|

Home Machine Tool Archive Machine-tools Sale & Wanted Vertical Milling Machine Riva Home Page Riva U.2/O.2 & V.2 Riva U.6/O.6 Riva U.8/O.8 Riva V.6 Riva U.20/O.20 Riva V.20 O.20-BA Riva U.30/O.30 Riva V.0, V.4, S.G.A. & S.G.M. Accessories An All-models Operation Book is available for Riva Millers |

|

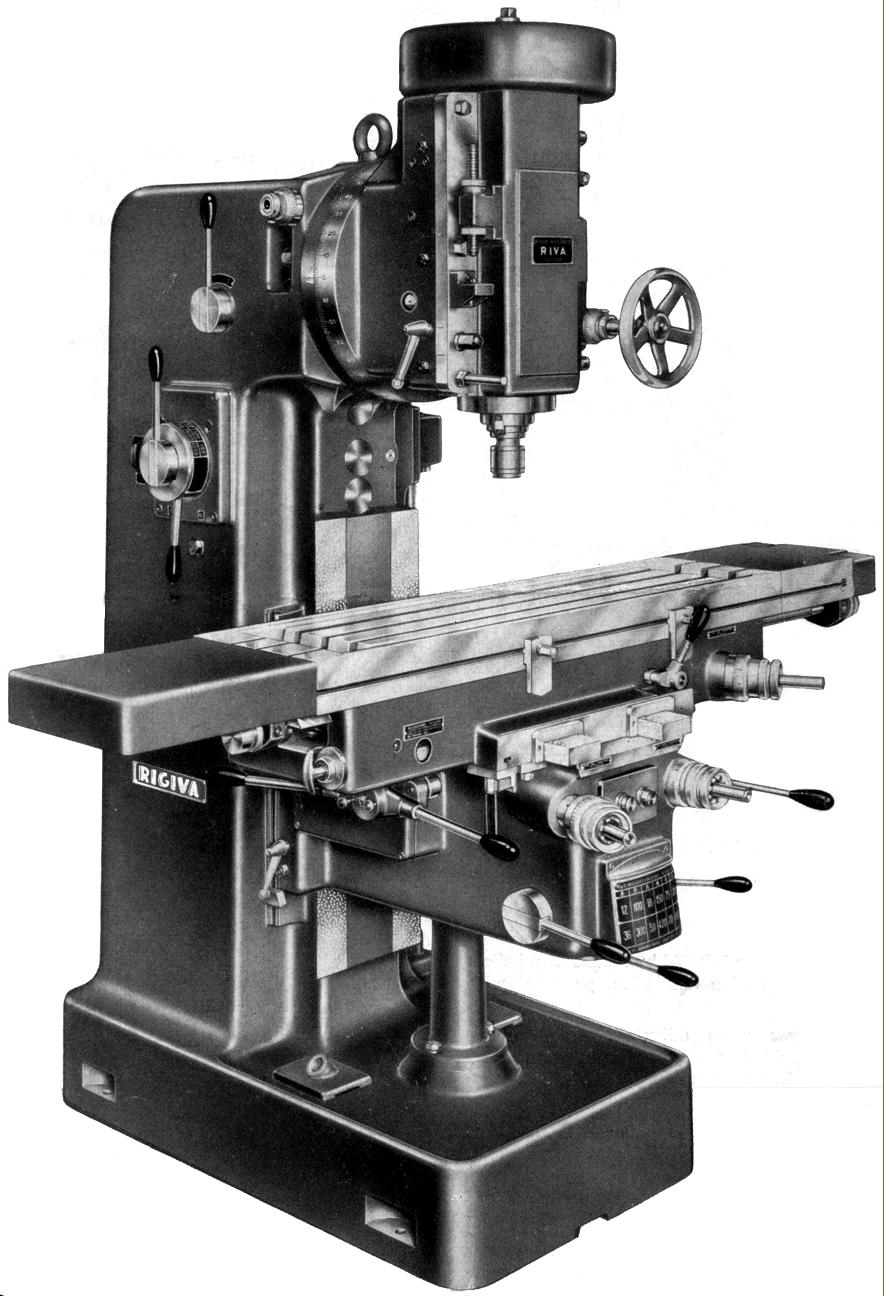

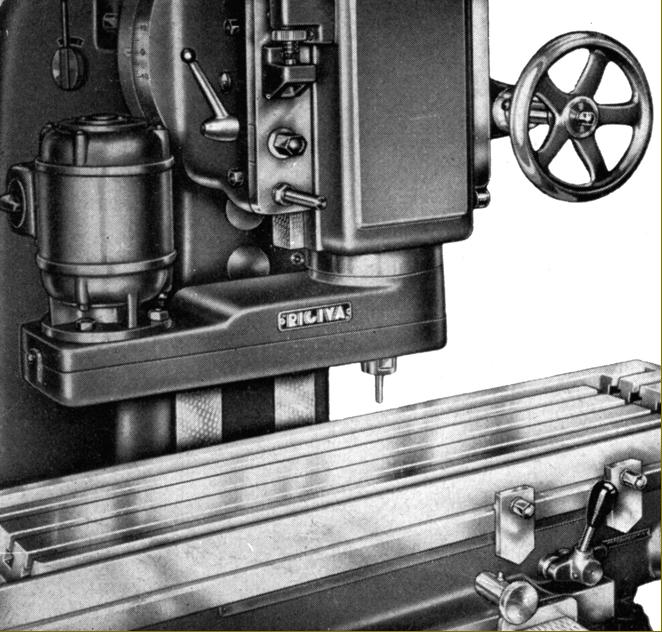

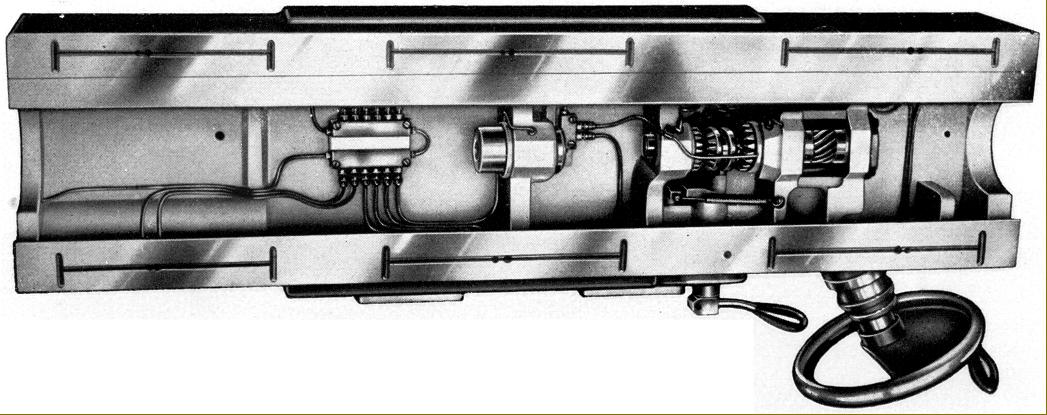

Almost identical, apart from the head assembly, to the Riva U.6 and O.6 Universal and Horizontal types, the V6 was one of a limited range of vertical millers produced by the Company. Built as both a standard model and as the V.6.C with 3-dimensional hydraulic copying, some confusion exists as to the precise dimensions of the tables fitted. However, the hydraulic-copy model of the late 1960s had one 1200 x 300 mm and the standard version 1100 x 270 mm with three 16 mm T-slots on 60 mm spacing and with longitudinal, traverse and vertical movements of 900, 300 and 500 respectively - figures rather more generous than the equivalent horizontal models. Because the table was comparatively long, in order that the operator could stand and observe the cut, the table's longitudinal feed handle was set not at the end, but to the right of the knee where it protruded, at an angle, from the table-support casting. |

