|

Home Machine Tool Archive Machine-tools Sale & Wanted Milling Machines Riva Home Page Riva U.2/O.2 & V.2 Riva U.6/O.6 Riva U.8/O.8 Riva V.6 Riva U.20/O.20 Riva V.20 O.20-BA Riva U.30/O.30 Riva V.0, V.4, S.G.A. & S.G.M. Accessories An All-models Operation Book is available for Riva Millers |

|

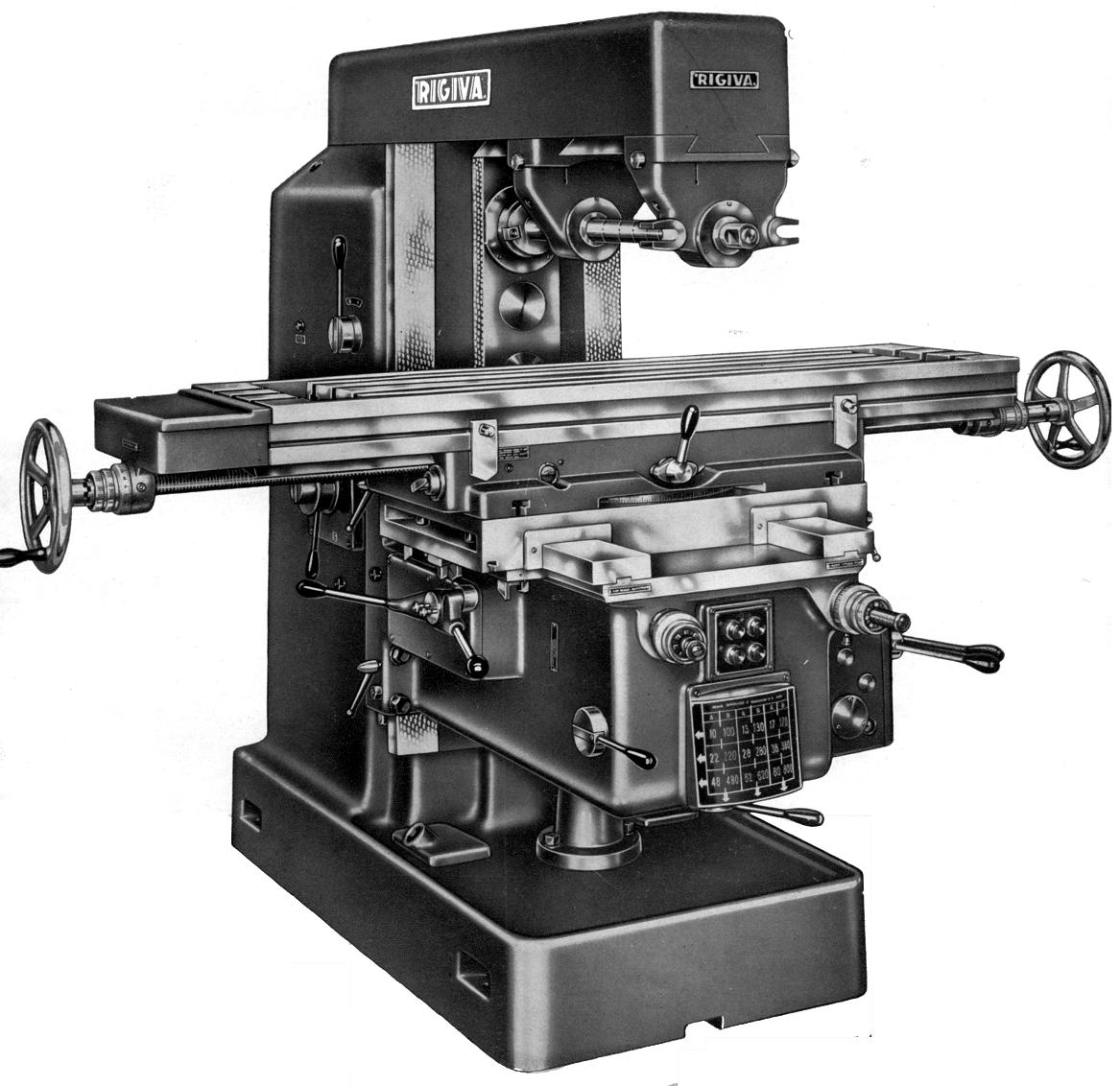

