|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Stark Watchmakers' Lathes

Stark No.1 Watchmakers' Lathe Stark Home Page Stark Millers

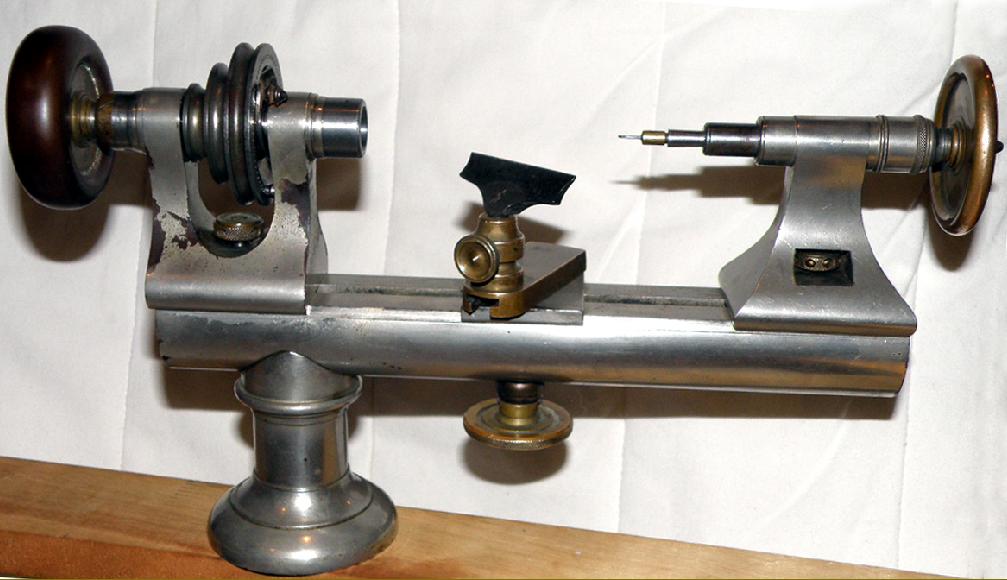

As pioneers in the business of supplying watchmaker's lathes (and specialized watch-making machinery) Stark can, perhaps, be forgiven for ploughing their own furrow and making most of their lathes incompatible with the established standards of the day - especially the all-conquering WW type. The company also produced many one-off lathes, of a different specification to the ordinary types and fitted with special equipment, yet all based upon standard components and often destined for use in watch-making factories. Not only were Stark accessories not able to be used on other makers' lathes (in comparison to the wide interchangeability of the standard WW type) but the expensive collets were also unique and not transferable either - a factor that must have limited sales to customers with other brands of well-equipped, 8 mm lathes who would have had to buy entire new stocks from Stark.

Stark watchmakers' lathes were listed by numbers - though one used a single letter - and are known to have included the tiny and rare No. 1 with its 83/8" long by just under 1-inch wide bed, the more common Nos. 2 and 3 and the Model E.

Very early types can be recognised by their distinctive headstock where the rear bearing was carried in what amounted to a swan-neck extension, the whole assembly being held to the bed by a single round nut with a knurled edge. Contemporary advertisements described these first examples as Stark's New Patent Combination Lathe. with a note that the patent had been extended from October 19th, 1872 (the original patent having been granted on May 30th, 1865). Of the three models listed, the No. 1 STEEL was the cheapest and sold for $36 (the word Steel indicated that this was a very high-quality machine fitted with a hardened and ground spindle running in honed and glass-hard steel bearings). Its bed was 63/4" long, the headstock had just a single groove in the drive pulley and it came with five split collets and one each of a cement collet, a patent cement, a centre and two "stops". The No. 2 STEEL had a 2-step headstock pulley, a bed 81/2" long, came with the same range of basic equipment as the No. 1 and sold for $39. The No. 3 STEEL was, in effect, a No. 2 but fitted with a 4-inch diameter faceplate equipped with three adjustable clamps (this being described as a universal head), a 3-step pulley, a screw-driven compound slide assembly and eleven collets; it sold for then astronomical sum of $120. The second machine shown on this page is a much later, more modern example with a typical WW (Webster Whitcombe) flat-topped, bevelled-edged bed 15.5-inch long and 1.5-inch wide with a central T-slot - and so typical of the design as used by many other makers. The Model 3 or "E", and the largest or next-to-largest in the range, had a centre height of 65 mm and, apart from its size, appears (with the exception of a few small refinements) to have been a beautifully-made if conventionally designed type. While many watchmaker-lathe headstocks had two or more rings of indexing holes drilled in the outer face of the headstock pulley (together with a locking arrangement based on a long, flat spring-steel arm pivoting from a point on the headstock) the Stark had just a single ring of holes - though a generous 120 in total. The indexing system was, however, much more rigid than many makes with the spindle held positively by a pin contained within a separate housing screwed to the headstock and able to be positioned at either its front or back. To allow the use of a larger indexing plate (as would commonly have been either screwed to the outer face of the drive pulley or secured on the end of the spindle) an additional mounting point for a conventional spring arm was provided (with a set-screw for retention) on the rear face of the headstock. The collets were the usual Stark specials, sized differently to other makers with a 9.1 mm body diameter (0.305 in.) a length of 1.745", a 20º angle and a 40 t.p.i thread. The "Swing Tailstock" was of a similar design to those used on the larger Stark bench lathes and worked in exactly the same way' the three fingers enabling different dimensions to be used for jewelling without having to reset for each change in diameter.

Though early on the scene, Stark soon met increasing competition and, with many others makers joining the market for watchmaker's lathes, their range of models was never developed beyond the normal for this class of machine. However, with their range of precision bench lathes, and busy making specialized tooling and machinery for factories producing watches and clocks, no doubt their was insufficient capacity or interest to take them any further.

