|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A range of different heads and head accessories has been available for the Bridgeport since its introduction, allowing the customer to choose between heavy-duty, fixed-quill models and very high-speed "sensitive" units with either (or both) power down and up feeds and hand operation though worm-and-wheel fine-feed or quick-action, sensitive drilling mechanisms. Heads were at first available with a choice of either a No. 2 Morse taper, or Brown & Sharpe No. 7 or B-3 tapers - but later the "designed-for-Bridgeport" R8 fitting became the standard. Whilst some heads will fit only on the front of the ram, others can be mounted on the back as well; details of the adaptors that allow rear mounting can be found here.

In the past a variety of heads were available, including:

Model M*, the original head - see the bottom of this page.

Model R for heavy-duty use, but with a fixed quill.

Model C* for light-duty, high-speed use, with a sliding quill.

Model T for Cherrying.

*can be mounted at rear of the ram.

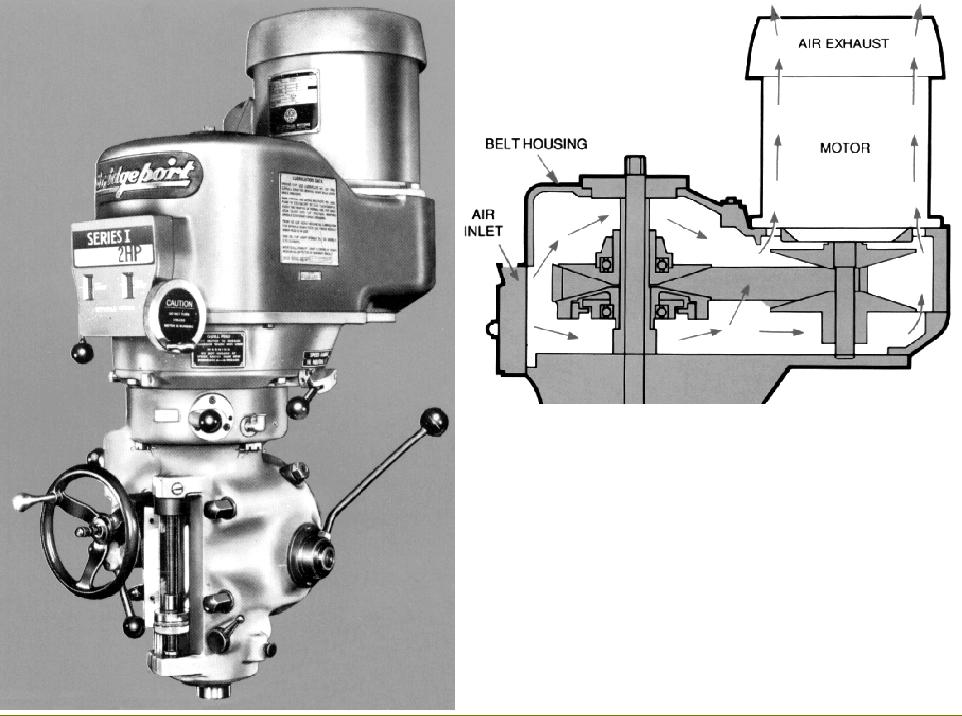

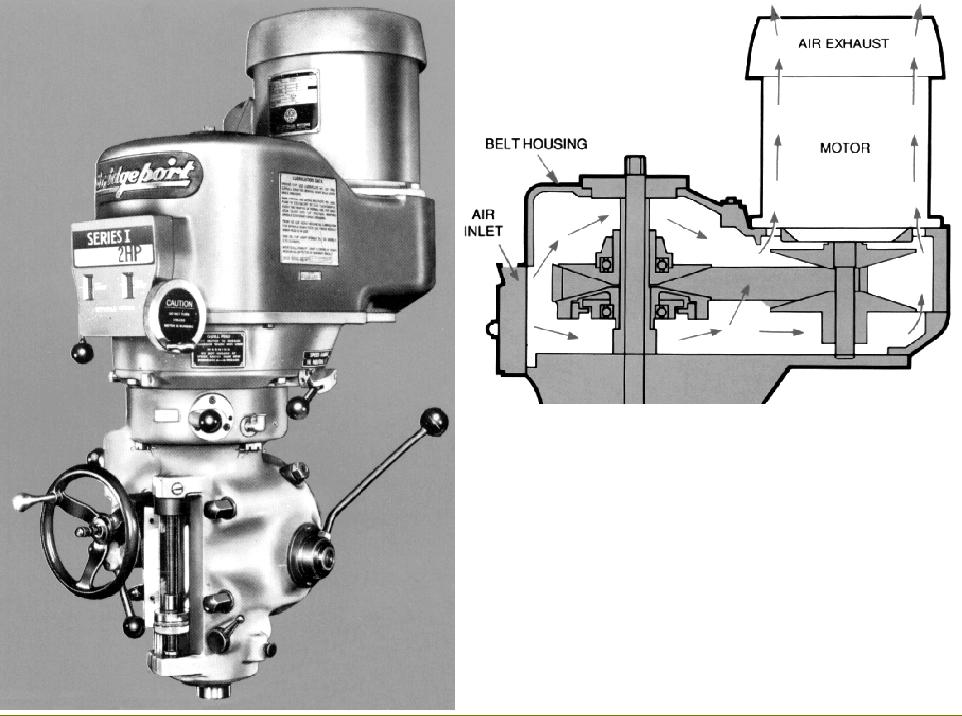

For many years the standard head was the V-belt drive "Type J" fitted, for slow-speed work, with a lathe-like backgear assembly. This was joined by what was, at first, listed as the "Type J Varidrive" but later called the "2J": fitted with expanding and contracting pulleys this provided, in conjunction with its standard fit backgear, two infinitely-variable speed ranges that ran from 50 to 450 rpm and, in direct drive, 450 to 3750 rpm - though small changes in the mechanical specification (and the type of electricity supply) dictated that these ranges did vary somewhat from country to country. By the 1990s the "regular" head had become the infinitely variable speed 2 h.p. Model 2J2, or, at a saving in cost, its less powerful predecessor the Model J with 12-speed V-belt drive. The J2J and 2J both had hand-operated and power feeds - and both quick-action drilling and fine-feed quills. To increase the versatility of these heads a special right-angle extension drive, the "Quillmaster", used to be available and even this could be further modified by the addition of a right-angle tip drive, the "QRA" or "Quillmaster Right-angle Attachment". Details of the Quillmaster and its capabilities can be found here. Also available for many years was the Model T slotting and forming head.

For new Bridgeport owners it is worth noting that, whilst the speed setting dial for the variable-speed head can only be turned whilst the motor is running, to engage backgear (and the slow speed range) the head should be stopped and the spindle "jigged" backwards and forwards until the gears engage. Importantly, in backgear, the spindle runs in the reverse direction to normal and hence the reversing switch has to be used to get the cutter rotating correctly..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

