|

Continued:

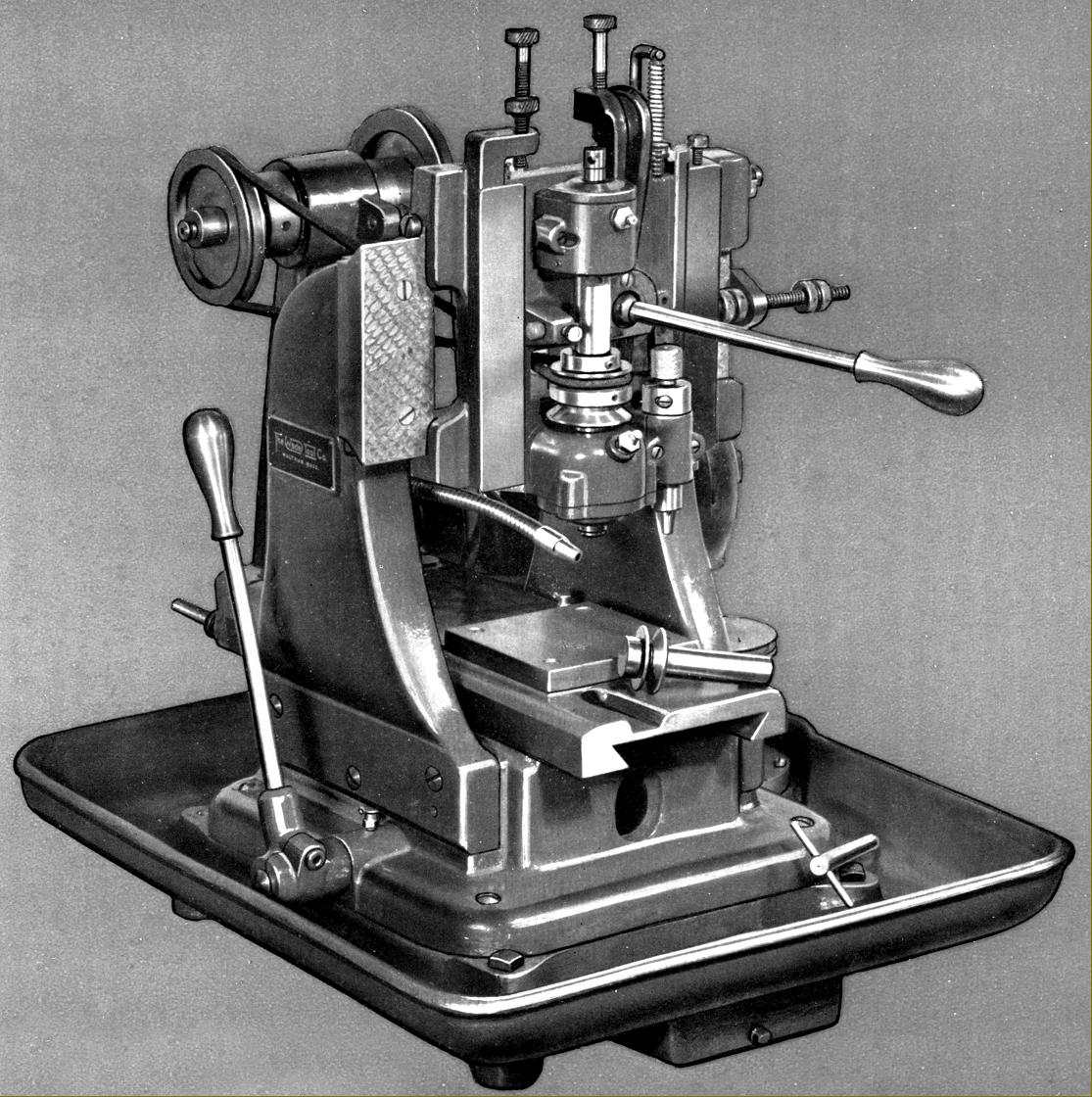

Work-holding facilities could hardly be described as convenient, with just a plain-topped, 4" x 4" x 1/2" steel block screwed to the horizontal slide - the intention being that the toolroom would make up a number blocks, as required, with jigs or fixtures arranged on them for production - the actual machining being carried out by women or unskilled help. In addition to the workpiece, when profiling or copying was to be undertaken, a hardened template (or some other form of guide) was positioned next to the job so that a tracer pin could engage with it. It was also possible for a skilled machinist to use the machine to cut its own masters or templates, the standard equipment including a cutter spindle and tapered end mill to fit in place of the ordinary follower - with a follower pin made to the same diameter as the cutter that would be later be used on the work, held in the regular spindle. Thus, when the master was cut, it was already clamped in position, ready to be used as a template and the job could then be handed over to the unskilled operator. It would also have been possible to replace the block with a custom-made example, perhaps having T-slots or lines of drilled and tapped holes for gripping one-off or short-run jobs. When set up for work, the cutter spindle could cover a maximum area of 2" by 4" with cutters held by draw-in collets with a maximum capacity of 5/16".