If you have a Stark watchmakers' lathe, the writer would be very interested to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

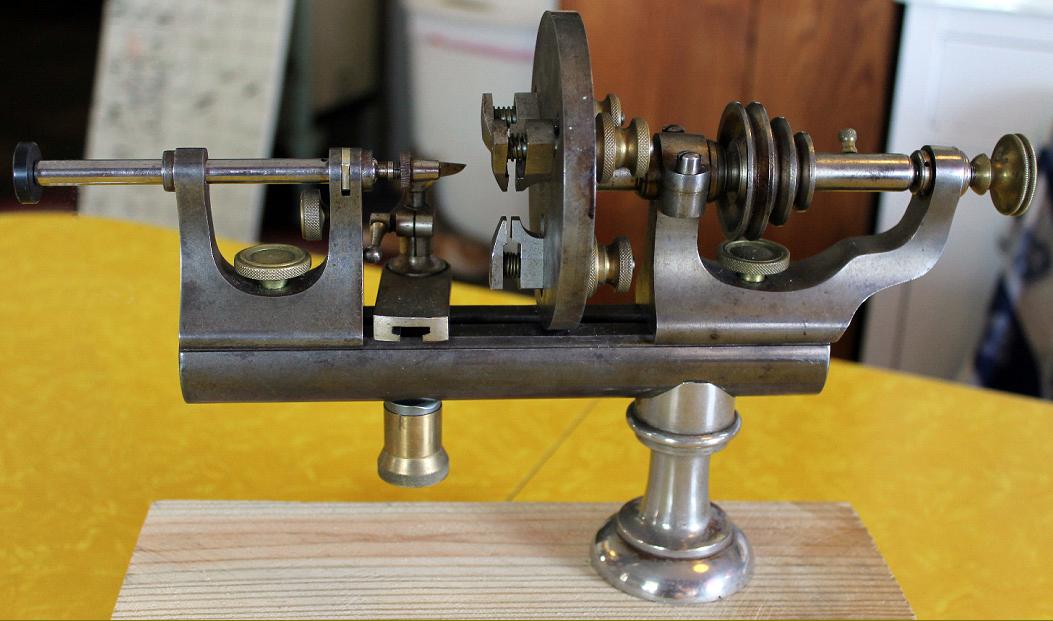

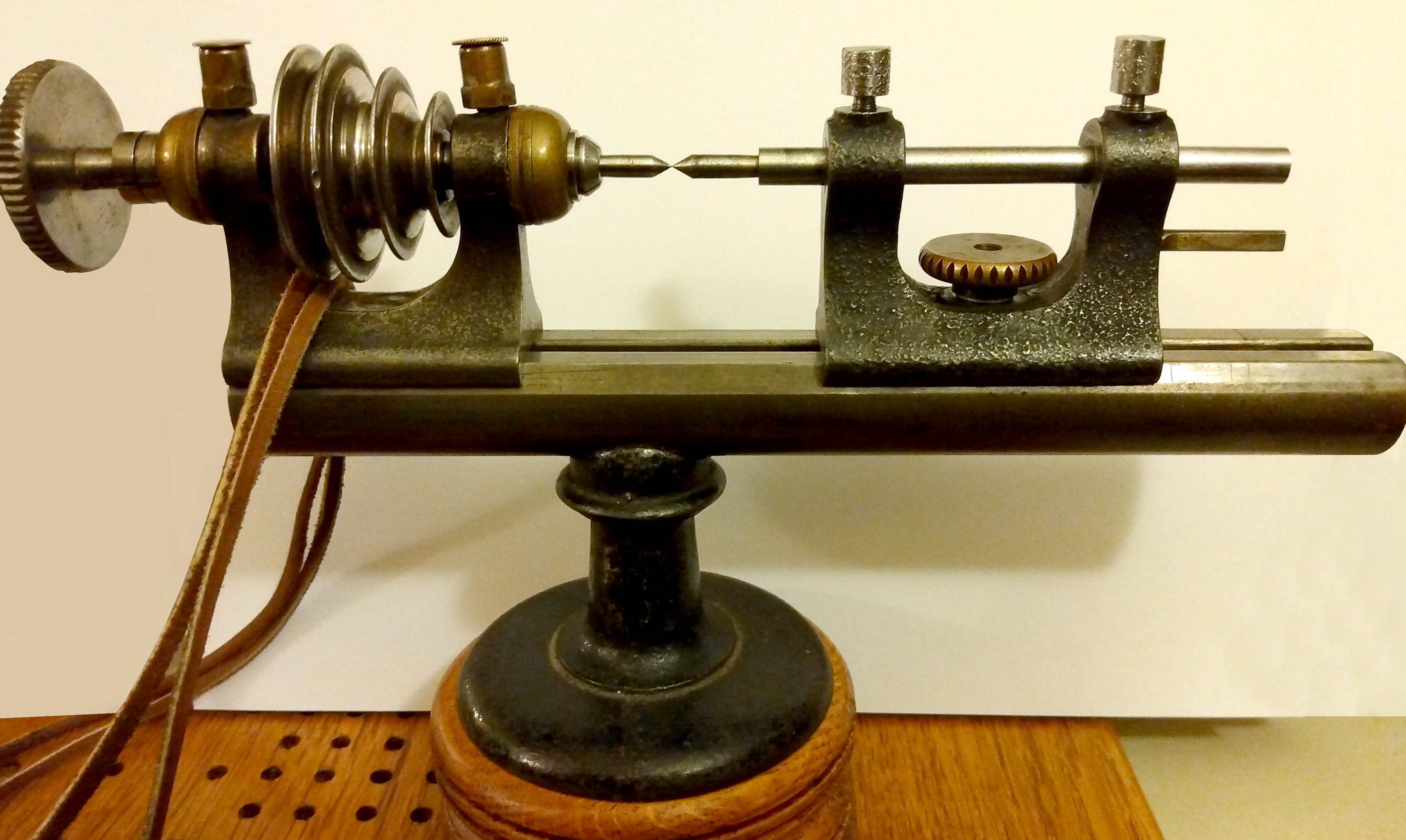

