|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Derbyshire Micromill

Derbyshire Home Page Micromill Page 2 Vertical Micromill

Reproduction Derbyshire Literature is available

Manufactured during the 1930s and 1940s, the Derbyshire Micromill was an unusual device in being a miniature, very high-precision milling machine that was built in both horizontal and vertical forms. A niche product, the Micromill was not a general-purpose machine but designed to handle awkward tasks connected with watch, clock, instrument and other particularly fine work made to critical dimensions. However, while the horizontal version is relatively common, the vertical is rare and, should any reader have an example, the writer would be most interested in hearing from you. Devised in its horizontal form as a dual-purpose milling and grinding machine, a number were imported to the UK during WW2, allegedly to handle production processes associated with the manufacture of timing fuses for very large shells.

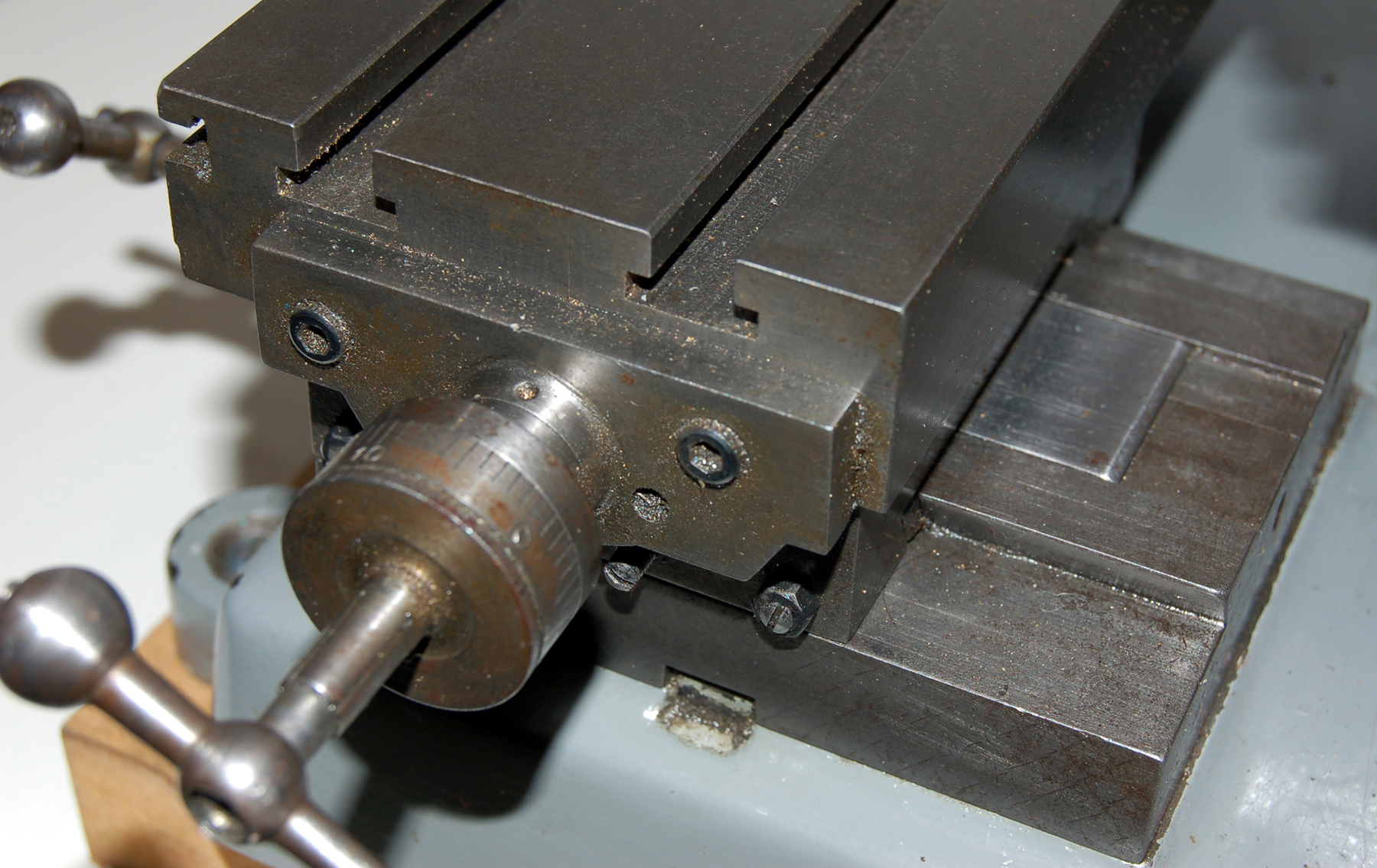

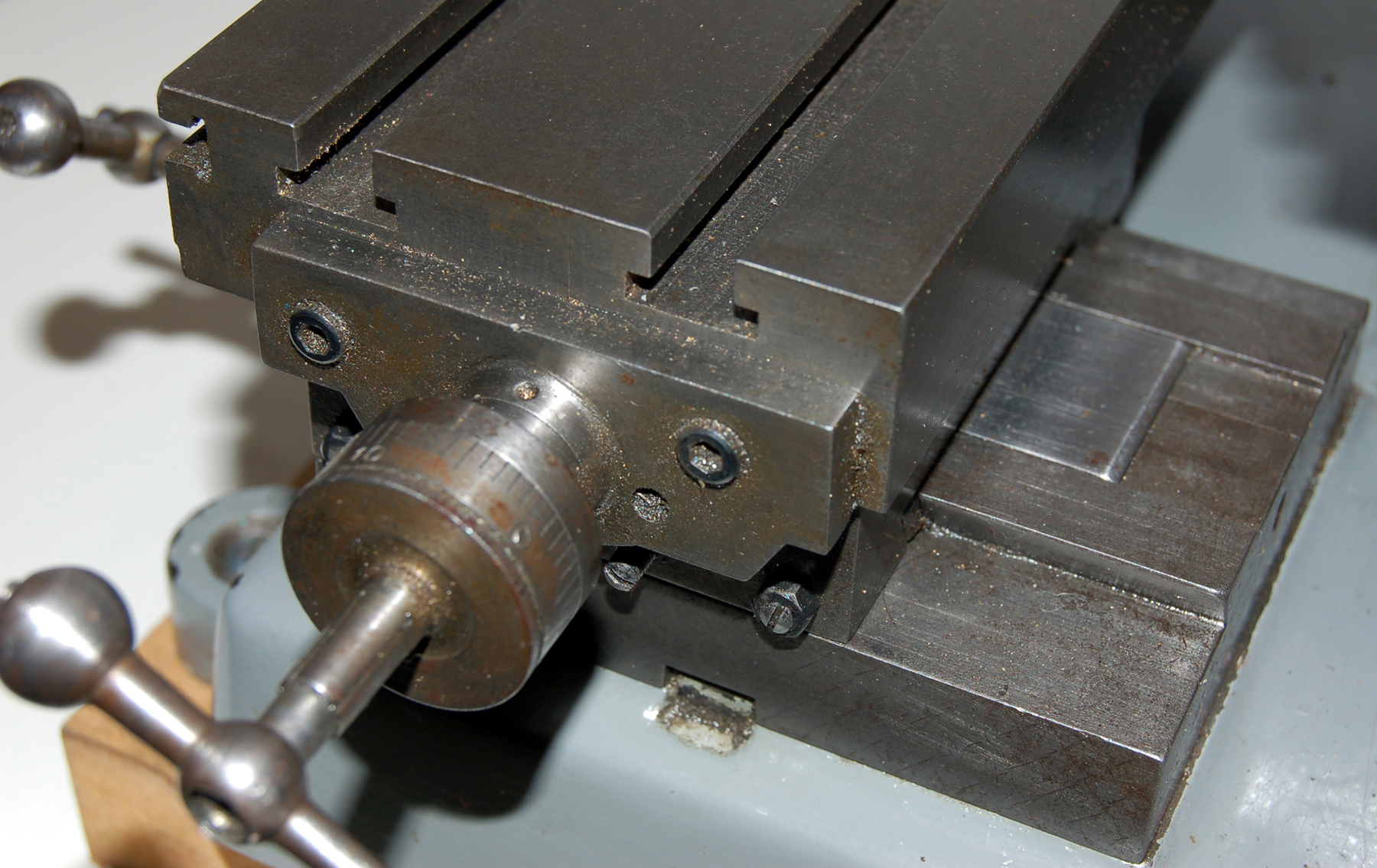

Although difficult to judge from photographs, the Derbyshire Micromill was extremely small, about the size of a portable typewriter - and with equally minuscule slide travels. The head could be moved vertically through just 1.73" (44 mm); the cross travel was 1.26" ( 32 mm) and the longitudinal feed 3.15" (80 mm). Because the table travel was so short, only 3.15" (85 mm), on some models a lever-operated cam, instead of a screw, was chosen as the easiest and cheapest way of providing a smooth, sensitive yet positive movement. The cam, in the shape of a sector and turning on the end of a block of metal screwed to the left-hand face of the cross slide, carried a slot near its periphery formed in the shape of an arch; fitted closely into this was a lug that extended from the end of the table.

Able to be run at up to 20,000 rpm the ball-bearing headstock spindle carried a draw-in 3/8"-diameter cutter arbor and was mounted on a two-part slide that allowed the operator the choice of either a quick-action cam or (very fine) screw-driven feeds; the screw-feed travel was 1.73", the cam feed 0.984".

