|

Home Machine Tool Archive Machine-tools Sale & Wanted Horizontal Milling Machines Models "2", 2AG & 2AGU Home Model "0" Model "1" Model 1AGU Model 1E & 1ES Model 2ES Model 2JR Late Model 2S Models 3HG and 4HG Manuals are available for most Adcock & Shipley millers |

|

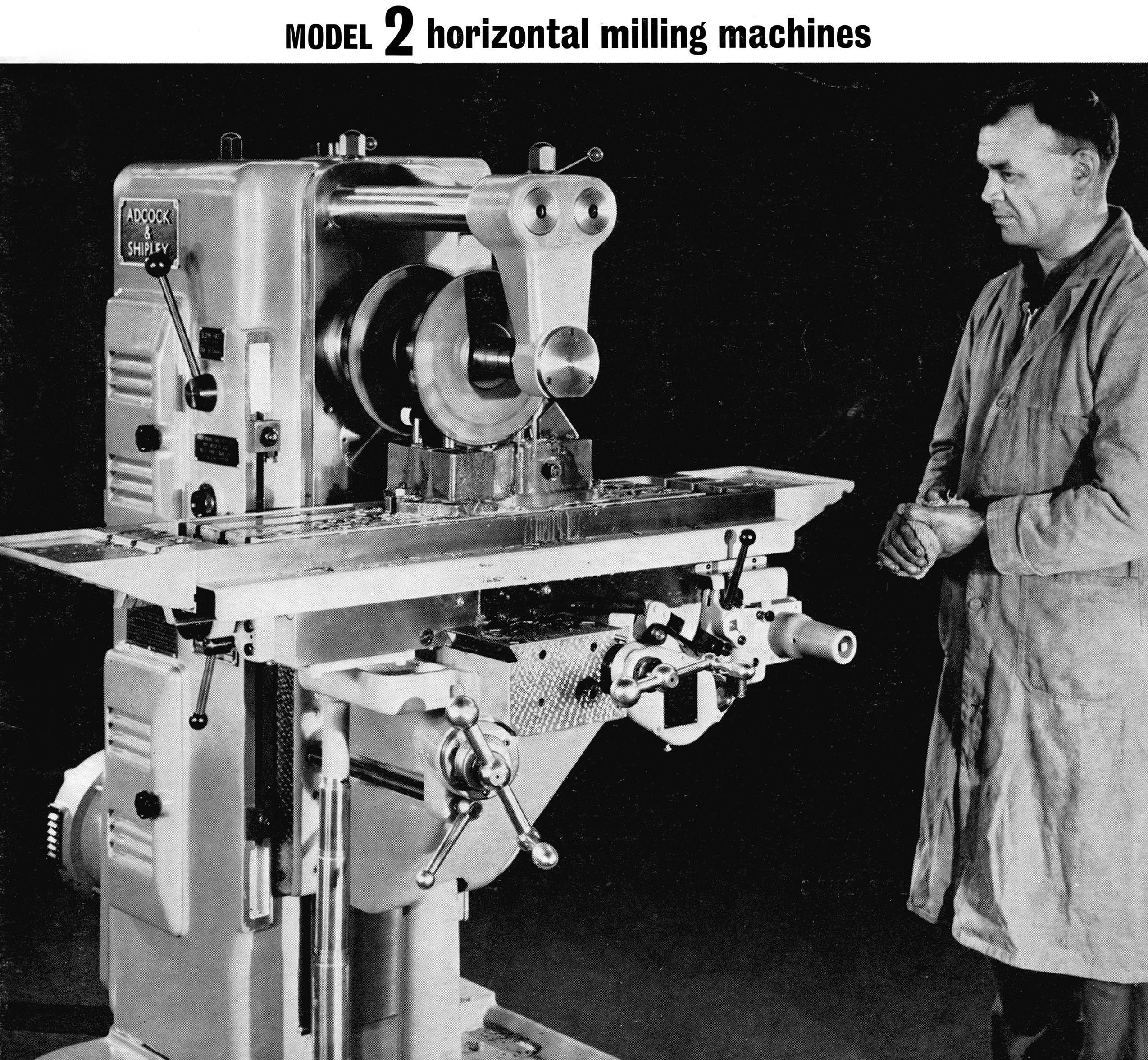

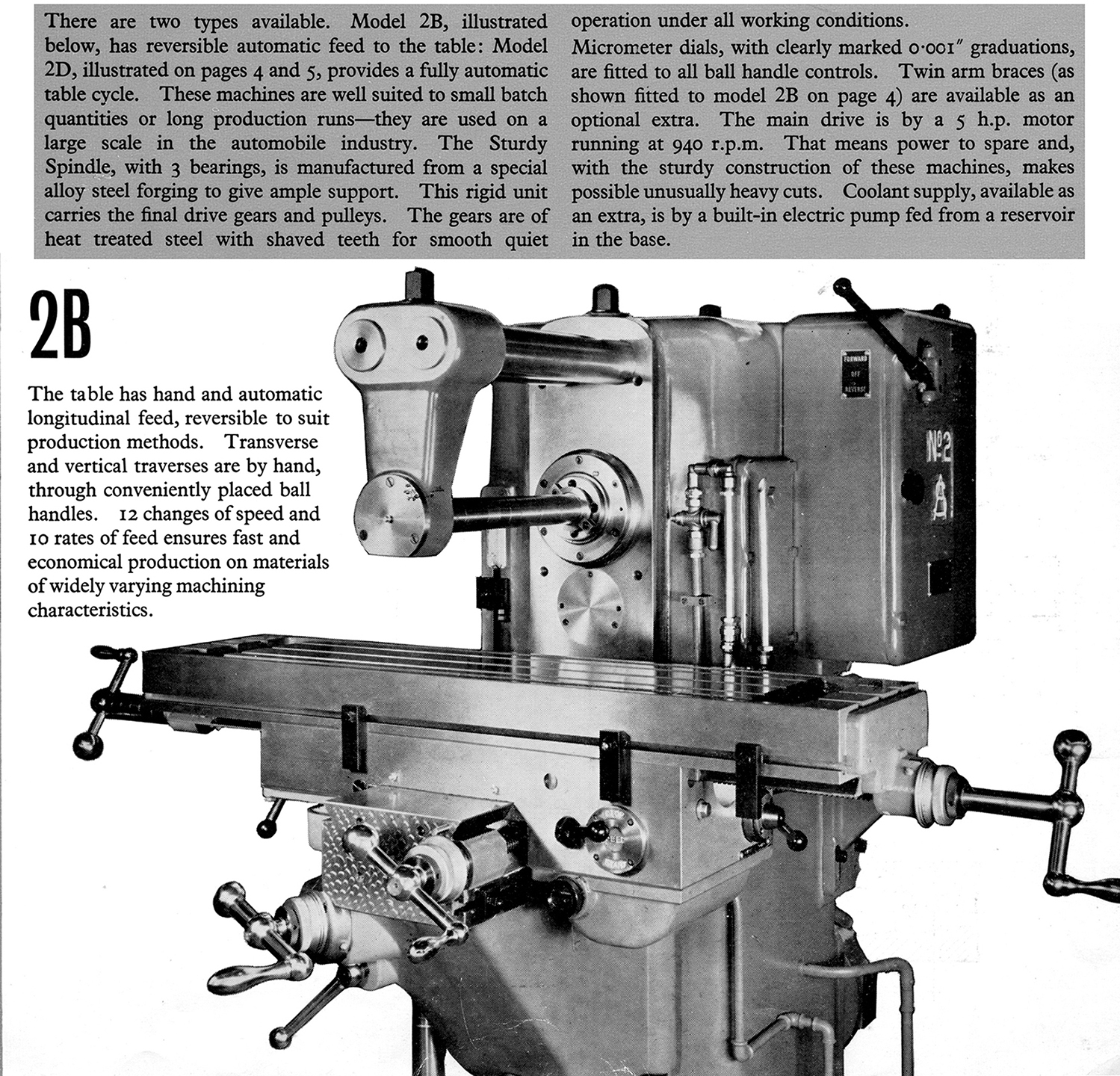

