|

Inside the headstock of the unusual Poly-V drive Viceroy 280VS. The serrated ring on the right is part of the pulse generator system for the digital speed read-out

Continued:

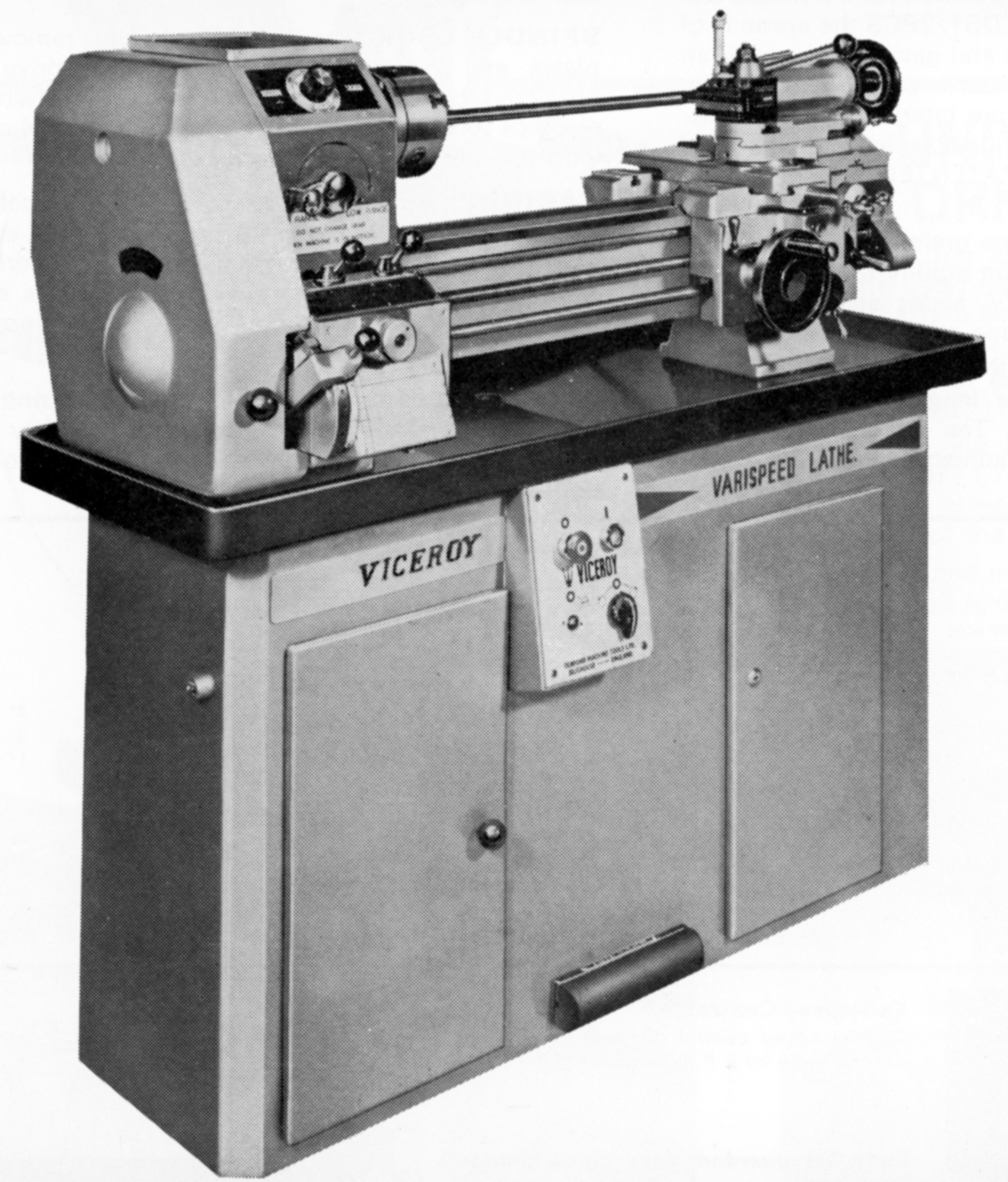

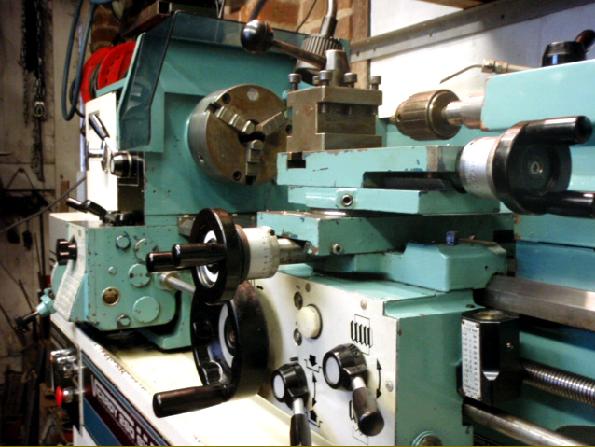

Design and location of the electrical-control panels varied widely; in general, those with electrically-operated pulleys had a pendant unit fitted above the headstock combined with stand-mounted controls (either in the centre or below the screwcutting gearbox) and usually shown on etched aluminum panels; others had controls confined to the stand. Many lathes, especially those purchased for training workshops, were fitted with an unreliable, full-length pneumatically-operated foot switch fitted to the front of the stand at floor level.

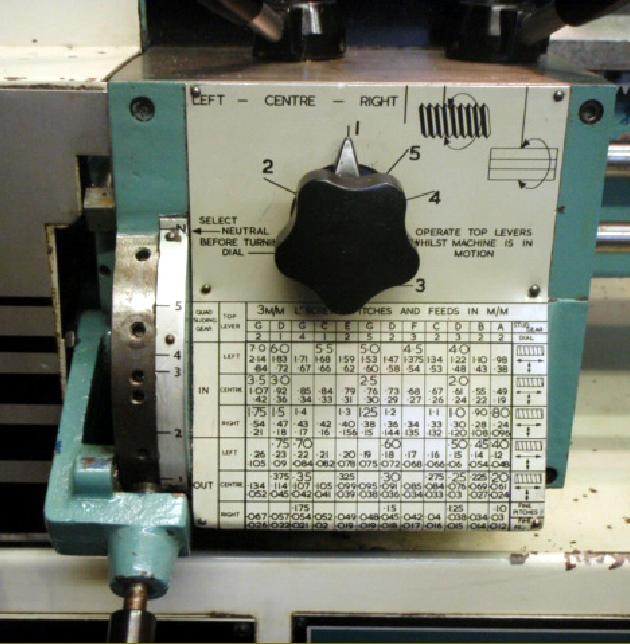

The screwcutting gearbox drove either a 3 mm or 8 t.p.i. leadscrew (with needle-roller thrust bearings) and a separate power shaft, the latter usually (but by no means always) fitted with a most useful automatic disengage to the saddle drive. The gearbox was a comprehensive affair with multi-lever operation, some of which had to be moved with the spindle stationary and others when it was turning and the changewheels in mesh - the arrangement allowing an instant change of sliding or surfacing speed. However, before operating the gearbox in this way a careful reading of the maker's operating instructions is essential: it is not safe just to play with the levers with the lathe running and "see what happens" - what "happens" may shatter the gearbox. On the metric box 72 pitches were available from 0.2 to 7.0 mm and on the English box 48 from 4 to 224 t.p.i. Feeds along the bed ranged from 0.03 mm to 2.14 mm or 0.0014" to 0.030" per revolution of the spindle.