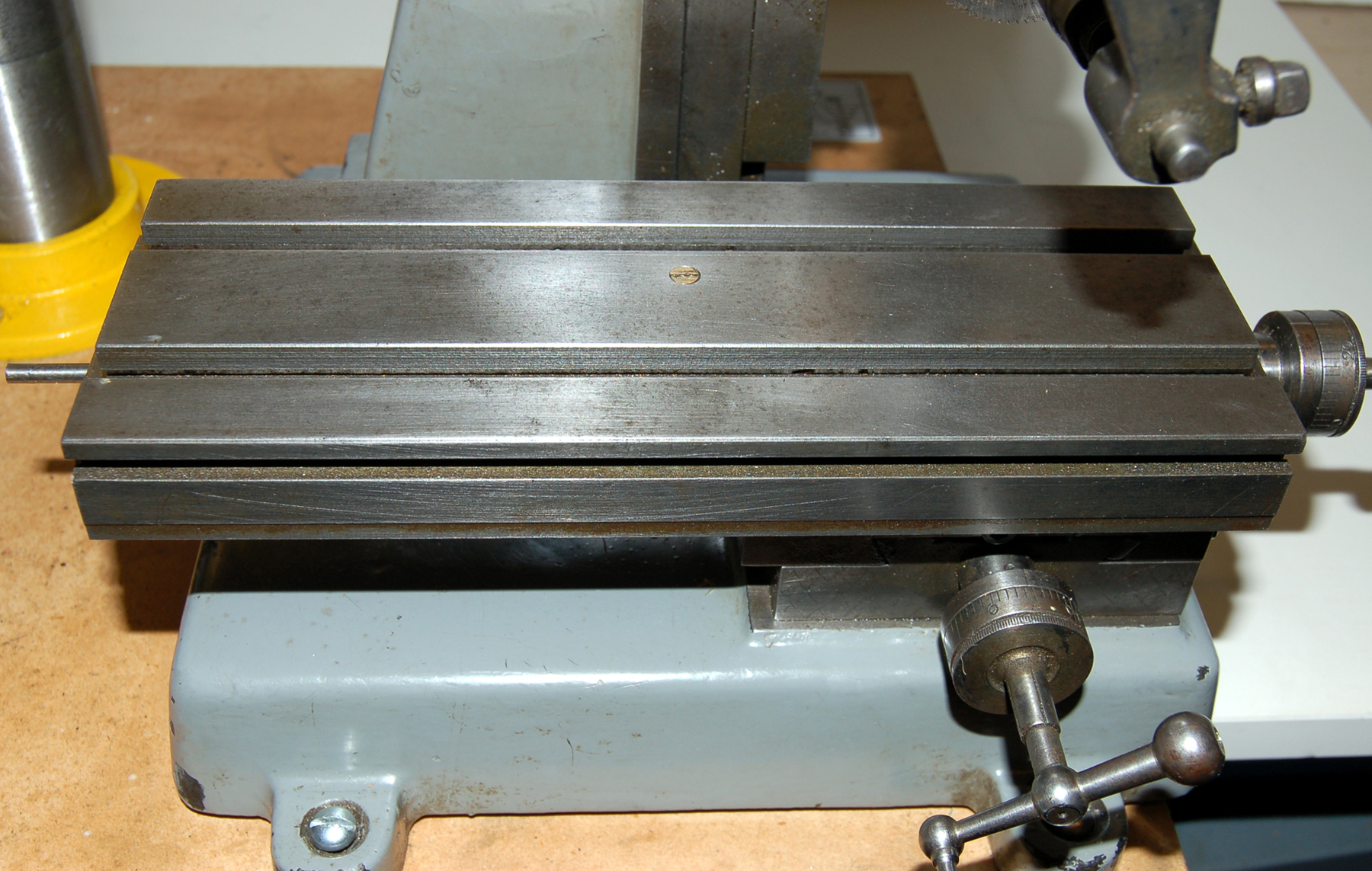

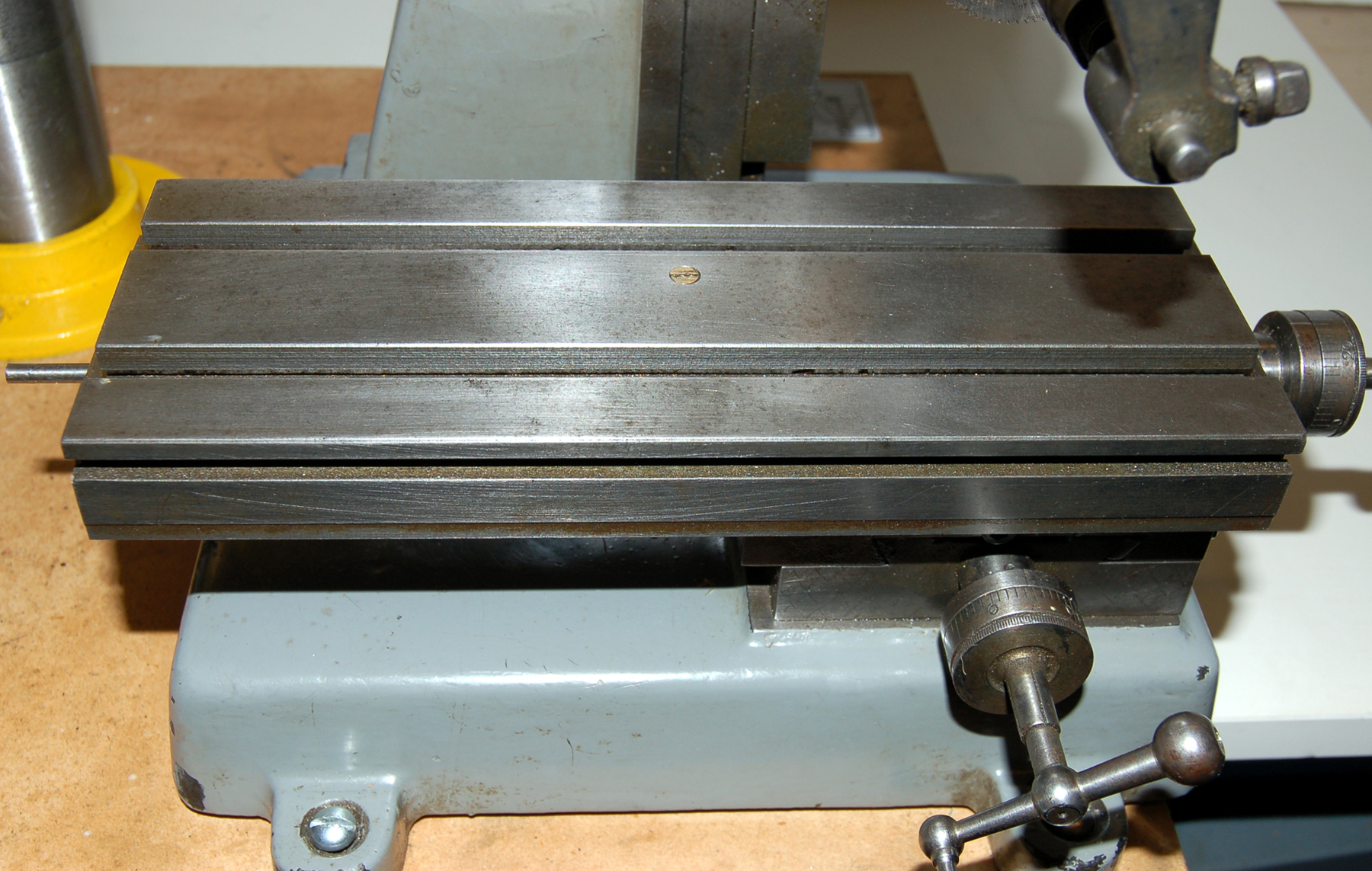

Various models of Micromill were offered over the years but, whilst each differed in some small detail from the others, or used a different drive system, all shared, except for the table, the same major components. Early types included the Model 651 with a table work surface of 67/8" x 23/8" and a single, central longitudinal T-slot; the Model 750 with a more heavily built and larger table of 77/8" x 23/8" with a single T-slot along the length and two traverse slots and the 750-M with a 12"-long table machined to replicate the Derbyshire lathe bed. Yet another, imported during WW2, had a beautifully engineered constant-tension chain drive and a large, 2-slot table. Changes could also be specified as to how the head and table were moved: the standard set up provided a cam-operated head (with a screw for fine feeds) a cam-driven longitudinal feed and a screw for the traverse motion. Alternatively, at no extra cost, both head and table could be moved by rack and pinion, or the table by a screw in both directions. When a cam-operated table was specified the model was given a suffix C (as in 651-C), with a rack-and-pinion drive the suffix R and with a screw feed the suffix S. Later models included the 750-12R (really the same as the older 750-M); the vertical-head equipped 750-SV (screw-feed table) or RV (rack-feed table) and the 750-CV with a cam-operated table and vertical head. Able to be used as either a miller or grinder the former required a 1/4 hp motor of 1725 rpm and 3450 rpm for the latter. If you have a Micromill of any type, the writer would be interested to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

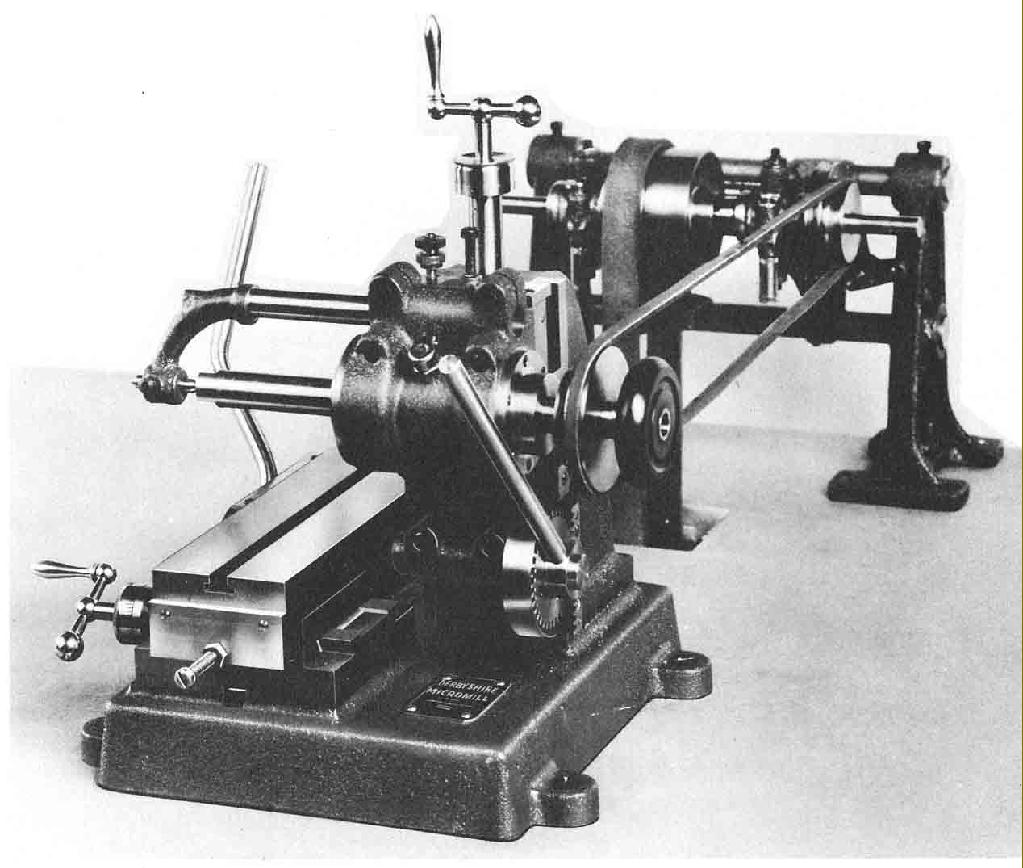

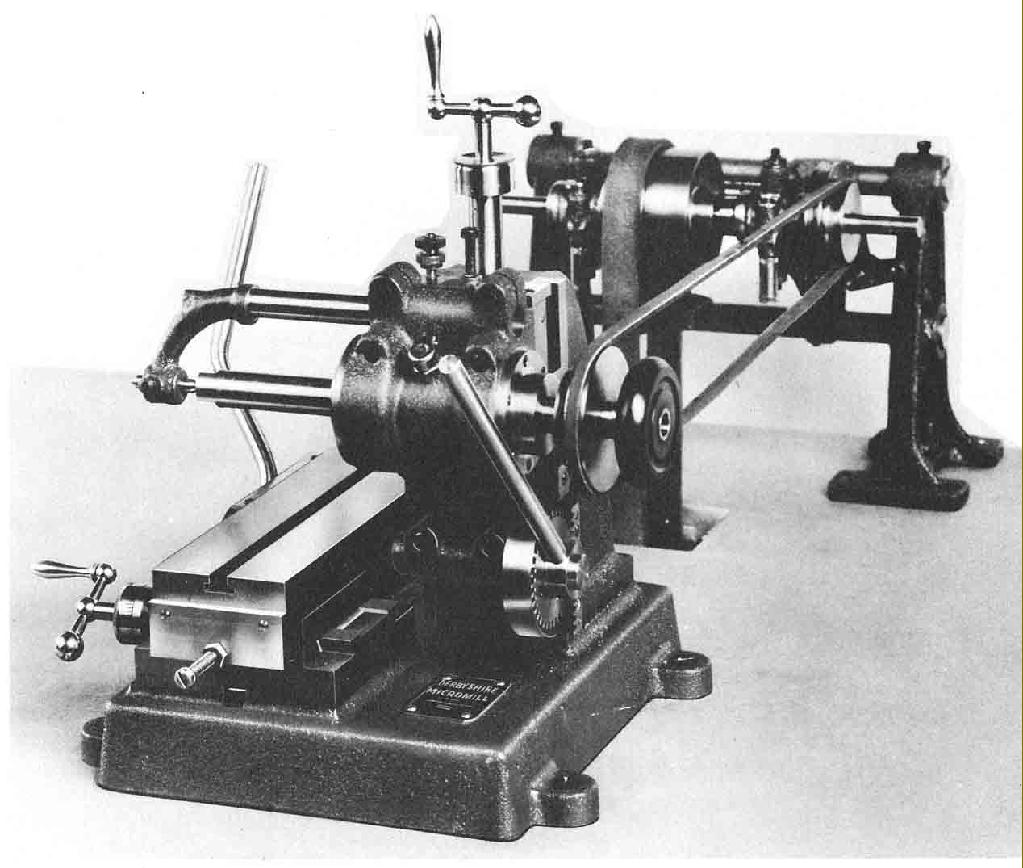

Finished in the glare-reducing and rather fetching crackle-black finish this Micromill, a Model 651-R has rack-and-pinion driven movement to both the vertical head and the table's longitudinal feed. The drive countershaft carries a flat-belt, fast-and-loose pulley arrangement with the belt striker (to shift from idle to drive) probably foot-pedal operated and concealed beneath the bench

