|

Viceroy-branded products for wood-working shops included a variety of lathes, the Sharpedge T.D.S. 12/16 and T.D.S. 12/10 edge-tool sharpening machines, the T.D.S. 25 Models D and B disc and belt-sanding machines, bench and pillar drills listed as the Types T.D.S.22 and T.D.S. 23 and a drill-sharpening machine, the T.D.S.29.

With a neat and safely-enclosed drive system, Viceroy wood lathes were especially popular with educational establishments who, as a further safety precaution, often specified a motor less powerful than the 0.75 h.p. 3-phase unit recommended for commercial use. If you buy one of these lathes for home use (their compact dimensions in relation to their strength make them particularly popular in this role) and convert it to single-phase operation, a 1 h.p. motor will be found adequately powerful for most purposes.

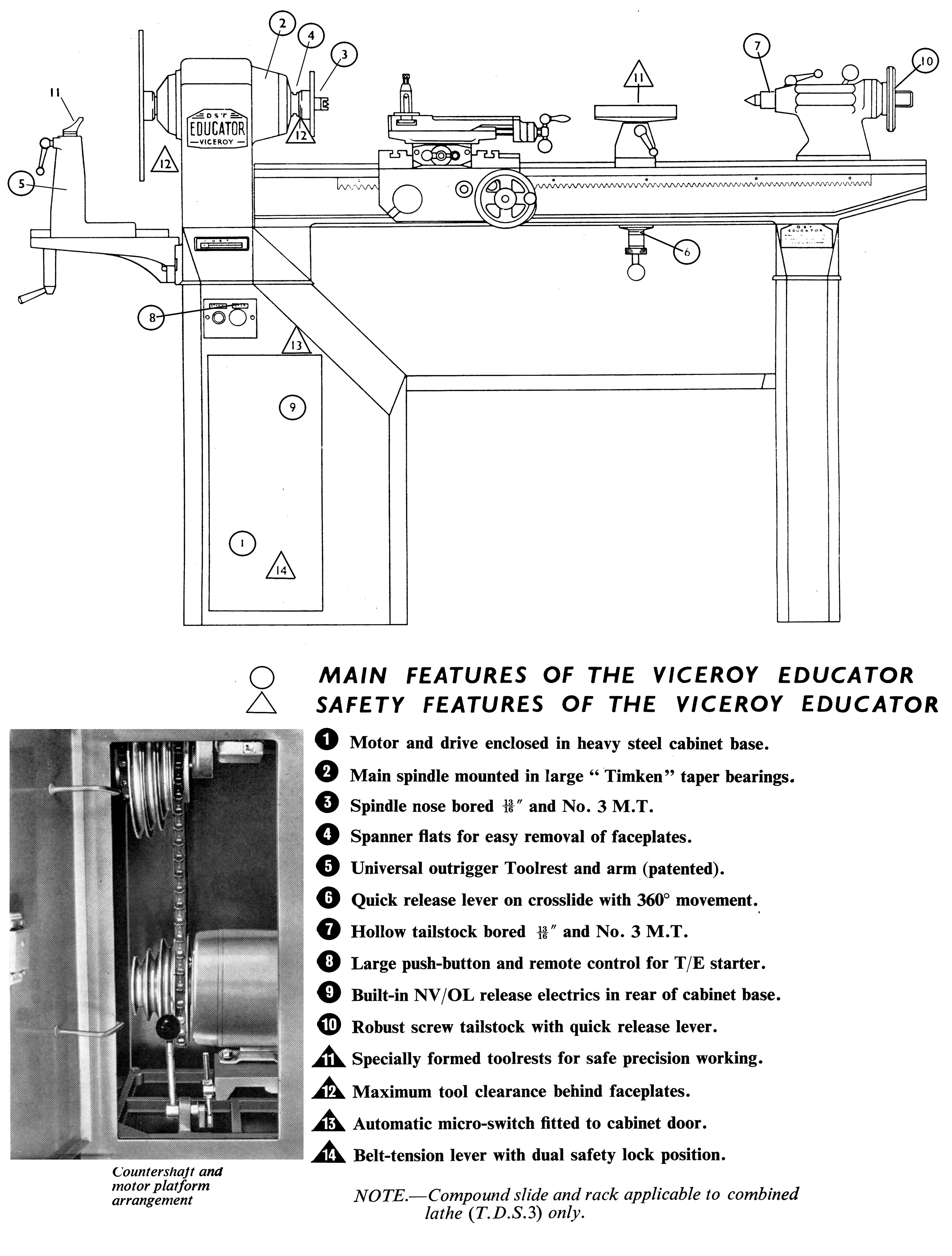

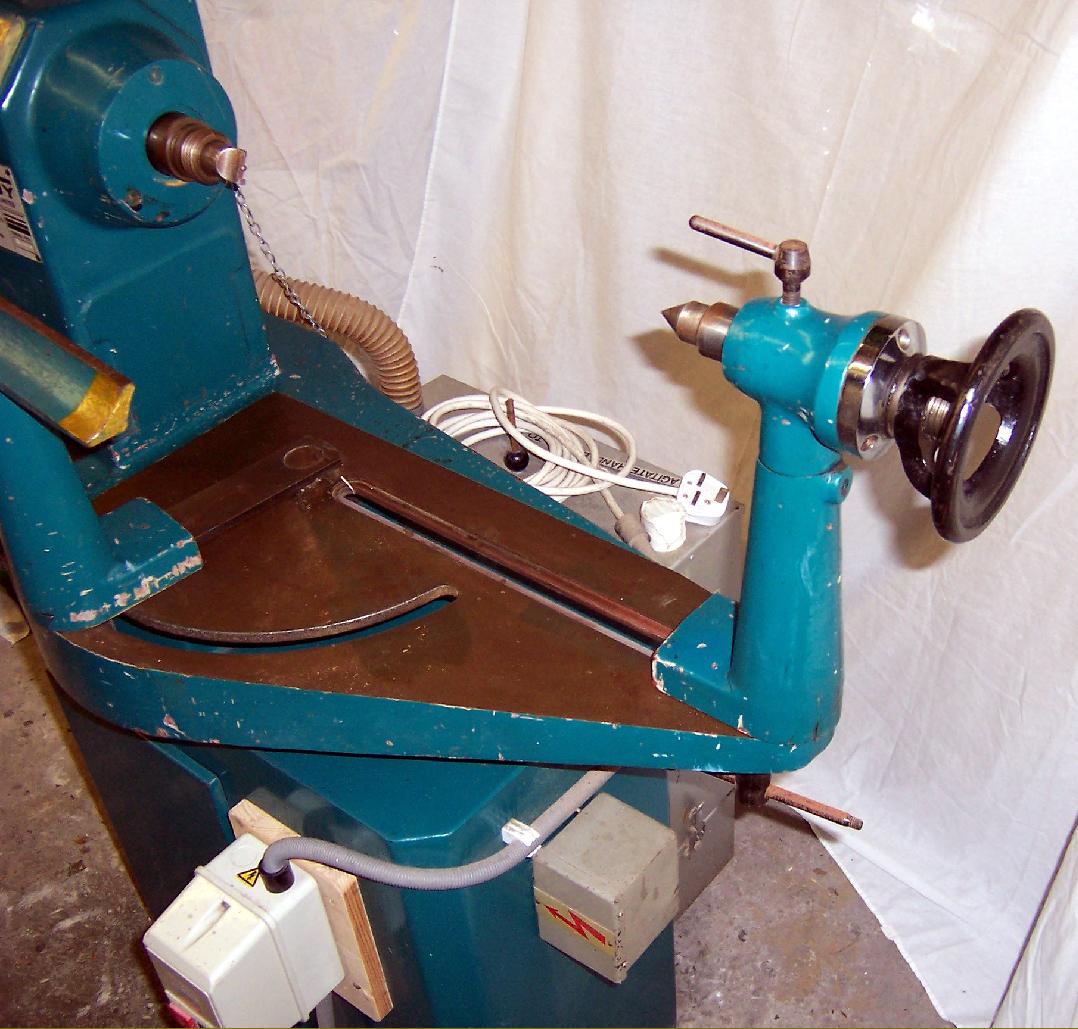

A number of different models were offered dedicated to just wood turning, all based on the same headstock cabinet leg in welded steel plate and its enclosed drive system (dual-purpose lathes of a different design were also listed, shown here). Although early versions often carried badges proclaiming "Educator", the basic wood lathe was listed as Type TDS 6W.L., this having a heavy bed in cast iron with the separate headstock and tailstock-end support plinths joined by a useful if narrow tool tray. Two different beds were used - the standard type being a simple flat-topped design to take the ordinary tool rest with another having a V-shaped way at the front and a flat at the back. This latter arrangement was intended to take the (rarely-found) rack-driven carriage assembly intended for light-duty metal turning, the Model type being the T.D.S.3, a lathe that also carried the name "Educator". On all models, the centre height was 5.125 inches (130 mm), the distance between centres 36 inches (914 mm) with a very large diameter bowl-turning attachment provided as part of the regular equipment. For dedicated bowl turning the makers offered the Type T.D.S. 6B.T. this being available with either a single tool rest to the right of the spindle, or one to the left as well when the configuration was referred to as the T.D.S. 6B.T.D. Both sides were arranged to turn the same maximum diameter as the bowl-turning unit on the standard lathe. Also offered was a short-bed lathe for between centres work, the T.D.S. 6S.B. - a lathe usually found with the end-mounted bowl-turning attachment.