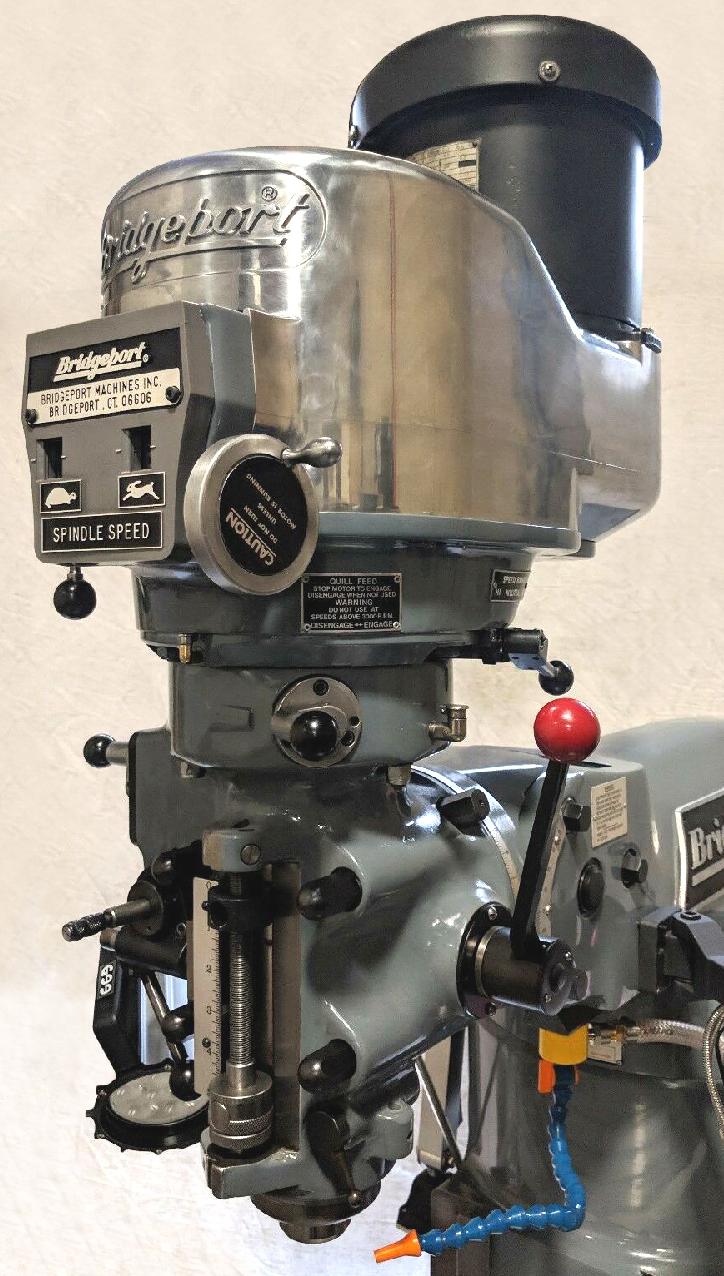

For most late-model machines (catalogue here) the Model 2J2 was the "Standard" and much improved head offered for the Series 1. It had a 2 hp. (1.5 kW) motor driving an expanding and contracting pulley system, incorporating a lathe-like "backgear", to give infinitely variable speeds from 50 to 3750 rpm.

Like all Bridgeport heads the quill was hard-chrome plated, ground and then lapped to fit the honed bore in the main casing. The handles of both the quick-action drilling ("sensitive") and wheel operated fine-feed were detachable and three rates of power down (and up) feed provided.

The spindle was fitted with a brake - to slow it rapidly from high speeds - that could also be positively locked to aid tool changes; a clutch, designed to slip in overload conditions, protected the spindle from damage.

As a point of interest 3 different lengths of drawbar were used on the 2J2 head: 19.5", 23.5" and 26.5" - so, if the one with your newly-acquired machine doesn't fit, you'll know why.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