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

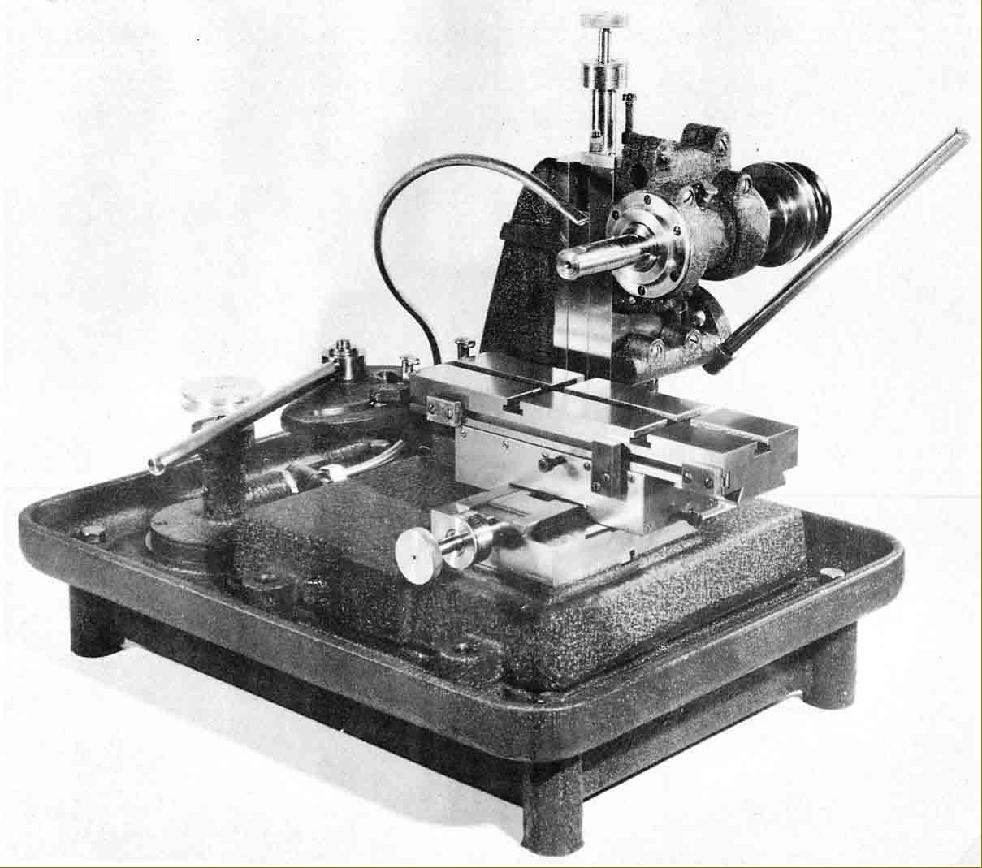

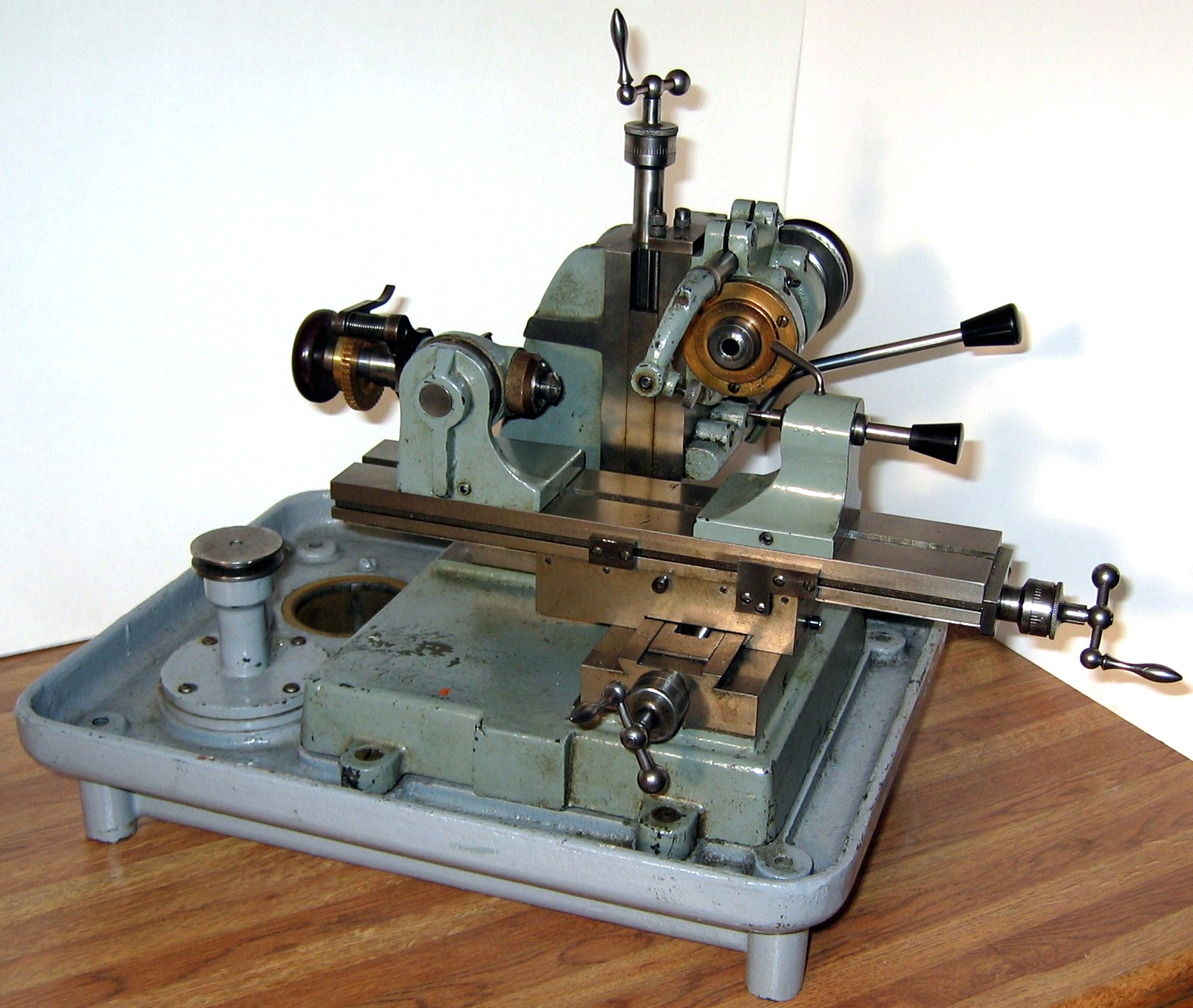

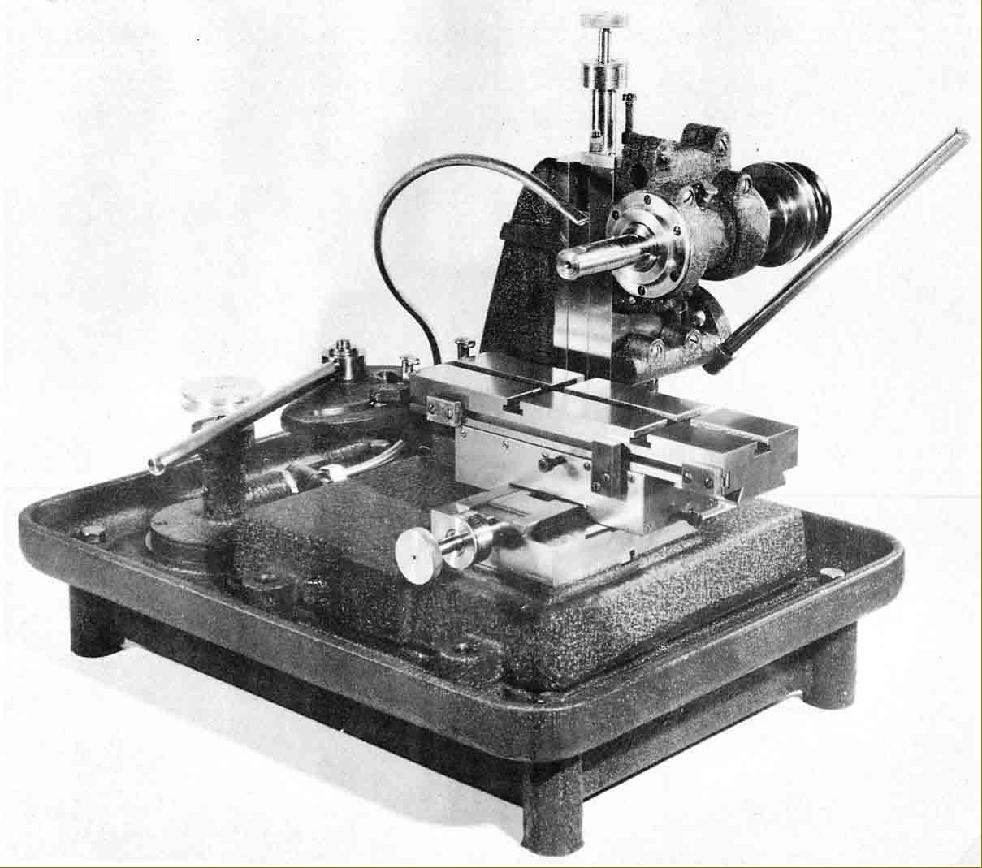

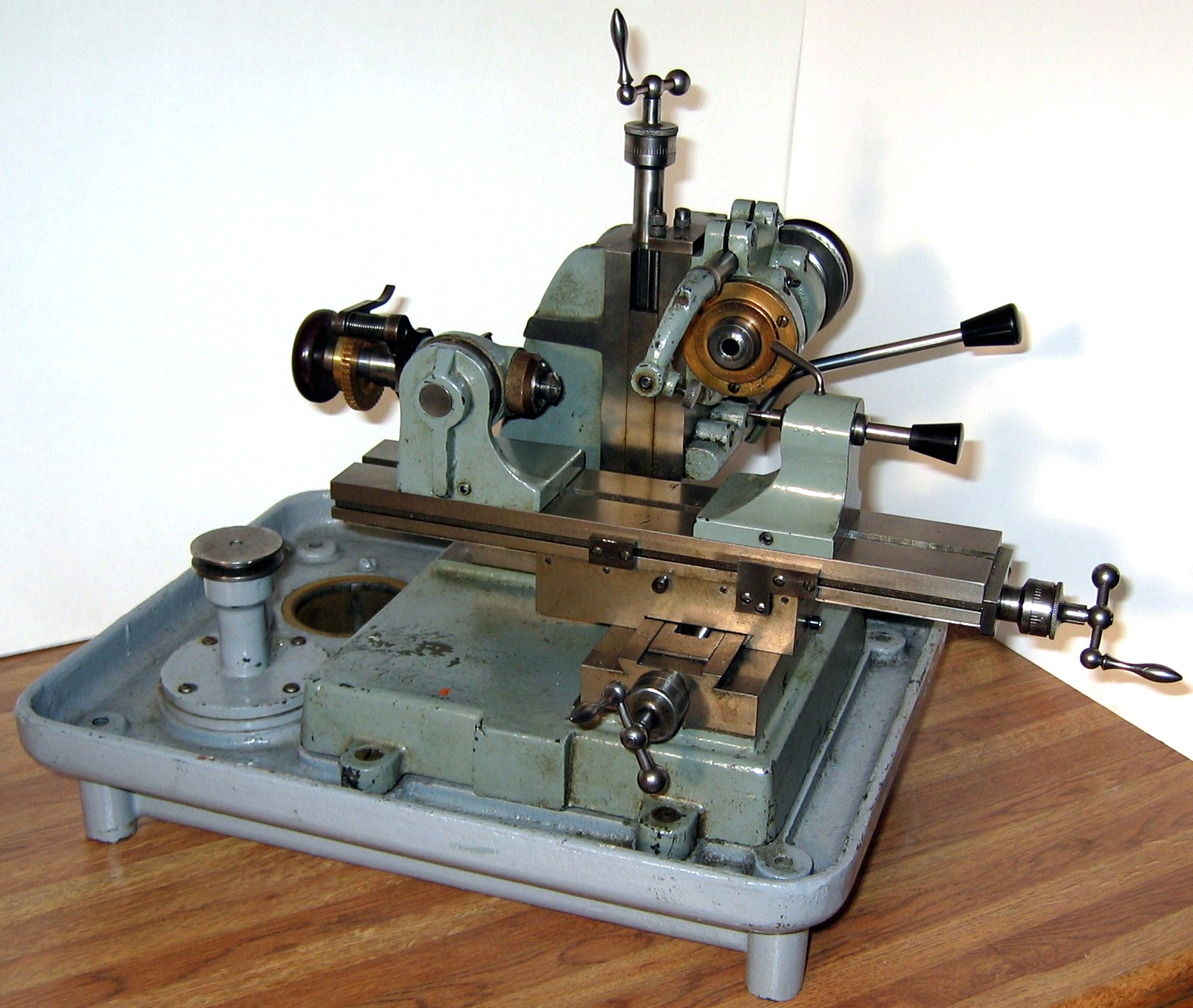

Micromill Model 750 with cam-operated feeds to both head and table. Because the table travel was so short, only 3.15" (85mm), a lever-operated cam was chosen as the easiest and cheapest way of providing a smooth, sensitive yet positive movement. The cam, in the shape of a sector and turning on the end of a block of metal screwed to left-hand face of the cross slide, carried a slot near its periphery formed in the shape of an arch; fitted closely into this was a lug that extended from the end of the table.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

