|

Founded in 1898 and based originally in Bienne, Switzerland, Hauser was eventually absorbed into the Societe Genevoise (SIP) group and today still forms a part of that now international and greatly-expanded company. Today that organisation - now listed as resident in China - makes a variety of high-quality conventional and CNC controlled machine tools.

Although Hauser always placed a strong emphasis on their high-precision jig boring and jig grinding models, they were also famous for a vast range of specialised equipment and tooling made for watch, clock and mechanical instrumentation industries. However, unknown to the writer - until 2017 - was that they also made both what appears to be a specialised version of the traditional WW (Webster Whitcombe) watchmaker's lathe together with a small 80 mm x 250 mm "precision bench lathe" for use by toolmakers. The latter machine was constructed along traditional lines for the type, these being established by the American Stark Company, their claim as originators of the type was bold, unequivocal and printed on all their sales catalogues. The first examples were built by John Stark personally in 1862 and, so successful was the design that lathes of this type quickly became established as an essential part of any precision workshop. Even today, in the 21st century, their manufacture continues with Derbyshire and Levin in the United States and Schaublin in Switzerland all making a number of different types. If you would like to know more about this class of lathe, a list all known makers and types can be found here, some common, some very rare: http://www.lathes.co.uk/precision-bench-lathes-list/