|

|

|

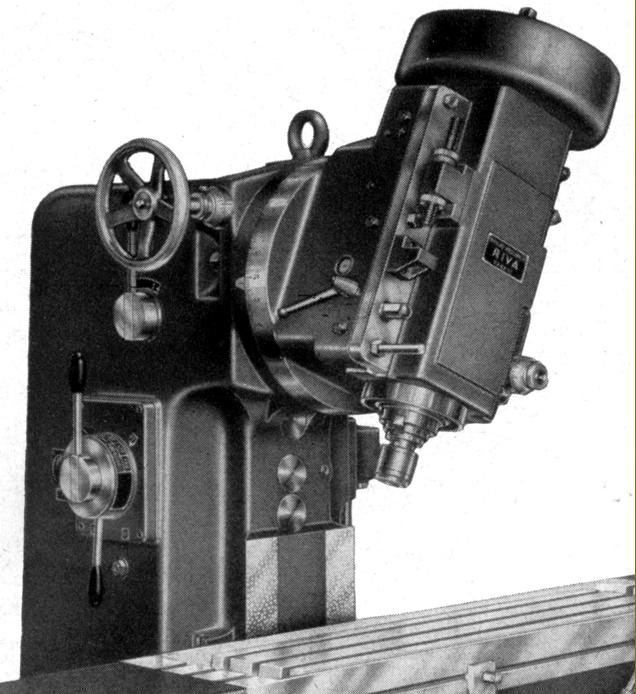

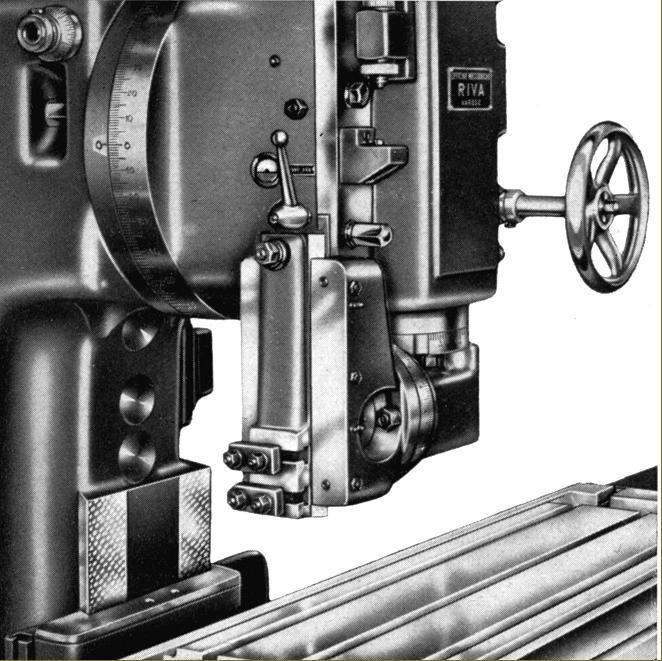

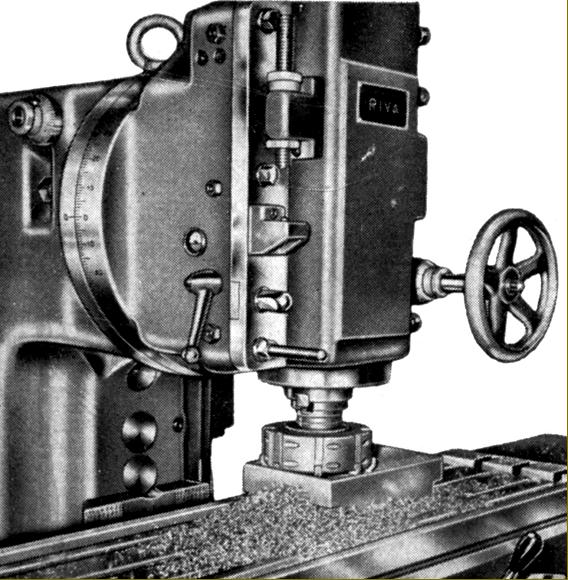

A useful accessory: Vertical Head Extended Projection. This extended 375 to 525 mm - and consisted of a small right-angle gearbox that clamped around the end of the spindle flange with sets of bevel gears to turn the drive through two right-angles. To add to its usefulness', the assembly could be rotated in each plane through a full 360° |