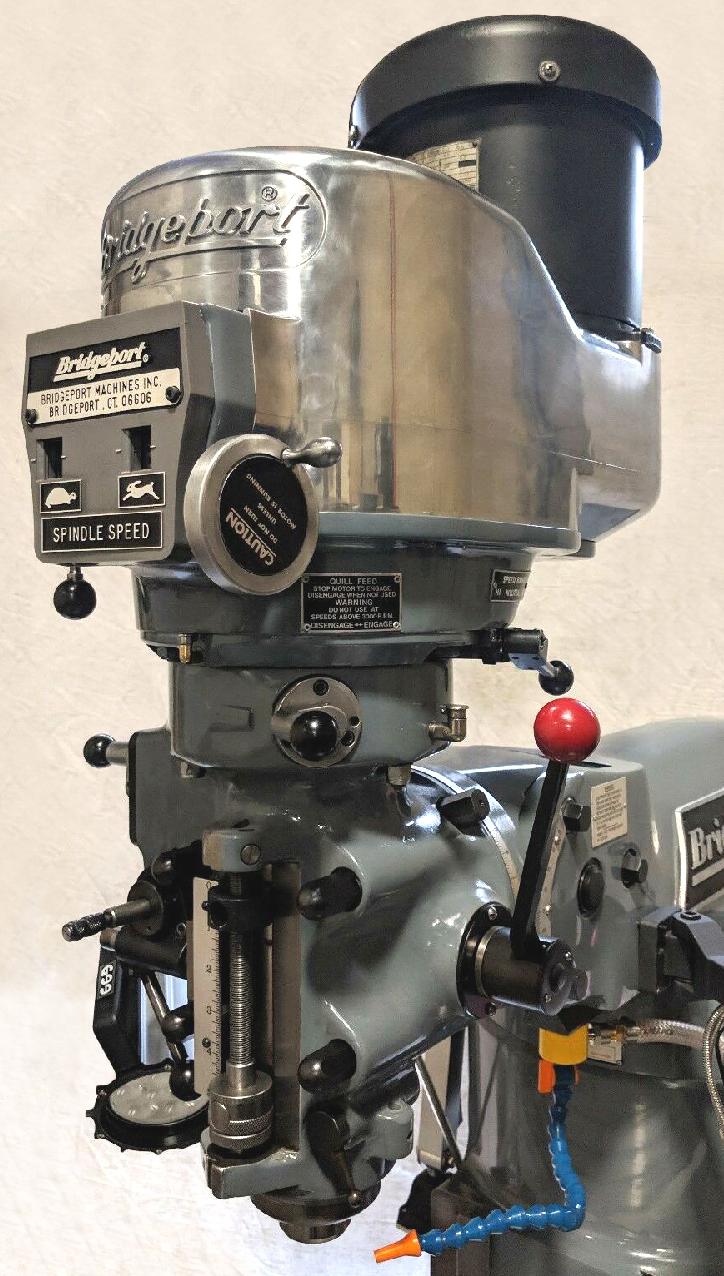

A late version of the 2J2 variable-speed head as fitted from the mid 19870s onwards

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One the left, the Model J head, the standard fitting used between the original M head and the later more effective variable-speed types. However, when the latter types were introduced, the head continued to be available as a lower-cost option, and numbers of machines - usually destined for training establishments, were so fitted. The counterbalanced R8 quill - hard-chrome plated and ground, then lapped to fit the honed spindle bore - had 5-inches travel and was fitted with both hand and power feeds. The hand feed could be applied through either a quick-action lever when drilling - or by a handwheel for fine feeds. The power feed, at the rate of 0.0015, 0.003 and 0.006 inches per spindle revolution, worked in both directions and could be set to trip out automatically; a 0.001" graduated micrometer stop was fitted as standard. A wide range of spindle adaptors was available to mount a variety of tooling.

Whilst the specification of later versions of the head varied, originally it appears that a choice of two motors was offered: a single-speed 1 h.p. that gave a spindle speeds (including backgear) of 80, 135, 220, 330, 660, 1100,1800 and 2720 rpm - and a 1.5 or 2 h.p. unit that had the effect of doubling each of the aforementioned speeds.

When vertical, the head could be run continuously - but needed modification to the lubrication system if used in the same way horizontally.

Some later model J heads have been found with 2-speed 1--2 h.p. motors that gave fifteen speeds that spanned 67 to 2300 r.p.m. in low speed and 134 to 4600 r.p.m. in high - these machines carrying a plate warning not to use the power down-feed at above 3000 r.p.m.

On the right, the Model M Head This was the head fitted to the first Bridgeport milling machines and had 3.5-inches of quill travel through both fine and quick-action feeds by hand operation only.

