|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early Model Super 7 on the ordinary "octagonal-form" 16-gauge sheet-steel (with angle-section stiffening) all-welded cabinet stand. with deep chip tray and levelling blocks

|

|

|

|

|

Late Model Super 7B with power cross feed on the "new-style" Industrial Cabinet. Click HERE to read details of the Super 7 & ML7R Specification

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early Super 7B with screwcutting gearbox on the original (and highly desirable) Industrial Cabinet with roll-edge chip tray, built in switch gear and locking cupboard.

|

|

|

|

|

Early Super 7 without screwcutting gearbox

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

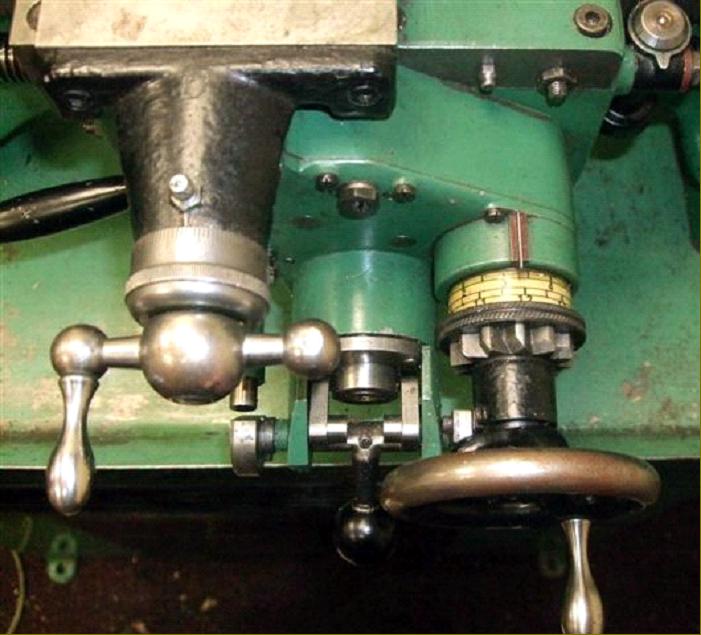

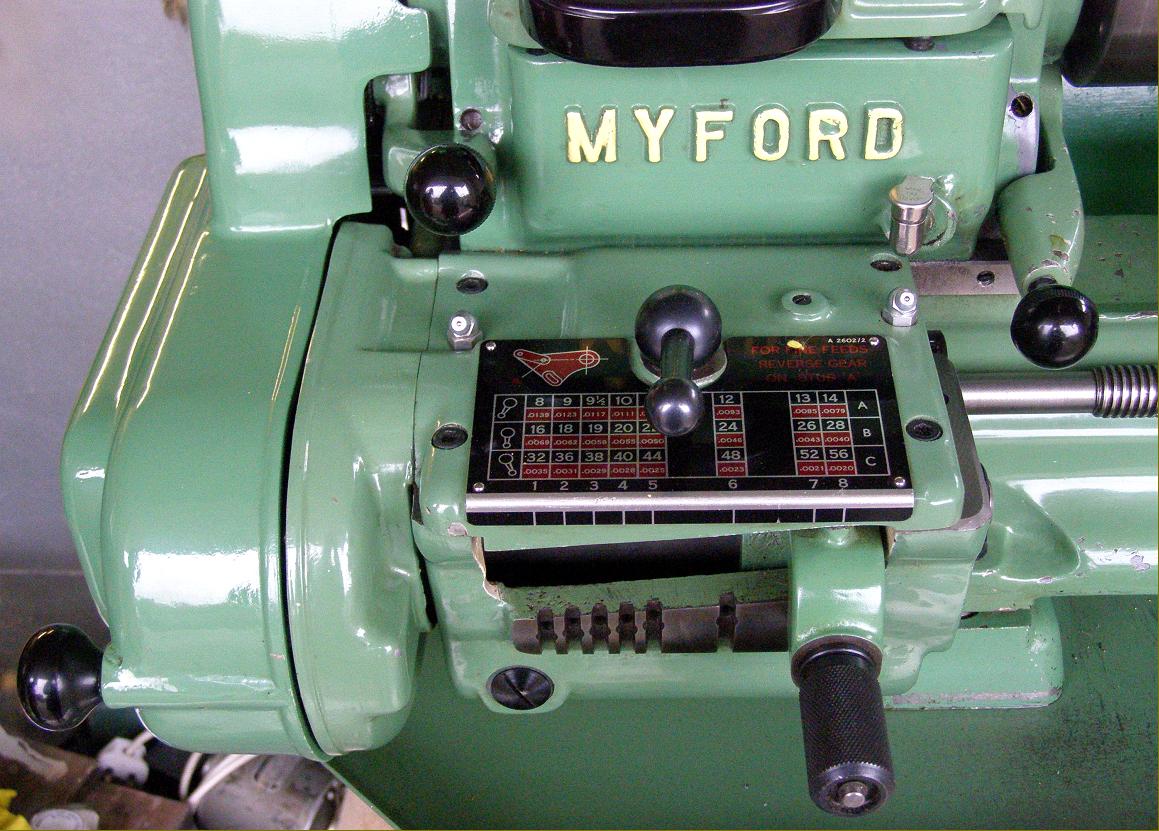

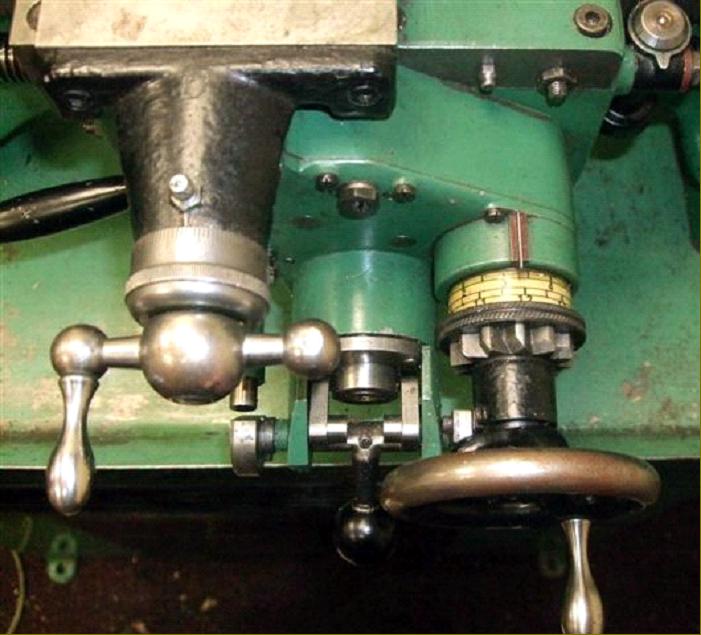

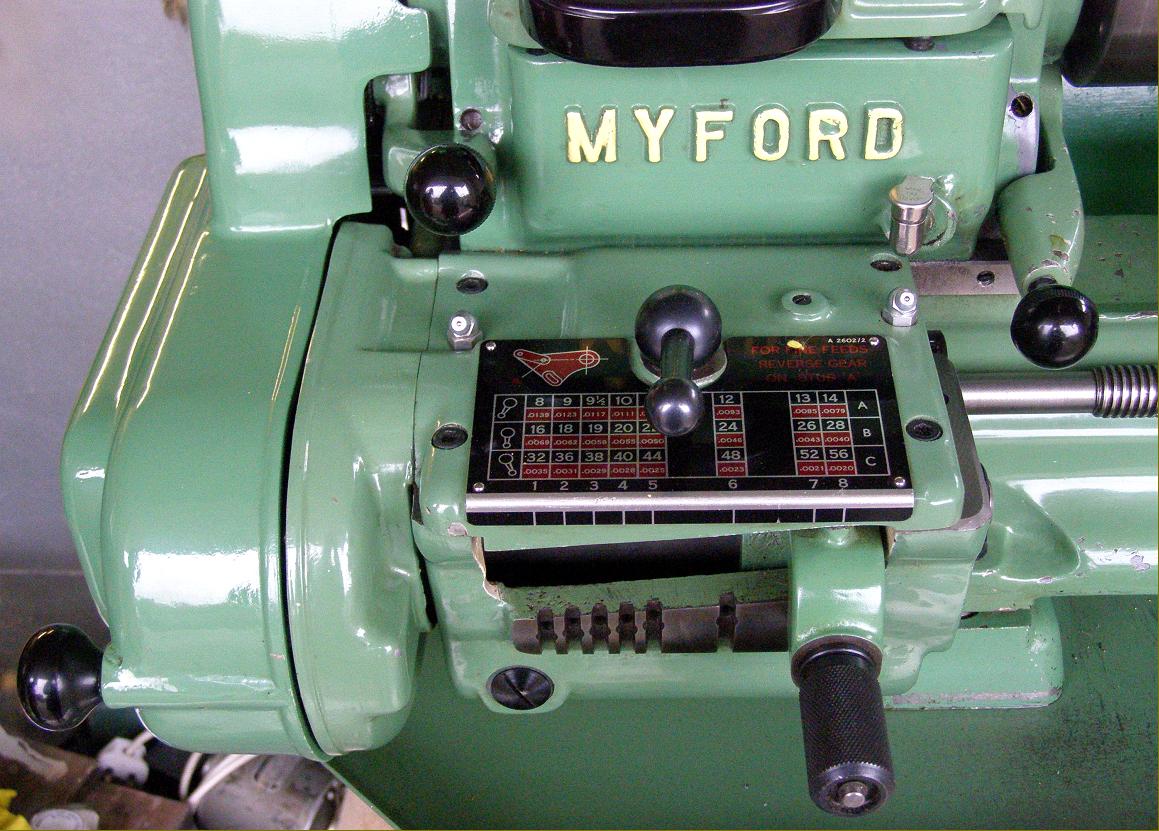

Screwcutting gearbox with the end cover open - fitted in this case to an ML7. The middle gear of the lower three reverses on its stud to select fine feeds or screwcutting.

|

|

|

|

|

|

|

|

|

|

|

|

|

A Screwcutting Gearbox to fit both the ML7 and Super 7 lathes was introduced in late 1954. The box generated 48 threads from 8 to 56 t.p.i. and the same number of feeds (by the simple expedition of pulling out a double gear mounted on the banjo) of 0.139" to 0.002" per revolution of the spindle.

The gearbox is shown fitted to a very early Super 7, some distinguishing features of which were the use of large, knurled-edge threaded fasteners on the selector levers for tumble reverse, backgear and the gearbox and countershaft covers and the integral headstock drip-feed oiler - the circular window of which can be seen just to the left of the chuck. This latter (expensive-to-make) feature was abandoned after 1959.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