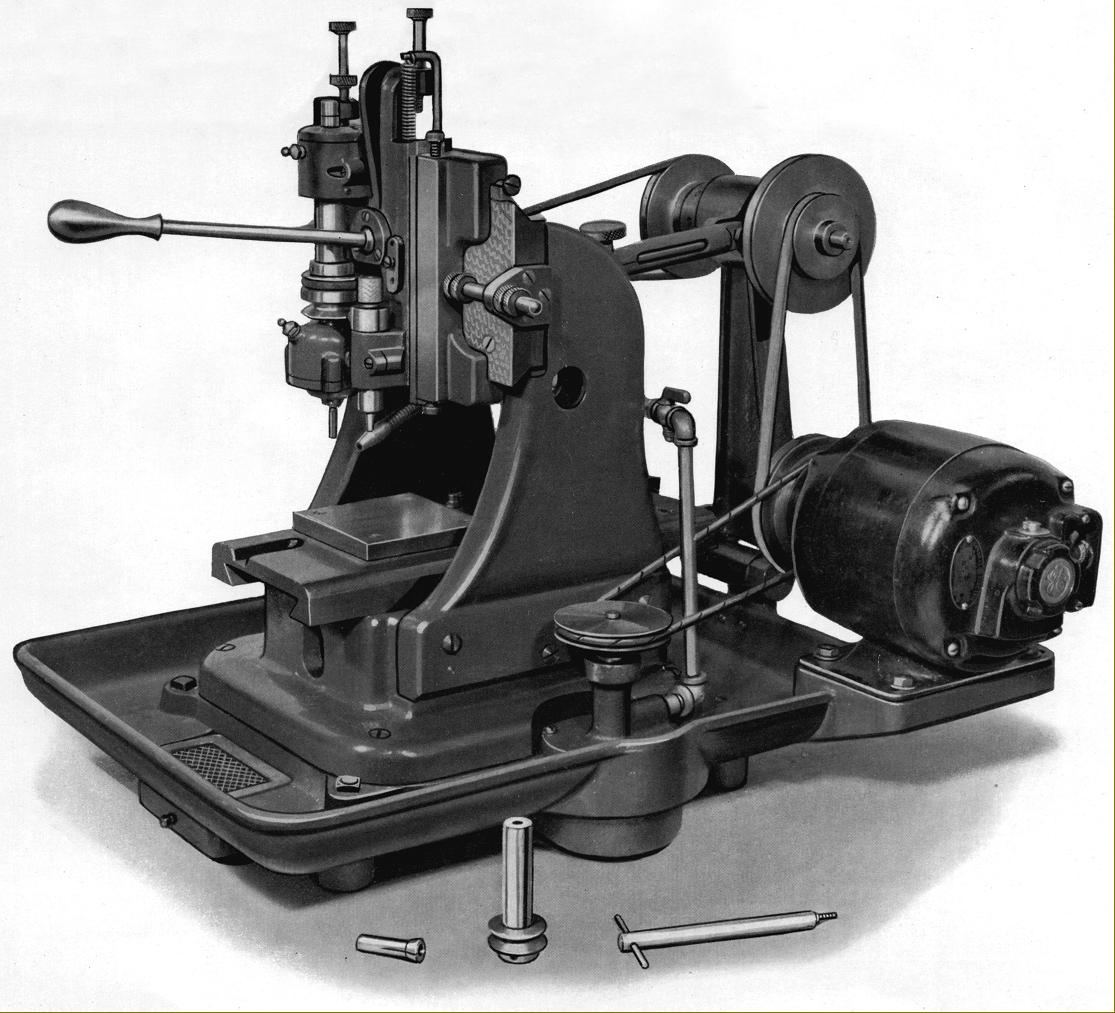

Power on the countershaft version came from a 1/4" h.p. 1700 r.p.m. 3-phase motor, mounted on plate formed at the back right-hand corner of the base, with initial drive by a 2-step V-pulley to a hinged-base countershaft that gave four speeds spanning 2000 to 4000 r.p.m. A central bearing assembly, using sealed ball races carried in an eccentric housing to allow adjustment of the motor belt tension, was fitted with a through shaft that had the pulleys overhung, one to the left the other to the right. To tension the final drive belt the countershaft was pushed backwards and a thumb screw tightened against a bar connected to the machine and passing into a tube fastened to the countershaft. To allow the spindle to move freely up and down, the final drive belt was normally a round, woven endless type of impregnated cotton, twisted through a quarter of a turn so that it could run round one of two pulleys positioned between the spindle's pre-loaded, ball-race bearings. However, if work involved using lower speeds on steel, a V-belt could be substituted, the change from one to the other eased by the removal of two cap-head screws that allowed the upper bearing assembly to be rotated half a turn to expose a gap though which