The spindle could be ordered with a No. 2 Morse, B & S No. 7 or a B-3 taper - and the maximum collet capacity was 0.5 inches. Special tapers were available to order and it is highly likely that a factory already equipped with tooling to a different specification might have ordered its machines so as to be able to mount cutters already in stock.

The 0.5 h.p. motor was available as either a 1200 rpm unit - which gave spindle speeds of 275, 425, 700, 1050, 2100 and 4250 rpm - or as a 3600 rpm model with rather higher spindle speeds of 950, 1350, 2200, 3250, 6500 and 12000 rpm.

The unit could be mounted either on the front or back of the ram and, if on the latter, fitted to a swivel adaptor that allowed it to be angled in both planes.

Details of the various head mounting adaptors can be found below

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The original product of Bridgeport, the Model C Head: fixed quill for light-duty but high-speed use with a 2-bolt flange fitting.

Motor 1/4 h.p.

Speeds: 465, 675, 1000, 1500, 2140 and 4250 rpm.

Height: 26 inches

Depth: 1113/16 inches

Width: 83/8 inches

Collet capacity: 1/2 inch

Spindle fitting: B-3

|

|

|

|

|

|

|

|

|

|

|

|

|

Model R Head: fixed quill for heavy-duty use with a 4-bolt flange fitting and a larger spindle and bearings.

Motor 1/2 h.p.

Speeds: 275, 425, 700, 1050, 2100 and 4250 rpm.

Height: 213/16 inches

Depth: 15 inches

Width: 91/8 inches

Collet capacity: 13/4 inch

Spindle fitting: R-8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Model T Cherrying Head was designed to assist with die sinking work. The head carried an oscillating quill that could move the cutter through both convex and concave circular paths to perform rough and finished cherrying operations. The radius of operation was adjustable from 0 to 1.75 inches.

The unit could also be used for conventional milling when the quill was locked.

Motor: 1/2 h.p.

Speeds: 275, 425, 700, 1050, 2100 and 4250 rpm.

Spindle: No. 2 Morse, 7 B 7 S or B-3 taper.

Collet capacity: 1/2 inch

Height: 273/8 inches

Depth: 20 inches

Width: 173/8 inches

A head with a similar function was manufactured by the Everede Company of Chicago, IL, USA. This was made in at least two versions, the RH-1 and the manual had RH-2. Details are sketchy and, unfortunately, the maker's handbook almost useless in describing their functionality.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model E Slotting (Shaping) Head.. Motor: 1/4 h.p. Stroke length: 0 to 4 inches in increments of 1/4 inch. Stroke rate per minute: 70, 100, 145, 205, 295 and 420.

Height: 2013/16 inches Depth: 177/16 inches Width: 81/8 inches The unit could be mounted on the back of the ram, ready to be swung into position should the job demanded it.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