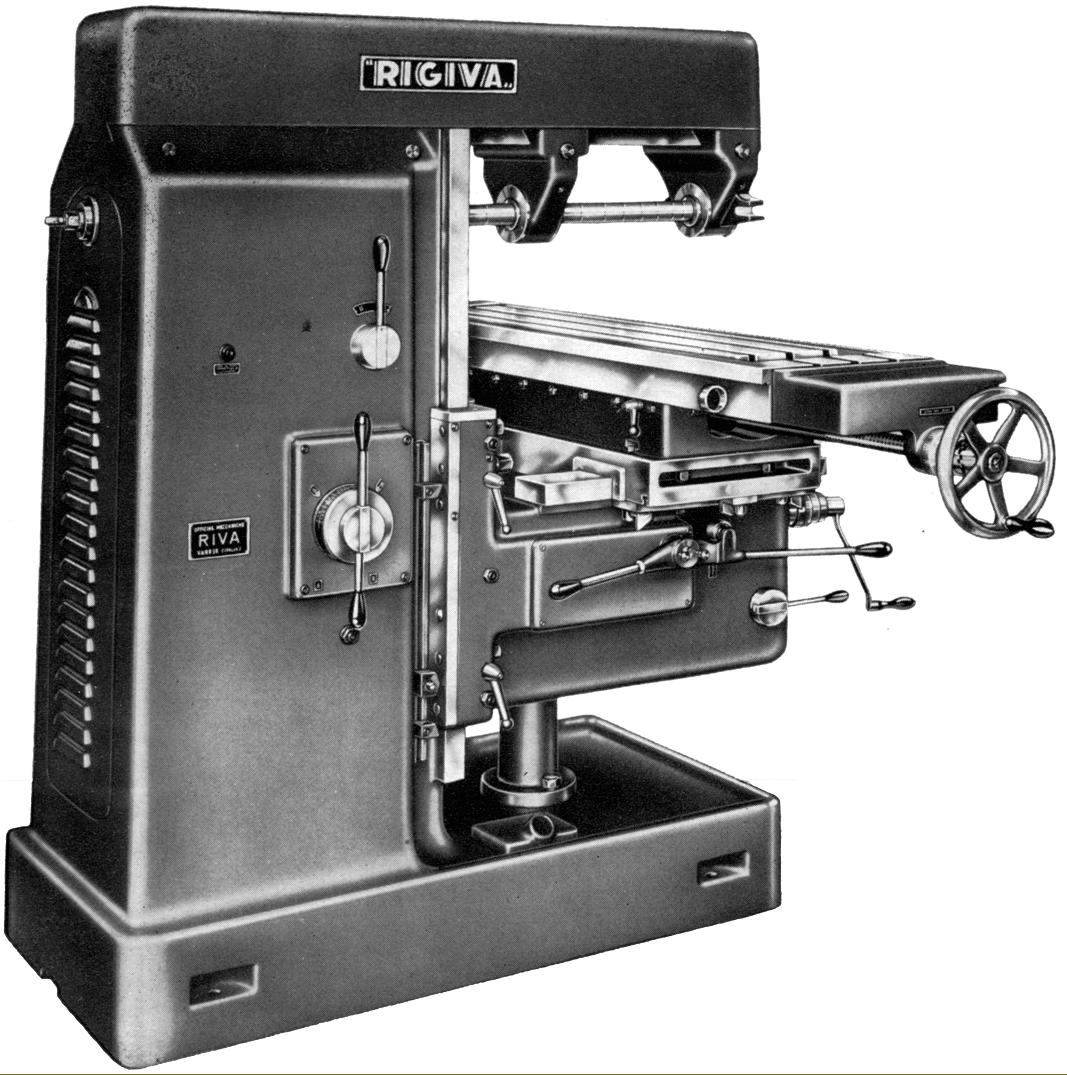

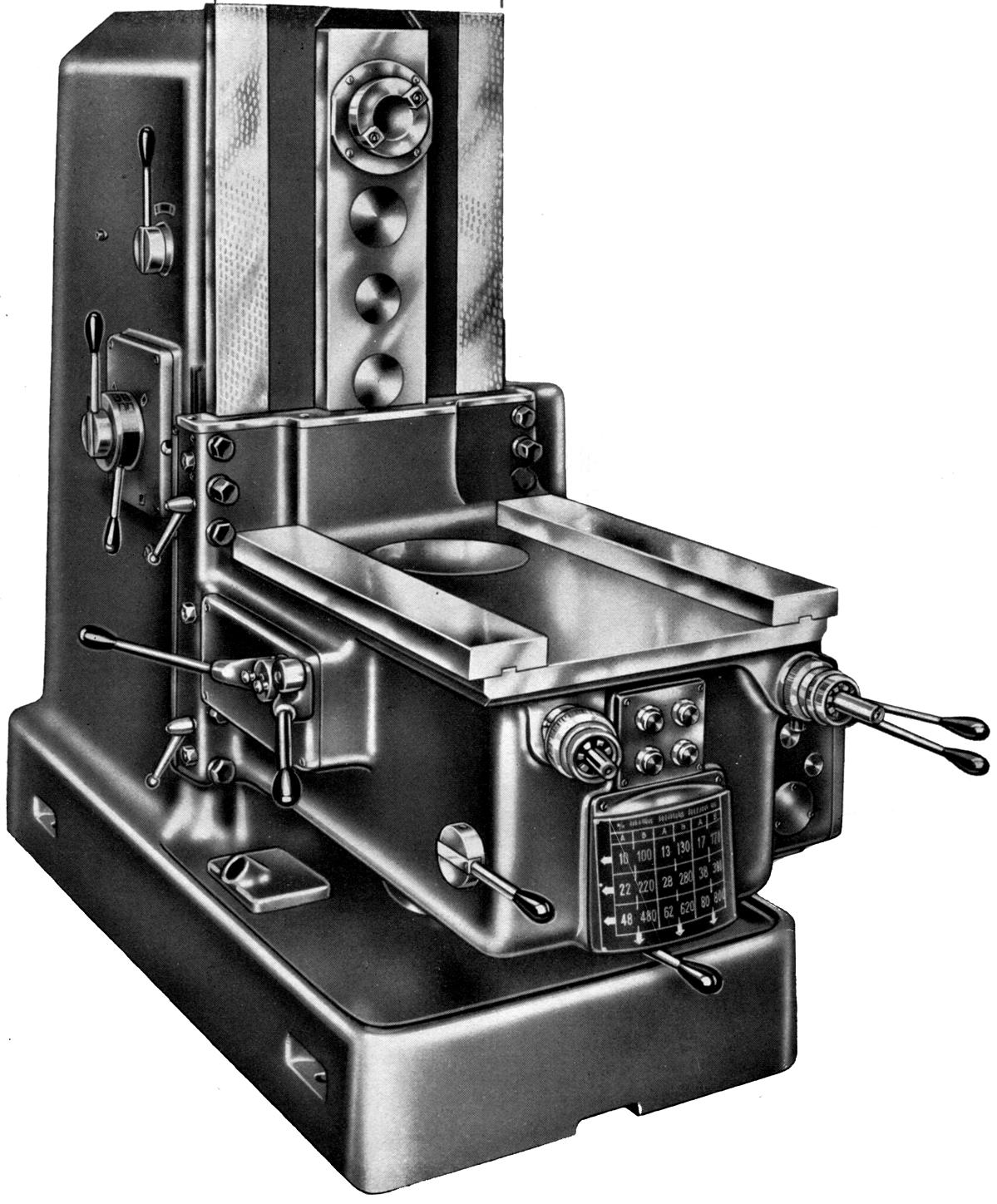

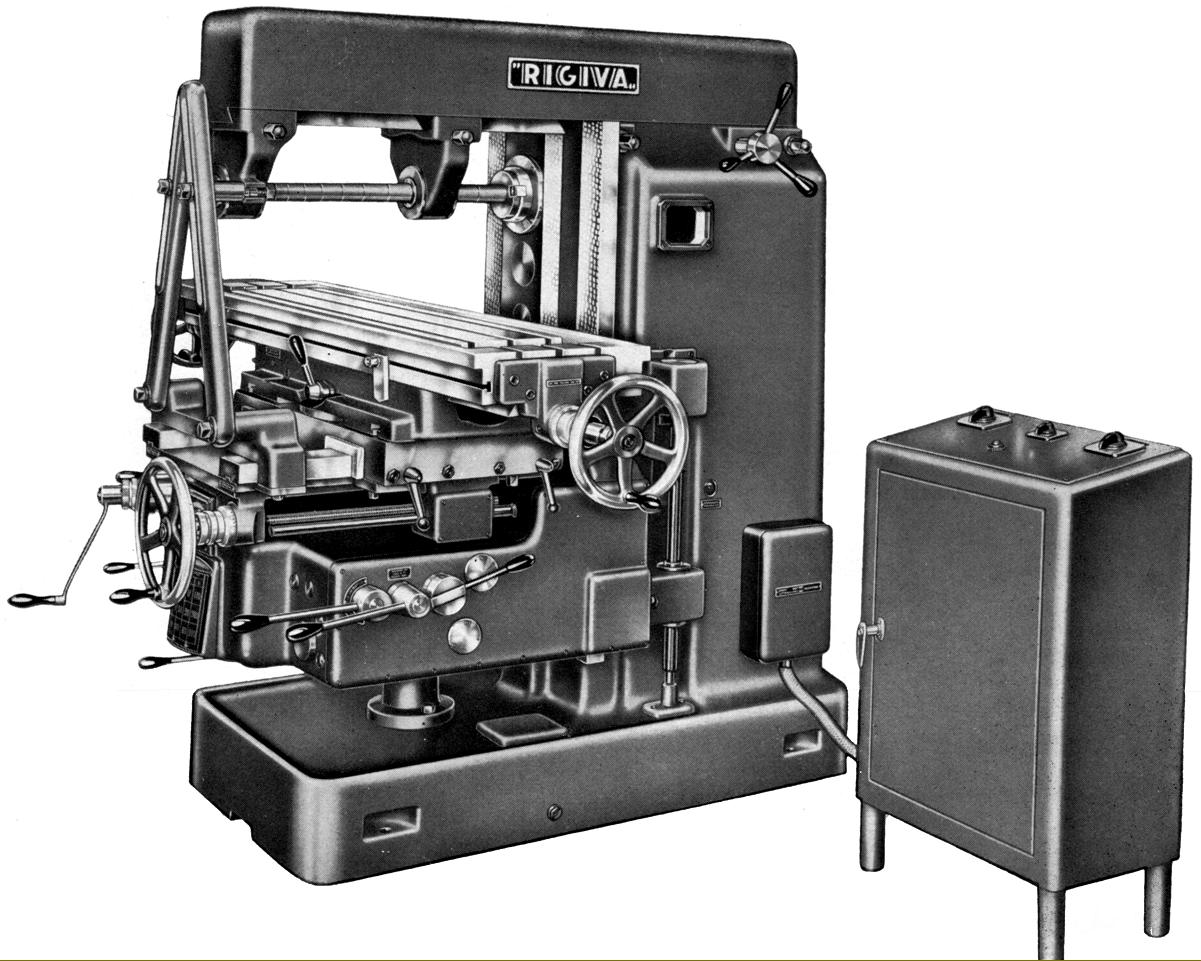

Largest of the Riva "Regiva" type milling machines, the U.30 Universal (with swing table) and the O.30 (a standard horizontal model) were manufactured until the late 1960s. Fitted with a 1600 by 4000 mm table with three T-slots 16 mm wide on 90 mm centres, power feeds were driven by a take-off from the main motor with the longitudinal, traverse and vertical movements being, respectively: 1200, 400 and 480 mm with 18 rates of feed, from 10 to 800 mm/min in both directions horizontally (with rapids at 2000 mm/min) and from 2.5 to 200 mm/min vertically (rapids at 500 mm/min). Unlike the V20 vertical, whose operator could maintain a mostly central position while using the table handwheel that protruding at an angle just to the right of the knee, on the U.30 conventional handwheels were fitted, one at each end. For lubrication, a hand-operated pump was arranged to supply oil via a manifold and a network of pipes to the table and knee ways. |