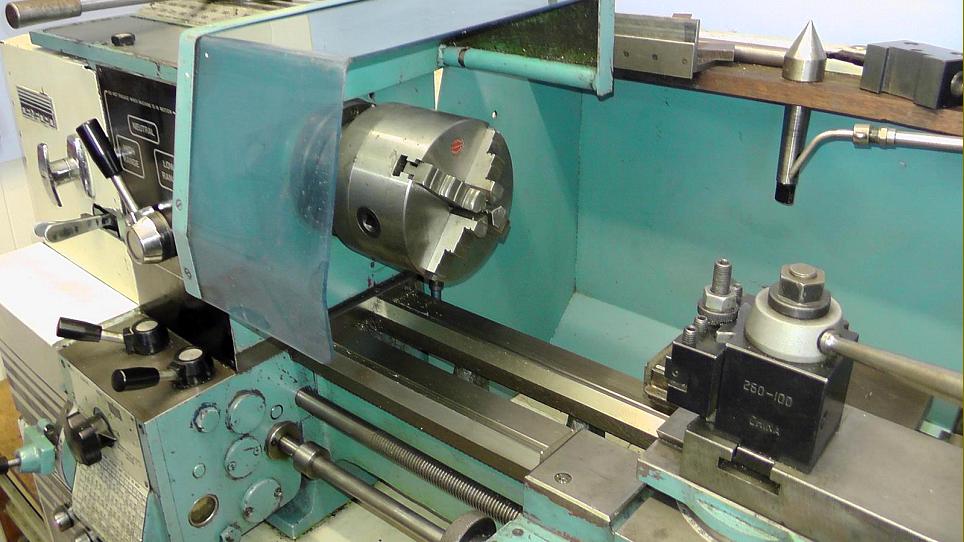

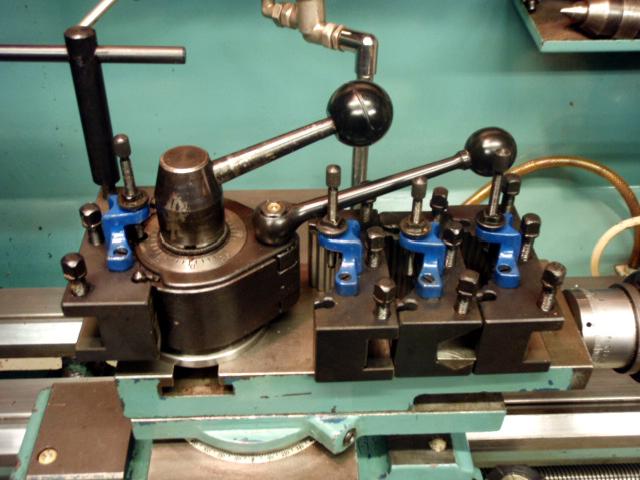

Following previous Viceroy practice, the compound slide rest assembly used the old-style feed screws and nuts - but with the top and cross slide castings squared-off to give a more modern appearance. One point worth mentioning is that some machines have not two but three socket screws to lock the top slide to the cross slide: the missing screw is hidden away at the front of the casting - and not mentioned in the original handbook. While some saddles had plain wings most incorporated "as-cast" T slots in the rear pair that allowed, for example, a travelling steady to be mounted, a toolpost for turning at the extremes of the machine's capacity, jobs to be bolted down for machining by cutting tools in the chuck or coolant pipes clipped in place .

While most 280 lathes had metric cross and top-slide feed screws, a few were produced to inch specification and some carried dual dials, with metric on the inner ring and inch on the outer. The tailstock was particularly strong and, because it carried a No. 3 Morse taper, drill shanks were far less likely to slip and ruin the spindle. All the handwheels - carriage, compound slide rest and tailstock - were in metal with a durable plastic coating, but retained by cheap and nasty spring-dowel pins.

Late-model Viceroy lathes offered a generally good quality of construction and a very decent specification that - while not up to the standard of a Colchester Chipmaster - was available at a considerably lower price and represented excellent value for money. Little-known and underrated, they offer terrific value second-hand.

If you have one of these lathes and its specification differs from those described, the writer would be interested to hear from you..

An owner writes with some most interesting and educational points

Now I've owned and used my 280 Synchro for nearly a year, can I offer a few comments to add to your own on the topic?

Generally, I like it a lot, it's accurate, relatively quiet, except at the highest speed setting, thanks to a combination of belt primary drive and steel/Delron back gears, and (for a home-workshop lathe) can take off serious amounts of metal. Mine is 3-phase, run off an elderly inverter and is the model with 12 speeds controlled by the lever at the top, so I don't have any issues with the 3-phase speed control motor which the VS model is prone too when inverter driven.