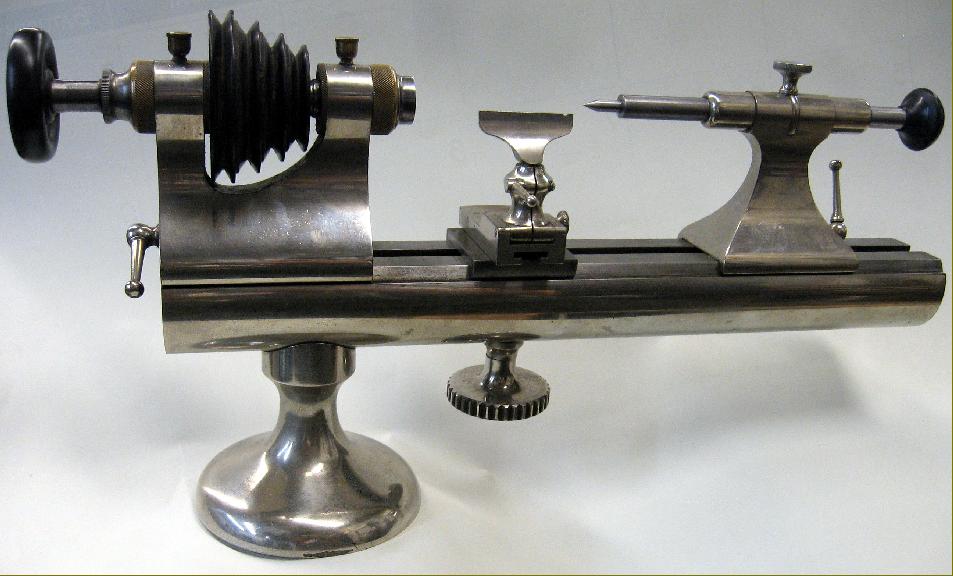

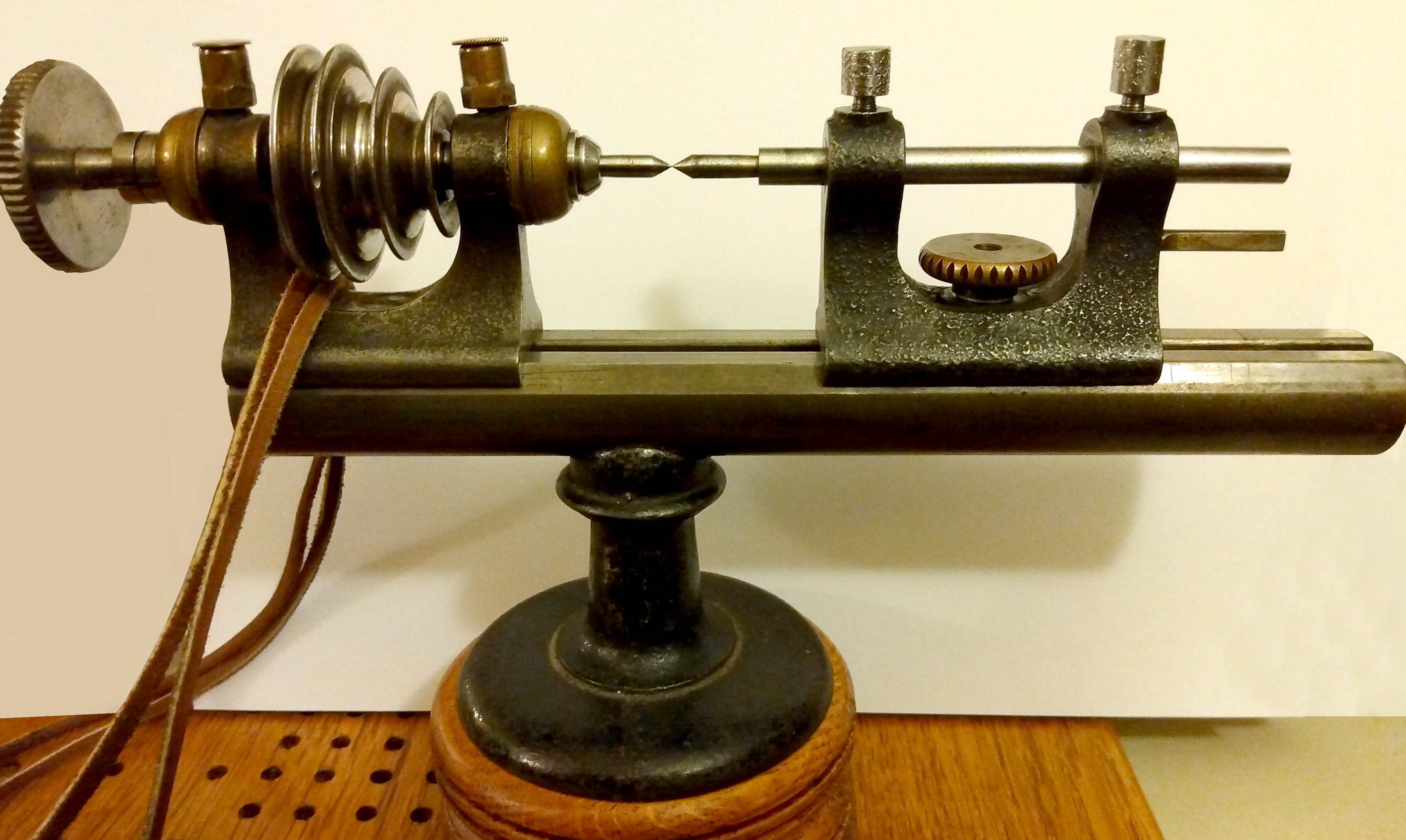

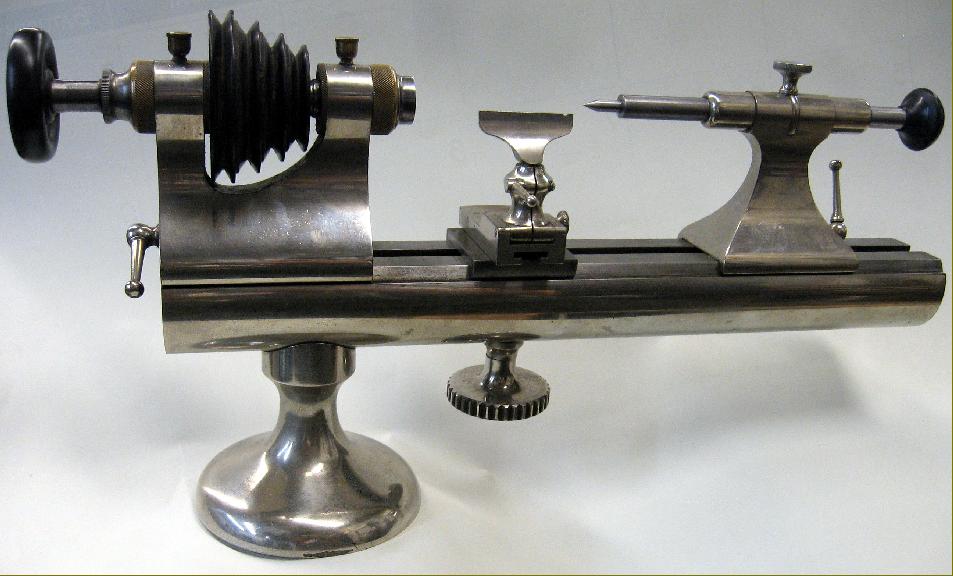

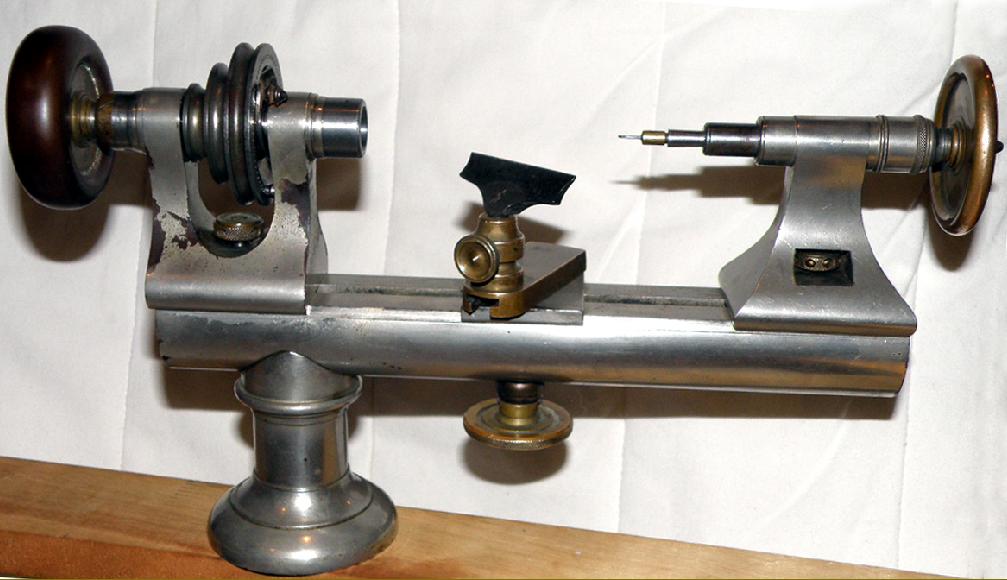

A rare and very desirable early Stark watchmakers' lathe with its distinctive headstock casting extended out to the left-hand side. This is a No. 3, a top-of-the range version that was sold complete with a faceplate that mounted a set of adjustable jaws