|

|

|

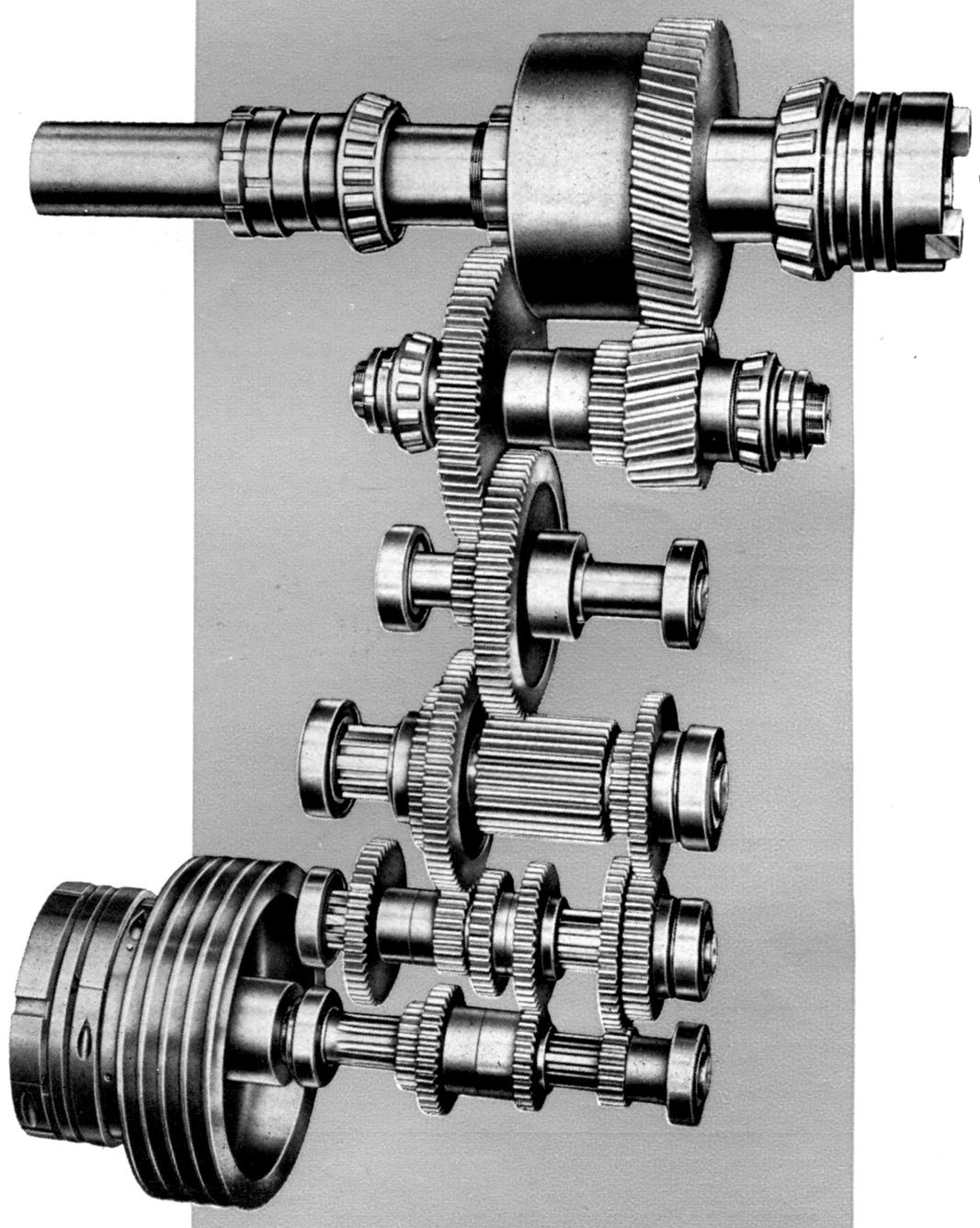

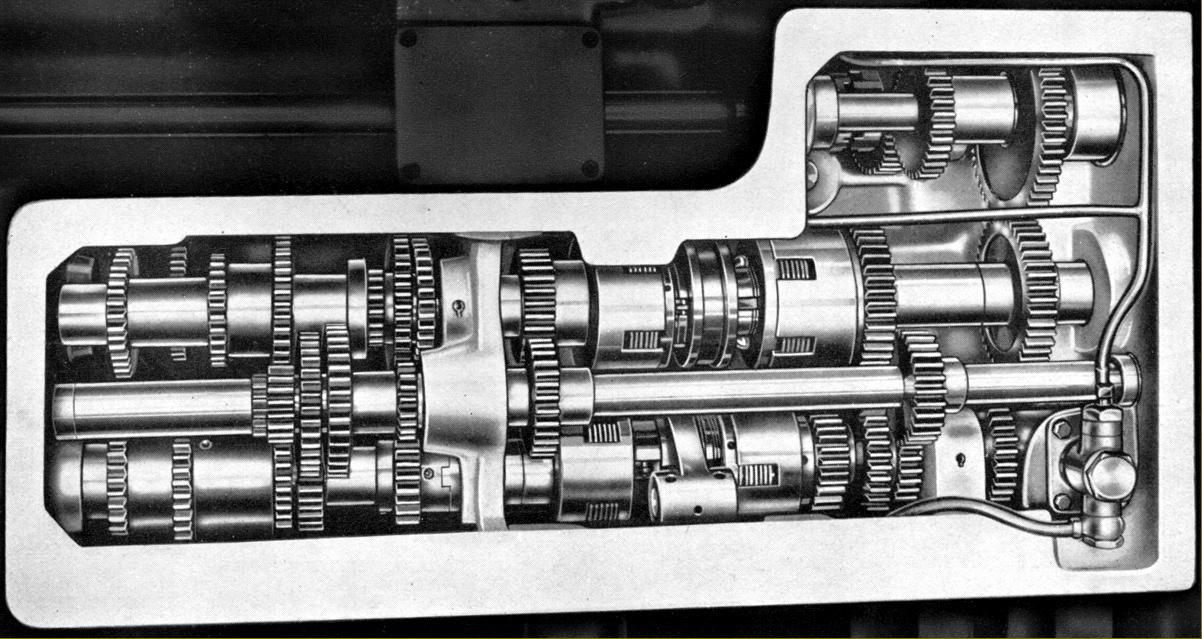

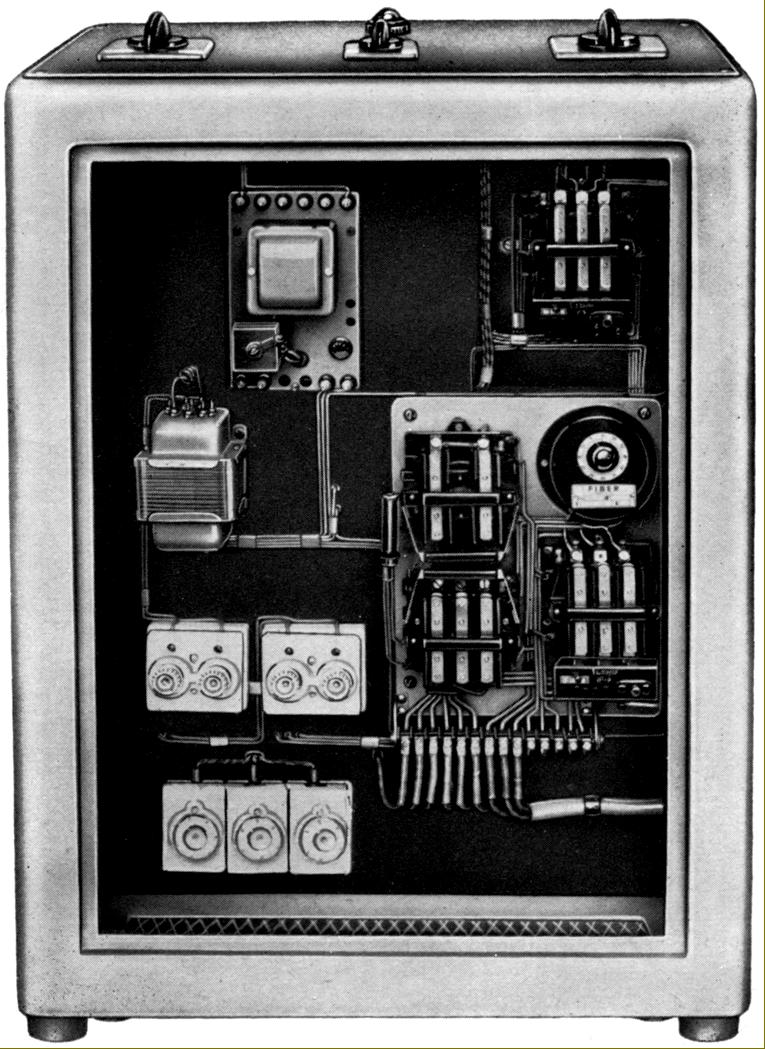

Running in specially selected, high-precision taper roller bearing the spindle incorporated a flywheel immediately behind the main driven (helical) gear. Drive came from an enclosed, based-mounted 10 h.p. motor driving upwards using a 4-step V-belt pulley (with an attached electromagnetic clutch) to a 5-shaft, pressure-lubricated gearbox holding hardened and ground chrome-nickel gears. 12 speeds were provided that spanned 20 to 1000 r.p.m. |