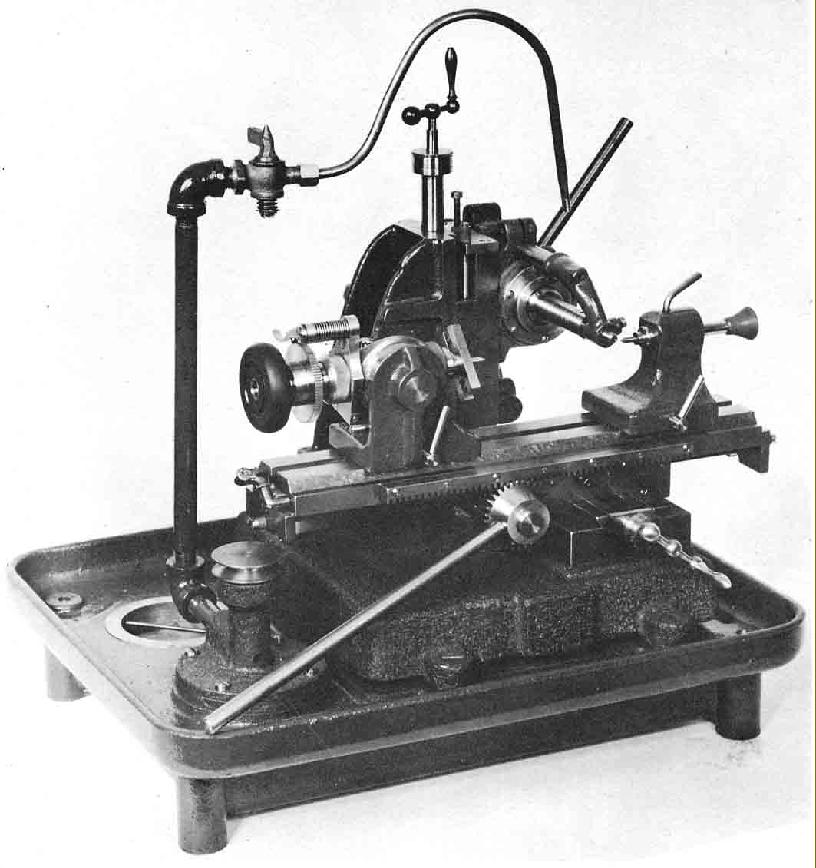

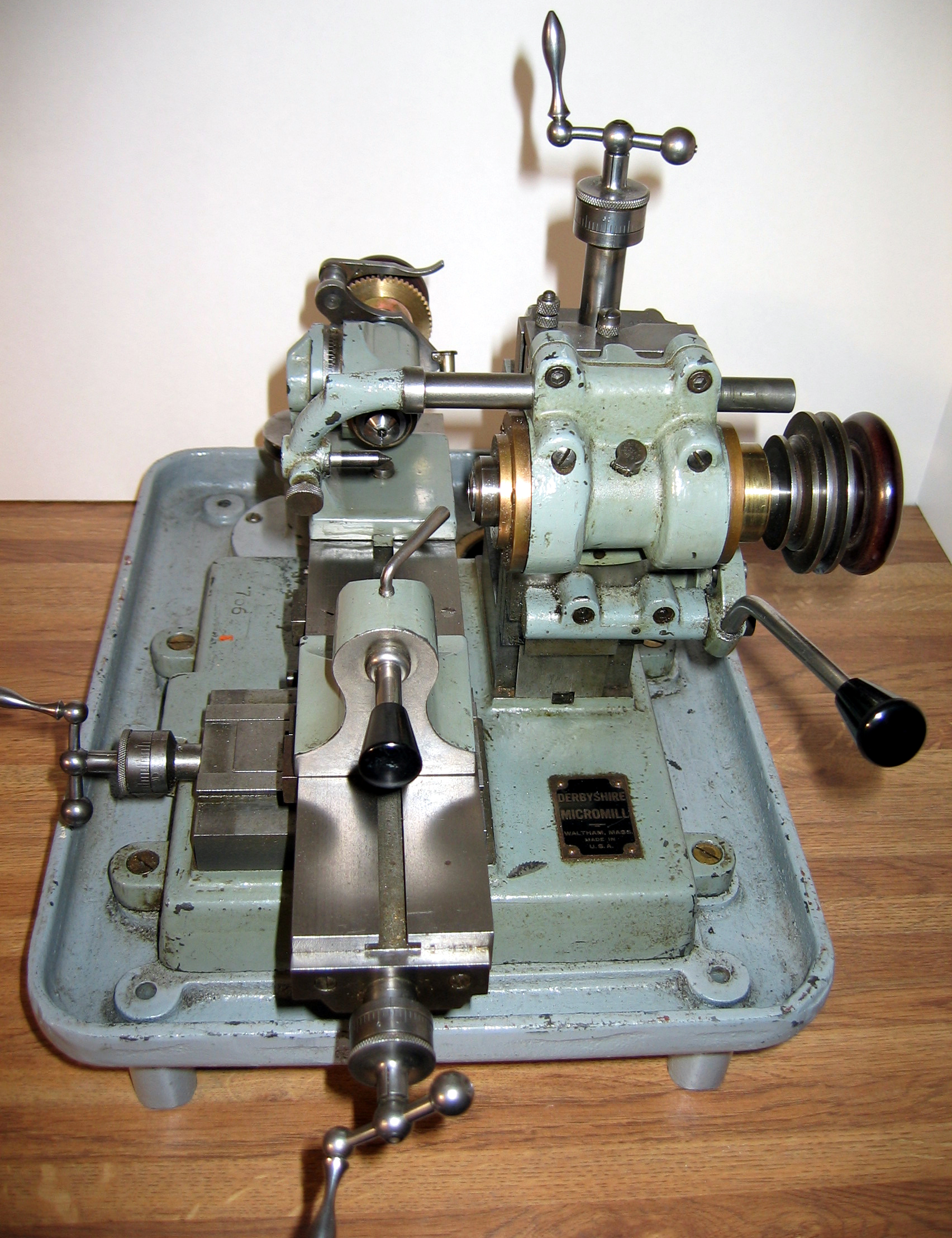

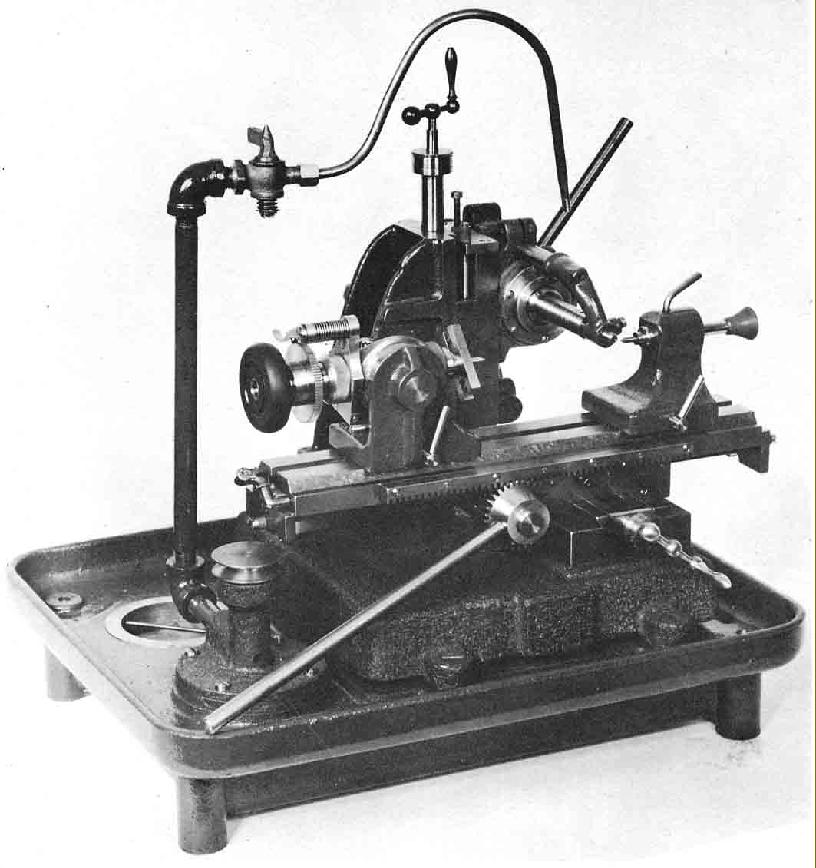

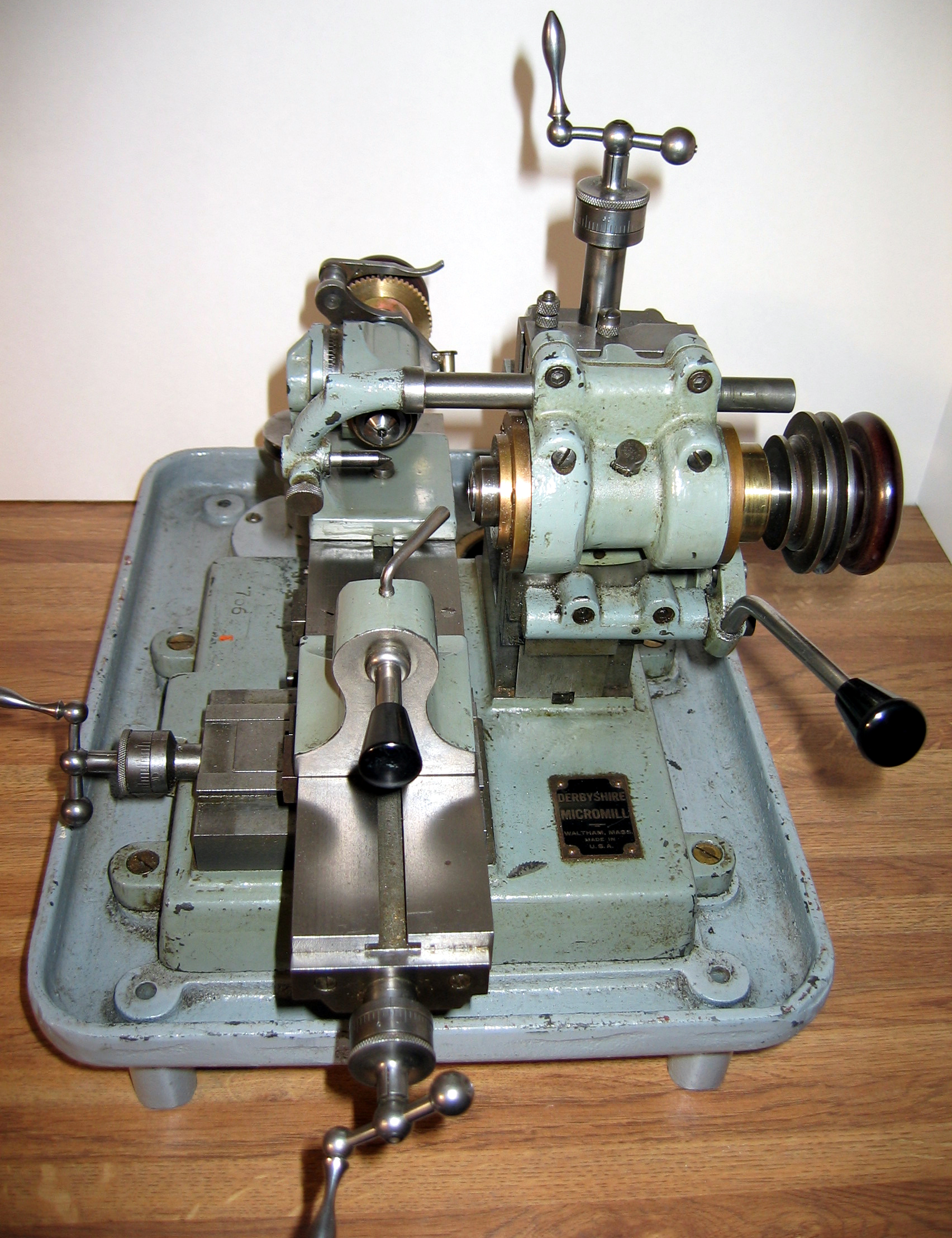

Model 750-M Micromill with a 12-inch long rack-and-pinion feed table the top surface of which was formed as a replica of the watchmakers' lathe bed. Mounted on the table is the maker's "Semi-Universal Indexing Attachment"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arrangement of the table's cam feed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A WW2 Micromill Model 750-C Horizontal finished in WPB (War Production Board) Slate Gray instead of the traditional crackle-black. This unit is fitted to the optional stand with oil pan and coolant pump - the horizontally-mounted drive pulley for which can be seen at the far end of the stand.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A beautiful and original Derbyshire Micromill Model 750-S with ball-bearing headstock and cam-operated vertical slide with screw-feed vertical adjustment. The 12-inch table has screw feeds to each axis and the machine is complete with a cutter arbor, overarm support and the rare "Semi-universal Index Centers"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

