|

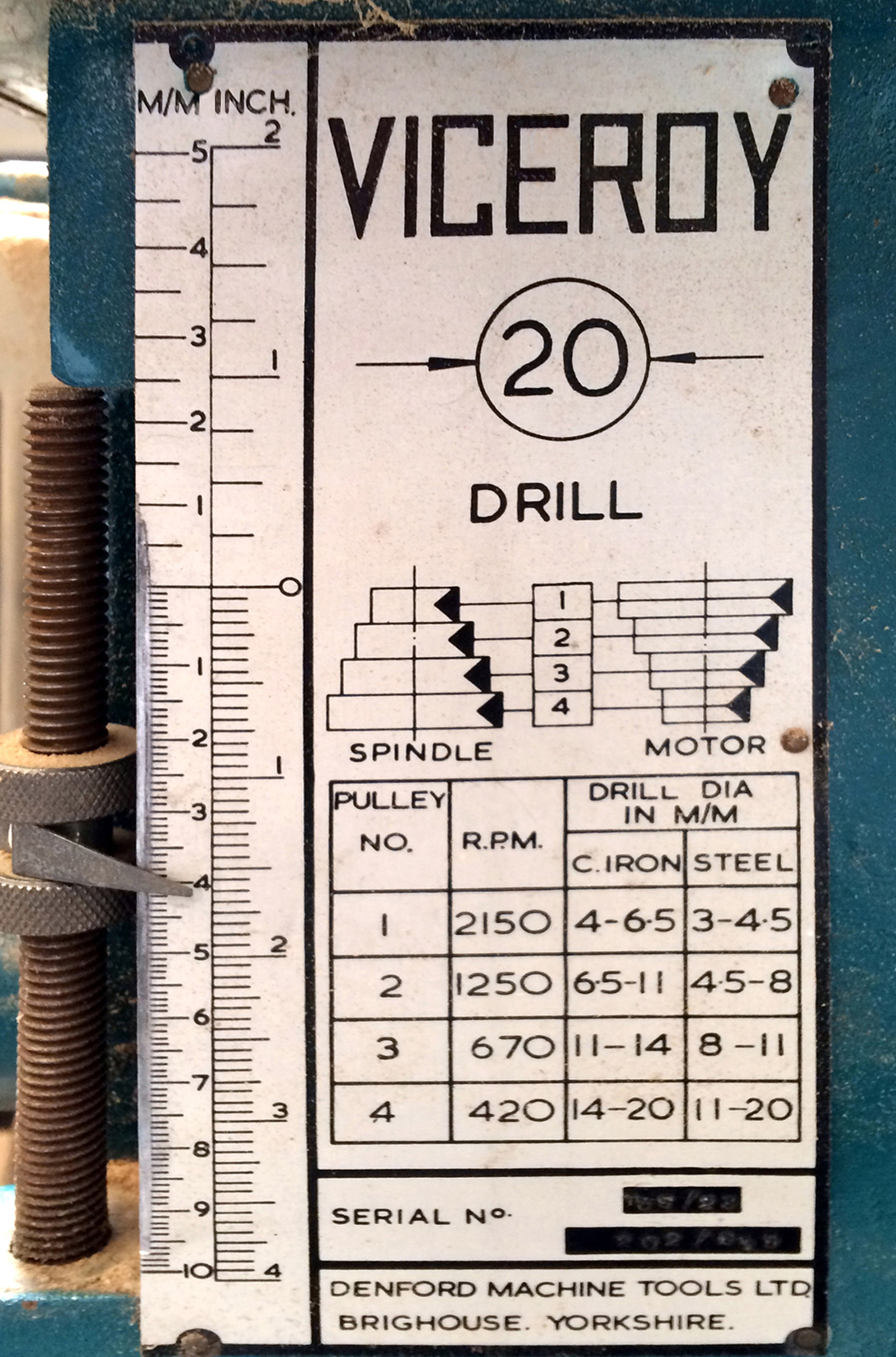

Denford "Viceroy" drilling machines were made in both bench and pillar form, the former listed as the Types T.D.S.22 and T.D.S. 22-BG and the latter as the T.D.S. 23 and T.D.S. 23-BG. Standing for BackGeared, the BG models had the advantage of speed-reduction gearing in the head, this extra-cost option doubling the number of speeds from four to a much more useful eight, the ranges being: 420, 670, 1250 and 2150 r.p.m. and 100, 180, 250, 450, 750, 1200, 1700 and 3000 r.p.m.

