|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

Progress Junior Drilling Machines

No.10, No.11, No.12 & No. 12S

Progress Home Page 3A Pillar Drill

Progress 2G & 2GS Drills Progress 0, 1 & 1S Progress 16 &16S

Manuals and catalogues are available for Progress Drills

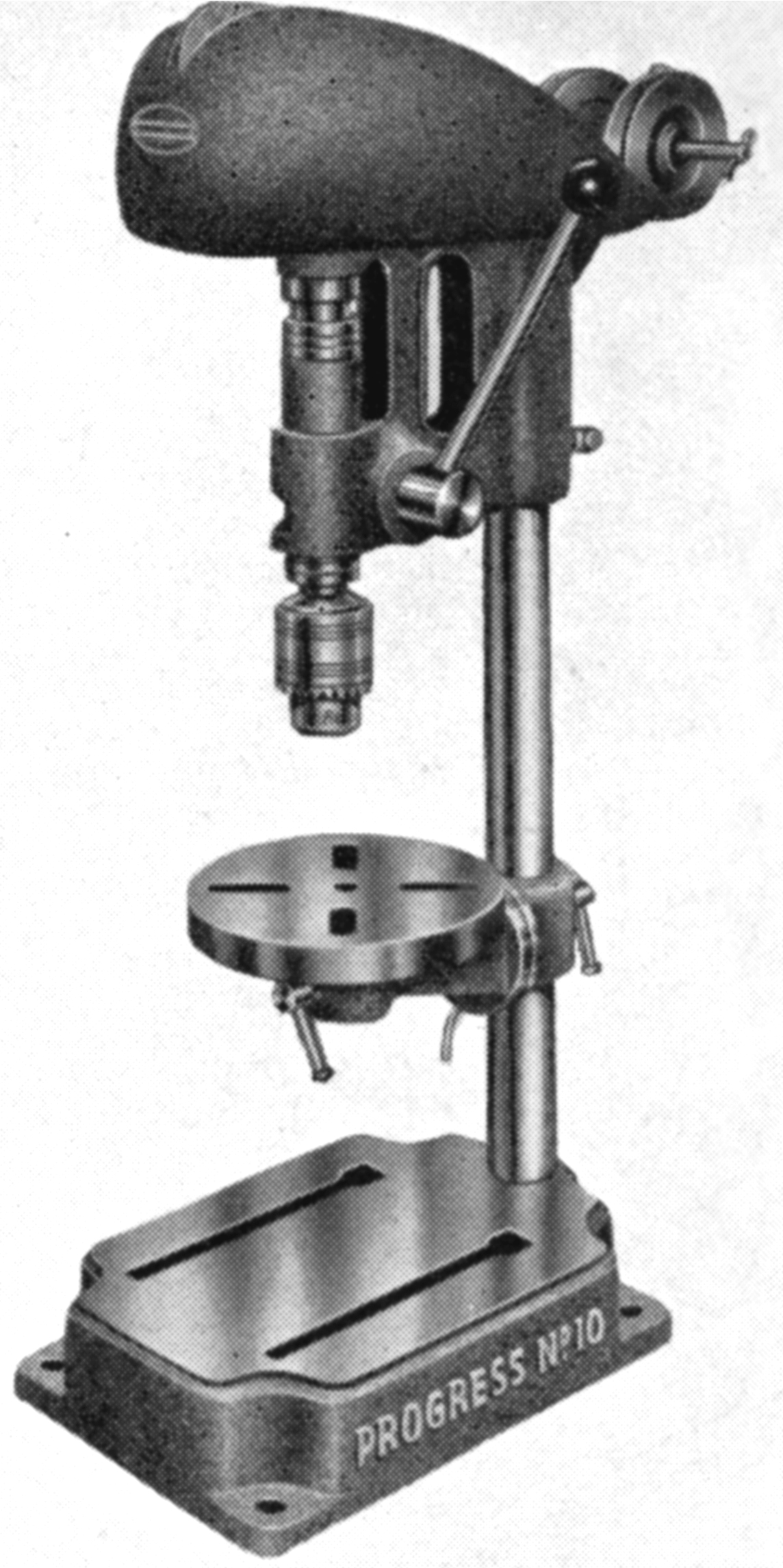

Made in England during the 1950 and 1960s, the little Progress "Junior" drills were made as the models No.10 and No. 11 - both for bench mounting and with a drilling capacity of 3/8" - and the 1/2" No. 12 and 12S, the former for use on a bench and the latter as a floor model. All versions are uncommon and were to be replaced in the early 1970s by the much more modern-looking, but similar-sized Model 16. Each drill in the series was well made and finished, the base model of the range being the No.10, a version that weighed 27 lbs (12 kg) and intended for light use only. Its design reflected an arrangement of parts that went back to the Victorian era, with drive from a separate bench-mounted motor and drive up to the spindle by a small V or round belt that passed over a pair of jockey pulleys carried behind the head. With any convenient fractional h.p. motor mounted on the bench, the drill was marketed as a low-cost alternative to the larger, heavier and expensive Jones & Shipman, Pollard and other makes of high-precision, very high-speed 1/4-inch toolroom types. Competing drills might have included the Bantam by Startrite, the ones named "Junior" by Progress and Kerry, the much smaller WA-CO, the costly Oldak and Apex and very expensive types by the Swiss Aciera and Dixi companies.

Unusually, for what was a prosaic item, the drill was finished in a crackle-black paint and all the small fittings blued using a hot-oil process - this cosmetic embellishment being an effort, presumably, to move it upmarket where the application of such a finish was usually reserved - at the time - for items of high quality.