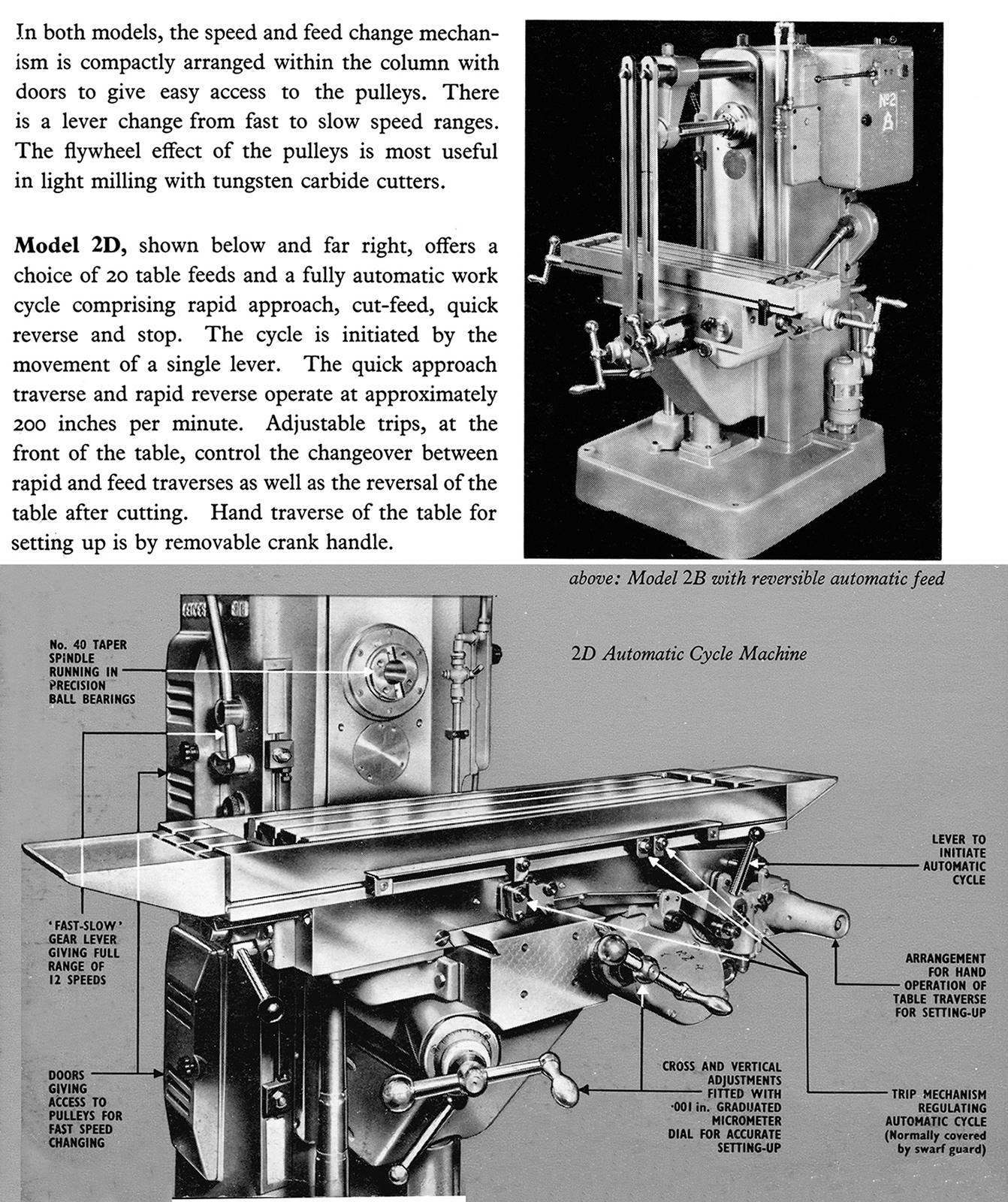

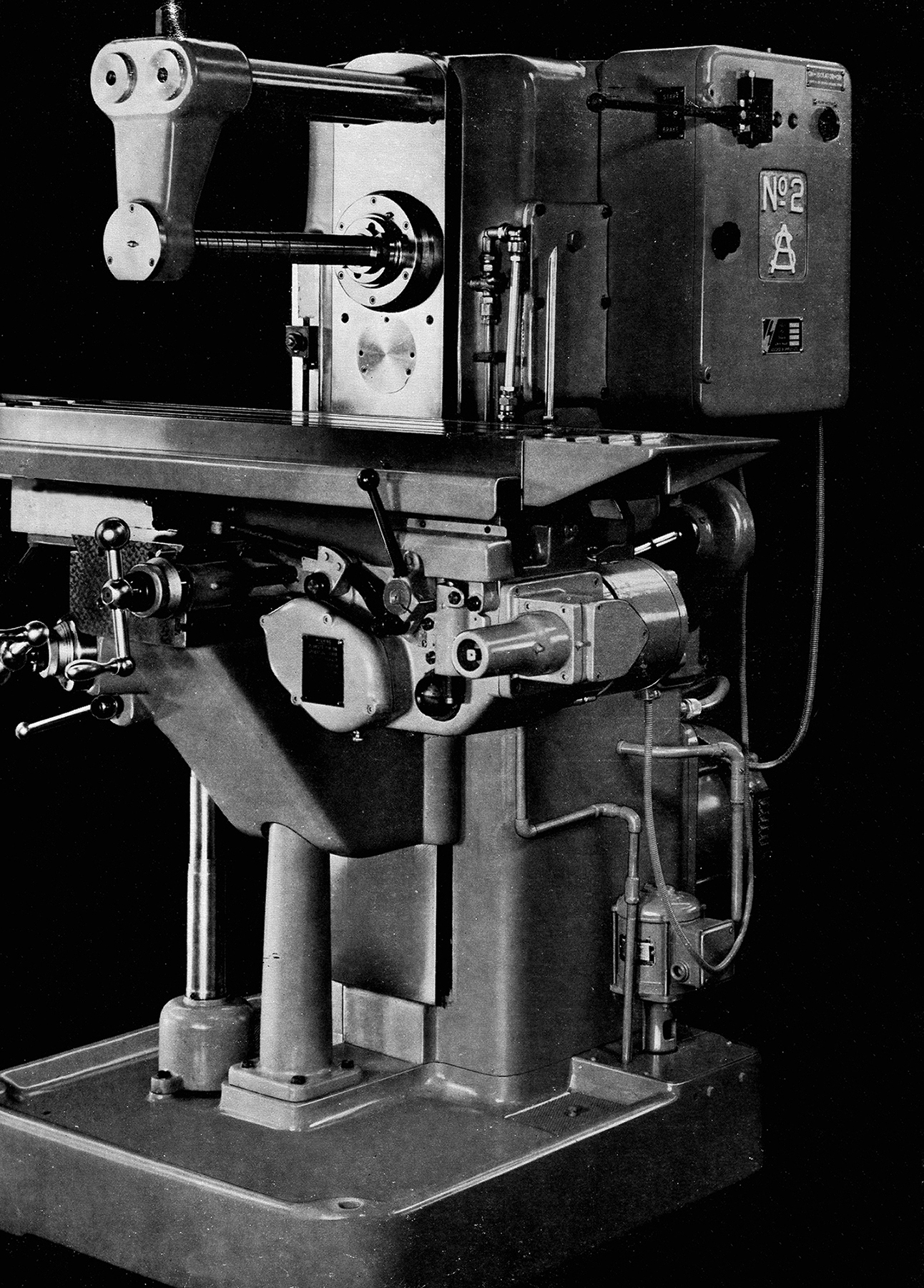

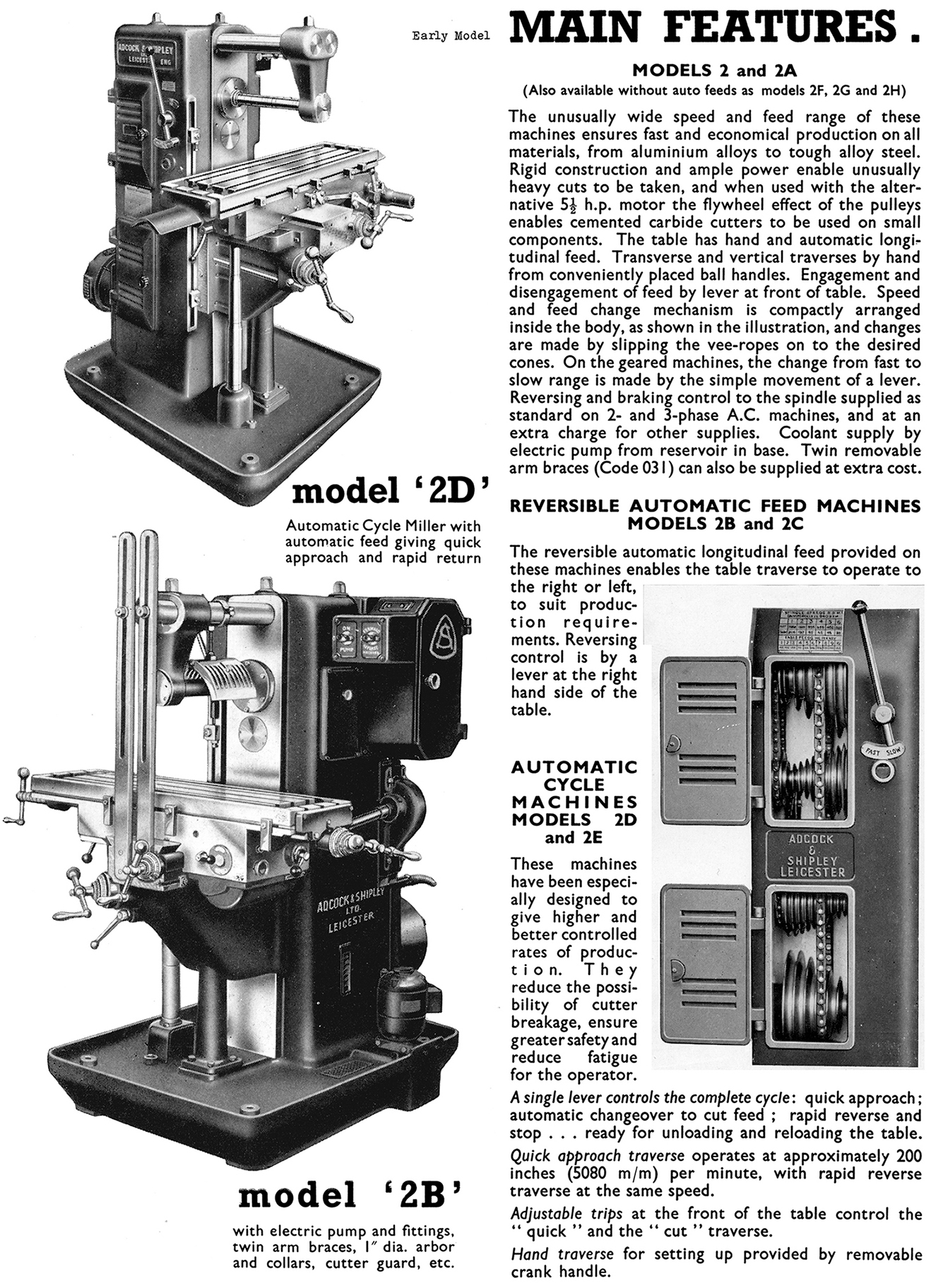

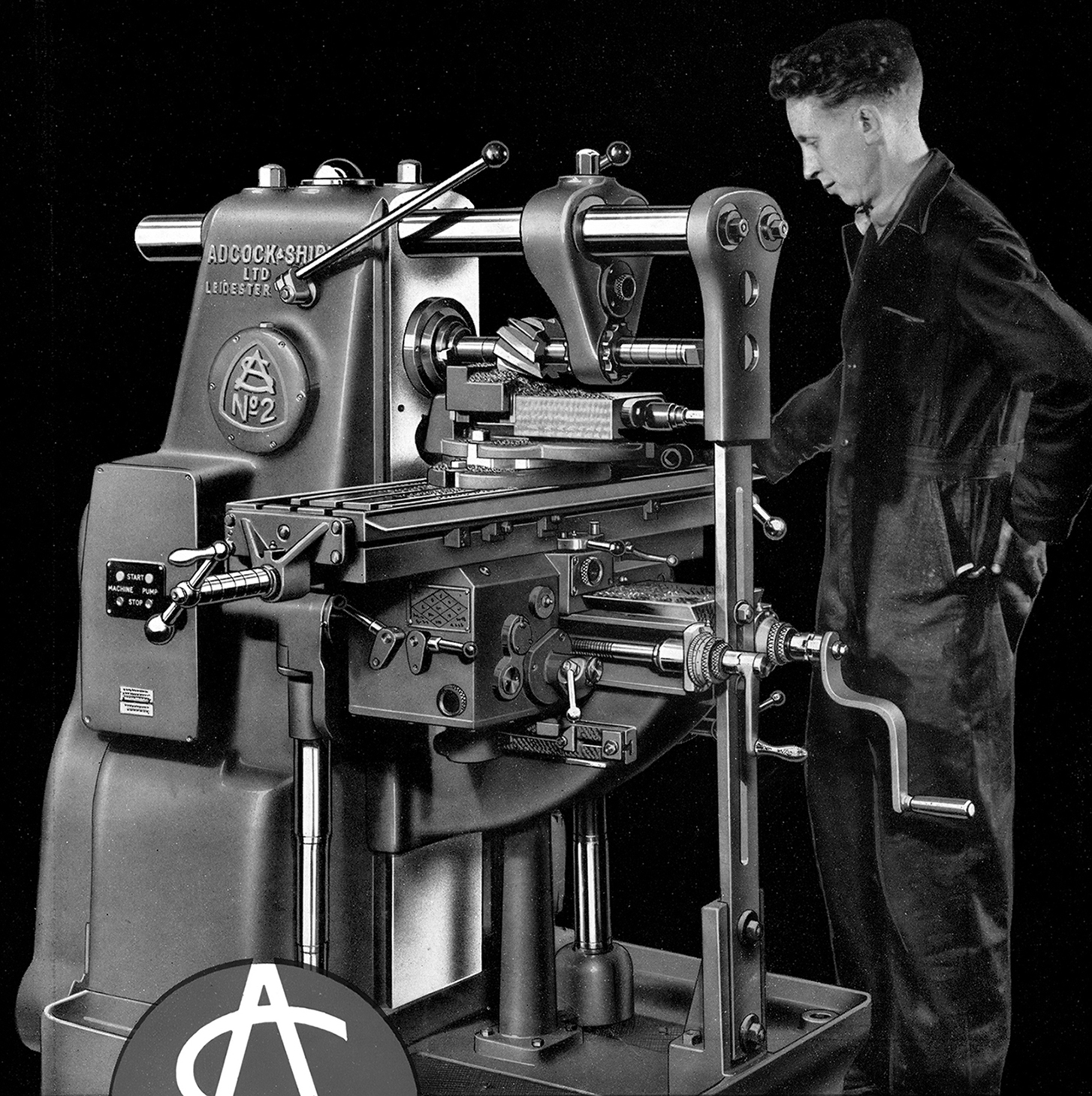