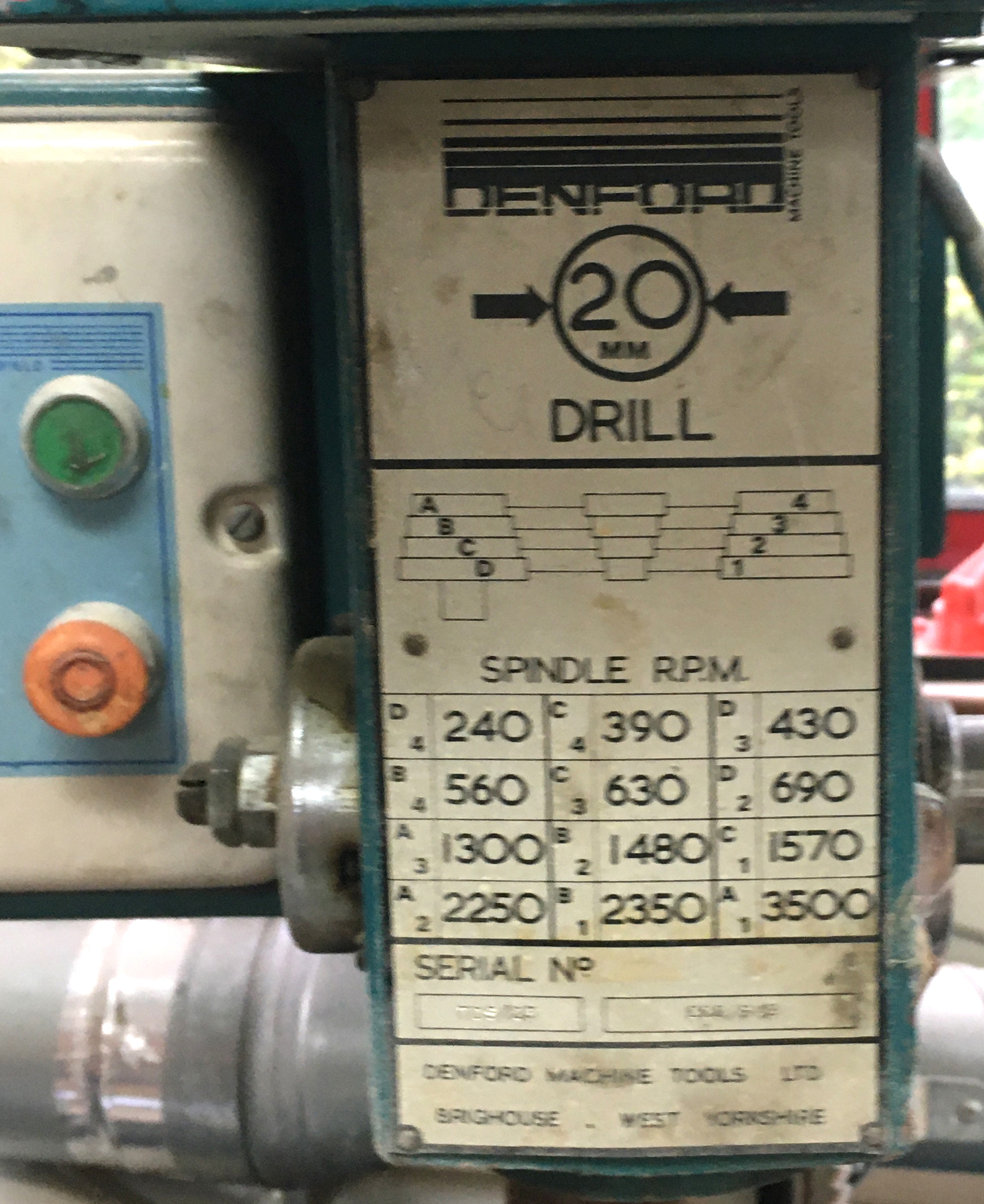

The T.D.S.22 and T.D.S 23 were both all-V-belt drive machines made in two forms, one being a simple 4-speed model the other having an intermediate pulley between the motor and spindle that gave an enormous range of twelve speeds spanning a very useful 240 to 3500 r.p.m. The main components of these belt-drive drills, their quill travel and table size were identical to that of backgeared types.