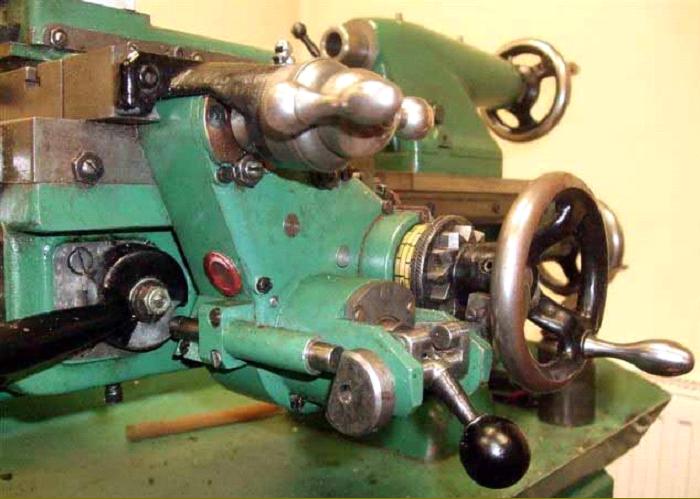

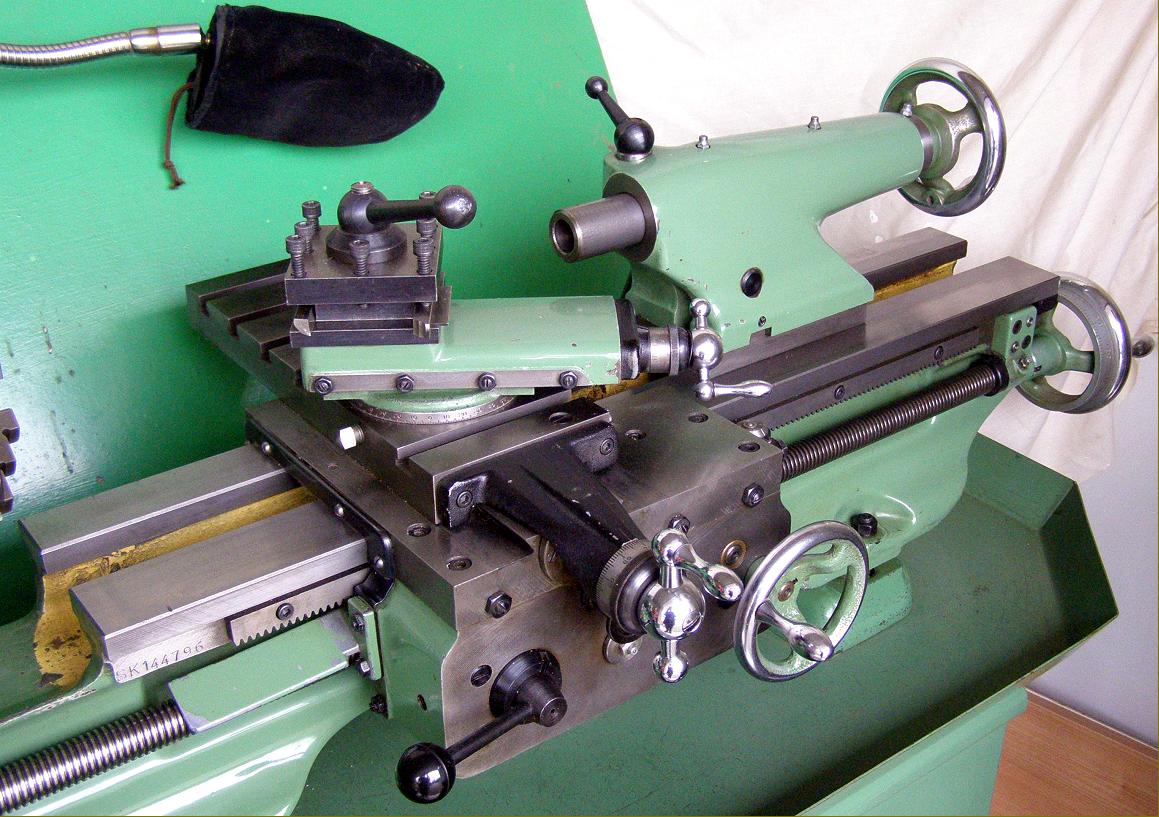

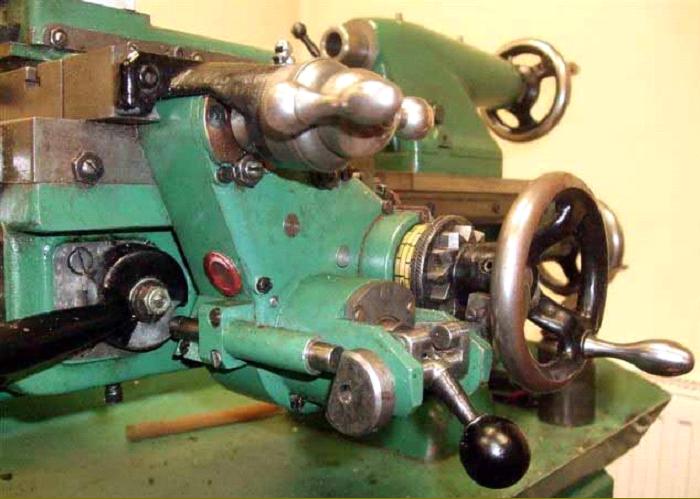

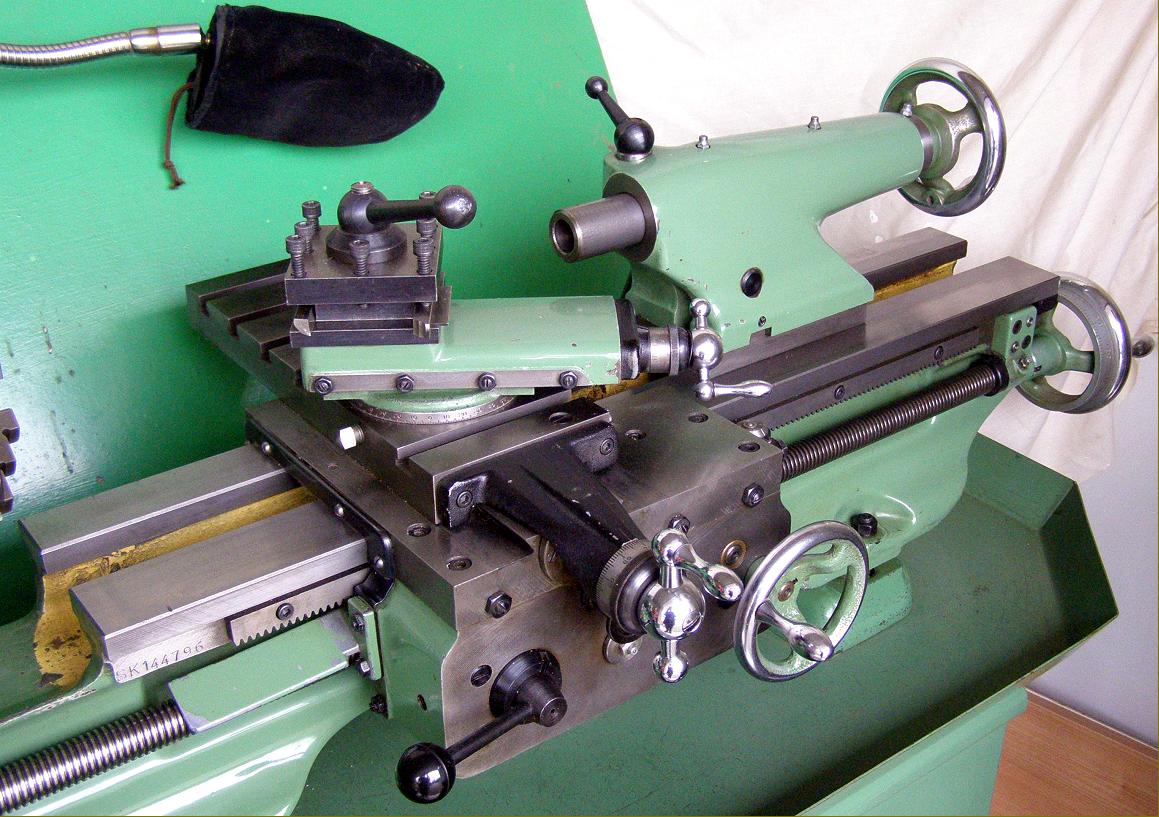

Very early (1953) Myford Super 7 with the integral headstock drip-feed oiler, the circular window of which can be seen just to the left of the chuck - this lubrication system was abandoned after a few year's production.

Another distinguishing feature of early machines was the clutch contained within the countershaft 4-step cast-iron pulley. This works perfectly well, but is prone to rattling unless correctly adjusted. Reference to the maker's instructions on this point is vital.

The levers to operate the tumble reverse and backgear - as well as those to open and close the changewheel and countershaft belt guards - were fitted with screw-operated knobs; the later change to "spring-loading" made the machine rather more convenient to operate but more vulnerable to careless selection of the wrong lever …..

Super 7s of all years are well finished, but these early models appear to have enjoyed especially fine detailing - and to have been very carefully painted.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