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

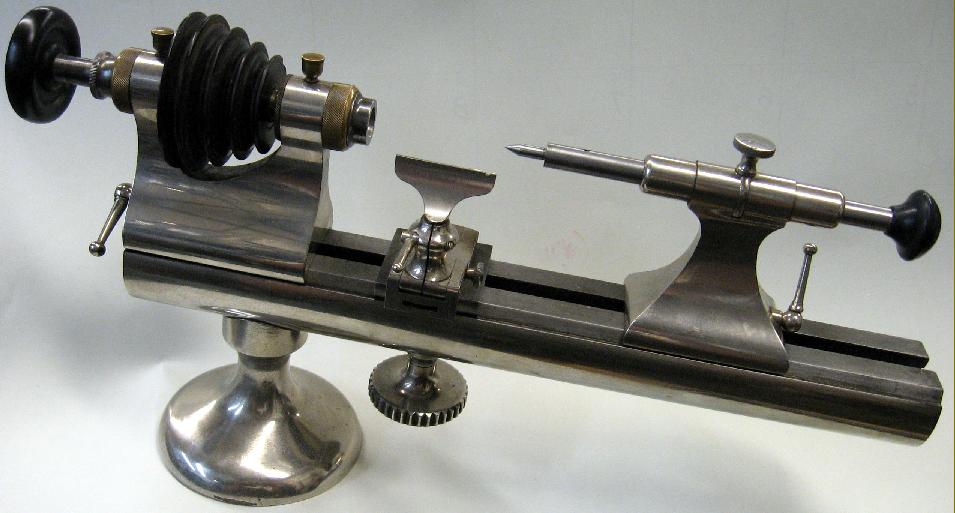

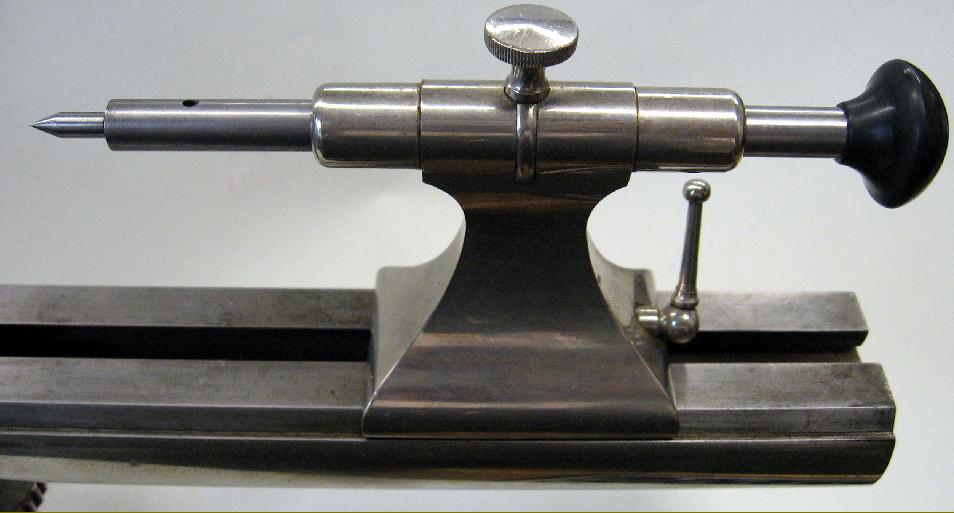

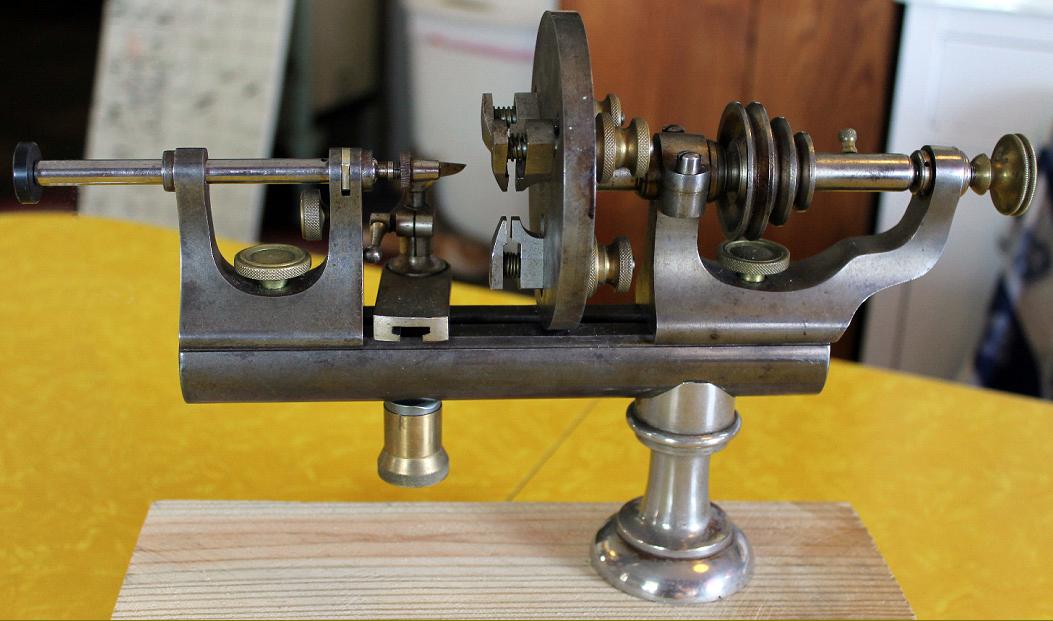

