|

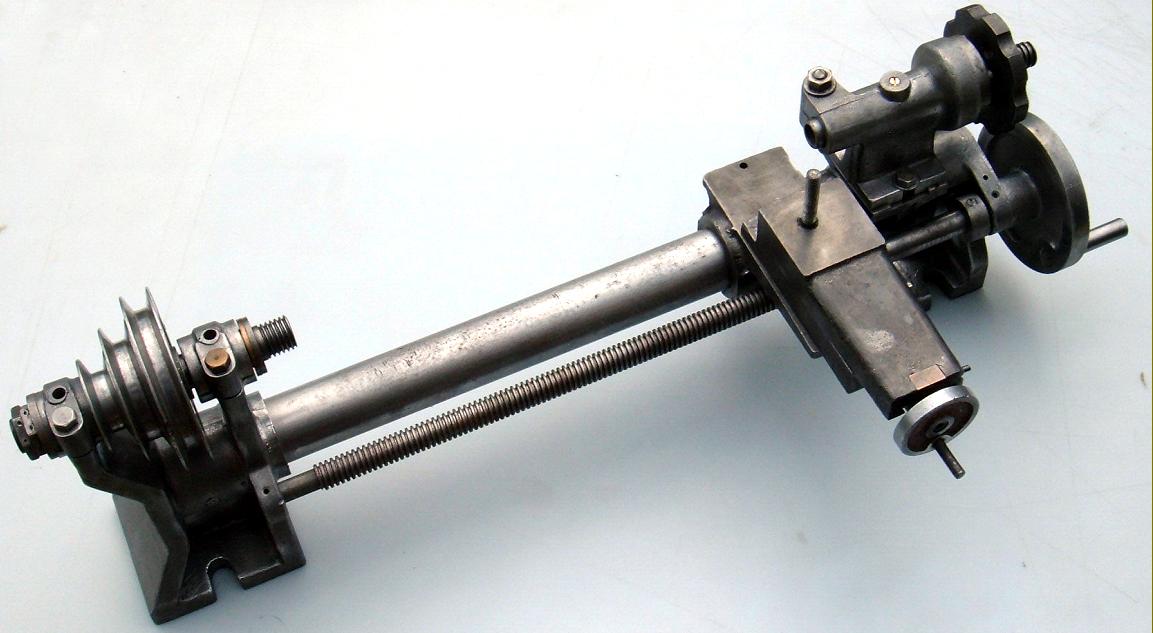

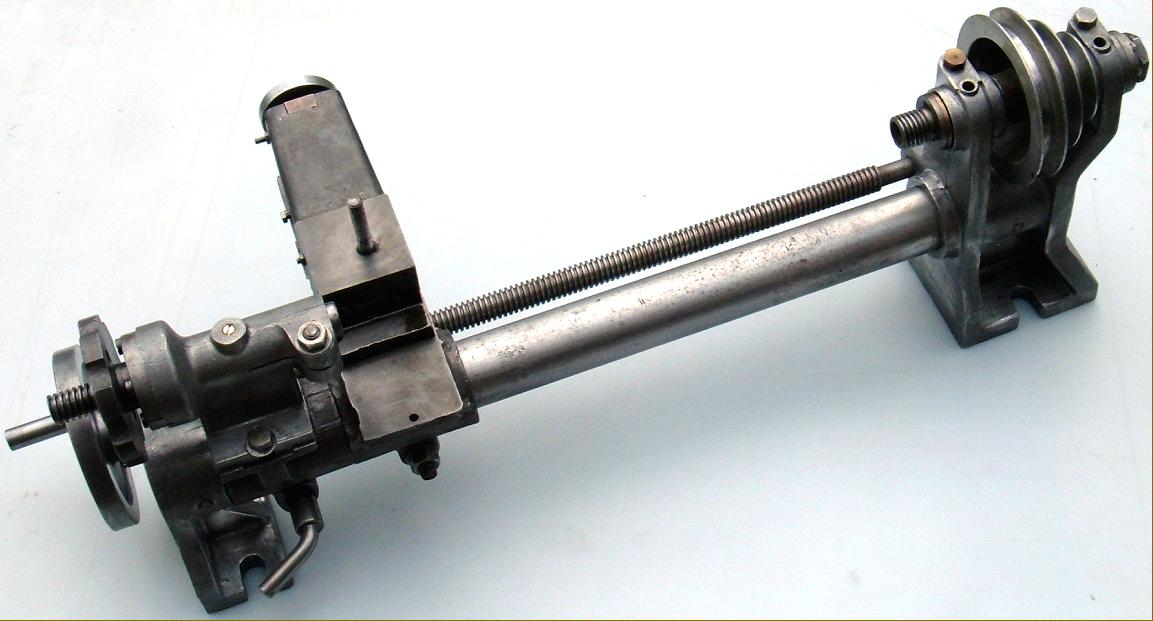

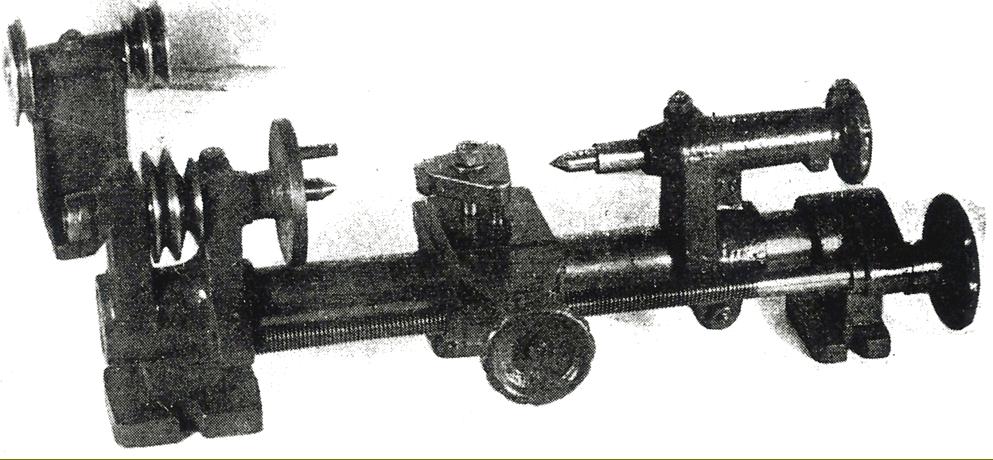

Little advertised (though it was sold by the London department store Gamages) few of this model can have been manufactured and today they are almost unknown with very few appearing to have survived. Two versions were made: the one made for Gamages having a 2-step headstock pulley and the other, most likely sold direct by Portass or supplied to other retailers, having three - with the left-hand bearing support being cantilevered out to create room. The tailstocks also differed with what must have been the cheaper, Gamages version having a one-piece, non-adjustable type while the other was made in two parts with the upper adjustable for the turning of slight tapers.

With feed wheels on tailstock and top slide looking remarkably like those used on other Portass lathes, this plain-turning round-bed machine had a centre height of 113/16" and admitted 61/4" between centres. 25.5" long, 8" height and 10" deep it weighed about 22 lbs.

Constructed in a similar fashion to the once-popular Wade CAV lathe, aluminium castings were used to support the bed - though in this case, instead of a tube, a solid steel bar 1.5-inches in diameter was used machined with a 0.5" wide slot along its underside to guide the carriage.

Running in thin, split bronze bearings contained within the aluminium casting and provided with spring-ball oilers, the 0.75" headstock spindle was bored through 3/8" clearance, carried a 3/4" BSW threaded nose and, like the tailstock, was equipped with a No. 1 Morse taper socket. A brass thrust washer was fitted at the nose end and a pair of opposed locknuts at the other for adjustment. A 3-step aluminium pulley was provided with diameters of 2", 2.875" and 3.75" - this almost certainly being original as only one spot drilling can be found in the spindle for the locking grub screw.