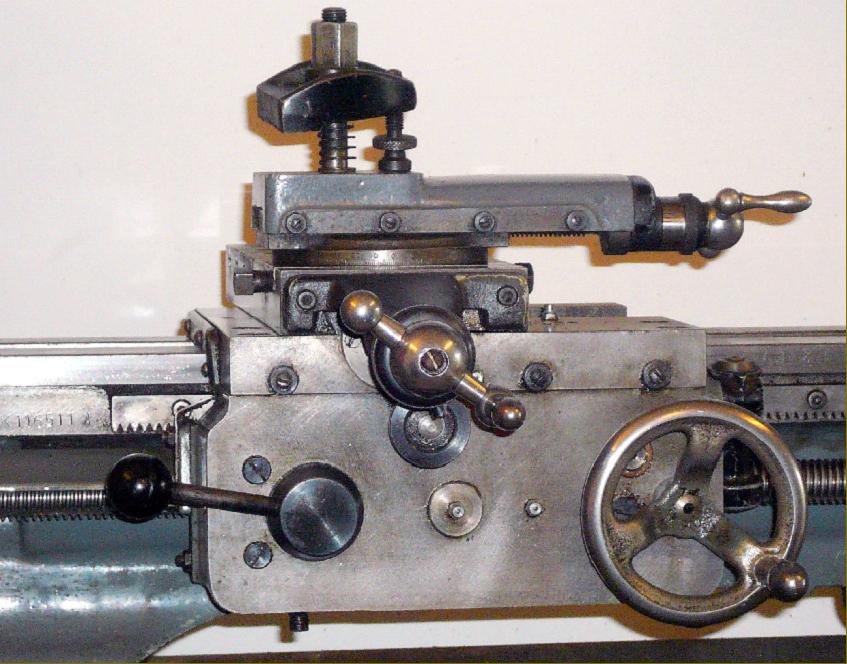

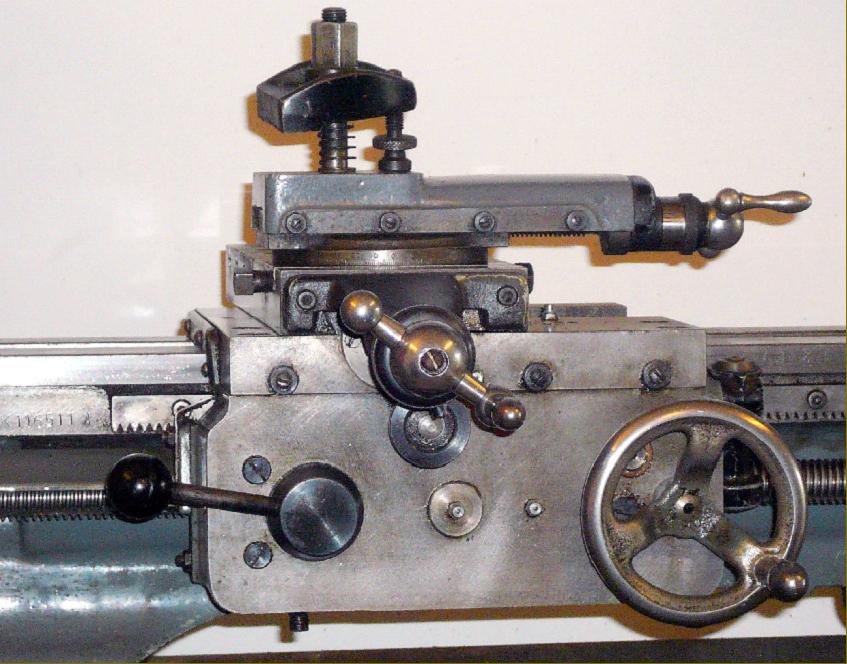

Standard Power cross-feed apron as fitted from 1974 and machine SK 115830

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Not known as a third-party accessory, this might be an experimental power cross feed unit. Note the interlock with the leadscrew clasp nut handle and the grease nipple to lubricate the cross-feed screw where it passes though the end support bracket.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Myford ML7R

Introduced at more or less at the same time as the power cross feed Super 7, this is the lathe that confuses people new to the make. Although called an ML7 - and you would therefore expect it to be a development of, or directly related to, the original machine of that name - it was actually a non-power cross feed Super 7, but without a clutch and fitted with ML7 cross and top slides. It was designed to fit below the Super 7 in place of the ML7 and allowed a rationalisation of production around just one design of bed, headstock and tailstock. The lathe was eventually to be fitted with Super 7 cross and top slides, the ML7R name dropped and the "new" model renamed "Super 7 Sigma".