the belt could be threaded. A second drive from the motor, using a twisted rawhide belt, was used to power a built-in coolant pump, the liquid being directed through steel pipes to a flexible nozzle head.

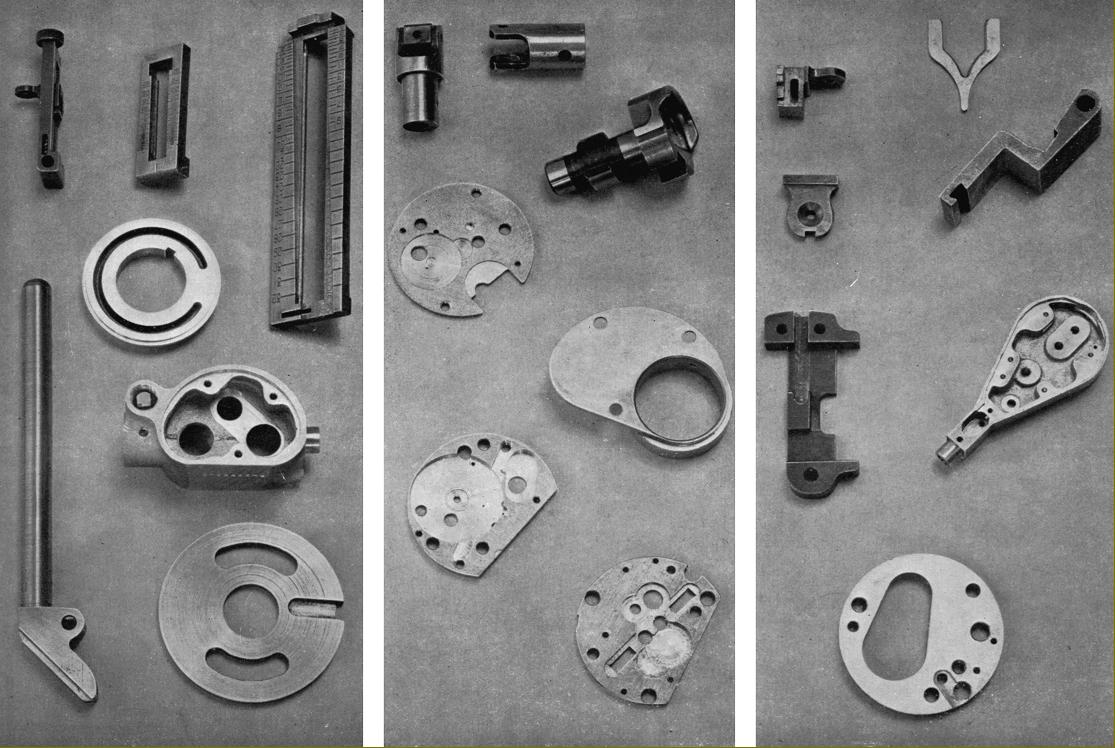

In use, the operator gripped the head lever in the right hand and the table lever in the left; the cutter was brought down to the work and, by means of the two levers guided the tracer pin around the template or master guide. The procedure obviously required some practice to master but, once well practiced, the makers claimed that the action was quick and certain and tiny jobs - mechanical time fuses, time bomb fuses, bomb parts, breech mechanisms, range-finder parts, gun sights, typewriter and adding machine plates and levers, etc. - could be turned out to very high standards of accuracy.

As was the case with many specialised machines, the maker's offered a service to customers inviting them to send work samples or drawings so that advice could be offered on the best way to proceed.

Although it is believed that several hundred examples were made, few if any can have survived. If any reader has a Wade bench profiling machine the writer would be interested to hear from you. Bench Profiler photographs here

|

|