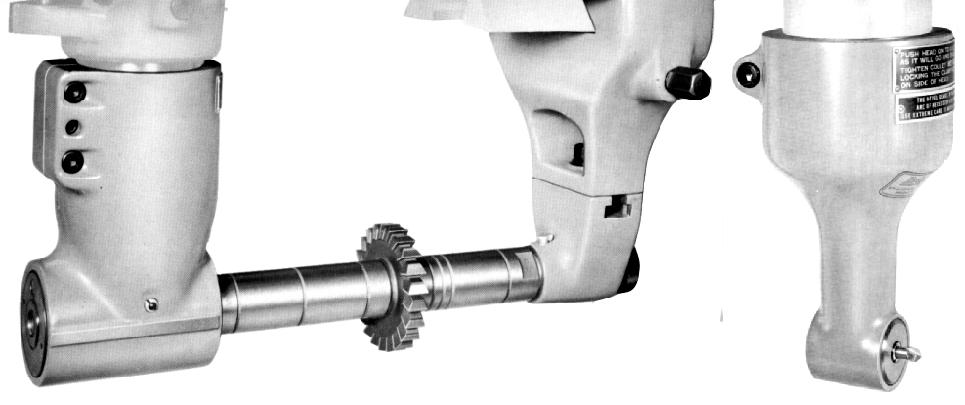

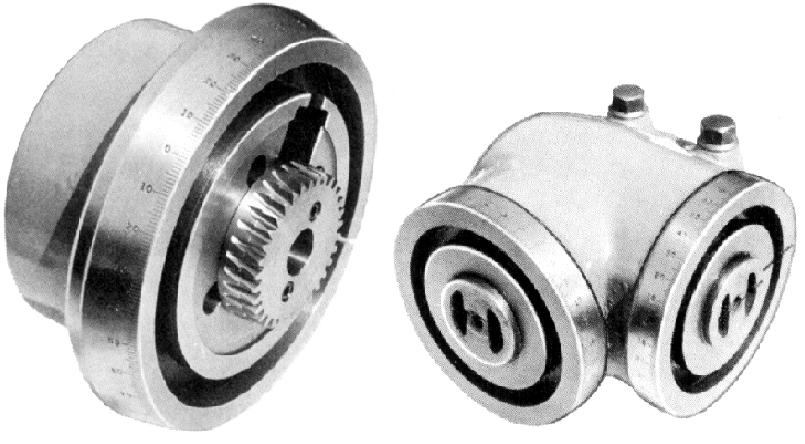

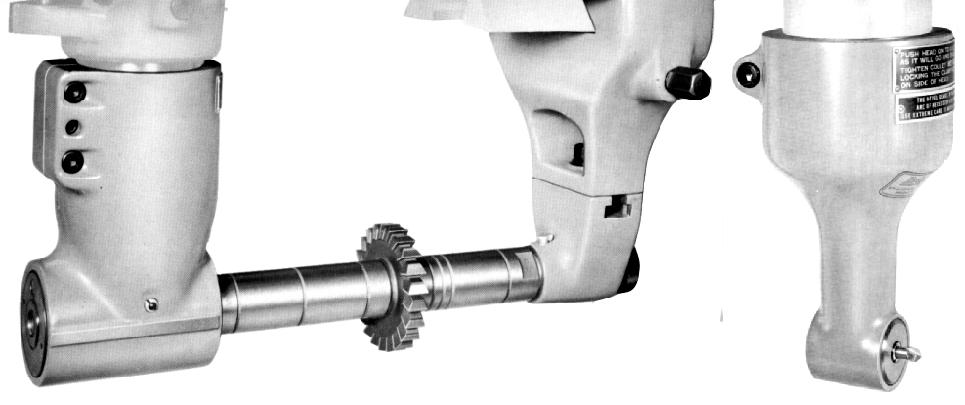

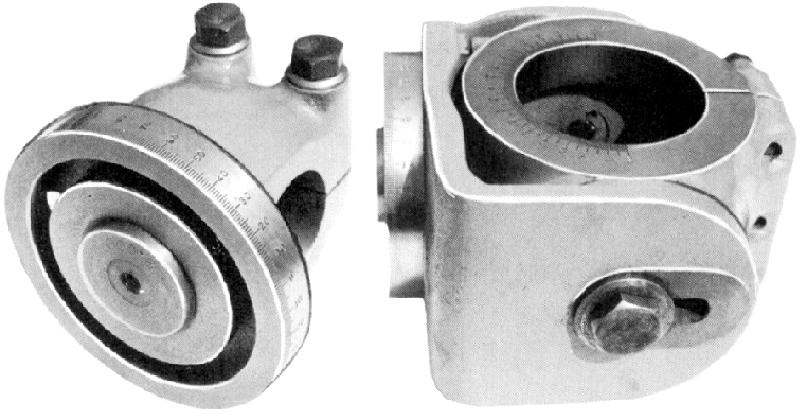

Quilmaster Unit. On the left the Type MA for the M and T heads

- and on the right the Model JA to suit the Type J Head.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