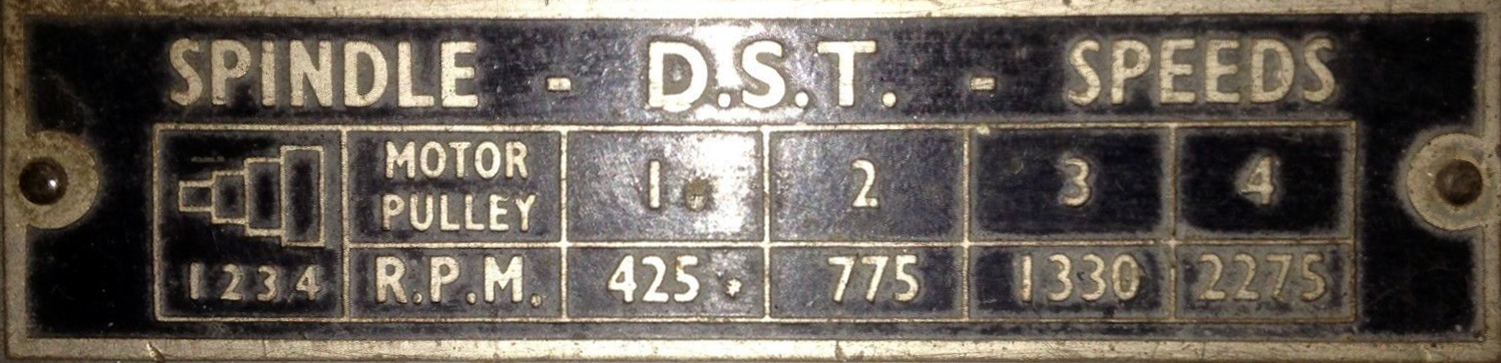

On all the mentioned models the 3/4 (or optionally I,5 h.p.) 1425 r.p.m. single or 3-phase motor sat in the base of the stand with drive to a ball-race countershaft by an "A" section V-belt - electrical control being by a no-volt safety-release starter. The motor was mounted on a hinged plate and could be set in the loose or drive position by an "over-centre" lever, speed changes being made by opening a door equipped with a safety micro switch that cut the power - though many educational users, just to be safe, secured the door with a padlock or other device. Drive to the No. 3 Morse taper spindle (that ran in either Timken taper roller-bearings or deep-groove, grease-packed, sealed-for-life ball races) was by a Brammer link belt - today replaced by the easier-to-fit T-link type. The spindle - fitted with a handy lock to ease changes of nose fittings - carried a 1.5-inch diameter by 8 t.p.i. right-hand thread to the right and, to the left for bowl turning, a 1.25-inch by 9 t.p.i. left-hand thread. An interesting point - and one usually unappreciated - was the use of a tapered "reach forward" housing to hold the front bearing - the design allowing the user to reach in and turn from behind when using a small faceplate. When driven by the standard-fit motor, the four speeds provided were 425, 775, 1330 and 2275 r.p.m. - a range just about wide enough to cope with both bowl and between-centres turning though five (or a 2-speed drive from the motor to countershaft) with a higher top speed would have been better for dealing with very small diameters. Very occasionally a T.D.S 6W.L. is found fitted with a speed-reducing backgear assembly, the speeds, in this case, being somewhat reduced to 25. 110, 175, 250, 400, 570, 900 and 1300 r.p.m. - and so far less suitable for woodturning. However, if fitted with the optional rack-driven carriage assembly, it did make a passably good combined wood and metal lathe.

Supplied new with the TDS6 were 5 and 12-inch faceplates, 6-inch and 12-inch T-rests, a soft No. 3 Morse centre and a hard Wood-prong centre for the headstock and, on some versions not equipped with the spindle lock, a 11/2" A.F. spanner to lock the spindle and a grease gun. On most examples of the TDS 6W.L. the tailstock-end bed support was arranged with a hinge-open door that gave access to a small but useful turning-tool storage cabinet.