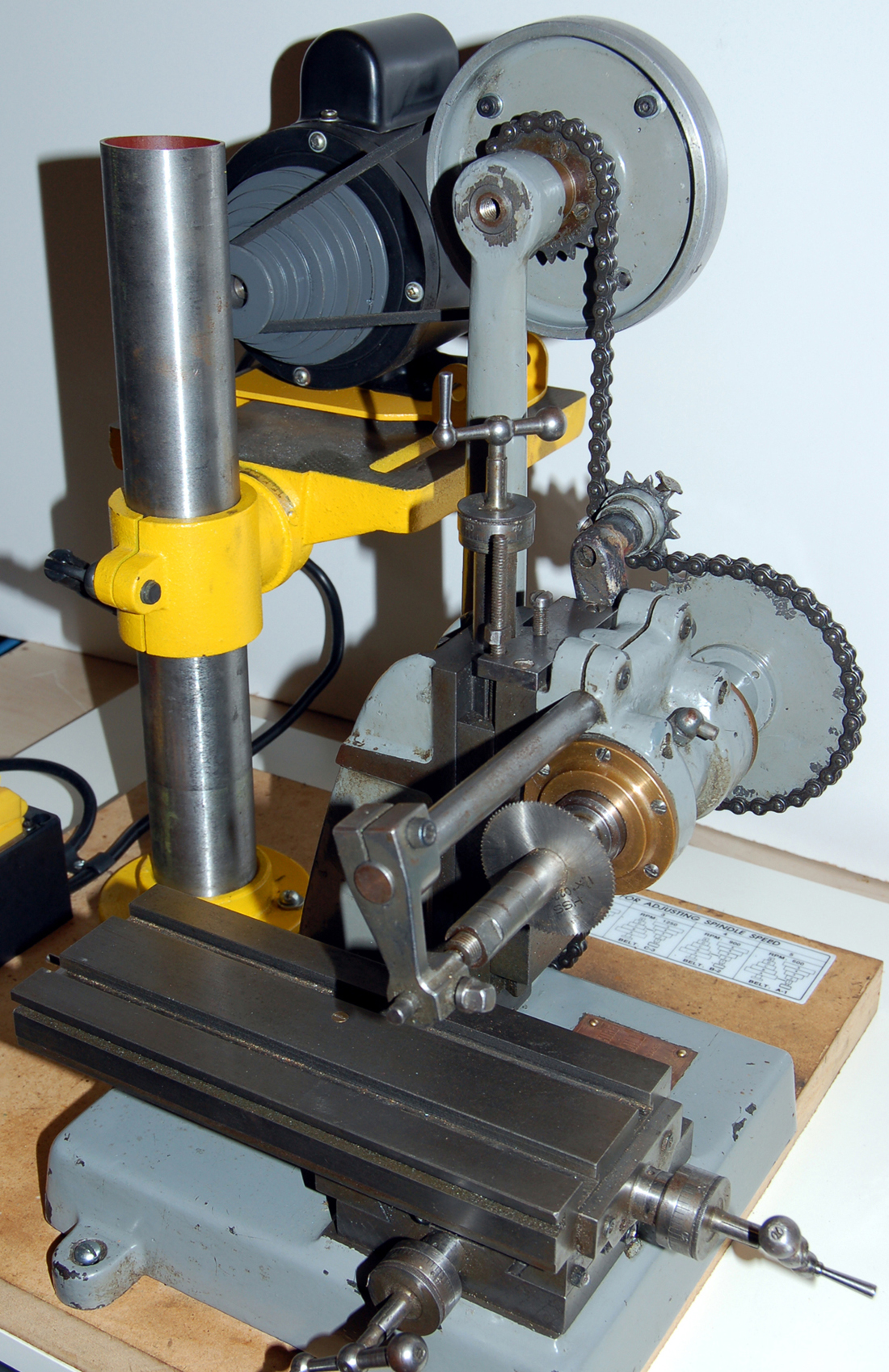

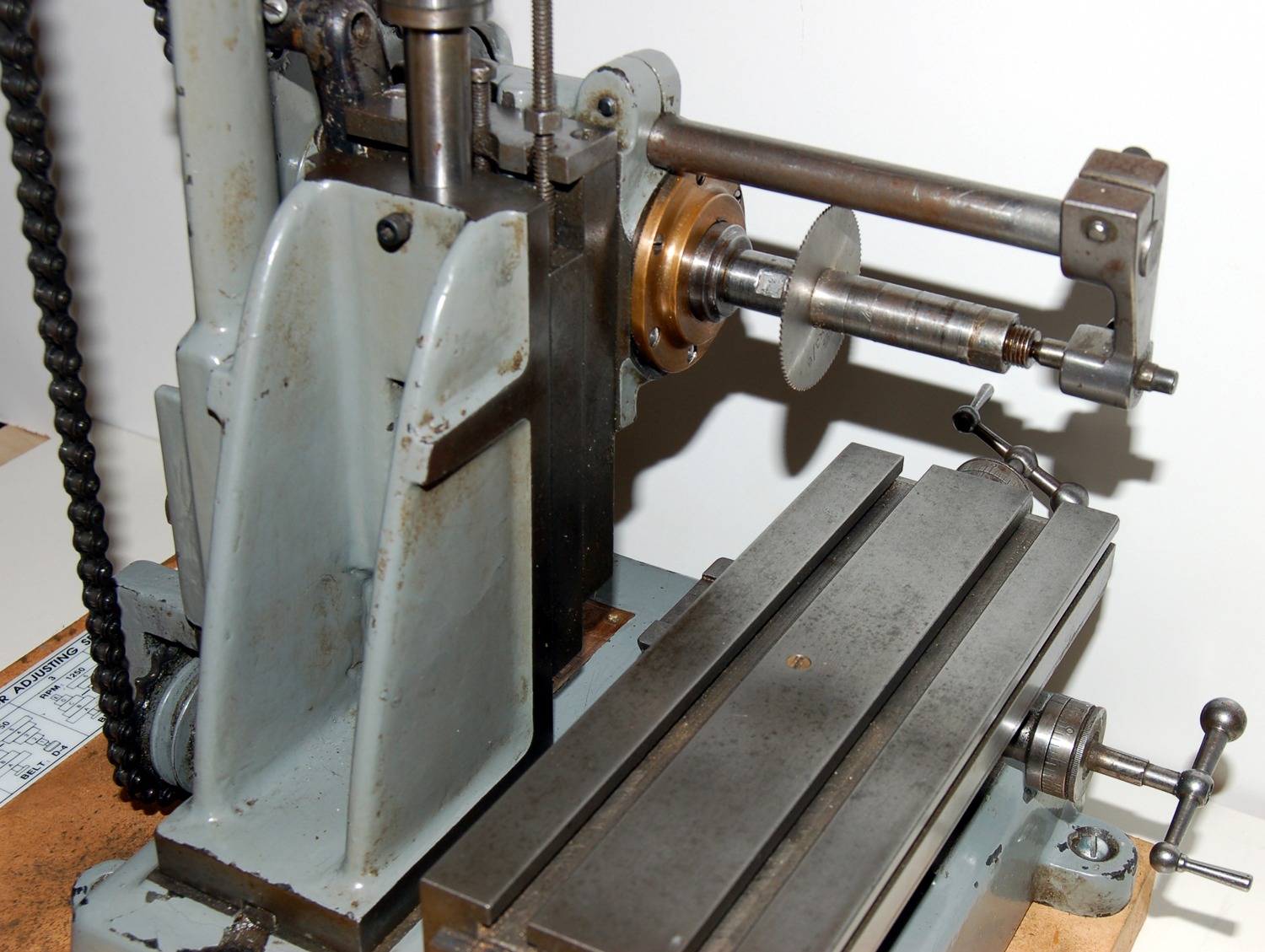

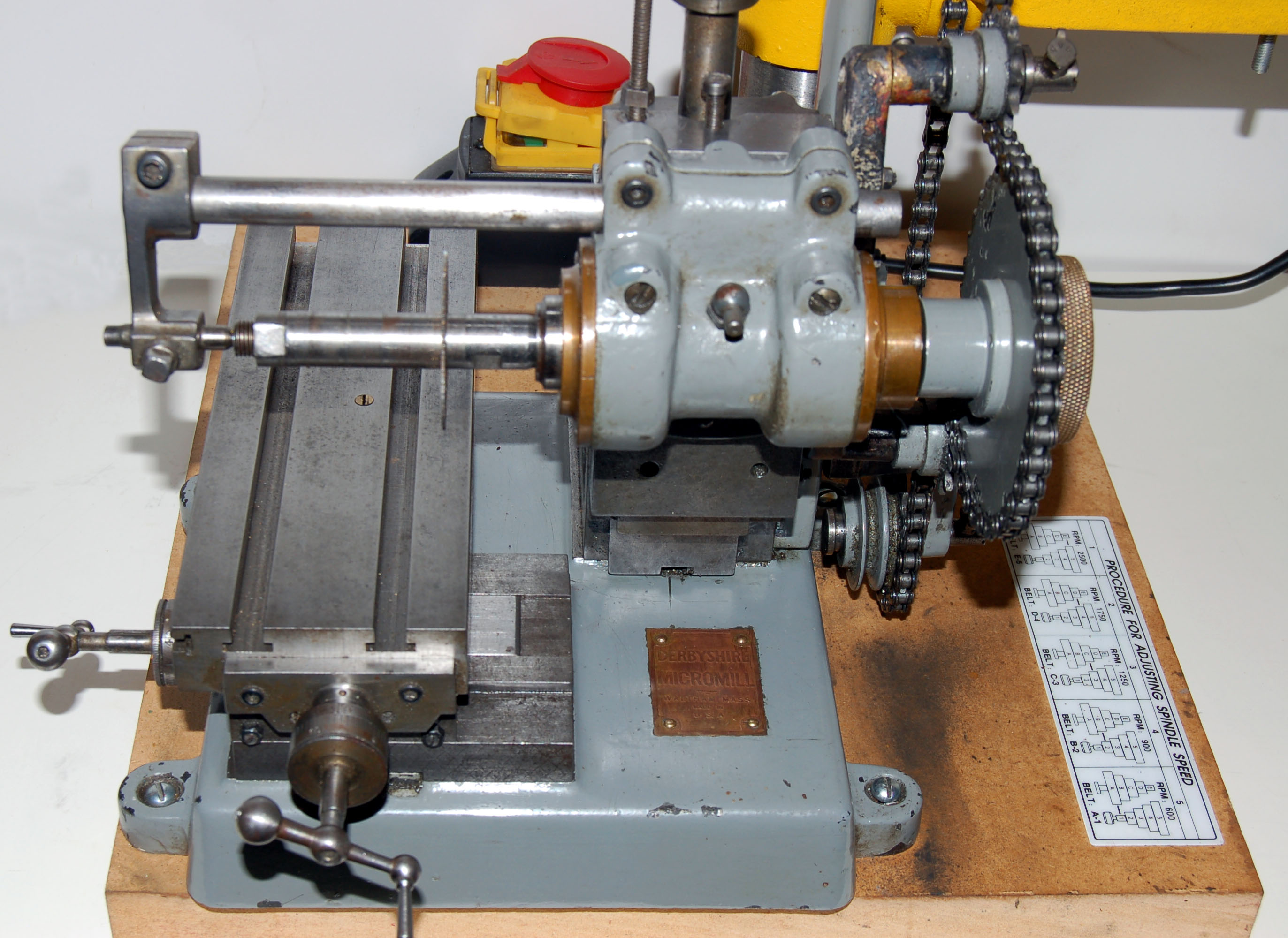

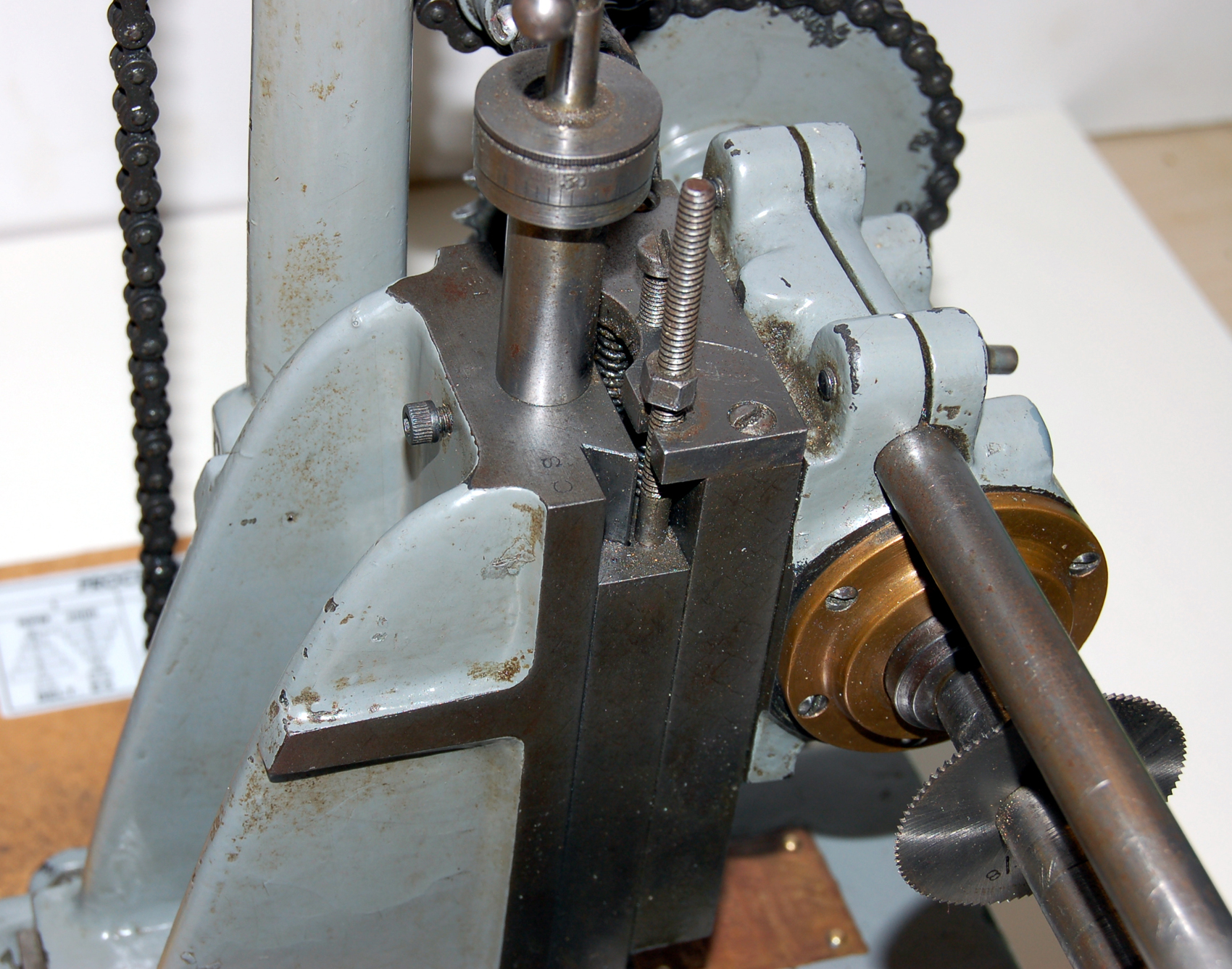

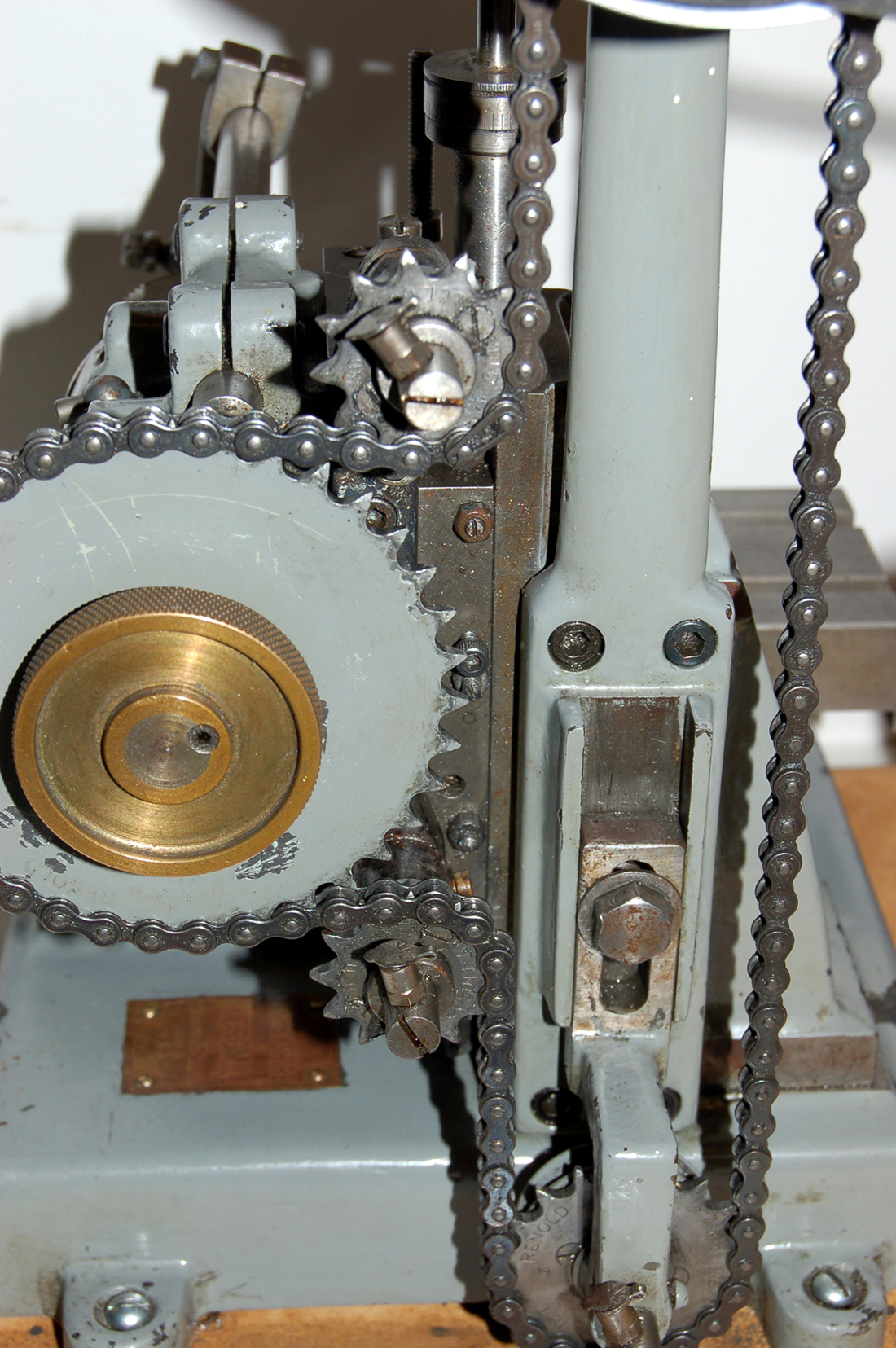

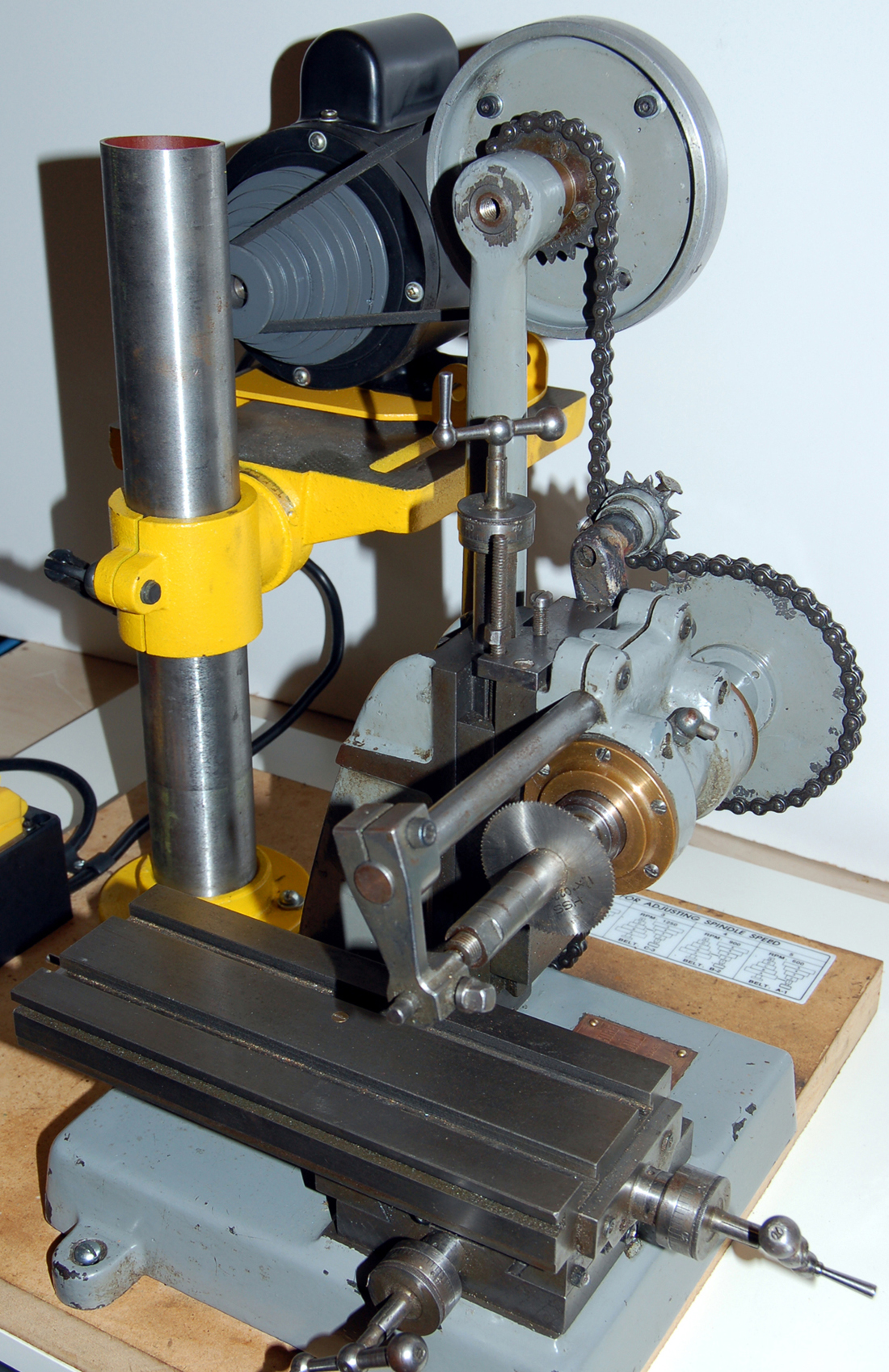

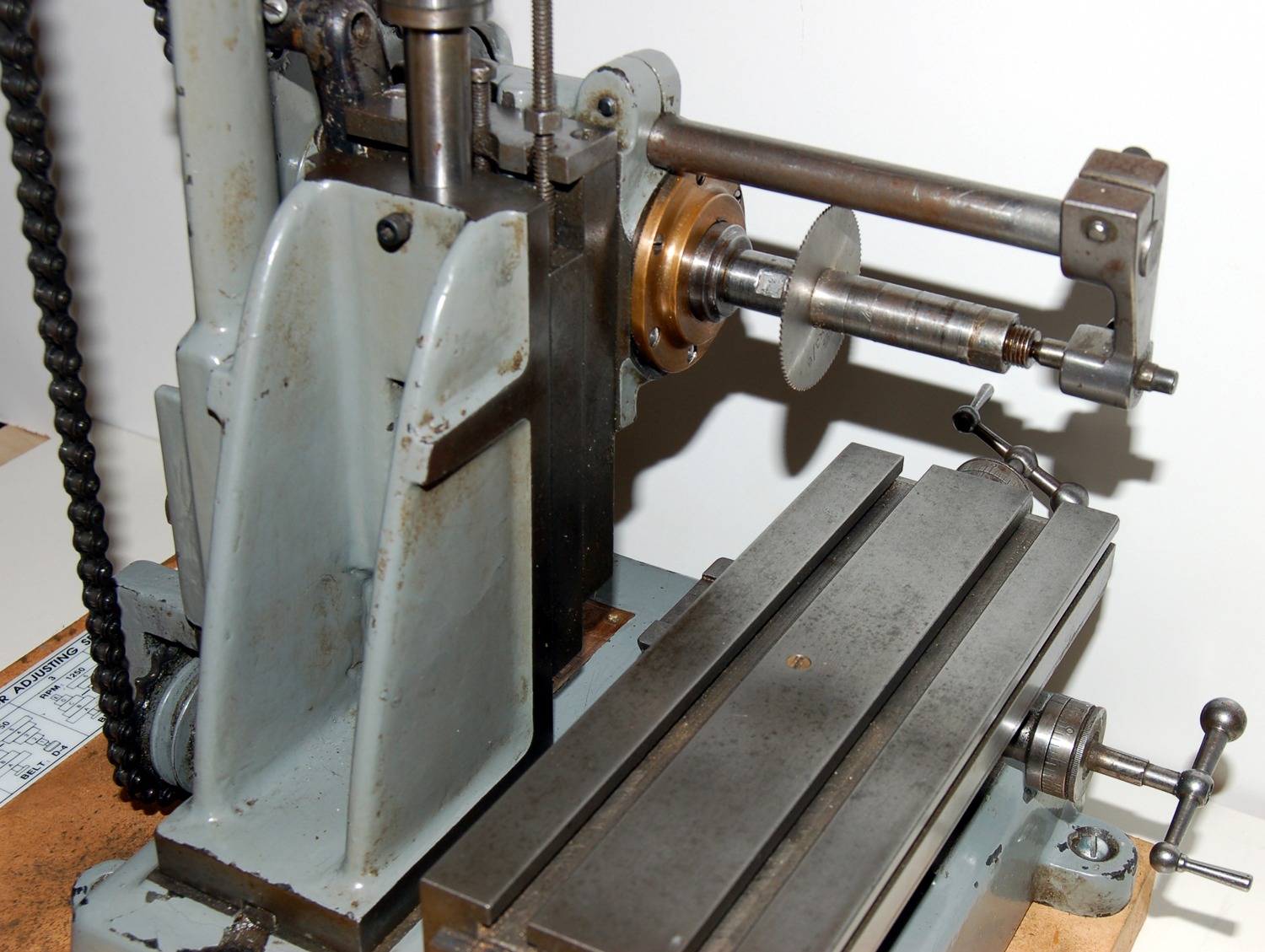

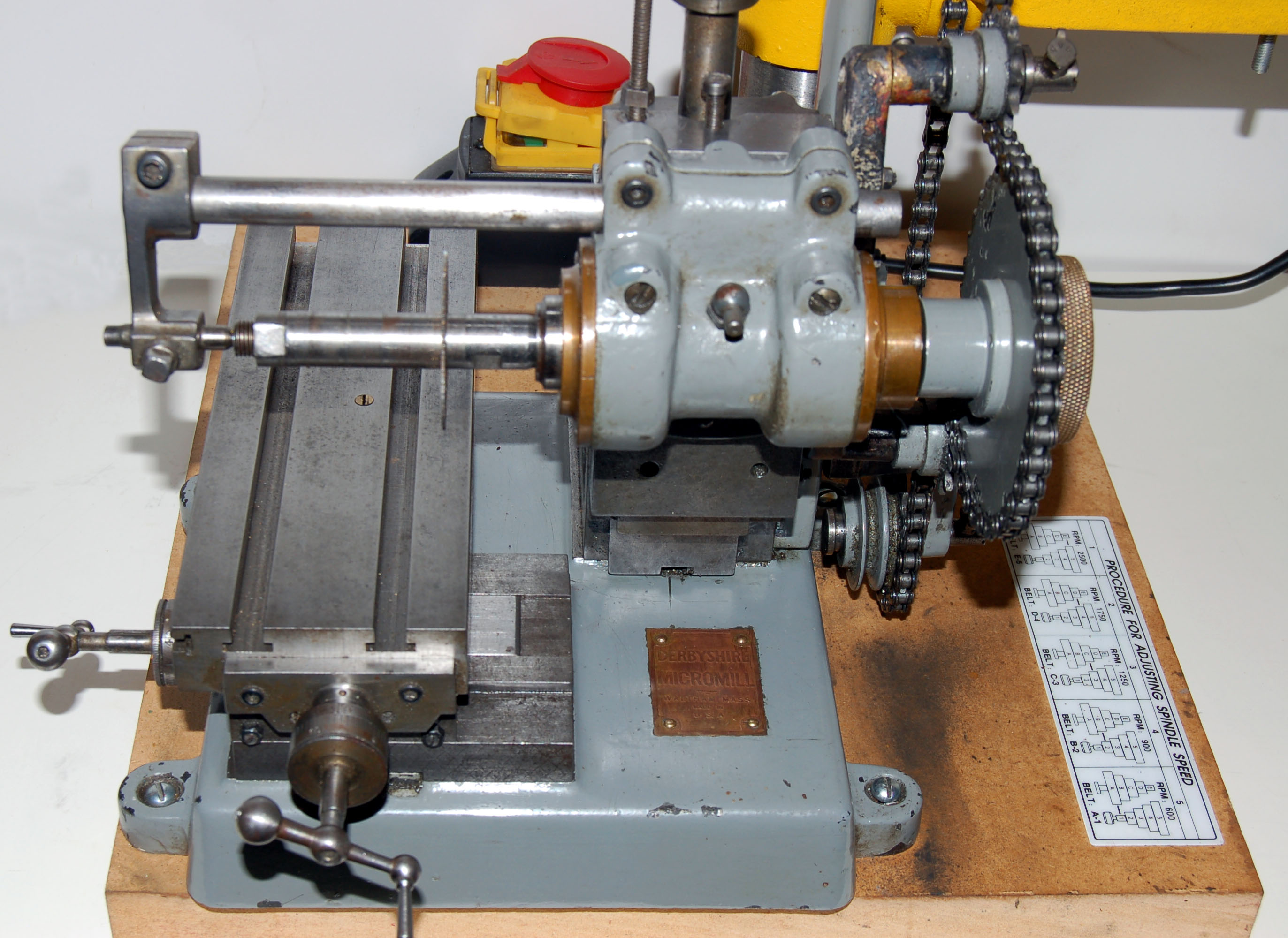

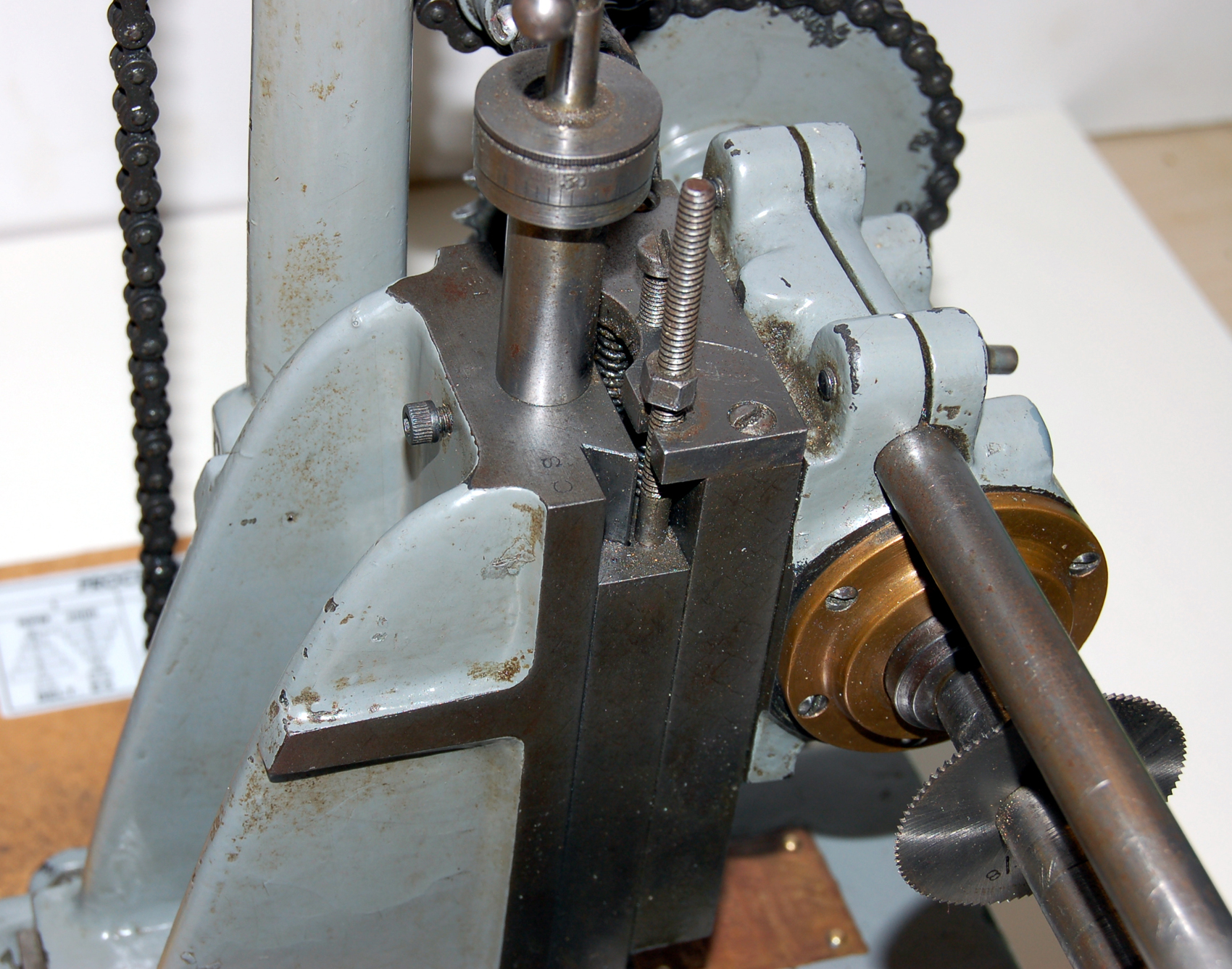