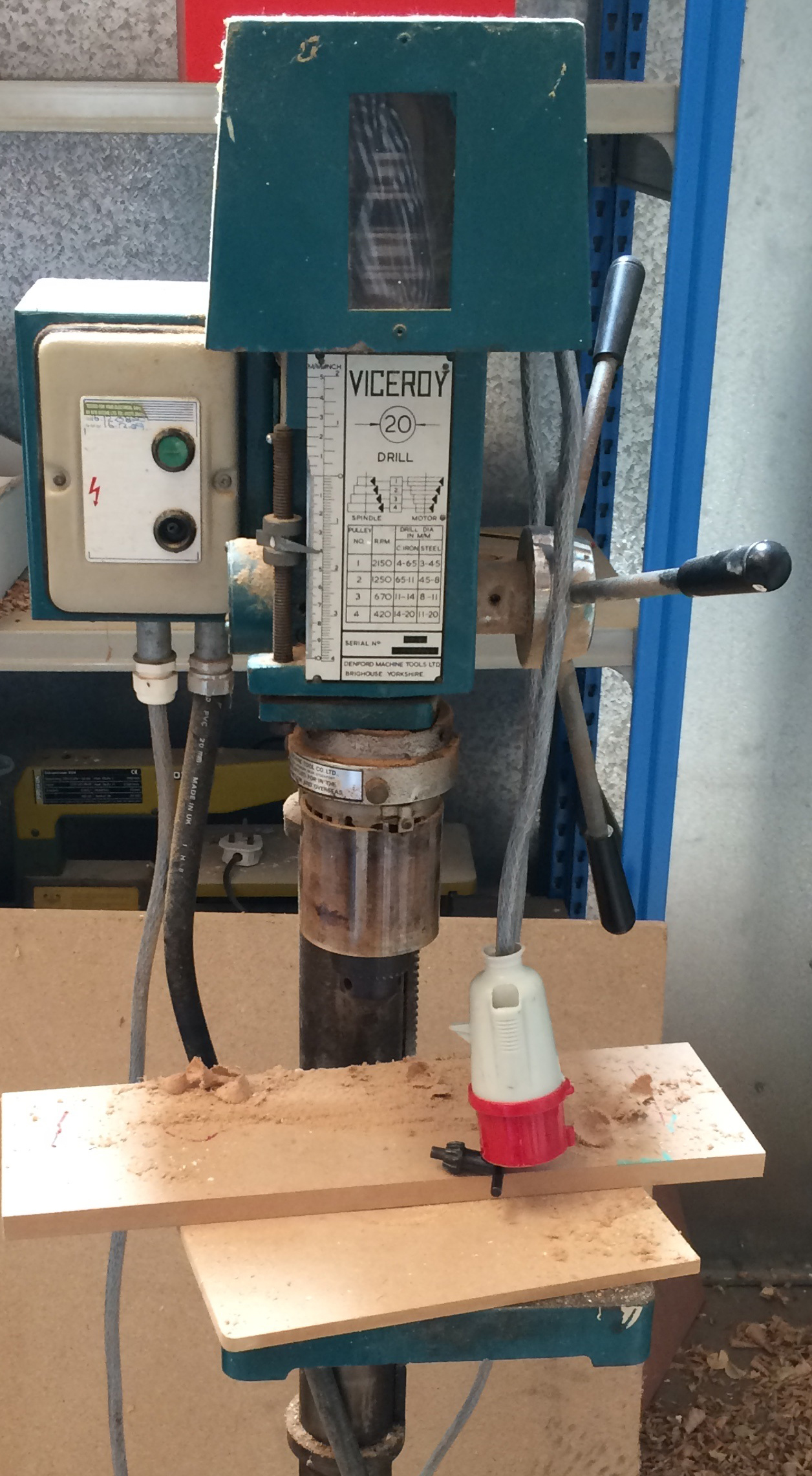

Apart from the length of the ground-finish, drawn-steel support tube and the larger, heavier foot of the column model, the two backgeared drills shared a very decent specification that made them especially easy to use. Fitted with two work-holding slots, the standard 10.5-inch (267 mm) square table was ground finished, raised and lowered by rack-and-pinion gearing and could be angled left and right. Incorporating a standard-fit, low-voltage work light, the head was fitted with a side-hinged steel guard with an unusual front face that incorporated a window in steel mesh - thus the operator could see, at a glance and very conveniently, which speed had been selected. While early drills had just a small mesh window, on later ones it was improved to cover almost the full area of the front face.

Opening the belt guard activated a micro switch that stopped the single or three-phase, 3/4 h.p., 1425 r.p.m. ball-bearing motor - electrical control being by a no-volt release safety starter (usually with a built-in the 25-volt transformer for the work light) fitted with a large, mushroom-shaped stop button that could be locked in the off position. On the pillar drill an emergency stop switch was built-in behind a long, rubber-covered housing on the front face of the foot - though a loose foot switch, at extra cost, was also available for the bench drill. To slacken the drive belt for changes of speed, the motor-mounting plate could be moved in and out by a very handy, quick-action, "cam-locked" lever.