A comprehensive range of accessories was offered including backgear for slow speeds, a rack-operated saddle and screw-feed compound slide rest to convert the machine for precision wood or light-duty metal turning; a dust-extraction unit that could be fitted to the back of a lathe's stand; left and right-hand curved tool rests for bowl turning; a 300 mm sanding disc; a200 mm faceplate; a combined 74 mm faceplate and screw chuck; a dowel collet chuck; cup chuck; 100 or 125 mm self-centring 3-jaw chucks; tailstock drill chuck; tailstock rotating centre; tailstock Morse taper mounted V-pad; a plain drill pad; heavy-duty hollow rotating centre; a quick-action lever-operated conversion for the tailstock to permit deep hole boring; a long-hole auger drill; cup and fork centres; a screw-on spindle nose "false nose" spindle to take polishing mops; a screw-on 12 mm capacity key-operated drill chuck; a tilting sanding table with mitre fence; low-volt lighting; an extra-long 750 mm tool rest; sets of tuning tools and a "combination coil-grip chuck" of a design that appears not to have been over popular...

Finished in a blue-grey oil-resistant paint the T.D.S. 6W.L weighed 476 lbs (228 kg) when fully equipped or, as a dedicated bowl-turning or short-bed lathe between 275 and 350 lbs, all models were heavily built to survive the rigours of attention from the boys of Form 1VB.

The ideal Viceroy wood-turning lathe? The writer came across one T.D.S. 6W.L with the rack-driven carriage feed and compound slide rest, sanding table, a polishing set-up, a three-phase motor controlled by a variable-speed 1-phase to 3-phase inverter that gave a top speed of 3500 r.p.m. and, at floor level, a second heavy steel tray joining the headstock and tailstock-end plinths on which the owner had parked four 56 lb weights of the type once commonly used by coal-delivery men.

An interesting modification of the Viceroy T.D.S. 6W.L was the treadle-powered O.T. Larvic, a lathe intended for use in building up both the muscle strength and dexterity of people with limb and other serious injuries - "O.T." standing for occupational therapy. The lathe, designed and developed by Mr. John Large with help from Vallis of Denford, had a long production run and was eventually to be offered in Mk. 1, Mk. 2 and (possibly) Mk. 3 versions. A detailed description can be found here..

|

|