Hauser Watchmaker's Lathe

Hauser Bench Precision Lathe Other Hauser Machine Tools

Other Lathes for Watchmakers

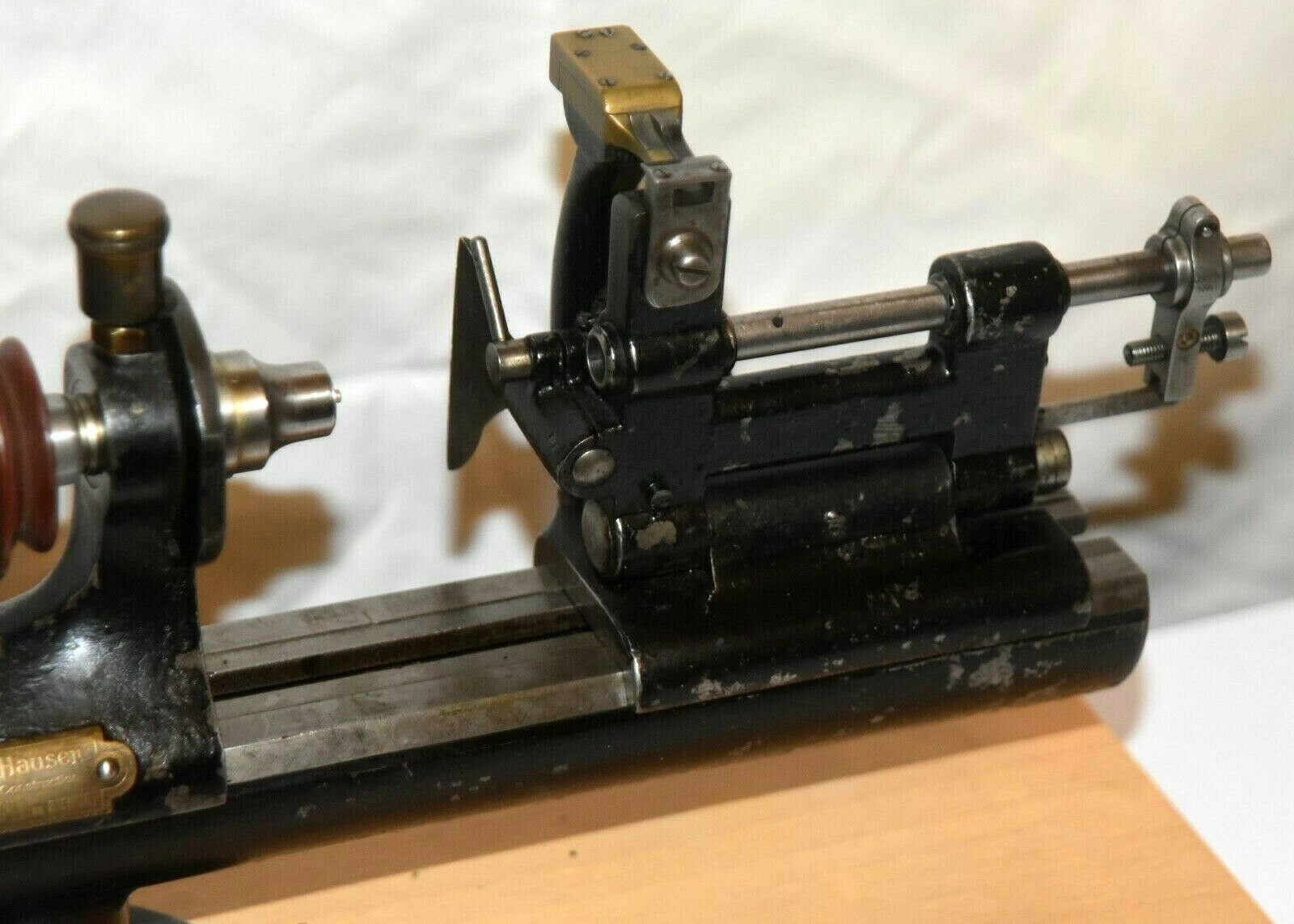

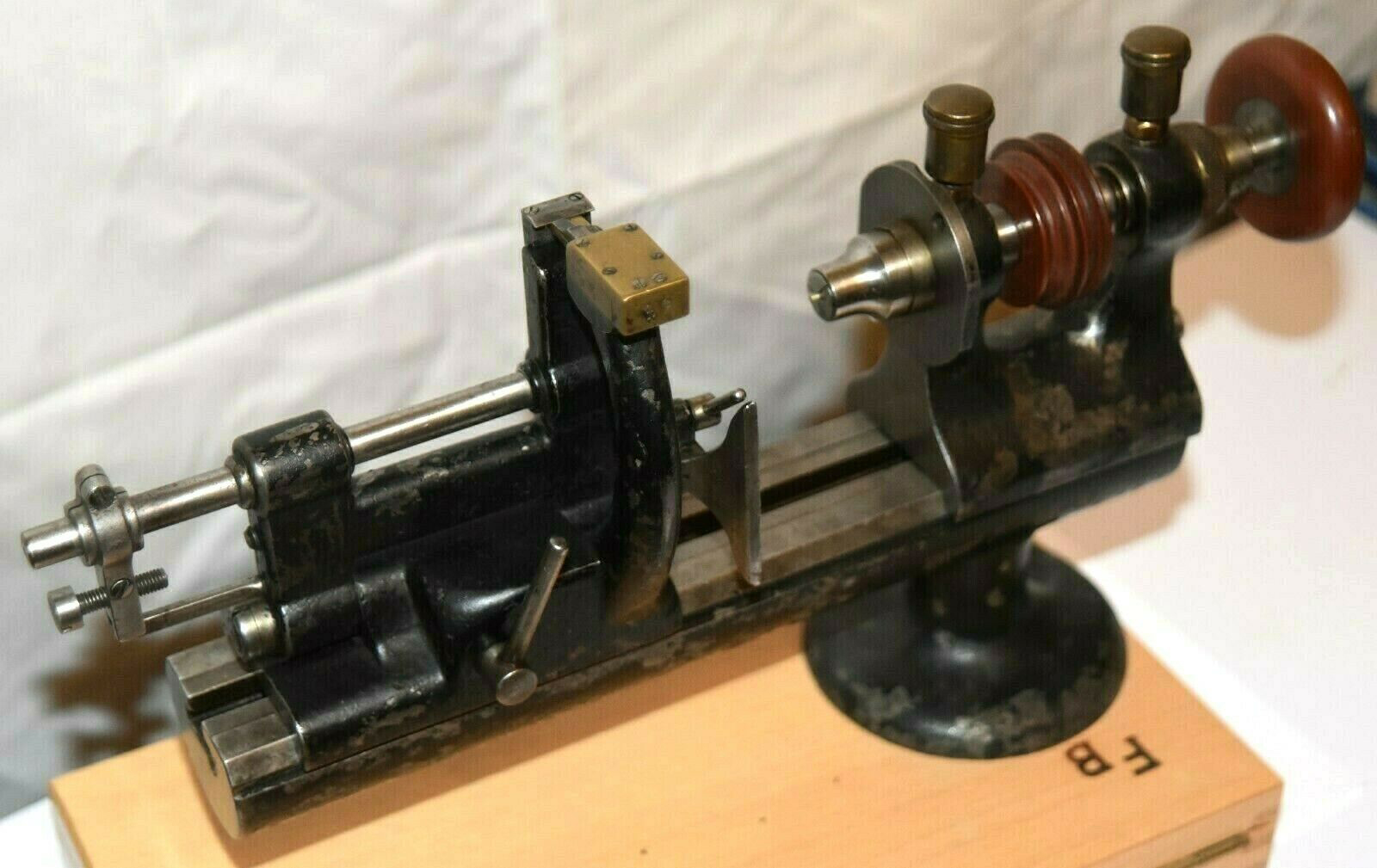

Marked on its brass nameplate "Henri Hauser, Atelier de Construction, Madretsch pres Bienne" the rare Hauser watchmaker's lathe looks remarkable like a heavy-duty WW (Webster Whitcombe) type with its flat-topped bed and bevelled edges. The Hauser appears not to have been for general use but dedicated to "jewelling" work or, possibly, production and special-purpose tasks. The headstock spindle took 8 mm collets and carried, instead of the normal 3 or 4-step kind, a pulley that gave just two speeds - while another clue to heavier-than-normal use was the fitting of wick-feed oilers to the bearings. Most unusually, instead of a normal flip-up, bed-mounted T-rest, this unit was combined with a special tailstock called by various names including "jewelling calliper", "swing" or "jewelling tool" - a fitting common to many makes of watch lathe including the American Stark and Clement. It is, of course, entirely possible that the lathe could have been had with the usual extensive range of watch-lathe accessories, though as the machine is so rare this seems unlikely.

Originally designed for rapidly opening holes in clock plates to receive jewels, the "jewelling calliper" tailstock was a unit was developed to enable it to accurately bore and fine-finish holes to receive parts that might vary slightly in diameter from piece to piece. The aim of the device was to ensure the highest possible precision by holding, between a gauge plate and three gauging fingers at the top of the unit, the actual jewel (or lens, etc.) that was to be fitted into the hole. If the setting instructions were followed, the bored hole would be exactly the same size as the part held by the gauging device and all would fit together perfectly. Instructions for the use of a jewelling tool can be found in this publication.

Jewels are used in watches as they provide an especially hard yet smooth bearing surface that reduces both friction and wear - so improving timekeeping and extending the life of the mechanism. Originally, jewel bearings were made from real and expensive gemstones - diamonds, sapphires or rubies - hence the name "jewel". Their use goes back to 1704 (at a time when the English watch-making business was the finest in the world) and one Nicolas Fatio de Duillier, together with Peter and Jacob Debaufre (watchmakers of Church Street, Soho, London) who were granted a patent for bearings made from pierced rubies. Typically, jewels are found in the fastest moving parts of a watch mechanism, the balance and escapement, but can also be found in the slower-moving gear trains. As rubies were the cheapest option, these were more commonly used especially, when later, they could be made artificially. The story of watchmaking is a fascinating one, especially that concerning the design and building of the first sea-going chronometers by John Harrison, timepieces that revolutionised navigation to an extent never seen before..