|

|

|

Feeds and rapids were engaged through multi-plate clutches, built into a pressure lubricated gearbox - with hardened and ground gears in chrome-nickel steel - that took up the full depth of the knee's right-hand face. |

|

|

|

|

||

|

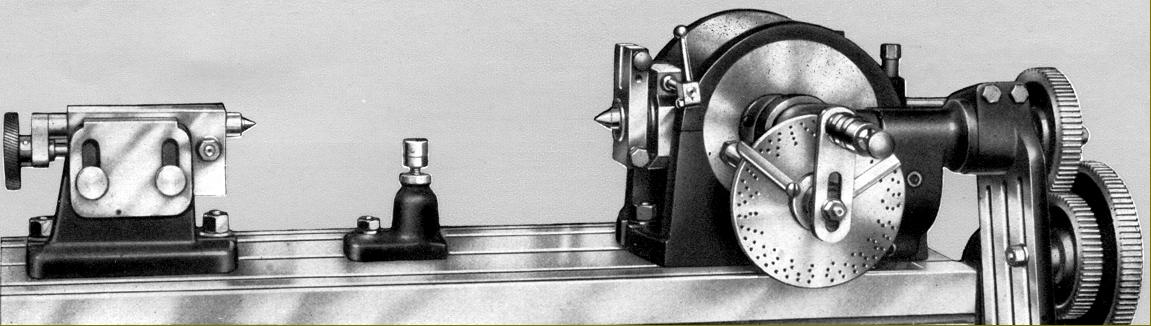

An effective and well-designed 130 mm centre height Universal Dividing and Spiral-milling Head was offered; complete with a tailstock it was driven from gearing at the right-hand end of the table with its spindle revolving in roller bearings. It was sold complete with 2 indexing plates, an adjustable intermediate rest, two centres, a catchplate, an extension arm to carry gears for differential indexing (13 gears were supplied) and a set of ready-reckoner tables for performing divisions - with 2200 already calculated for spiral pitches. |

|

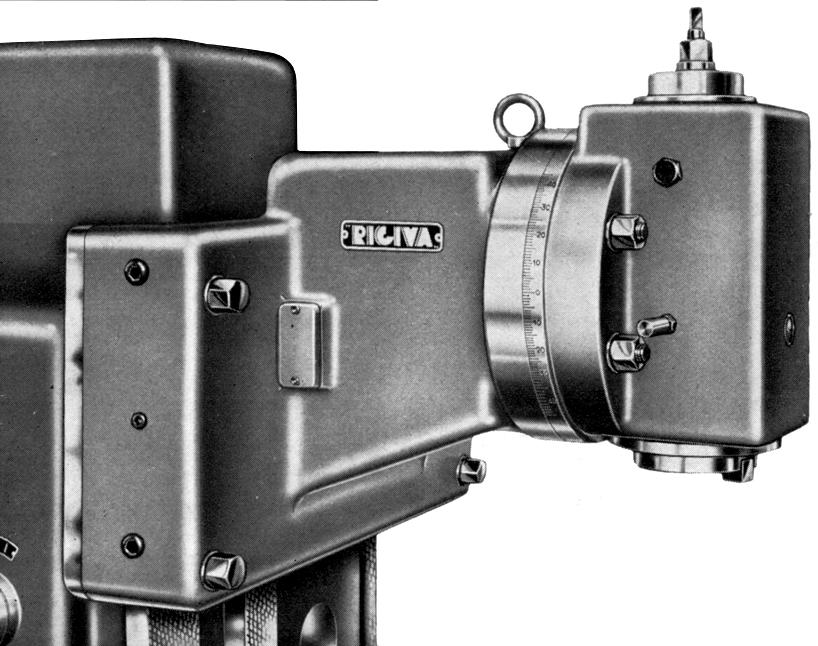

Unlike the smaller Riva vertical millers, for which a wide range of special vertical heads was offered, the buyer of a U.30 was limited to a plain head with a swivel end. Fitted with ISA 70 mm spindle nose to match that on the miller's horizontal spindle, the unit used oil-bath lubrication and taper roller and roller bearings throughout. |

|

Riva V.6 Riva U.20/O.20 Riva V.20 O.20-BA Riva U.30/O.30 Riva V.0, V.4, S.G.A. & S.G.M. Accessories Milling Machines Home Machine Tool Archive Machine-tools Sale & Wanted |

||