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Myford Super 7BPXF - with Screwcutting Gearbox and Power Cross Feed See also "new in the box"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

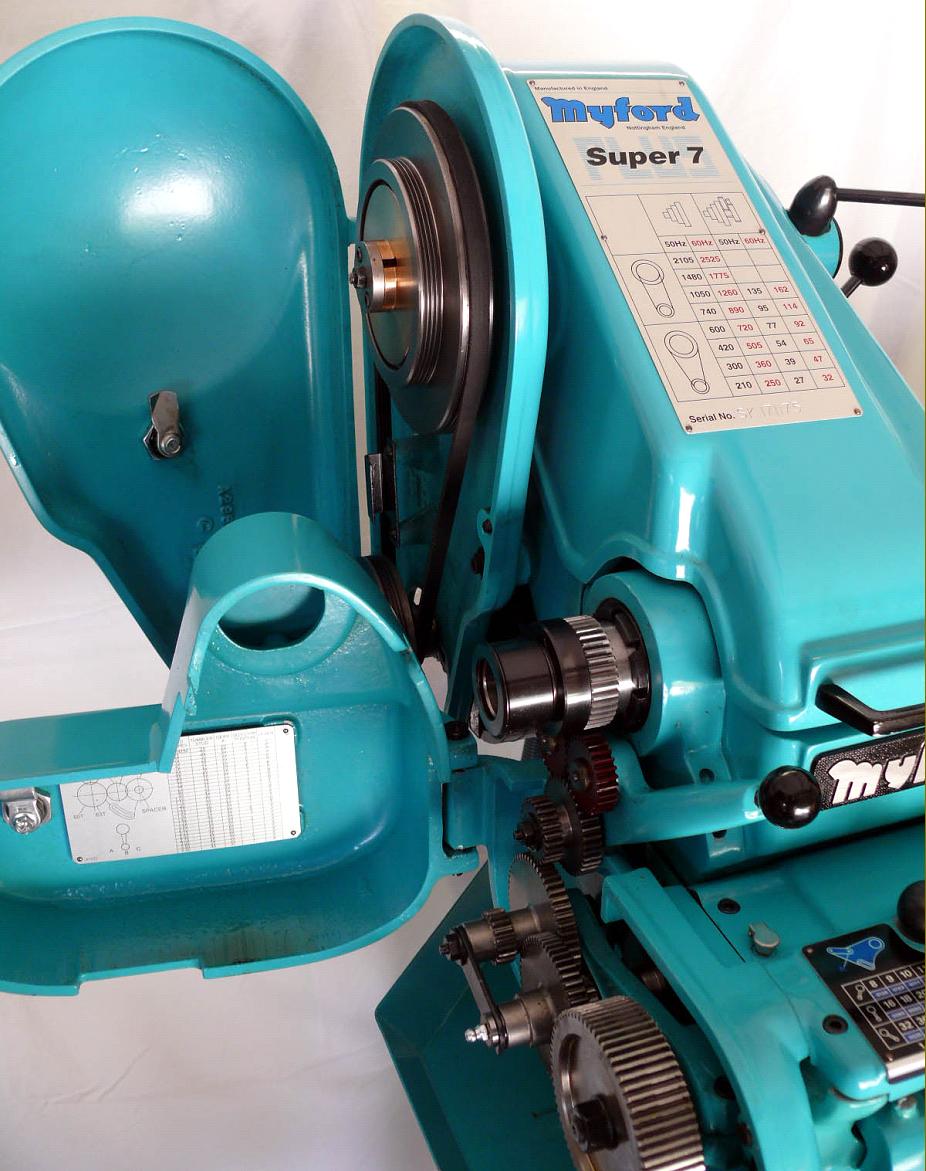

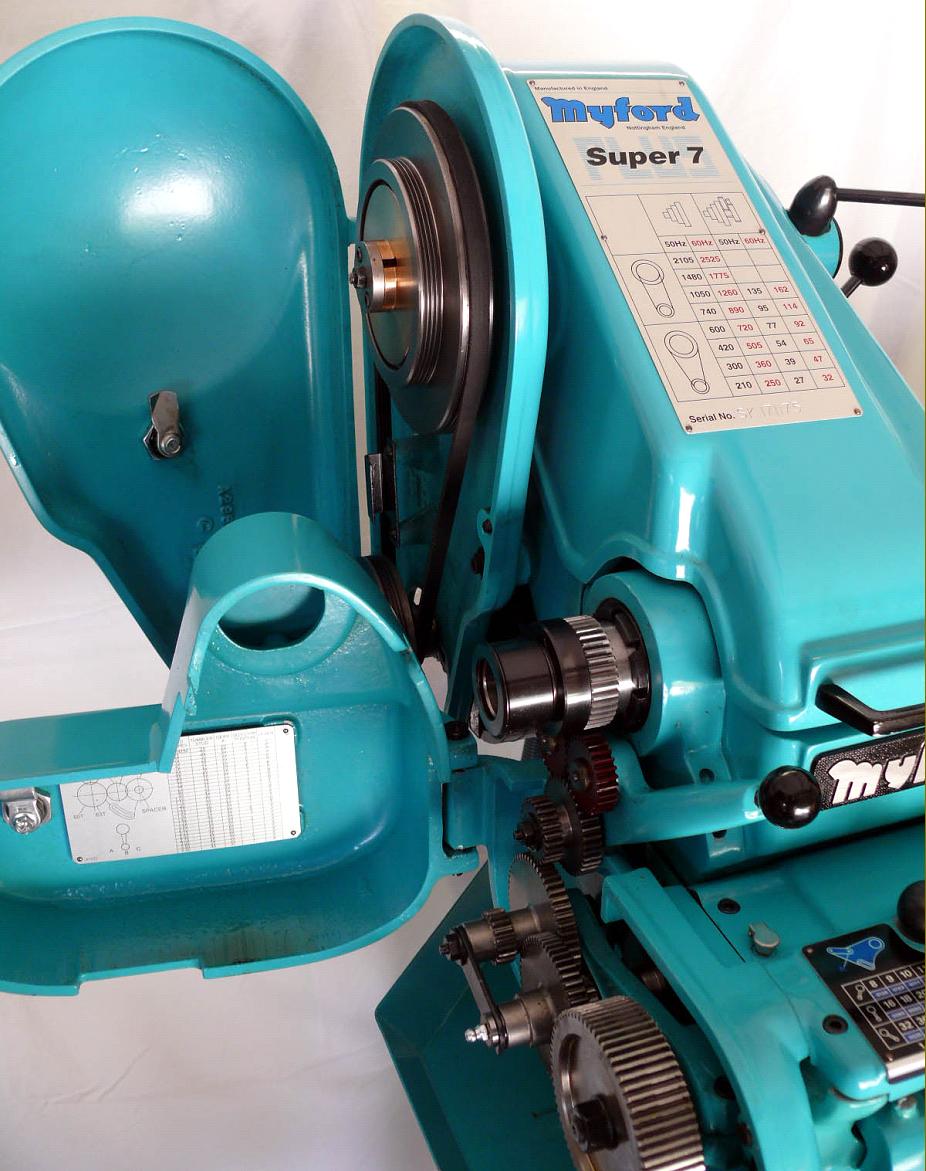

Myford Super 7 Plus "Big Bore"

