|

Continued:

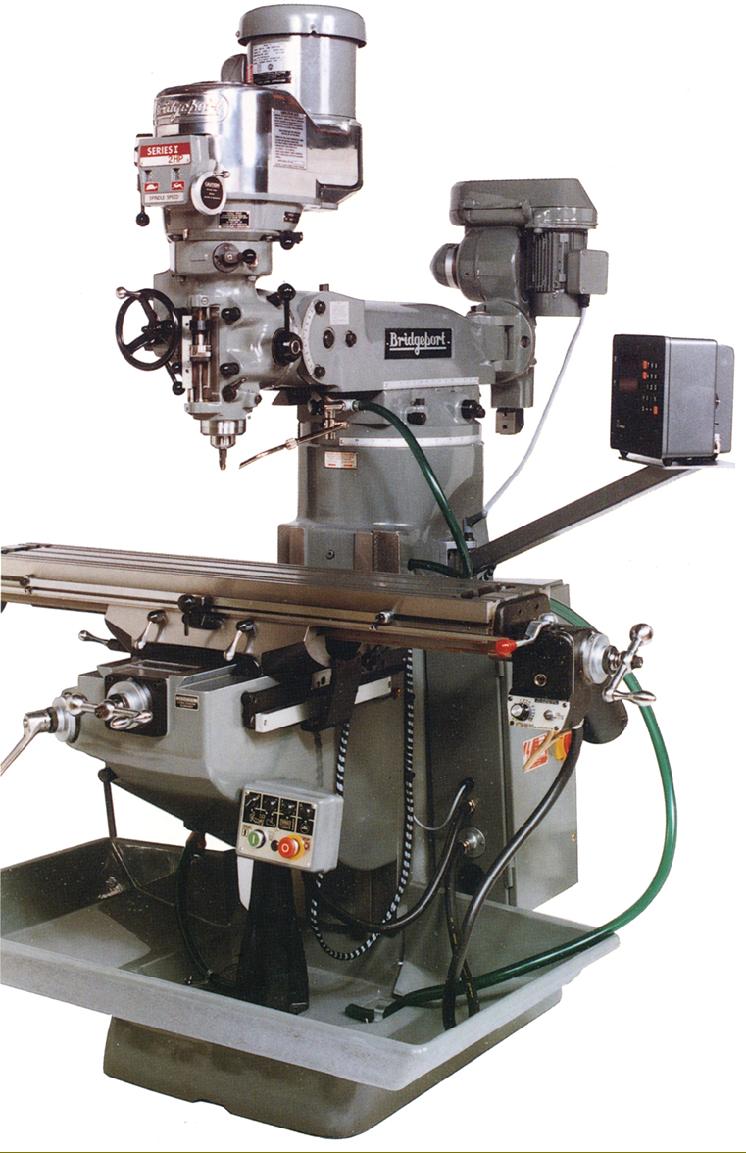

Another vital ingredient in the machine's success was the location of the motor to one side of the spindle, with drive by a V-belt; this meant that both the fine and drilling feeds of the quill could operate along the axis of the tool, no matter what its angle - and in a series of machining and drilling operations, which required different combinations of quick-action and fine feed movements of the quill, all could be carried out without having to reset the head. A further advantage of the side-drive motor was that the quill was left clear for a draw bar to pass through and retain cutters or their holders - some millers of this type, while having the same quill-feed arrangements, employed a motor fastened to (and so blanking off) the top of the spindle housing - so forcing the employment of awkward-to-use screwed retaining rings on their noses (a further consequence often being the need to use expensive custom or at least non-standard or modified cutter holders). Details of the various milling, drilling and boring heads can be found here.

Early Bridgeport millers had a relatively small tables, those listed being 30" x 9", 30" x 12" and 36" x 12". One advantage of a short-table model - especially a well-used one, is that wear across the central section - the most-used part - is better spread out when compared to the much heavier, longer versions. Later tables were offered (in the UK) with lengths of 32, 36, 42 and 48 inches with, respectively, 20, 24, 30, and 36 inches of longitudinal travel. As an option, hard-chrome plated ways and gib strips were available, the process being applied to the tops of the cross-slide and knee, the back of the knee and the column and cross-slide-to-table gibs.