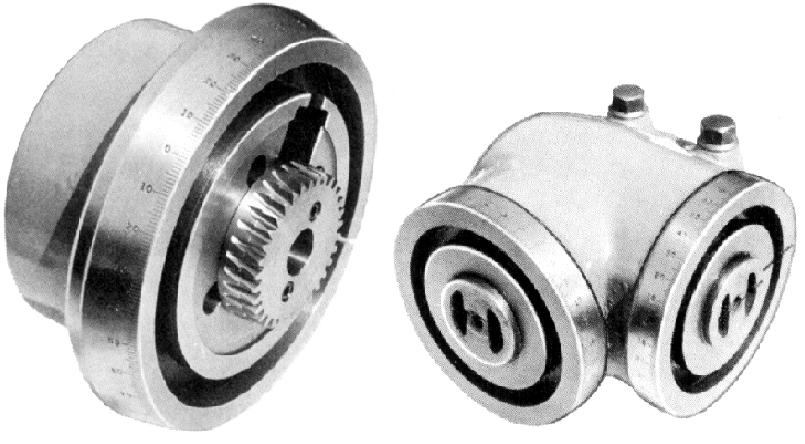

Above, the QRA Attachment. This right-angle Attachment

was designed to fit on the end of the Quillmaster unit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

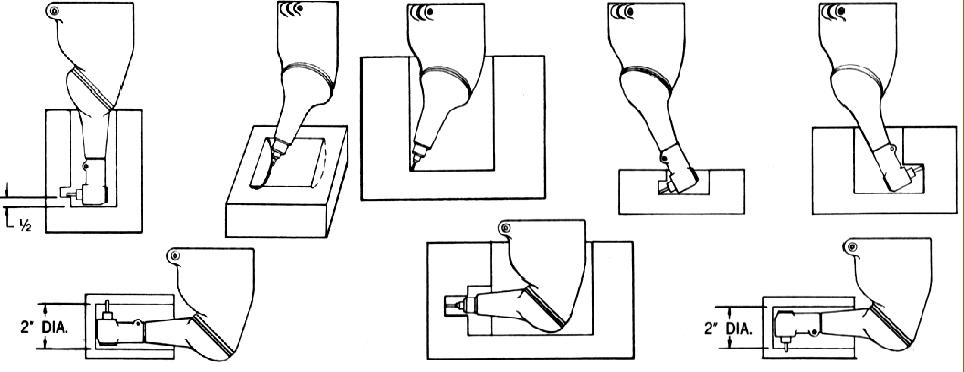

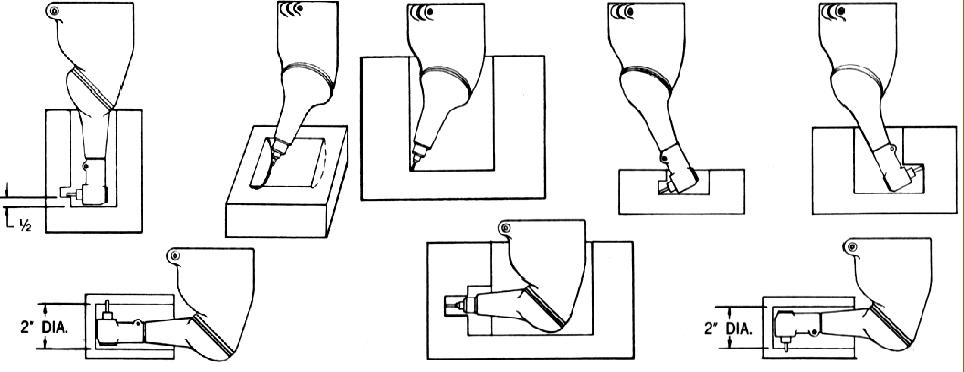

The sort of Jobs the QRA attachment was intended for

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

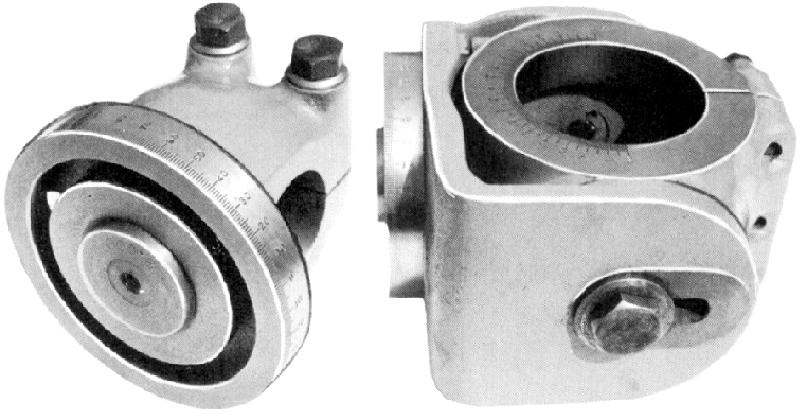

On the left, the No. 3 right-angle attachment for the Model J Head. This heavy-duty 4 to 3 reduction unit was very well made with hardened and lapped spiral-bevel gears and the hollow spindle, designed to accept standard R-8 tooling, running in pre-loaded ball bearings. The attachment is shown in combination with the Auxiliary Arbor Support, a device that greatly improved its performance when used for horizontal milling. The collet capacity range was 1/8" to 3/4".

To the right, the No. 4 Right-angle Attachment for the Model J Head. This was a lighter-duty, 2 to 1 reduction unit that took an N-2 collet in its spindle with a capacity range of 1/16" to 1/4".

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Above: dimensions of the No. 4 Right-angle Attachment for the Model J Head.

No. 4

A = 4.25"

B = 7.28125"

C = 0.84375"

D = 1.96875"

E = 2.1875"

Collet = N-2

Collet Capacity = 1/16" - 1/4"

Speed reduction 2 : 1

Min Working Space 2.625"

|

|

|

|

|

|

|

Above: dimensions of the No. 3 Right-angle Attachment for the Model J Head.

No. 3

A = 4.25"

B = 6.625"

C = 1.5625"

D = 4.8125"

E = 2.375"

Collet = R-8