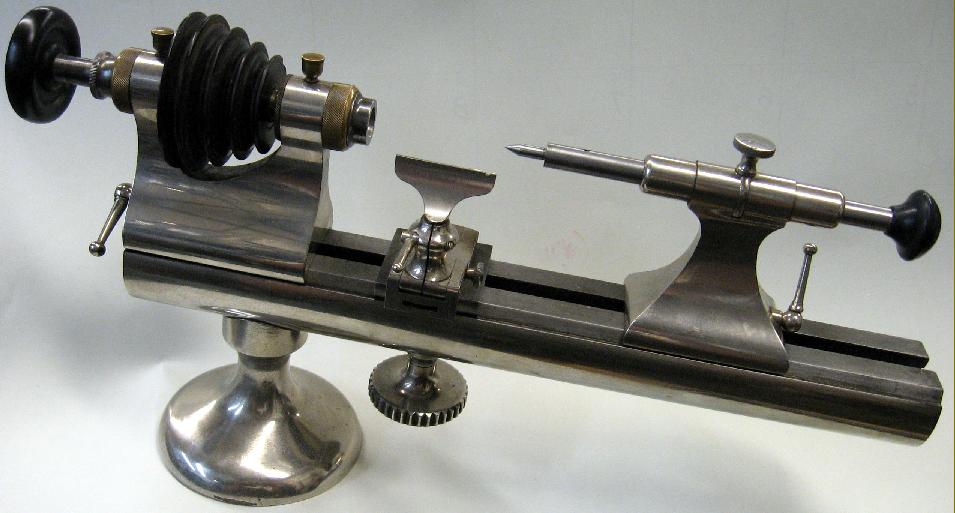

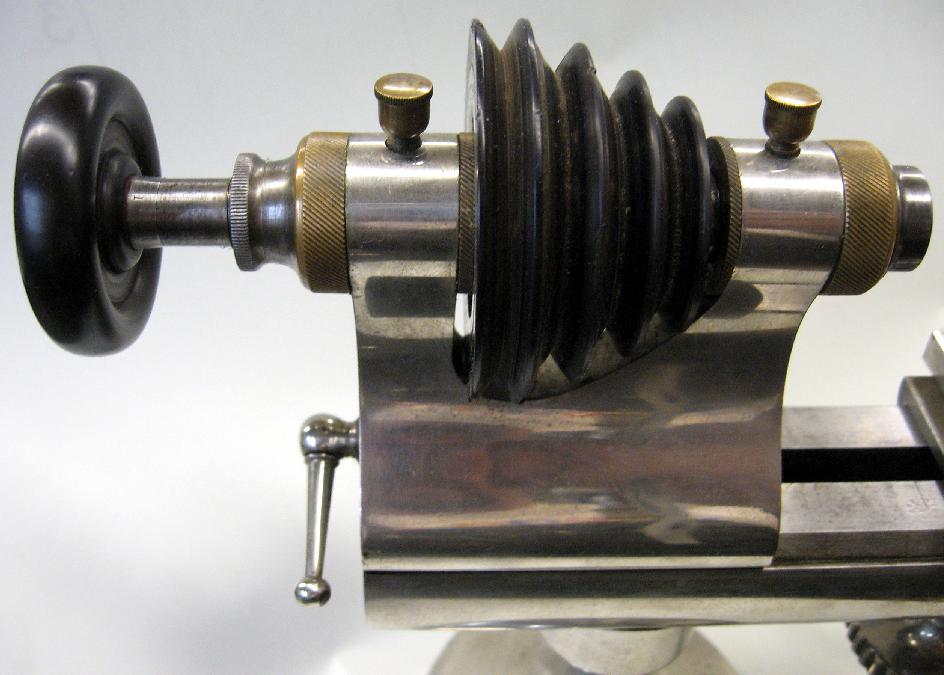

A much later Stark Watchmakers' lathe - probably a No. 3 - in its beautiful, nickel-plated finish