On March 18th, 1954 the 20,000th machine left the Bridgeport factory (a building newly-erected two years earlier) bound for the Pioneer Electric Research Corporation of Forest Park, Illinois. Despite one machine being produced every 45 minutes, such was the demand for machine tools in the early 1950s that a sixteen-month backlog of orders, totalling over 3,600 machines, was not an unusual position for Bridgeport to be in. Advertising expenses for 1953 of less than $12,000 point to how the millers virtually sold themselves - and it was not uncommon in such an active market for "little-used" examples to fetch three times the manufacturer's list price.

Although for many years Bridgeport produced only the "Series 1" (though a simple horizontal miller was produced for in-house use) it was eventually converted into many special-purpose examples, both by the factory and third parties: machines with 2D and 3D hydraulic copying in both manual and automatic versions; T-shaped heads to allow a single head to be moved sideways, or up to three heads to be mounted side by side; automatic copying and precision tracing machines and, by the early 1960s, the Moog Hydra-point three-axis, numerically-controlled miller that was manufactured in England by Moog Hydra-point Ltd. on a machine made by the Bridgeport subsidiary, Adcock & Shipley Ltd. of Leicester - who had first built the Series 1 model under licence in 1959 (the initial model having a 42" x 9" table). One version, the "Series 1 CNC" was heavily modified for CNC control as a "toe-in-the-water exercise; details can be found here.

By 1963 more than 60,000 examples had been manufactured, with plants in Bridgeport Connecticut, USA, Leicester and Bridlington in England - and Singapore. It was also a widely copied machine, with dozens of companies in Taiwan - and even fourteen in Spain at one time - turning out examples of greatly varying quality and performance. Today Bridgeport makes not just millers but turning and grinding machines as well, a sale being made to Rolls Royce in 2006 of a large and complex grinding machine on which to finish jet-engine parts.

As the years went by demand for the machine changed and costs came under increasing scrutiny; under various ownerships production was shifted around the globe and when owned for a time, by Textron, the machines for the USA market had their main castings poured in India and then shipped to England where the column, knee and table were built up. The part-finished millers were then sent to America where Singapore-manufactured heads were fitted and the machine put through final assembly and painting (at least, that's the story from an ex-employee.…). Even so, one would have thought that a single plant could have achieved cost savings equal to or even better than those involved in packing up and shipping components half-way around the world and back again.

After a series of ownerships, management buy-outs, amalgamations and trading, Bridgeport eventually became part of the Goldman Industrial Group together with other leading machine tool companies including Bryant Grinder, Fellows, Hill-Loma, J. & L. Metrology, and Jones & Lamson. In 2002 (at machine Serial Number BR-247388) Hardinge took over the rights to Bridgeport's knee-mill designs (on a 7-year arrangement) and then, in November 2004, acquired full rights to the Bridgeport name to join Hardinge-branded high-precision lathes, Kellenberger cylindrical grinding machines, Hauser jig grinders, Tschudin high-production cylindrical grinders, Tripet internal-grinding machines and Hardinge-branded collets, chucks and indexing fixtures. In the UK the Bridgeport division, formerly based around Adcock & Shipley in Leicester, continued in operation - but not the Bridgeport manufacturing operation which, by November 2004, was in receivership. A total of $7,250,000 was paid by Hardinge for the acquisition but this included finished goods (including CNC machining centres) worth an estimated $4,100,000 (a very late-edition of the Series 1 catalogue can be found here). The continued use of the Bridgeport name seems assured with Hardinge currently having over 800,000 square feet of manufacturing capacity in its operations in England, the United States, Switzerland, Taiwan and China..

An interesting article about manufacturing the Bridgeport can be found reproduced from the American Machinist Magazine for November 2000..

|

|