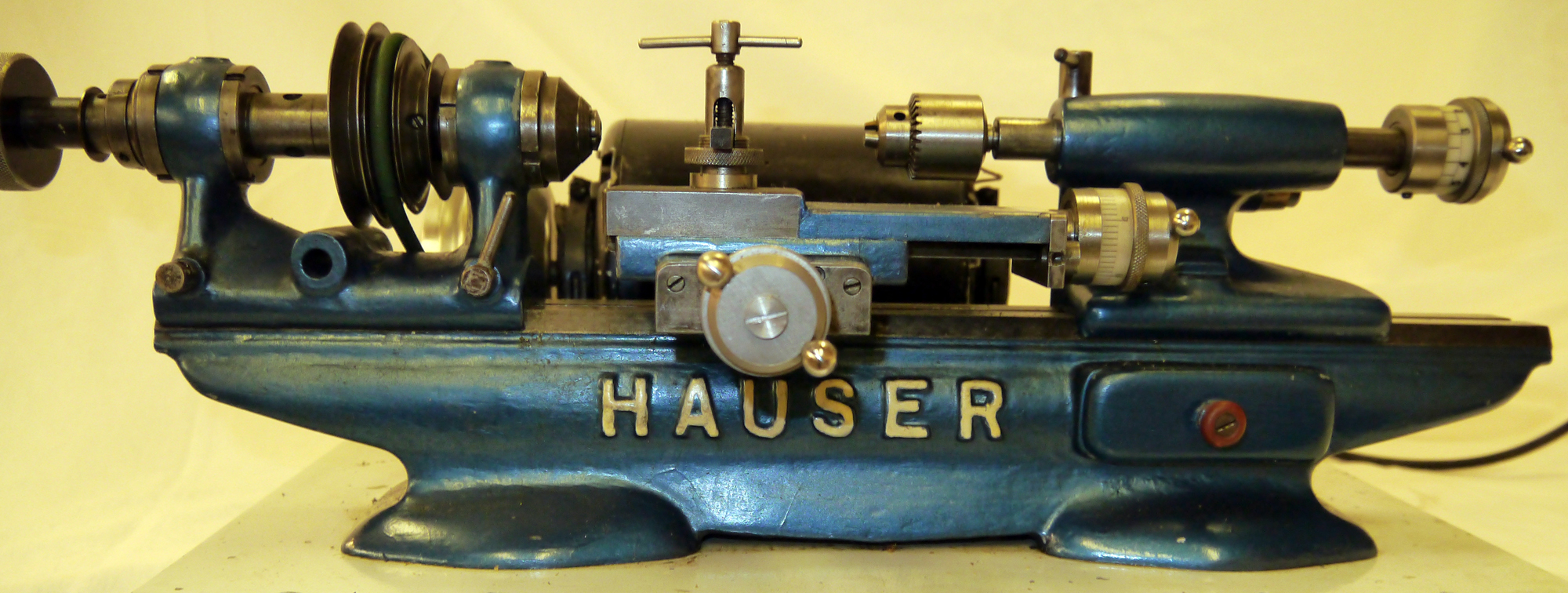

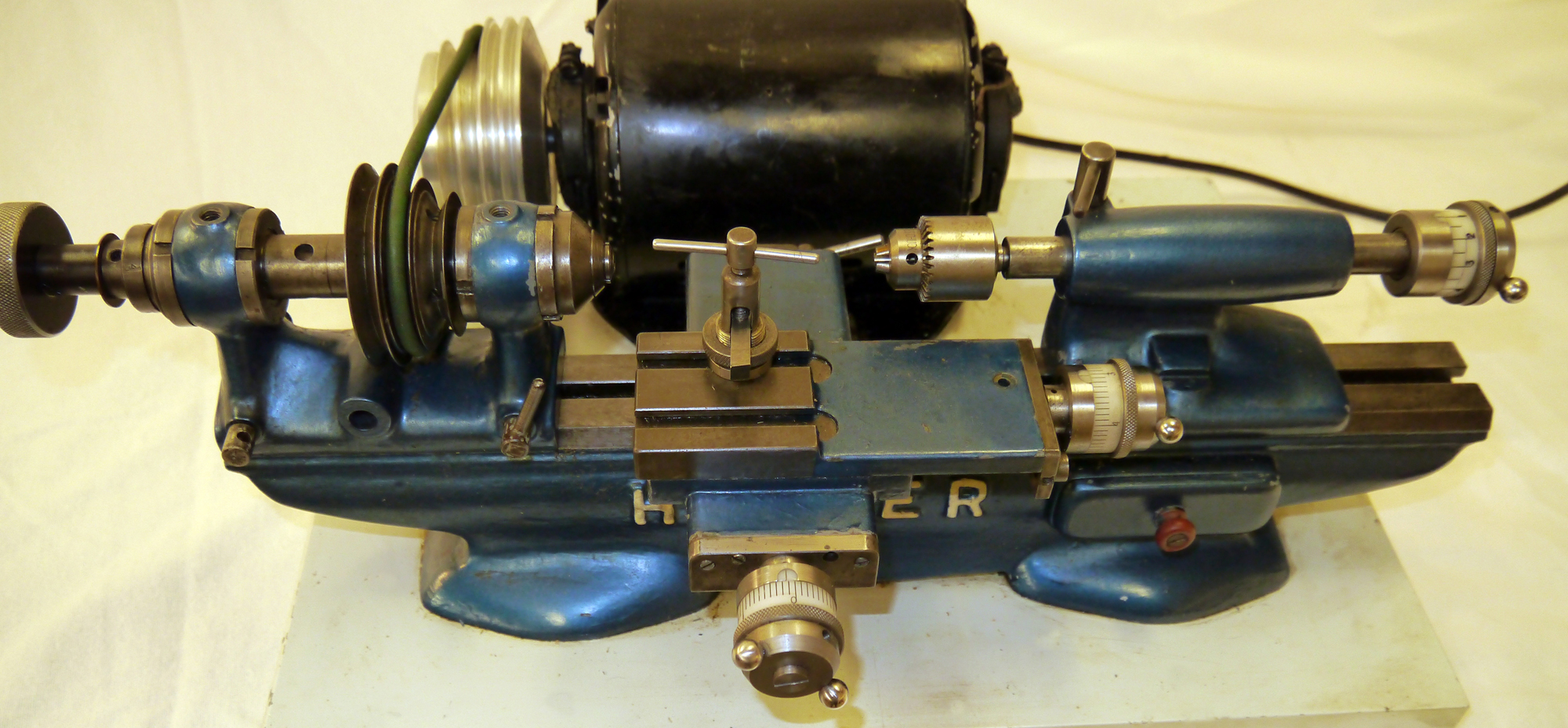

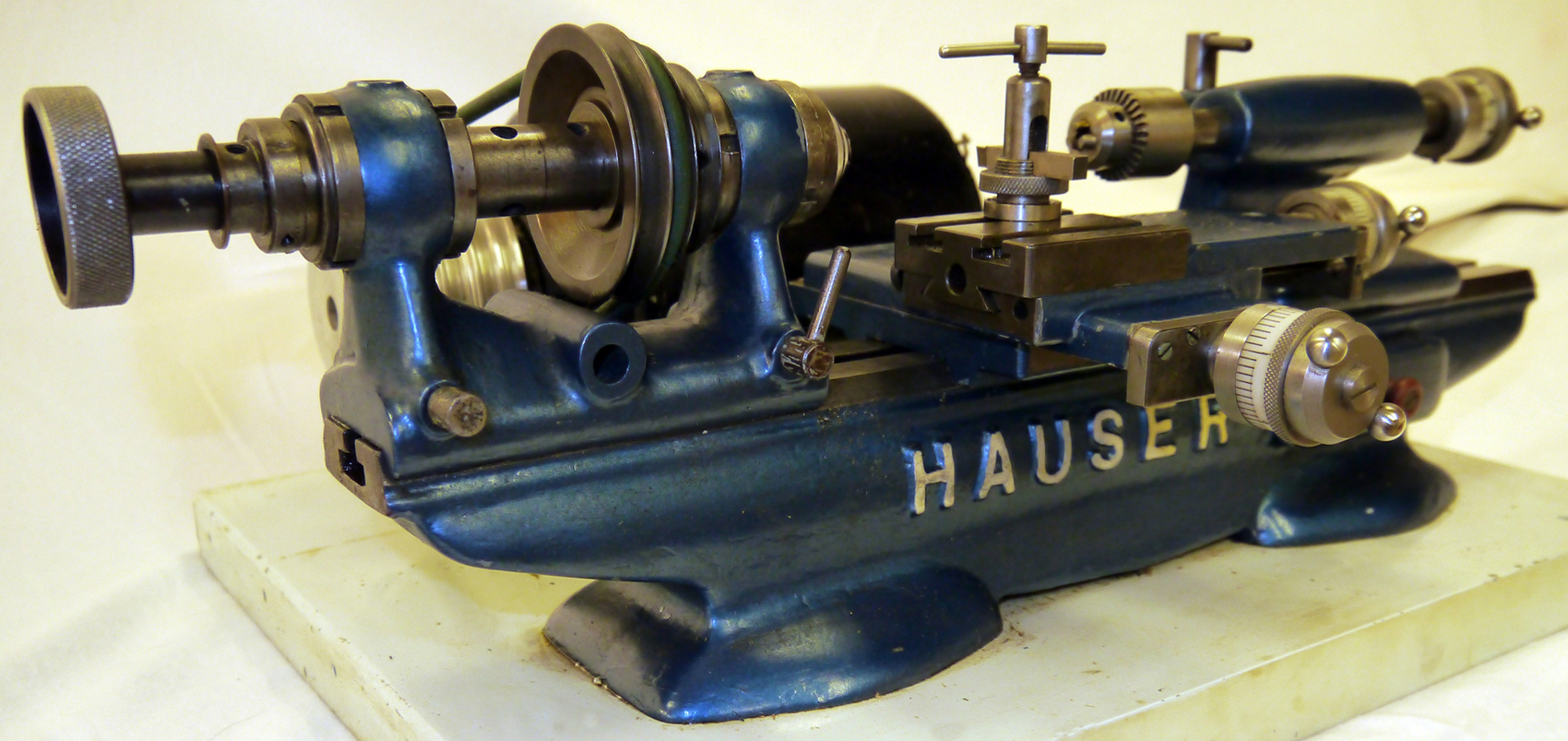

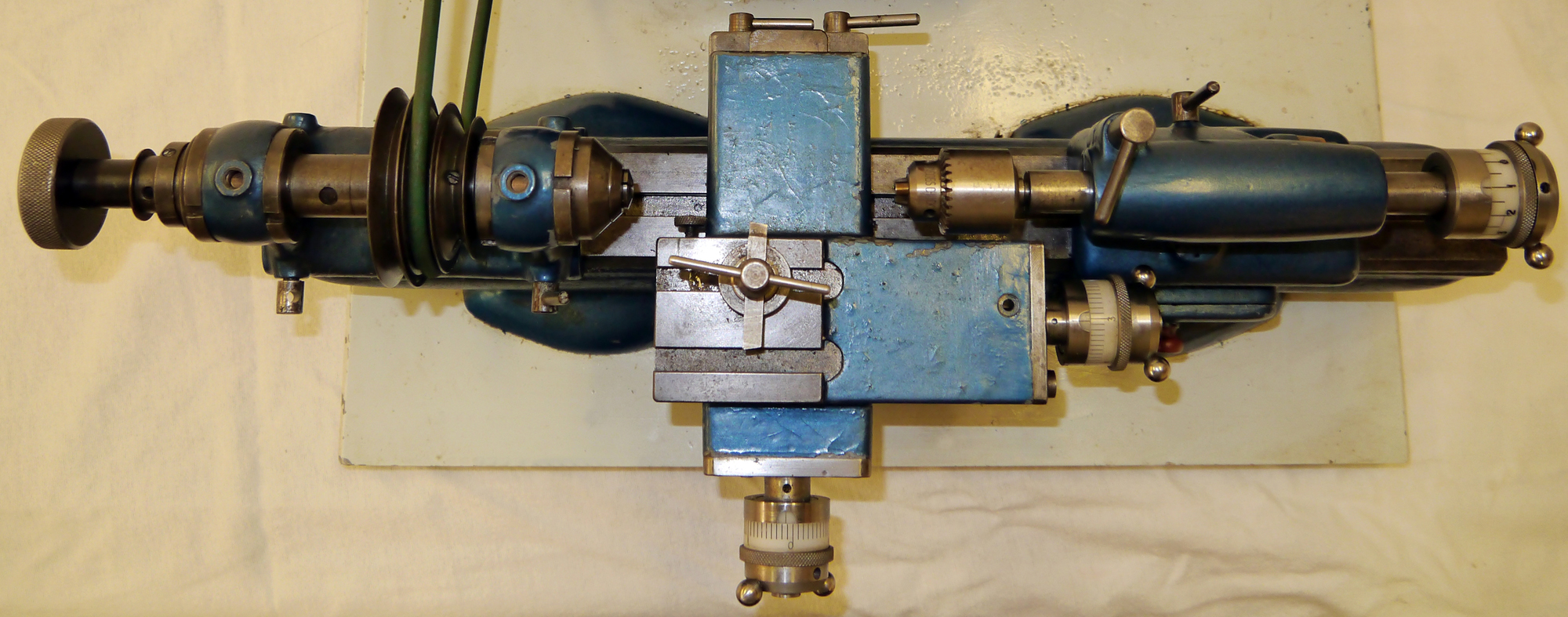

Though the "duck-feet" of the Hauser were unique, the bed had the usual flat-top with bevelled-edges, the latter used to locate the headstock, slide-rest assembly and tailstoc. While the headstock was locked to the bed by the usual pair of lever-operated cams drawing up T-headed bolts against a central T-slot that ran the down the middle of the bed, the saddle and tailstock were also clamped in the same way (more normally on this class of lathe through bolts with some form of capstan-headed handle or knurled head would have been used). The saddle clamping handles were at the back, a pair being used to provide sufficient locking power.