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

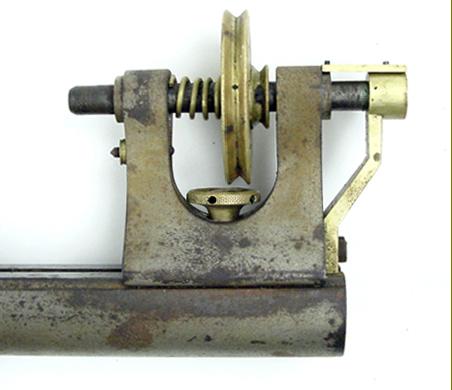

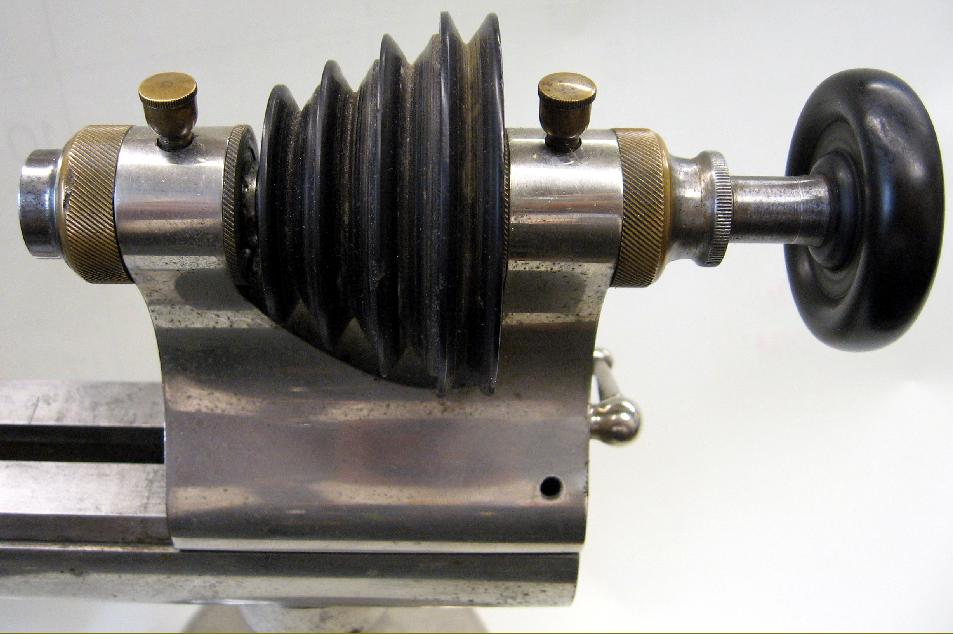

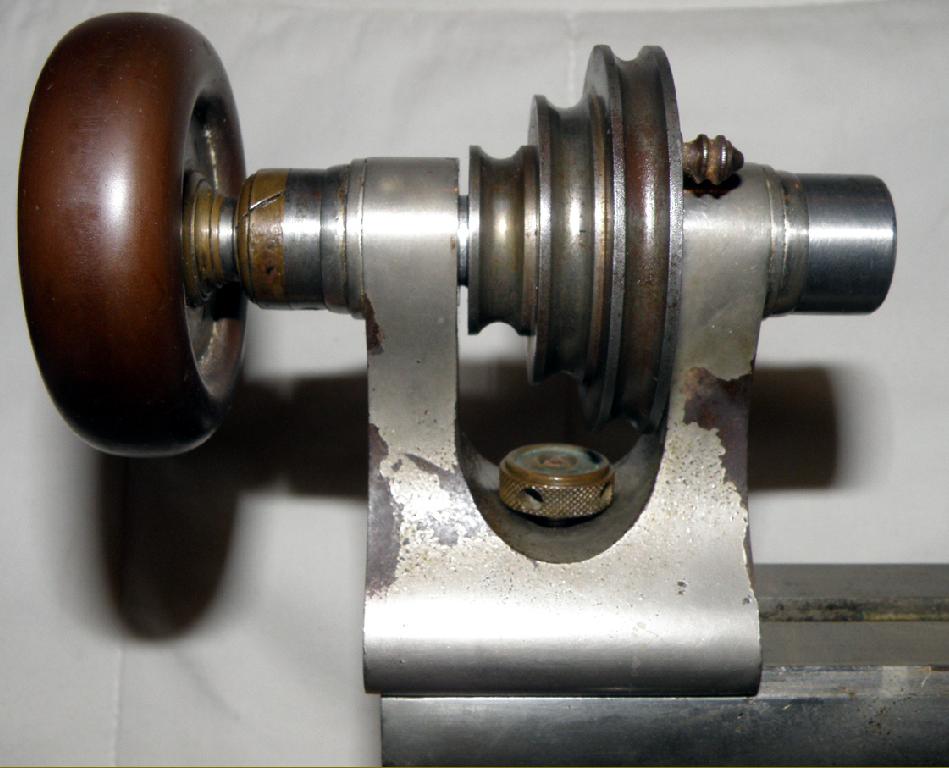

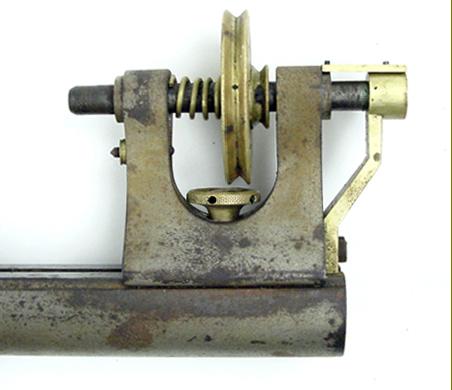

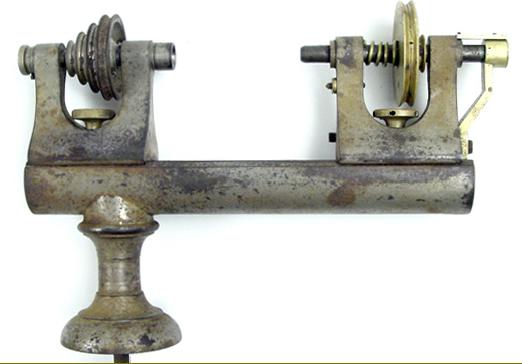

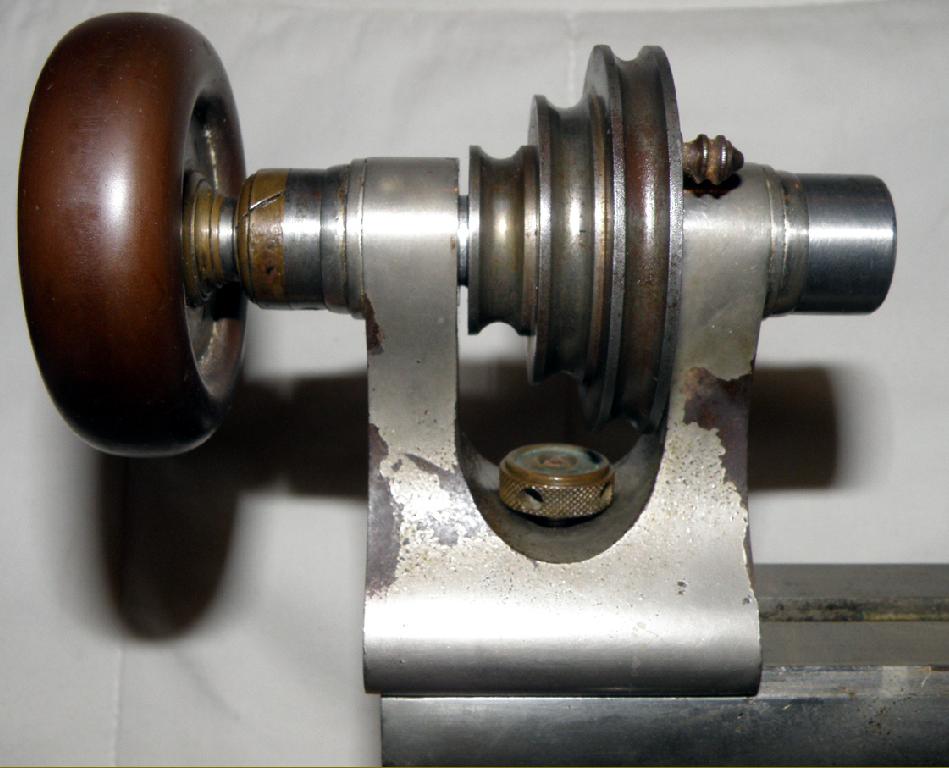

Rear View of Stark Watchmakers' lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