Carried on a 11/4" (32 mm) tubular column in steel 18.5" (269 mm) high, the head could be swivelled and moved up and down as required. It carried a spindle with a spring-return travel of 2" (50 mm), a Jacobs No. 2 taper on its nose and (at extra cost) a 3/8" (9 mm) capacity drill chuck by Belco. Unfortunately, no adjustable vertical stop-cum-ruler was provided, a basic specification lapse shared with the No. 11.

5.5" (140 mm) in diameter, the table had a ground top surface and - usefully - could be rotated on its vertical axis and tilted 90° in each direction from level; the maximum distance from chuck to table was 47/8" (124 mm) - and to the cast-iron, surface-ground base (with a 61/2" x 7" working area and two T-slots) - 8 1/2".

Progress No. 11

Very similar to the No. 10 - but slightly heavier at 31 lbs (14 kg) and with a 2-inch longer base - the Progress No. 11 had same basic mechanical specification, but with a plate at the rear of the head, supported in the conventional way on two bars, and intended to take a 1400 r.p.m. motor. When fitted with the recommended 4-step pulley - with diameters of 2, 3, 4 and 5 inches - speeds of 420, 1000, 2000 and 3700 r.p.m. were produced. Identically finished to the No. 11, the paint finish was crackle black and all the minor fittings "blued"

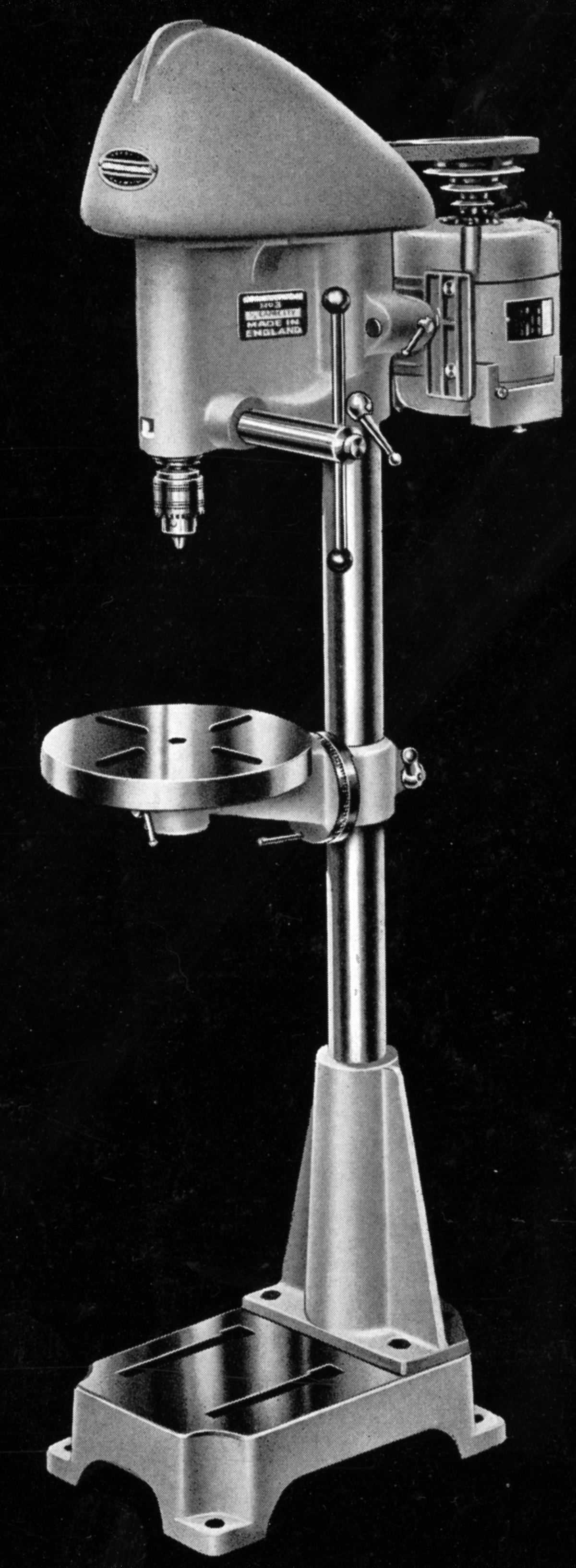

Progress No. 12 and 12S

Very much heavier at 105 lbs (47 kg) for the bench model and 112 lbs (521 kg) for the pillar, the 1/2" capacity Progress No. 12 and 12S used a 2-inch diameter column of solid steel with a ground finish that carried a clamp-on head similar to that on the No. 10 and No. 11 models, but larger in all dimensions. Where the quill passed through at the front, the casting was cut away to form a small "window" through which an engraved ruler scale could be read - though, as on the No. 10 and No. 11, no adjustable drilling depth-stop was provided. Spindle travel was 31/2", with return by a spring and its end machined with a standard Jacobs taper - a 1/2" drill chuck by Belco being listed as an extra.

Rather small for a 1/2" capacity drill, the 91/2" (140 mm) diameter the table was carried on a boss clamped to and adjustable up and down the column. Mounted on a central spigot, the table could be rotated on its vertical axis and canted each side of level through 90° - the maximum distance from its surface ground top to the drill chuck was 91/4" (235 mm) - and from the chuck to the cast-iron, surface-ground base 131/2" on the No. 12 and 38" on the 12S.

Included in the price was a 4-step V-pulley, a 0.5 h.p. motor being extra - its fitting giving a bottom speed of 460 and a highest of 2900 r.p.m.

Some pictures are high resolution and may take time to load

|

|

|

|