Made in steel (cast iron is more normal for this part), the quill contained sealed-for-life ball races and was moved by a three-handle capstan wheel, the position of which could be adjusted on its supporting shaft. Machined with six spindles to pick up the drive from the taper-lock secured aluminium V-belt drive pulley, the spindle was fitted with a No. 2 Morse taper socket, had a travel of 4 inches (100 mm) and the usual type of adjustable depth stop with twin circular locking nuts. However, instead of the vertical threaded rod on which the locking nuts ran being engraved with hard-to-read ruler markings, a separate inch/mm scale in clear black on white was provided to the right-hand side with a pointer attached to the stop screws. Another interesting provision was a speed chart that included a guide to recommended drill sizes for speeds when drilling in steel and cast iron.

Various accessories were available, including a rather small screw-feed compound table with travels of 100 and 50 mm, a mortising attachment, a foot-operated stop switch for the bench model, a tilting circular table and - surprisingly for a machine intended for educational use - a guard for the drill chuck supplied at an extra charge instead of being fitted as standard.

The Model T.D.S.22 bench drill stood 37 inches (940 mm) high, measured 24 inches (610 mm) front to back, had a throat of just under 7 inches (175 mm) and a maximum clearance between the tip of the Jacobs drill and the top face of the foot of 16.5 inches (418 mm). As a plain, 4-speed version it weighed 90 kg and, with backgear, 127 kg.

The Model T.D.S 23 pillar drill stool 64 inches (1625 mm) high, was 25 inches (635 mm) front to back, had a maximum clearance between the tip of the Jacobs drill chuck and the top face of the foot of 43.5 inches (1104 mm). In 4-speed form it weighed 104 kg and, with backgear, 136 kg.

Denford Viceroy drills are few and far between on the used market, but one that passed through the writer's hands some years ago proved to be particularly powerful, smooth running and very accurate..

|

|