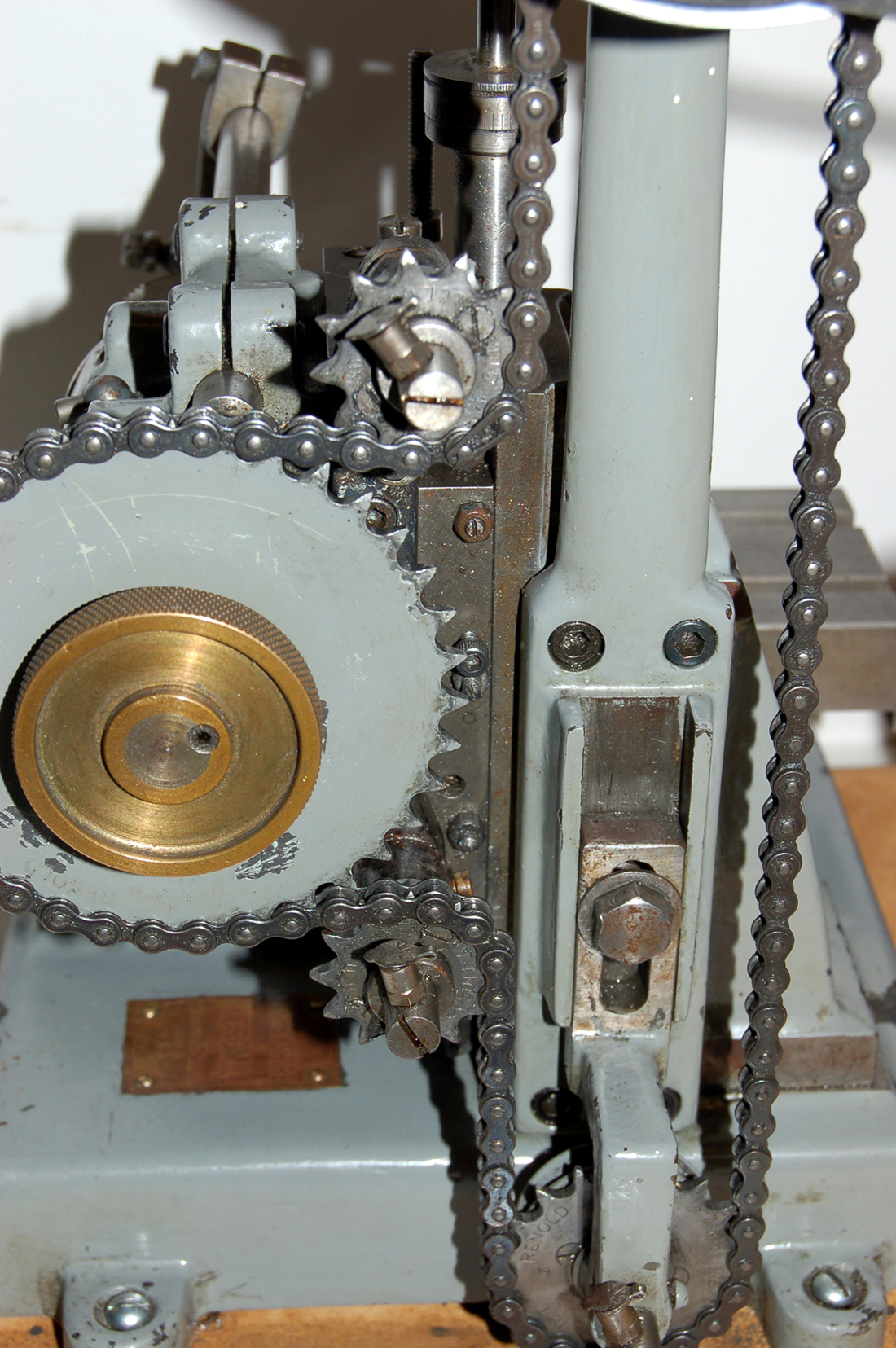

Brought to the United Kingdom during WW2 this Micromill has an all-screw-feed table and is unusual in having been converted to a well-engineered chain-drive system. So well done is the conversion that only the presence of "Renold" on the sprockets betrays that this is a UK and not an American installation. For a machine intended for very high-speed, light-duty work a chain conversion seems to make no real sense - apart from a total absence of slip - and that might have been the raison d'Ítre behind the change if all its work involved harder materials. The present owner has utilised the remains of a small drill press stand to hold the motor.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

