|

Home Machine Tool Archive Machine-tools for Sale & Wanted Milling Machines |

||

|

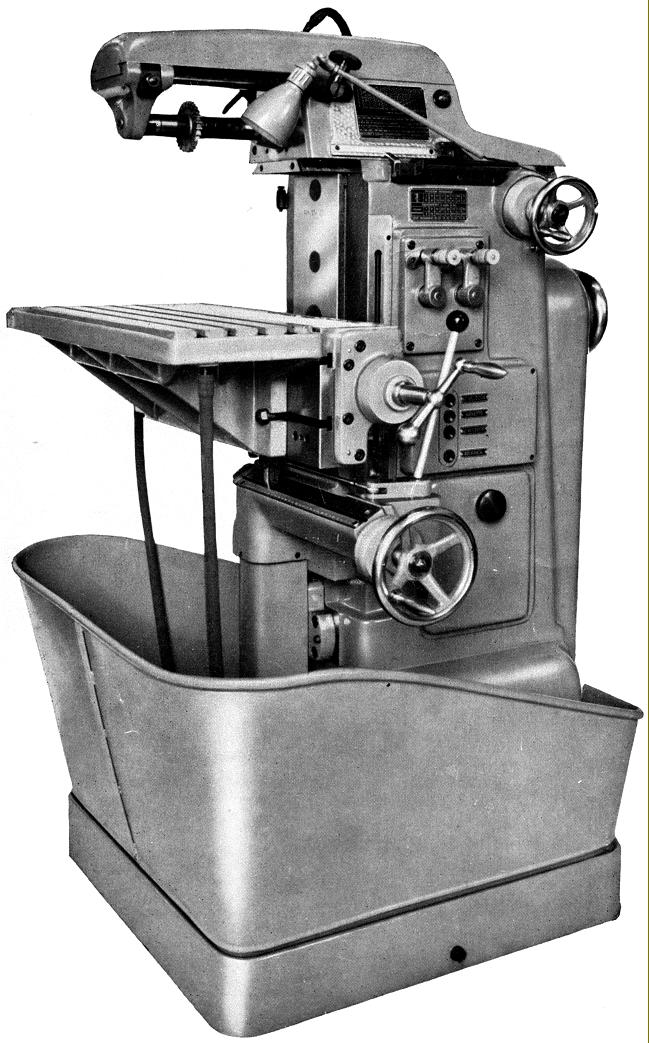

Manufactured by Costruzioni Elettromeccaniche Ing. Alberto Bandini in Firenze Via. Morosi, Italy, the Bandini Universal precision Milling Machine was an almost exact copy of the Mk. 1 Deckel FP1. Like all of its type, this was an ingenious, adaptable and versatile machine* that lent itself to solving a multitude of machining problems, the secret of the type's success being its ability to mount a number of different heads - horizontal, standard vertical, high-speed vertical and slotting - in combination with a variety of tables - plain, plain-tilting and compound swivelling. All the heads could be driven backwards and forwards across the top of the main column to provide an in-out feed, while the tables bolted to a flat, vertical T-slotted table equipped with power longitudinal and vertical feeds. By juggling the choice of heads and tables, and utilising other accessories, a skilled technician was seldom defeated in his attempts to produce the most complex of milled and drilled components - and all to a very high standard of accuracy. |

|

Continued: |

|

Home Machine Tool Archive Machine-tools for Sale & Wanted Milling Machines |

||