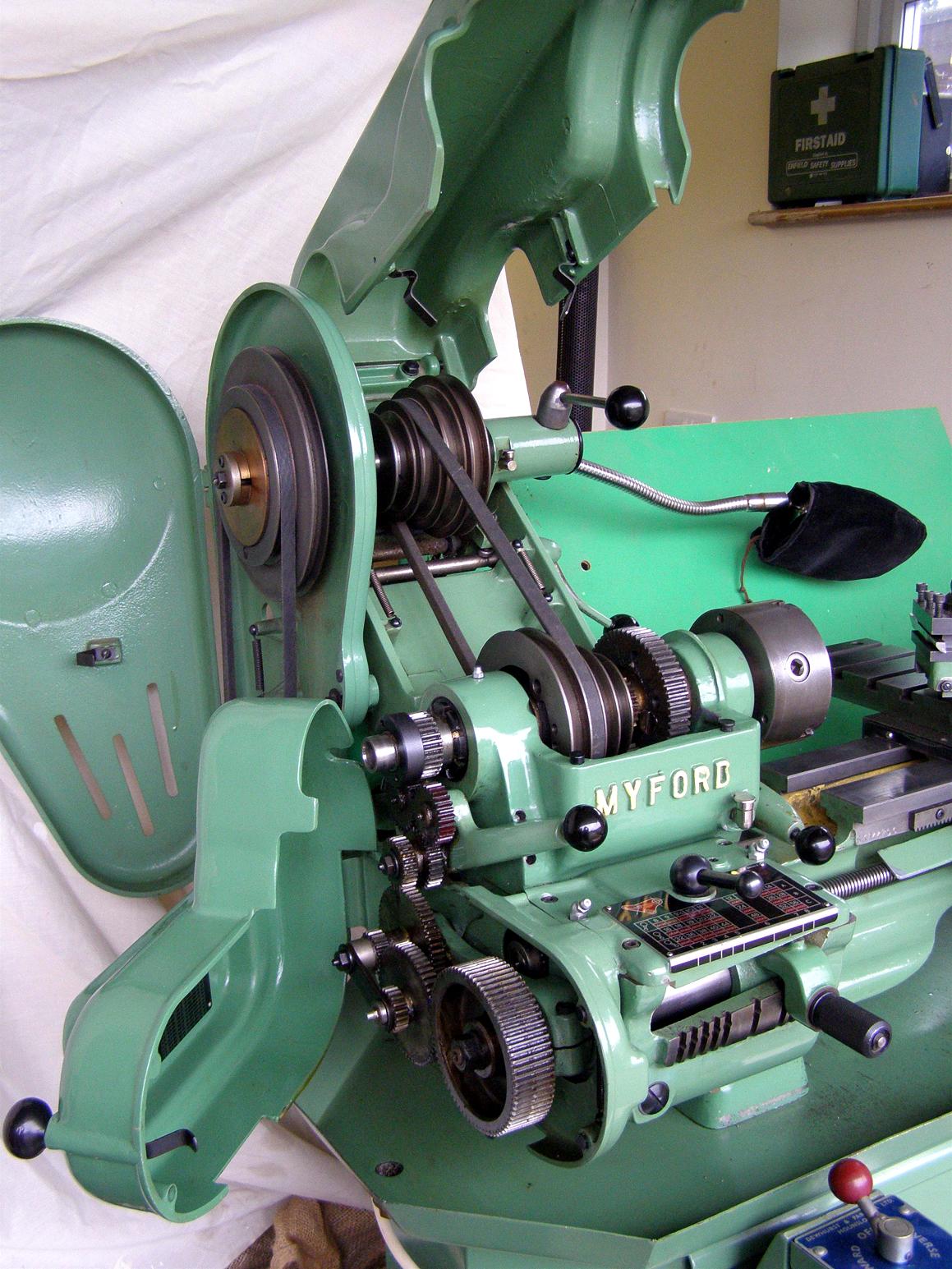

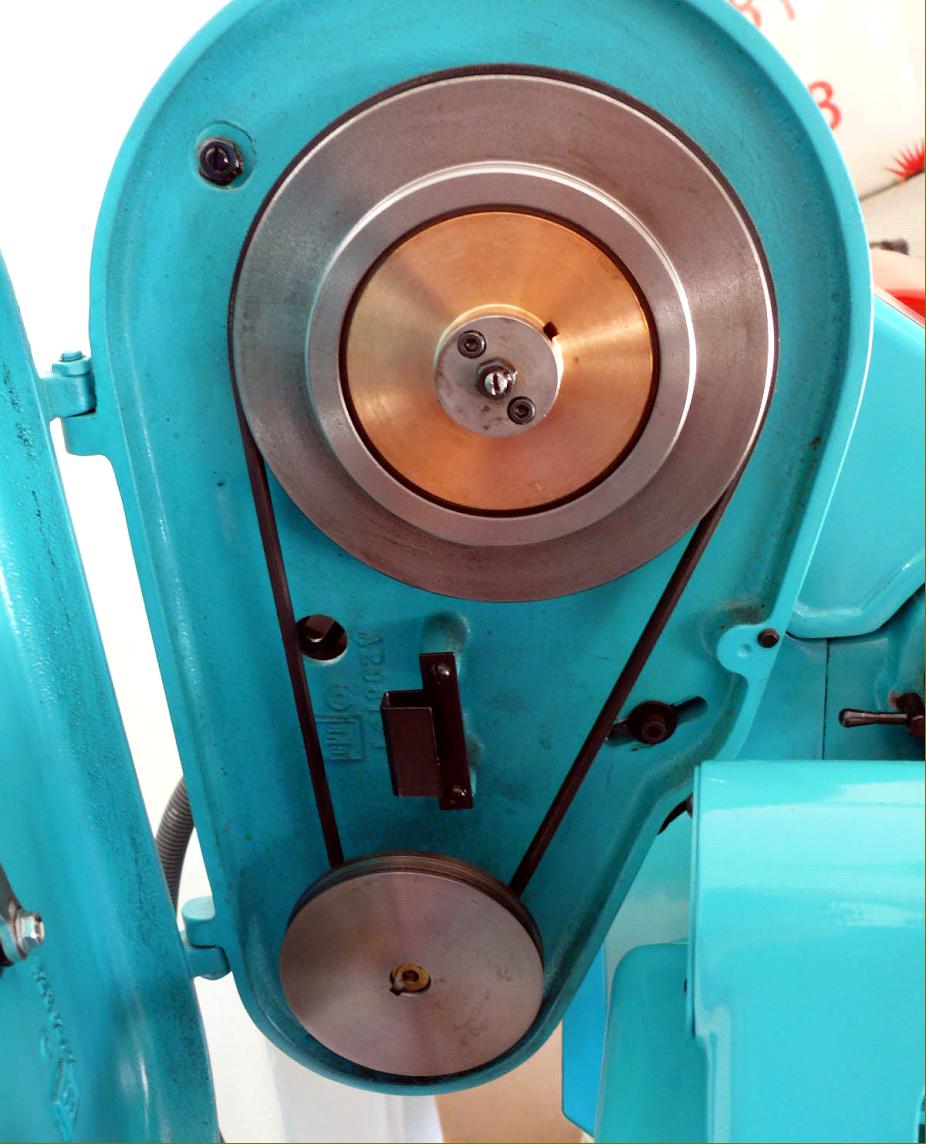

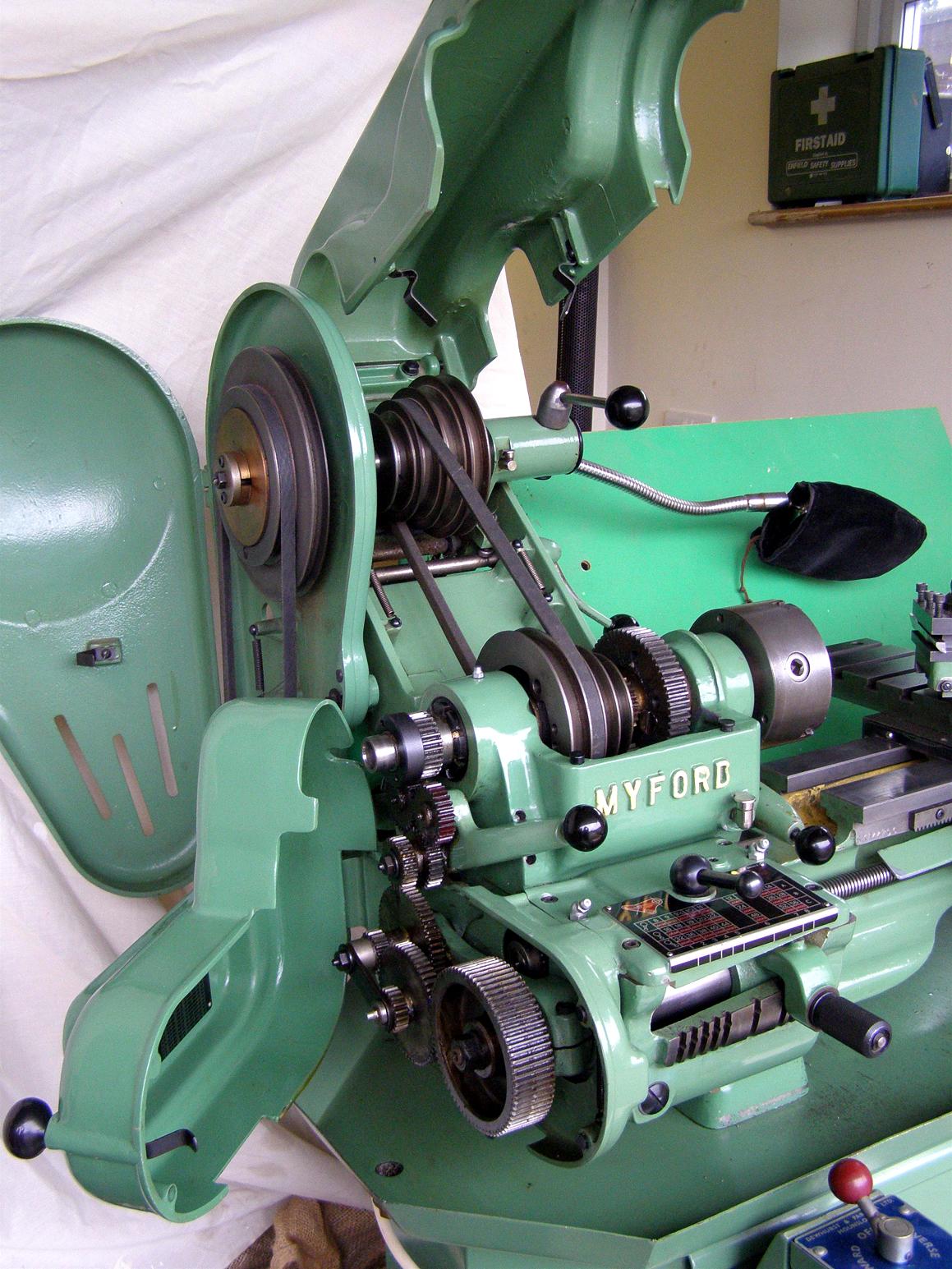

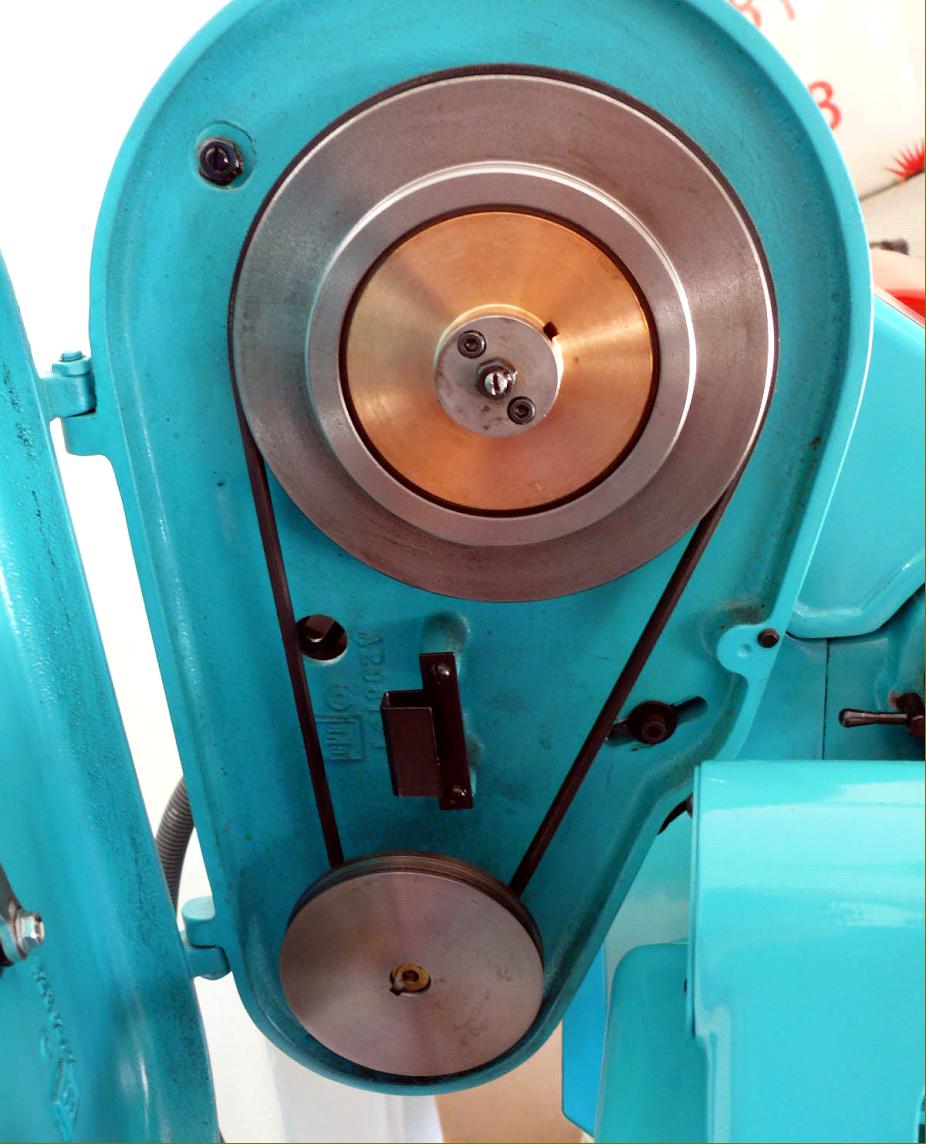

Although designed in the late 1950s, it was not until the Summer of 2001 that the last (Mk. 3) version of the Super 7 lathe was introduced. Welcomed as a long-overdue development of this classic lathe, it had a larger and stiffer spindle able to pass a 1-inch diameter bar (formerly limited to 0.75"), a M42.5 x 2 mm pitch nose and a 4 Morse taper socket. The greater convenience of the larger bore, the ability to carry a 5-inch diameter chuck and the increased mass of the headstock casting all contributed to a markedly-improved machine. Another significant and important change was made to the countershaft unit - the 2-step motor-to-countershaft belt and pulleys were changed to a Poly-V type giving much smoother running on top speed (a feature often lacking on earlier models) and extended belt life. However, on the ordinary "Big Bore" the drive from the countershaft swing-head to the spindle remained as before - a standard A-section V-belt that could be expected to give years of reliable service. To improve the feel of the cross-feed when using hand feed a needle roller thrust bearing was fitted to the cross-slide end bracket. The opportunity was also taken to improve the security and safety of the changewheel and countershaft belt guards - the inner and outer out sections were made much thicker and fitted with positive-action, 1/4-turn catches to replace the former rather weak spring-held closures that could easily be knocked open by a light blow in the right direction.

Fitted with numerous extras as standard, the top-of-the-range version was given the slightly embarrassing title of "Connoisseur". This version featured an inverter-controlled, variable-speed drive from 26 to 3000 r.p.m. , a spindle clutch, screwcutting gearbox, hardened bed, spindle indexing (by use of the backgear bullwheel), Poly-V drive to the headstock spindle and ready-mounted on the late-type industrial stand.

More photographs of the Super 7 Plus

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|