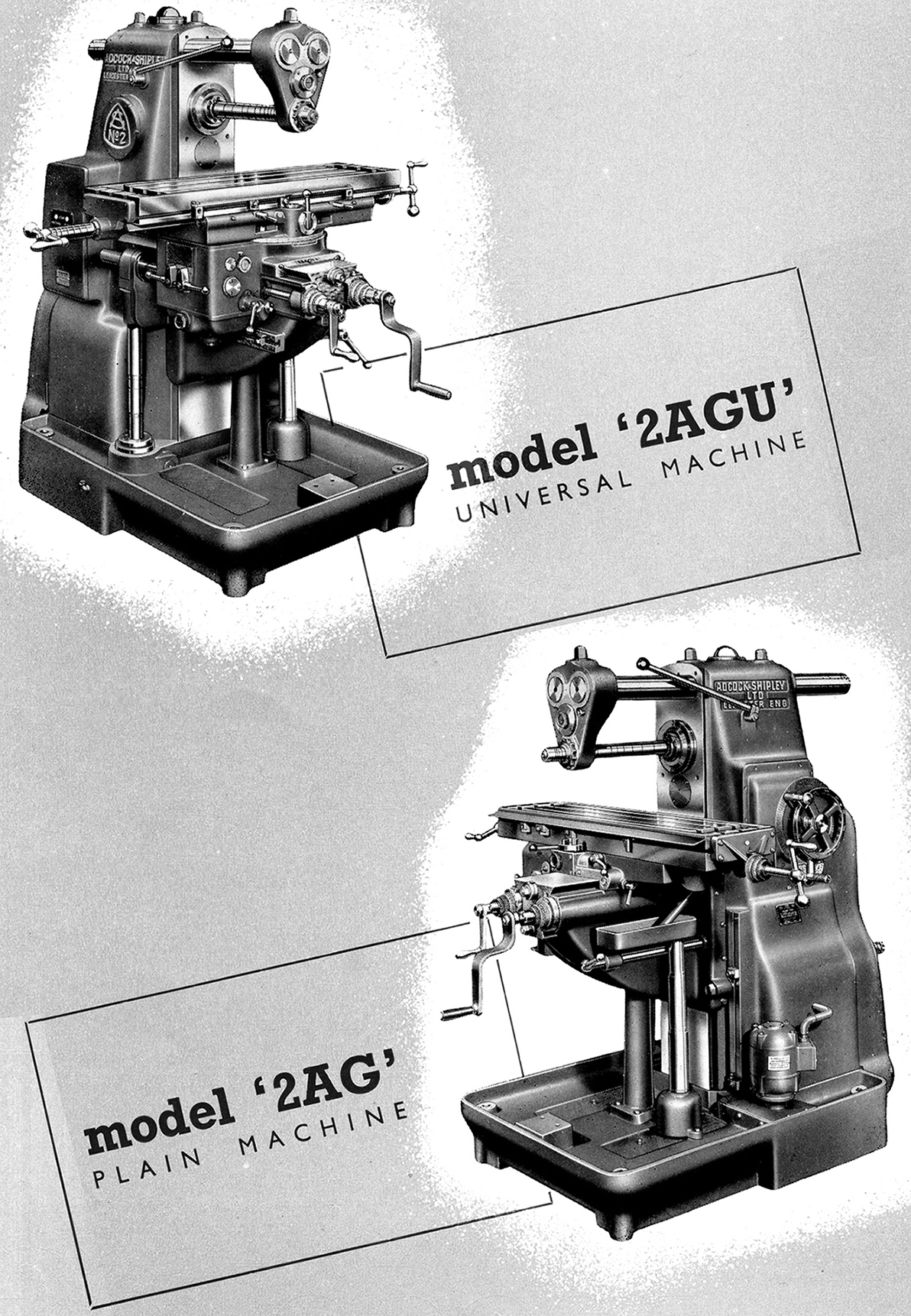

Built in early and late versions - the former from the mid-1930s until the lathe 1940s and the latter until the 1960s - the Adcock and Shipley No.2 was a heavy industrial-class machine. Featuring twin round overarms (instead of the more popular one-piece dovetail type preferred by contemporary companies) the miller was nevertheless very rigid and available as the 2B, with reversible automatic feed to the table, and the 2D with a table-cycle facility for production use. |

|

|

||

|

|

|

|

||

|

|

||

|

|

|

Home Page Model 1E & 1ES Model 2ES Model 2JR Horizontal Milling Machines Models "2", 2AG & 2AGU Home Machine Tool Archive Machine-tools Sale & Wanted |