Collet Capacity = 1/8" - 3/4"

Speed reduction 4 : 3

Min Working Space 5.75"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Left: No. 2 Right-angle Attachment for the Model M Head. The Spindle, with a speed reduction of 2 to 1, accepted a N-2 collet with a capacity range of 1/16" to 1/4".

Right: No. 1 Heavy-duty Right-angle Attachment for the Model M Head. The 2 to 1 reduction spindle accepted a B-2 collet with a capacity range of 1/16" to 1/2".

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Above: dimensions of the No. 2 Right-angle Attachment for the Model M Head.

No. 2

A = 3.375"

B = 6.5"

C = 0.84375"

D = 1.8125"

E = 3.1875"

Collet = N-2

Collet Capacity = 1/16" - 1/4"

Speed reduction 2 : 1

Min. working space: 2.625"

|

|

|

|

|

|

|

Above: dimensions of the No. 1 Right-angle Attachment for the Model M Head.

No. 1

A = 3.375"

B = 5.0625"

C = 1.28125"

D = 3.375"

E = 1.875"

Collet = B-2

Collet Capacity = 1/16" - 1/2"

Speed reduction 2 : 1

Min. working space: 4"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting Adaptors for J and M Heads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dovetail Mounting for J and M Heads. Double Overarm for J Heads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hand Miller type B for M Head Universal for M Head

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Overarm for J Head Type for M Head

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adaptor Plate for Type J and M Heads Hand Miller Type for M Head

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|