|

|

|

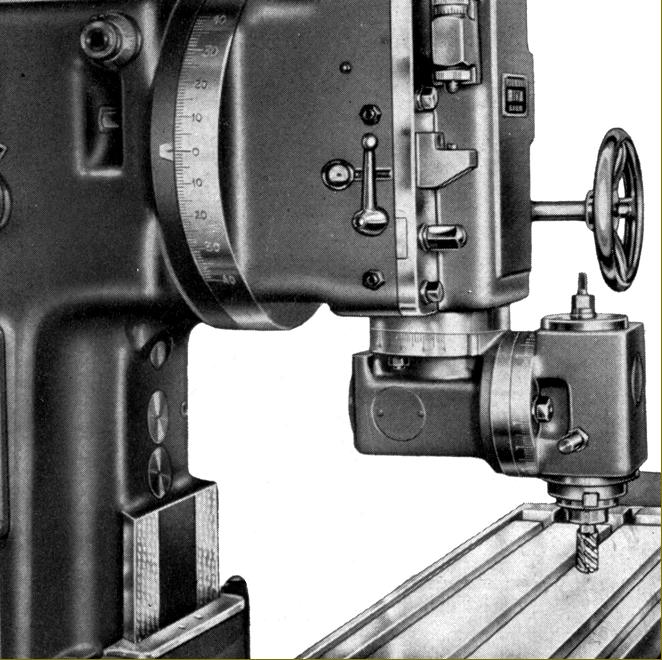

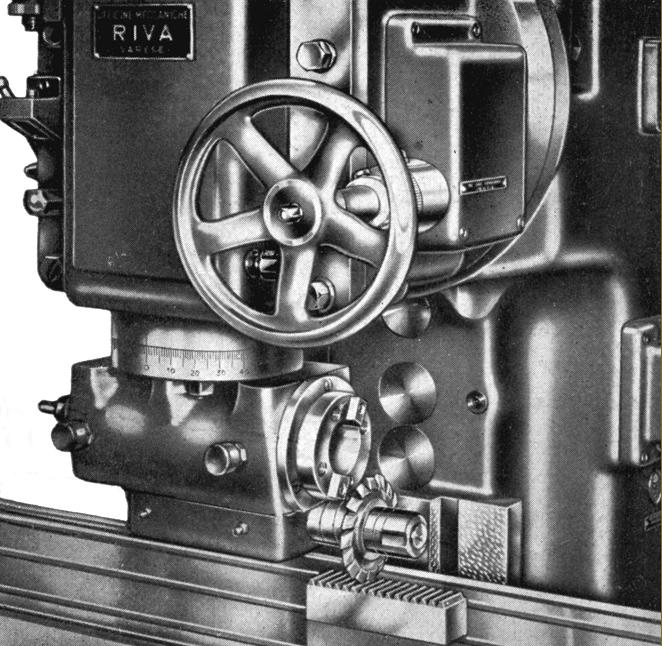

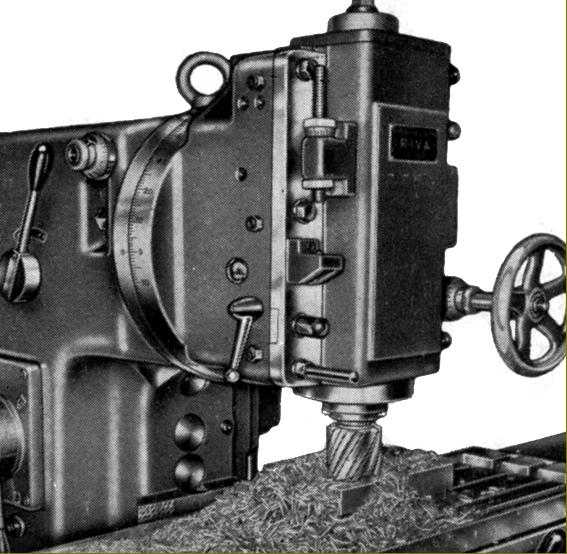

Coxial High-speed Head: an accessory driven by it's own 2-speed, 0.4/0.6 h.p. motor that gave speeds from 2500 to 5000 r.p.m. motor. Obviously intended only for delicate work using very small cutters, this device allowed the miller to be used for such jobs as die sinking and pattern cutting. |

|

|

|

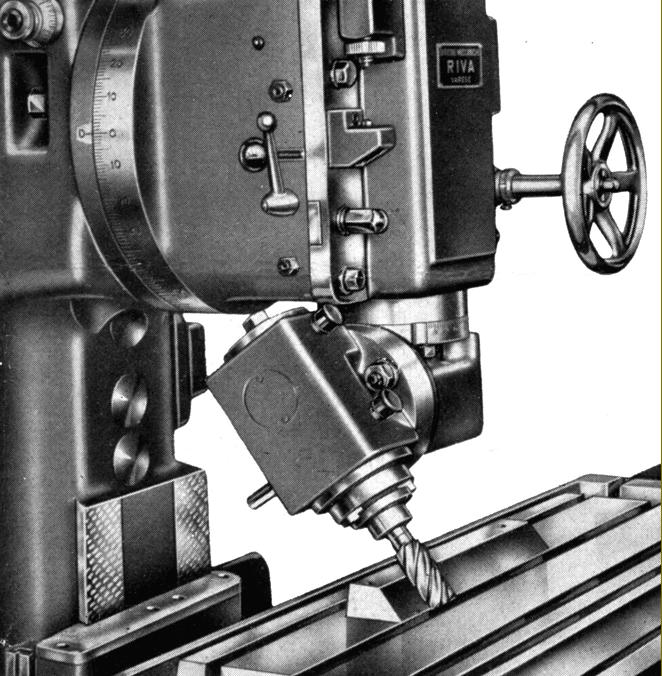

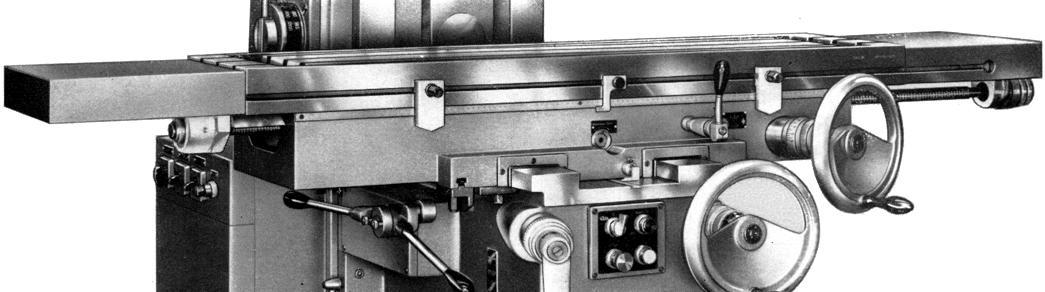

Horizontal milling was cater for by the Horizontal Milling Attachment, a bevel-gear driven accessory carried on the spindle end. A most unusual addition was offered for this unit - a second parallel spindle that bolted to the underside and allowed milling cutters of up to 50 mm diameter to be mounted - the device being intended to mill racks and slots. |

|

|

|

Riva V.6 Riva U.20/O.20 Riva V.20 O.20-BA Riva U.30/O.30 Riva V.0, V.4, S.G.A. & S.G.M. Accessories Vertical Milling Machine Home Machine Tool Archive Machine-tools Sale & Wanted |

||