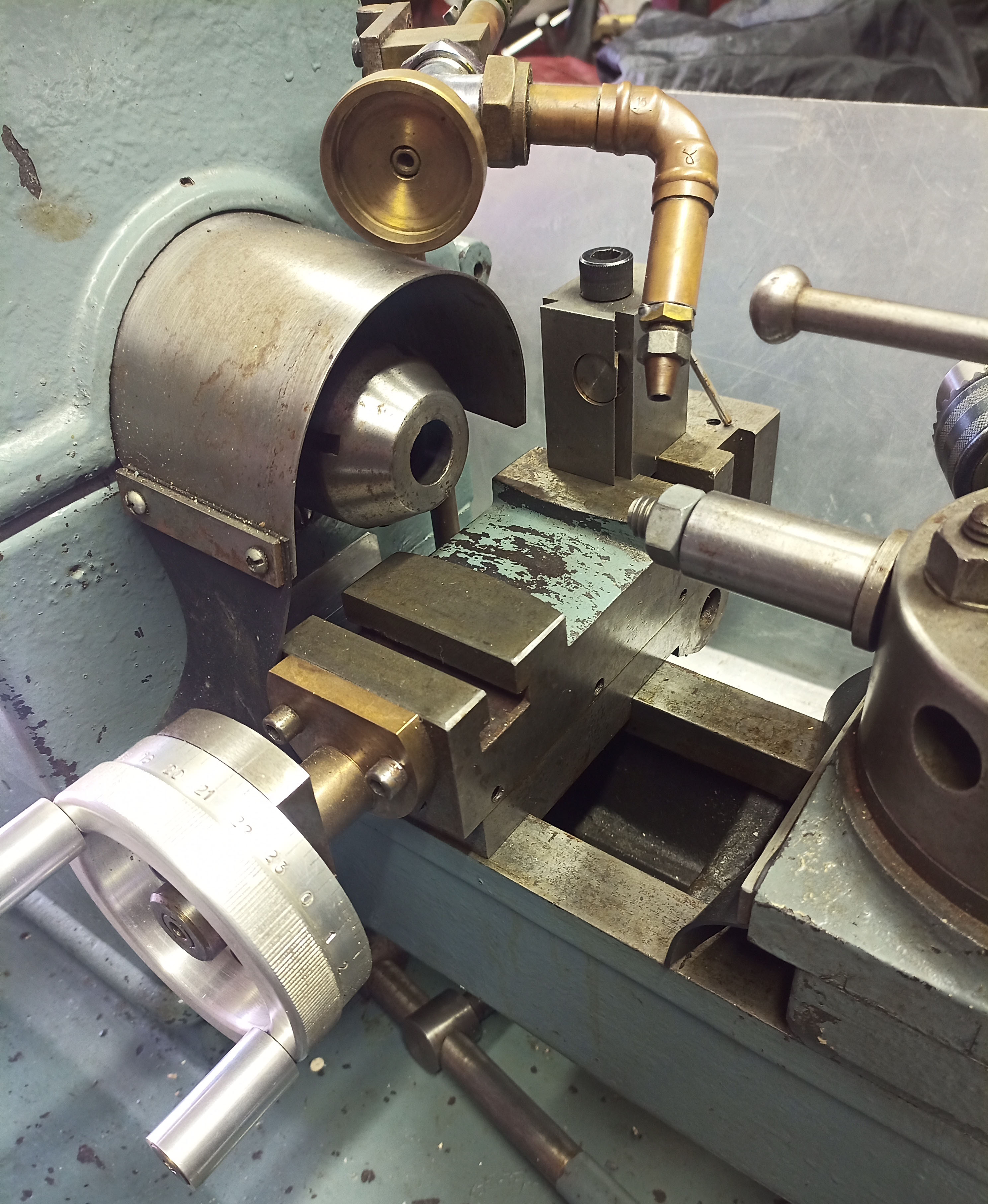

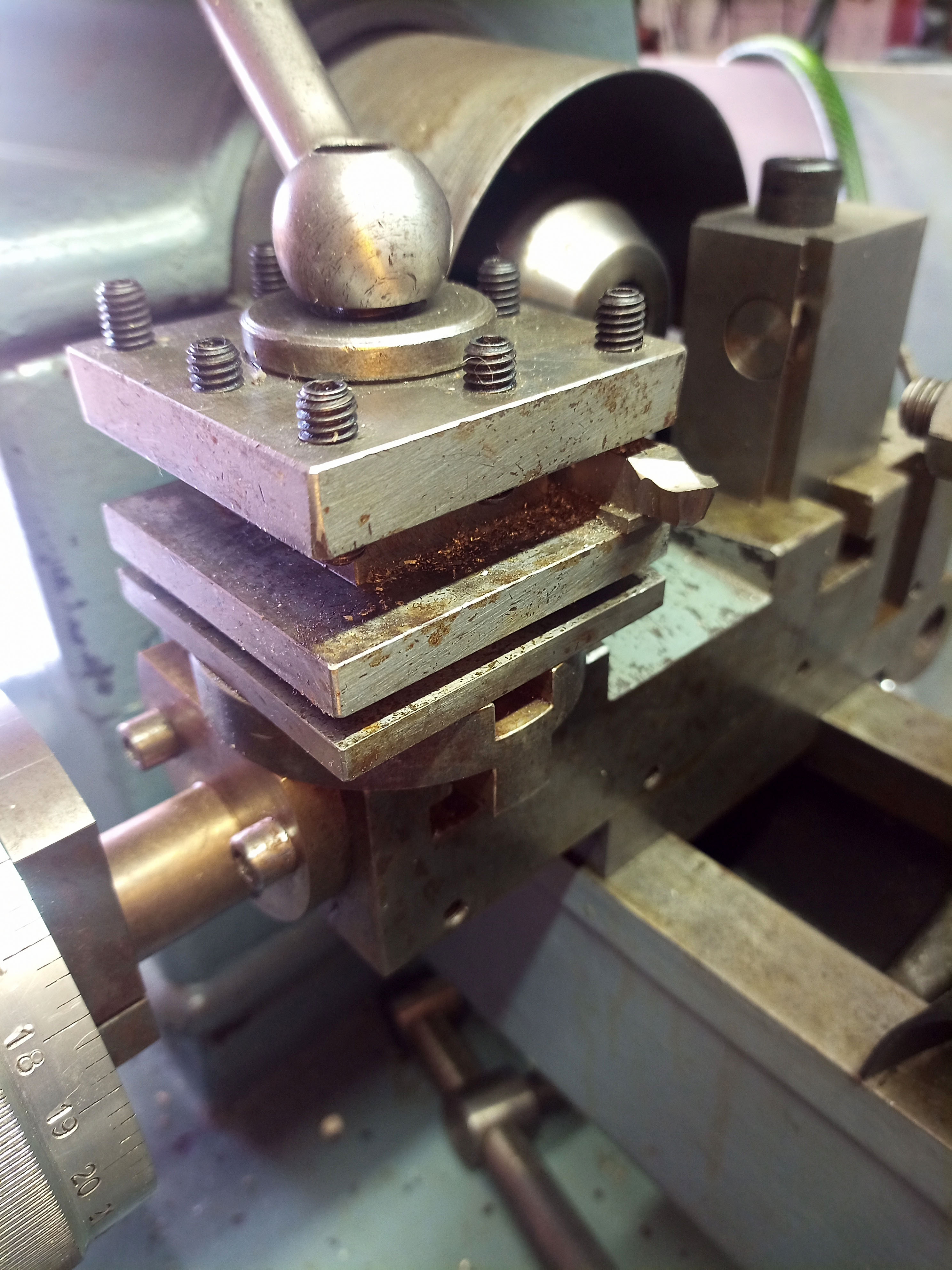

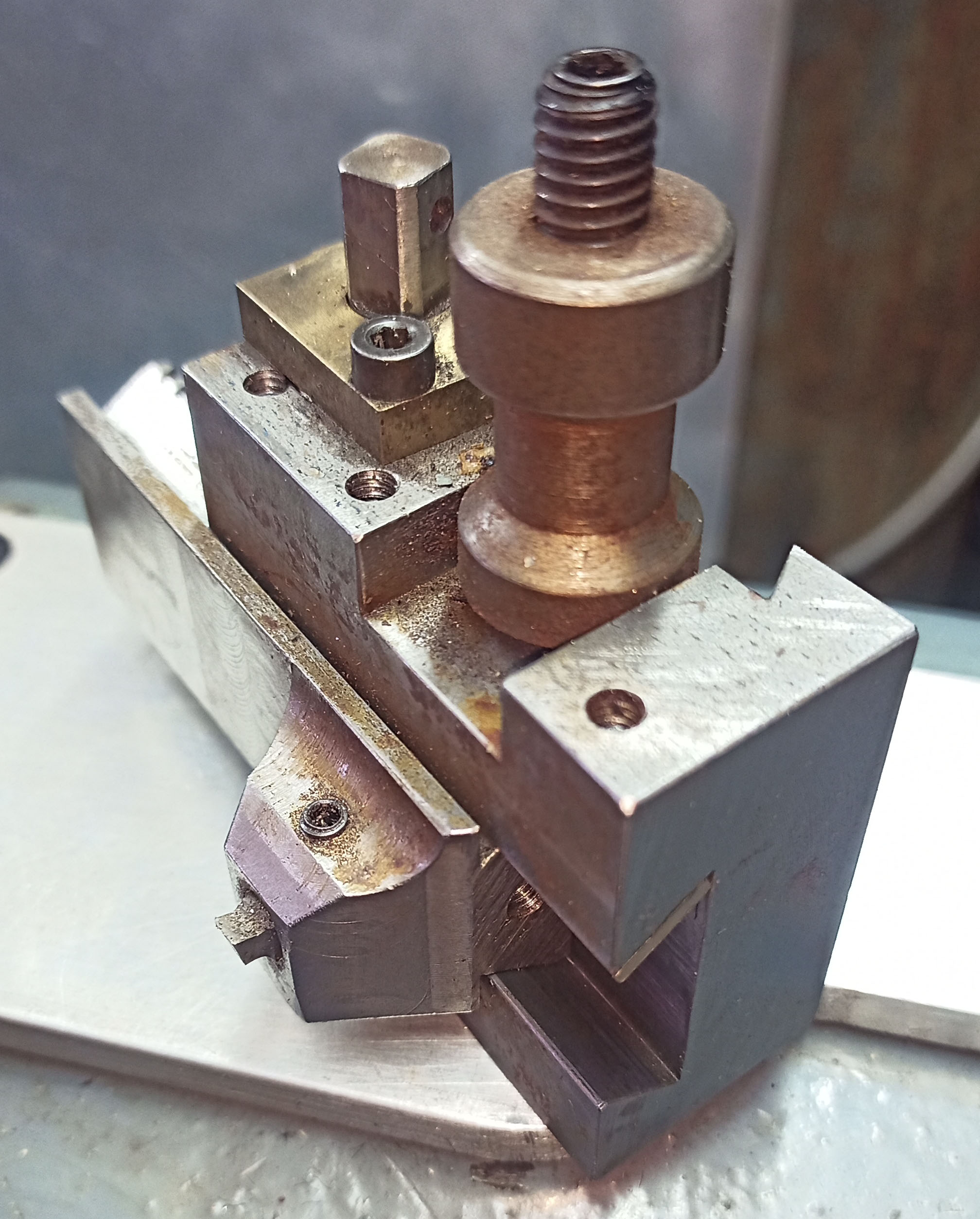

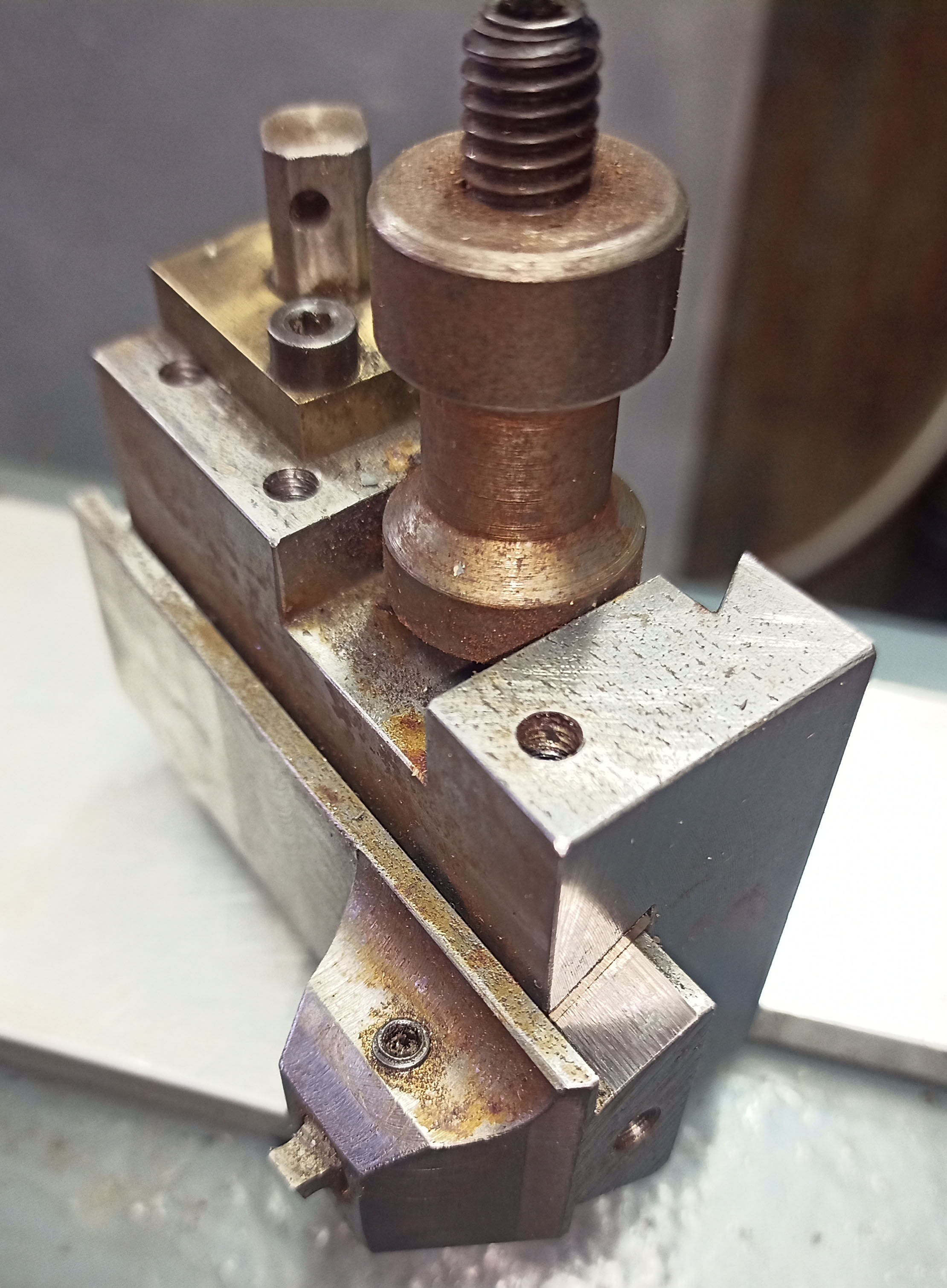

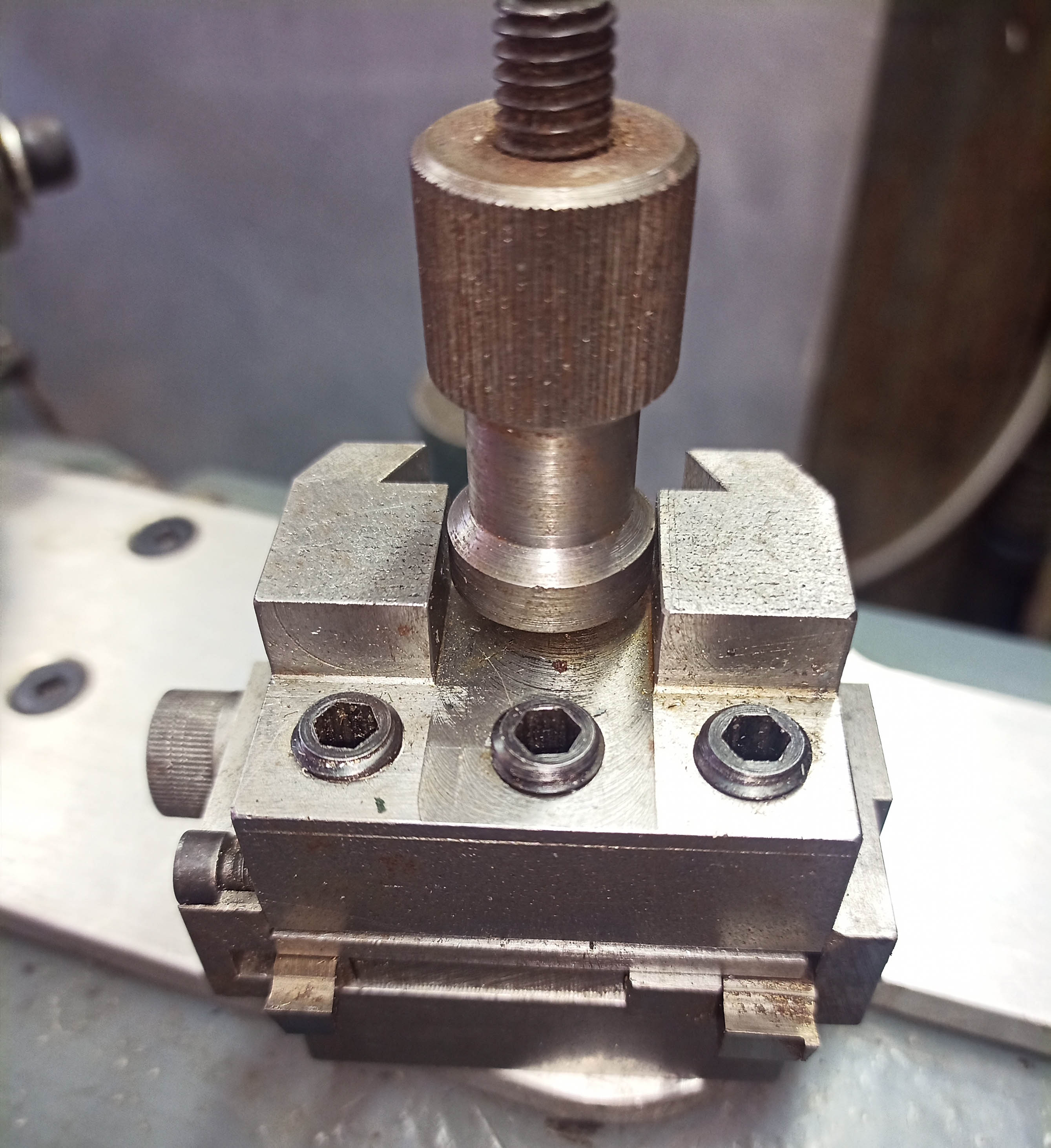

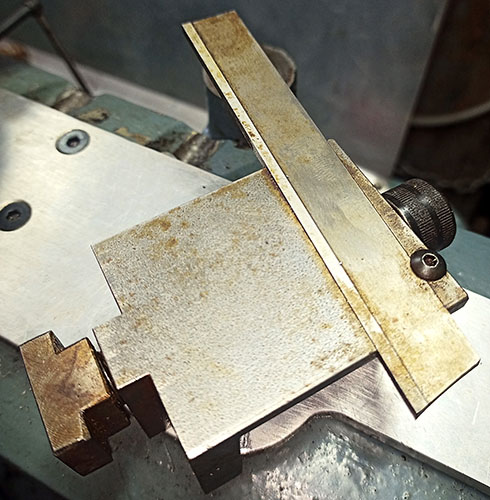

With a maximum through-collet capacity of 5/8", the lathe mounted a hand-operated, 6-station turret - with either automatic or hand-operated indexing - with its slideways protected against the ingress of grit and swarf by tightly fitting felt seals. The head took tooling with a 3/4" shank and had a maximum travel of 5 inches - each station being fitted, of course, with its own adjustable limit stop and The cut-off/forming slide was of the usual pattern being either lever operated or, optionally, driven by feed screws. Both types were fitted with front and rear toolposts and adjustable stops for travel in each direction.

Notably compact in its underdrive form, the lathe occupied a floor space of 25" x 52" x 42" and weighed approximately 700 lbs. Supplied with each new machine was a simple, weight-driven bar-feed assembly with the necessary supports; a lever-action collet closer; a set of seven collets from 1/4" to 5/8" in steps of 1/16", two toolholders for the parting-off/forming slide and, for the capstan head, a number of toolholders consisting of three for turning and two each for drilling and screwing. Also included was a set of open and C spanners, an oil can and a grease gun. Although a drip can was fitted as standard, if required a complete coolant set with tank and pump could be fitted inside the stand with the drive coming, economically, from an extension to the main motor or (at extra cost) from its own electric motor. Later machines were supplied, as standard, with a rear splash guard, a light unit, tool tray and blueprint holder.