Cast in iron, the lower section of the tailstock wrapped around the bed and was locked in place - very effectively - by a pinch bolt turned by a short cranked lever. The upper section of the tailstock was in aluminium and could be off-set on the base by some 3/8" for taper turning. Driven through its 1.375" of travel by a 5/8" acme-threaded screw, the tailstock quill was 0.625" in diameter and bored through 3/8" clearance with a No. 1 Morse taper nose; clamping was by a pinch-bolt closing down a slot in the casting.

Formed in cast iron, the saddle was clamped to the bed in the same manner as the tailstock - but without a cranked lever, just a nut being provided. To pick up the 5/8" diameter by 11 t.p.i. leadscrew, a bronze nut was located (freely) in a hole on the underside. Supported at both ends (a over-hung construction was common on cheaper lathes) the leadscrew was equipped with a good-sized 4-inch diameter cast-iron handwheel. Although no graduations were provided, a pointer was fitted (though this may have been a modification by a previous owner). The carriage was topped by a single, 360° swivelling tool slide fitted (rather unusually) with brass gib strips on both sides - with that on the left pinned in place and that on the right adjusted by 4 set-screws. The 5 inches of travel were provided by an ordinary (hence cheap) 3/8" BSF feed-screw fitted with an inadequate 17/8" diameter handwheel with a steel dowel handle - but no micrometer graduations..

|

|