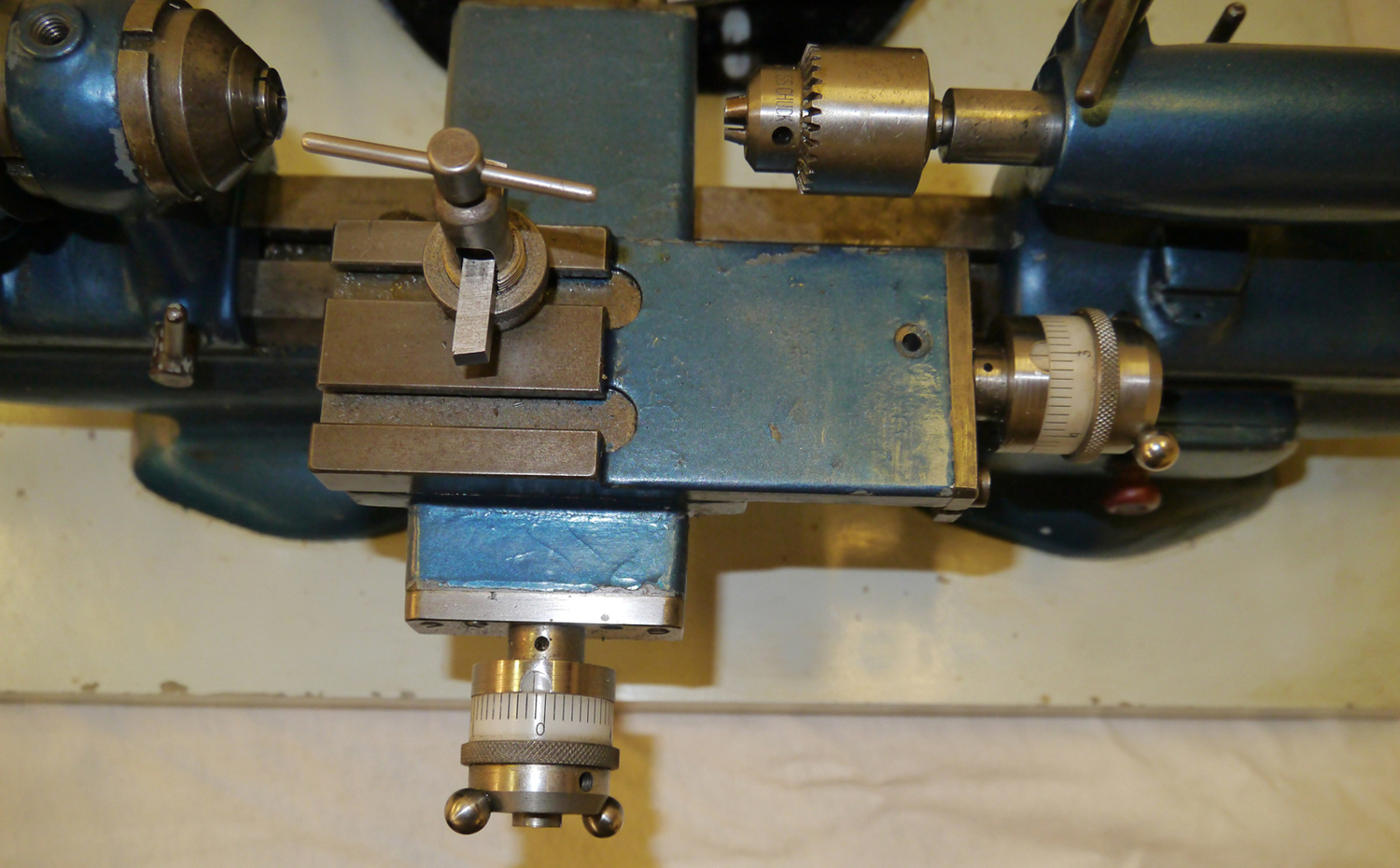

Of a quite ordinary arrangement, the compound slide rest assembly had the usual long-travel top slide - but also some interesting details: the end bracket holding the cross-feed screw was in the form of a short bridge, this being used to extend the slide's travel and an unusual fitting on this class of lathe. The micrometer dials were in a white plastic - similar to those used on some late versions of the Lorch LAS - and fitted with both a unique (and rather strange) design of "handle" - two diametrically-opposed balls protruding from the outer bevelled faces of each dial. The American style "rocker" toolpost was improved by being fitted with a knurled-edge, screwed ring surrounding the post by which means the height of the tool could be raised or lowered, an exactly similar arrangement being used on some Mikron slides.

Carrying 10 mm draw-in collets, the headstock spindle ran in plain bronze bearings and was driven by a 3-step pulley machined to take a round "gut" belt, the pulley being set so as to leave a large gap (pierced by a hole through the spindle) between the outer face of its largest pulley and the inner face of the left-hand bearing. On the example shown below it is likely that some parts are missing from the headstock for, beneath spindle, is a transverse hole through the casting, likely to have been used to carry some sort of index-plate equipped dividing attachment - a similar fitting, but arranged differently, being employed on the American UND precision bench lathe.

Screw-driven the tailstock spindle was fitted with a micrometer dial and the same "ball" handles used on the slide rest. Oddly, the spindle lacked ruler lines - nor was there the usual cut-away in the casting to view the marks and provide a zero line.

Should you have a Hauser lathe, or another interesting machine by the Company, the writer would be very interested to hear from you..

|

|