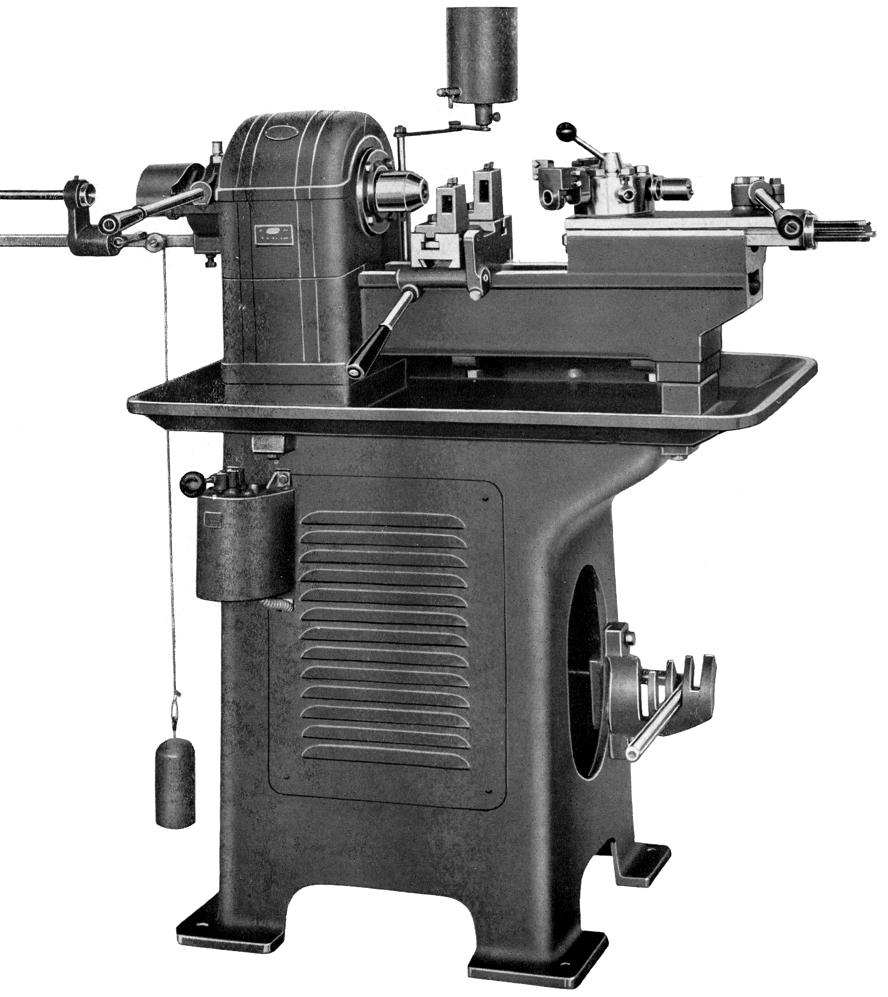

The Mk. 2 version would almost certainly have been built along the lines of the later Australian-built Milro - though with no more capacity through the spindle and only a 1/2" increase in capstan head travel. However, the machine was otherwise thoroughly revised with all-new major castings, the centre height increased to 5.25", safer guarding over the collet-closer mechanism, a more modern-looking cabinet stand with storage for coolant equipment and a substantial increase in weight to 1250 lbs. Instead of a sliding motor assembly, the new machine was entirely conventional with a 2-speed 1.5/0.75 h.p. motor controlled by push buttons (and a forward/reversing switch) with drive to the spindle via a 3-step V-pulley and twin belts. So equipped, the lathe was able to handle much tougher jobs with the wider speed range than the ordinary Mk/1 Exacta (350, 710, 770, 1400, 1562 and 2840 r.p.m.) allowing a better chance of getting the right one for the job. Lighting would have been from a 415 volt to 12-volt transformer and the coolant equipment of the proper sort with a built-in tank and separate electric motor.

Other examples of might be termed "late-type, professional-class compact capstan lathes" (as distinct from the smallest Ward and Herbert models) include the Italian Ceriotti, the British Accuratool and Britan, the Spanish Elgo, versions of the German Weiler 260 and the Emwee..

|

|