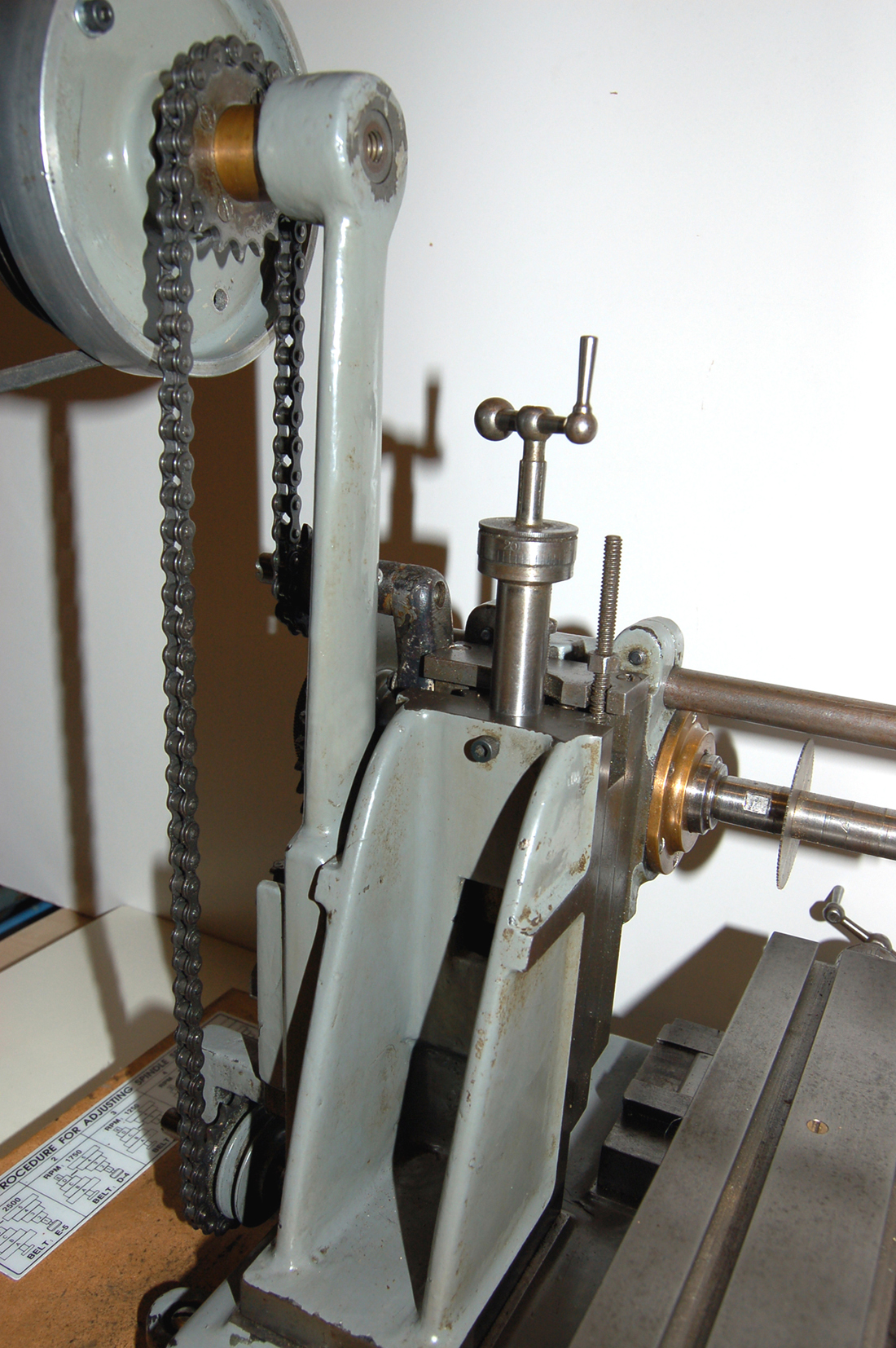

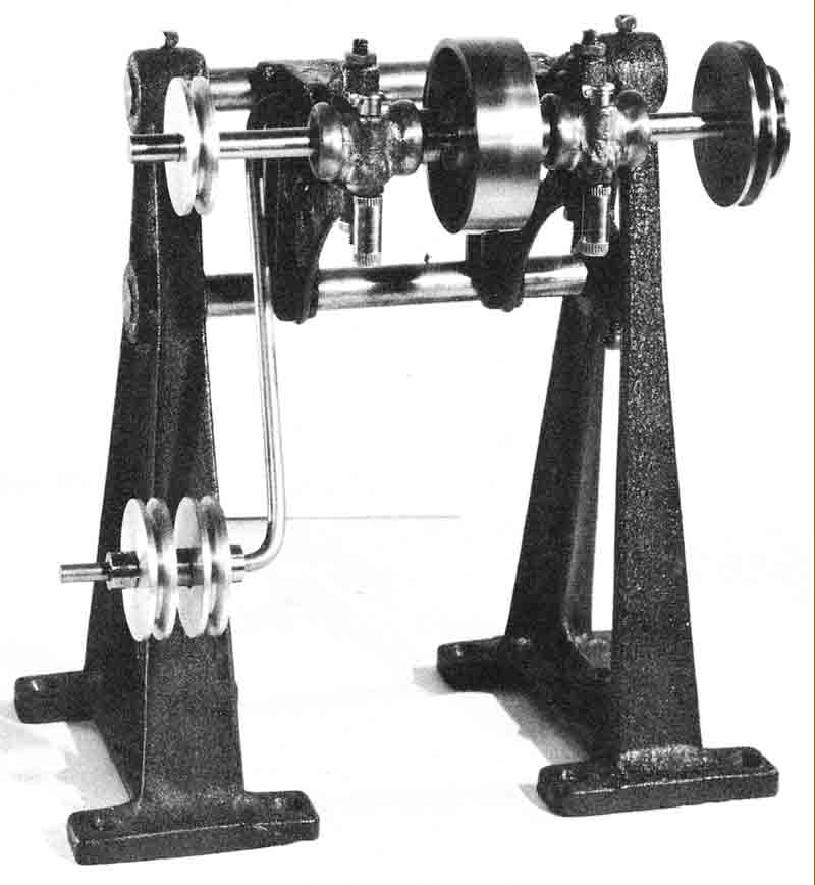

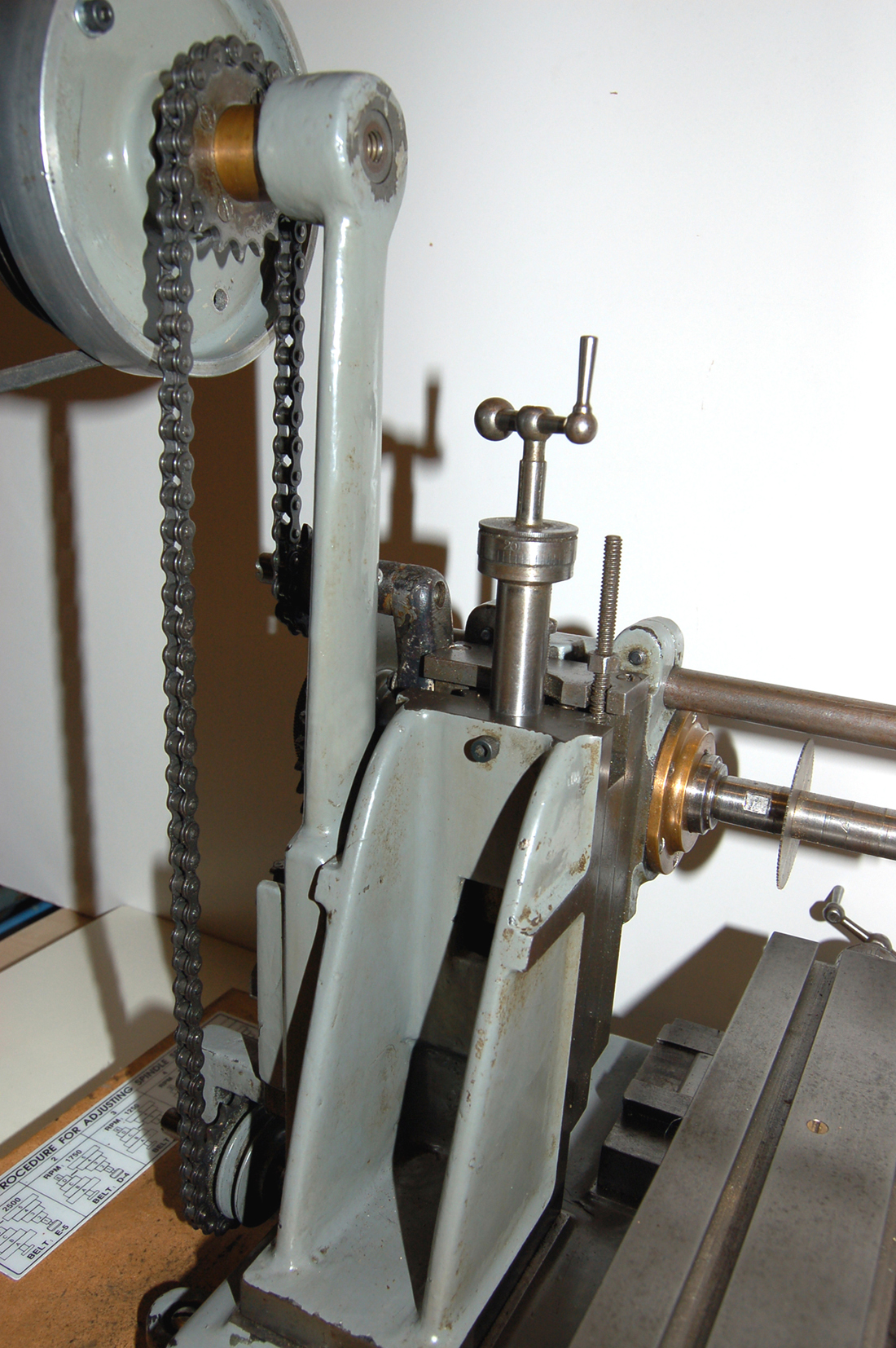

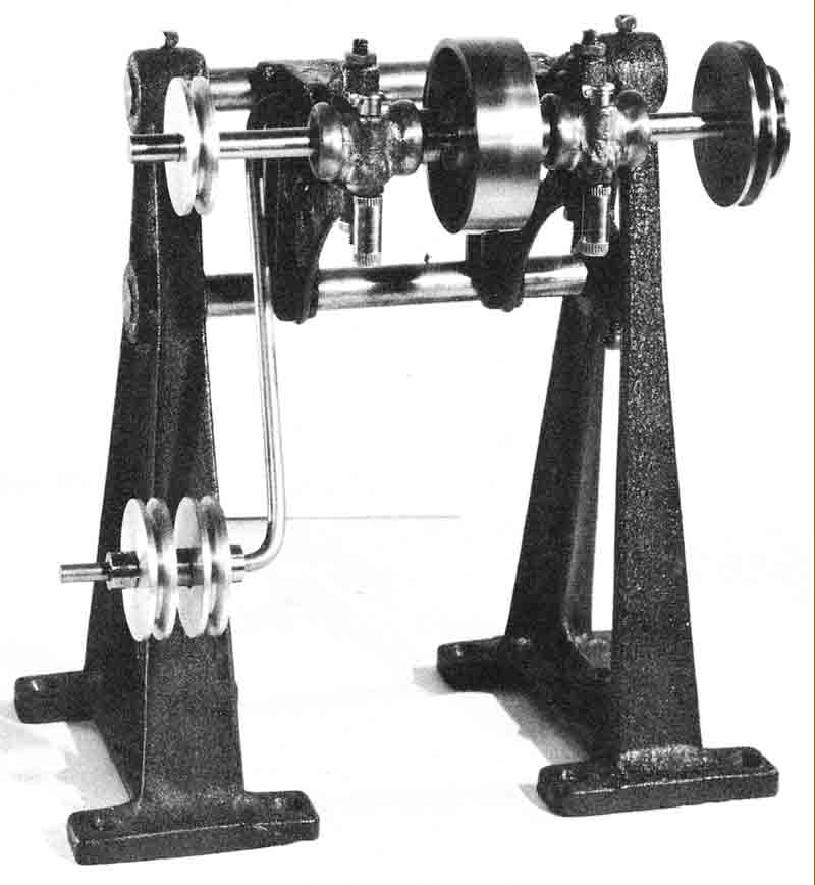

Fast-and-loose countershaft for the Micromill. This unit carries an auxiliary round-rope drive to power a separate grinding or milling head.

|

|

|

|

|

|

|

|

|

|

|

|

|