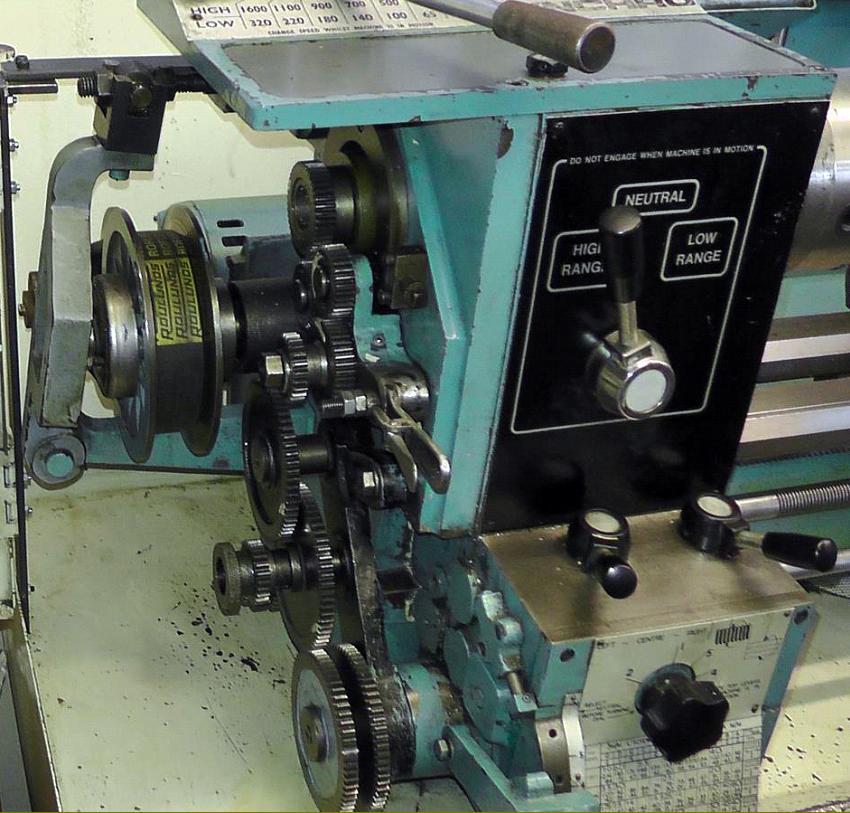

Actual spindle speeds are not what Denford claim them to be. The variable-speed pulley set up appears to be exactly in accordance with the factory drawings and there is no evidence that they have been 'messed with', but the resulting speeds differ from those stated on the machine plate which are 65, 100, 140, 180, 220 and 320 in low range and 380, 500, 700, 900, 1100 and 1600 in range. Even these differ from the Denford literature which claims 70-260 in low and 400 -1600 in high. Given a back gear ratio of 5.09-1, and taking the lowest speed as 70, which is the lowest I can get, then the lowest speed in high range must be 356, which doesn't correspond with either of the Denford figures. The best I can do, from a starting point of 70, is 70, 90, 120, 145, 175 and 225 in low range and 360, 460, 550, 745, 900 and 1150 in high range. My rev counter flickers a little, so it may be a few revs either side of this, but not enough to account for the difference. Yes its possible to get a higher top speed by adjusting the pulleys, but at the expense of raising the lowest speed correspondingly. Anyway, 70 - 1150 is fine for what I do, and when eventually my old inverter, which doesn't have speed control, gives up the ghost, it will be replaced by a modern one which does, so the whole thing becomes academic. The saddle has power sliding and cross feed, and the engagement/disengagement is very light even under load. A surprising omission for a machine built around 1980 is that the saddle is not fitted with 'wipers' to keep the dirt out of the slides, and this appears to have been common across the whole Denford range.

Like late model TDS1 lathe, the Synchro is fitted with a safety auto trip on the longitudinal feeds, and this seems to work well, though Denford emphasise that it's only a safety device and not to be used as an auto-stop mechanism during regular work. For accurate working to a shoulder an adjustable carriage stop is used. Curiously, according to the Denford Forum for all Viceroy lathes, some TDS 1 machines had an auto knock off on screwcutting as well, but as this worked by means of a rack mechanism opening the half nuts, and taking about 1/2" of travel to do so, this must only have been intended as a safety device, and not as Denford's equivalent of the Ainjest, for rapid thread cutting up to a shoulder. As yet I haven't heard of a 280 with this feature, but as the aprons appear identical, I can see no reason why not.

I like my 280 very much, and consider it to be solid and well built, and I can't understand why they don't seem as popular in the second-hand marketplace as the equivalent Boxford lathes, let alone the fabled Myford 254 or 280. My Denford, with a full set of chucks, faceplate, catchplate long slotted cross slide and both steadies, from a well known commercial dealer, delivered to my door, was less than 1/4 of the price the Myfords seem to fetch, if and when they ever come on the market..

|

|