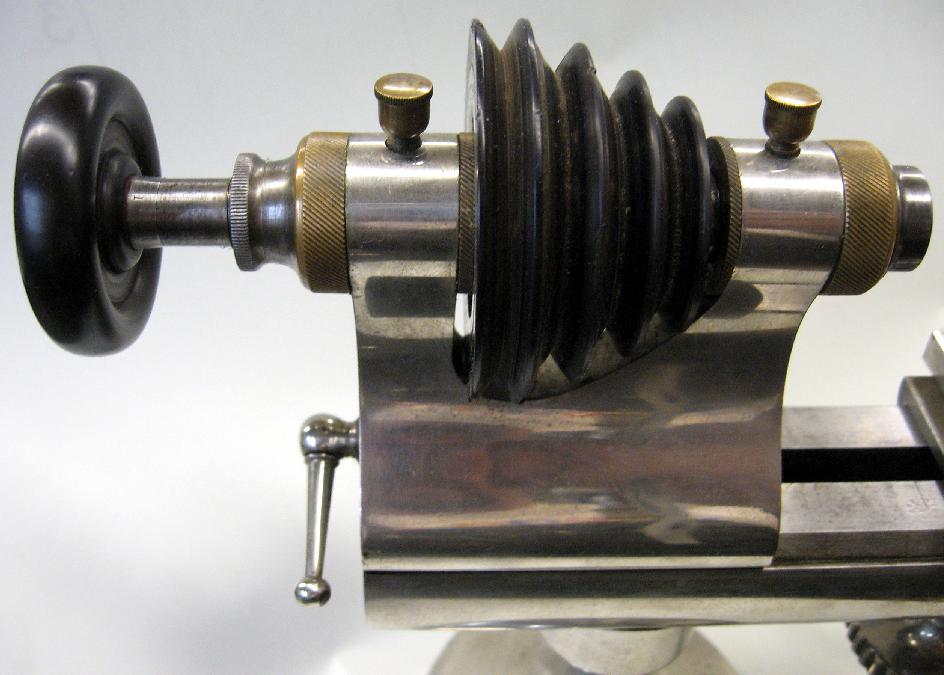

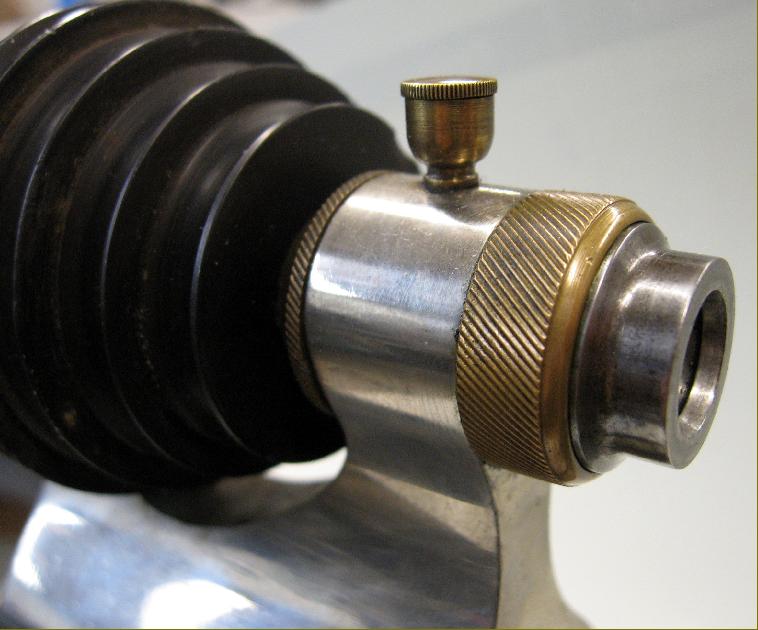

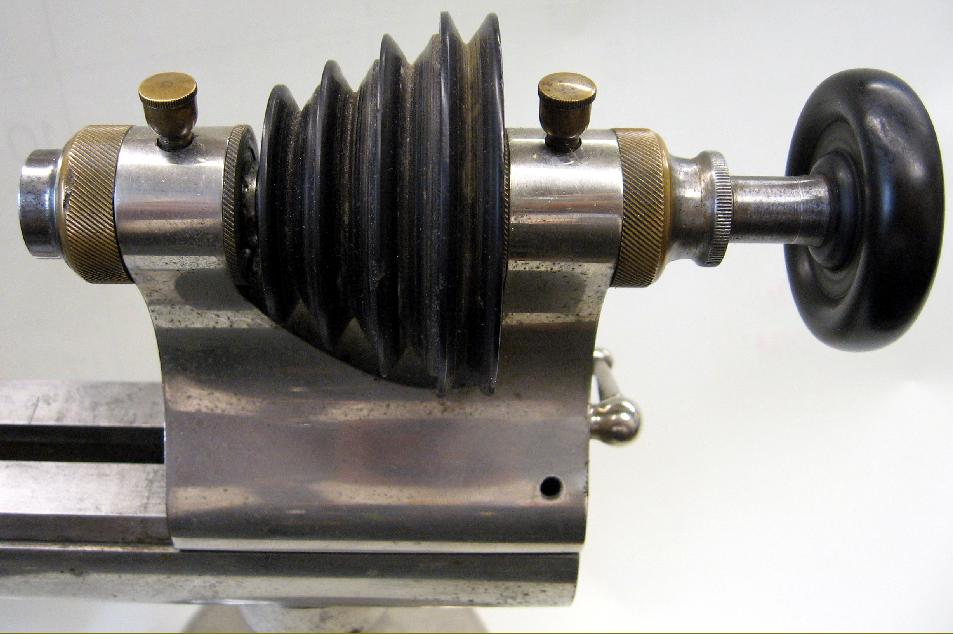

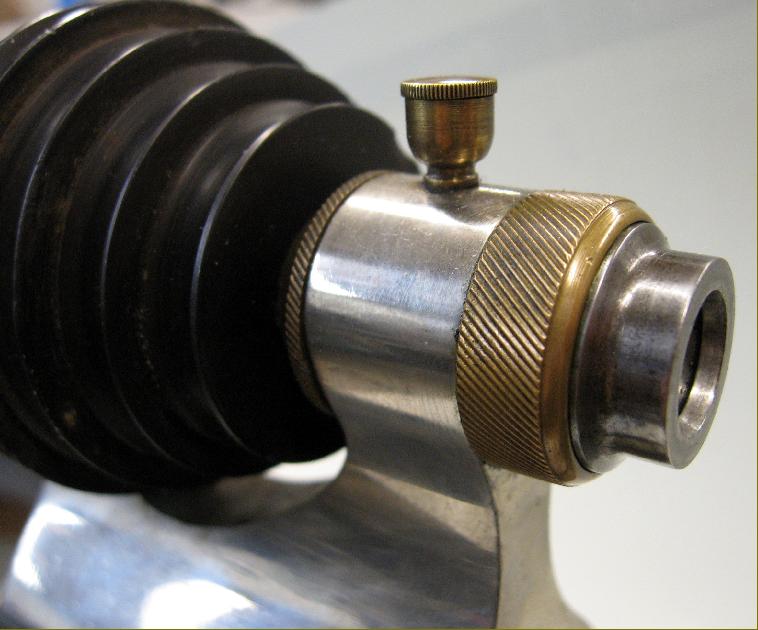

Stark Watchmakers' headstock with inner and outer dust covers protecting the spindle bearings. Unlike many competitor machines the Stark's bearings could be lubricated through external oilers and the spindle indexing arrangement was a positive-location pin rather than the usual flat spring-steel arm. The locking-pin housing could be repositioned, if required, on the other side of the headstock casting.

|

|

|

|

|

|

|

|

|

|

|

|

Though the positive pin location of the spindle guaranteed a tight lock the method chosen restricted the lathe to a single ring of (120) indexing holes rather than the two or three that would otherwise have been possible.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

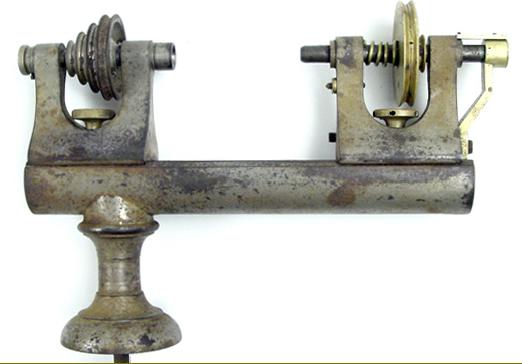

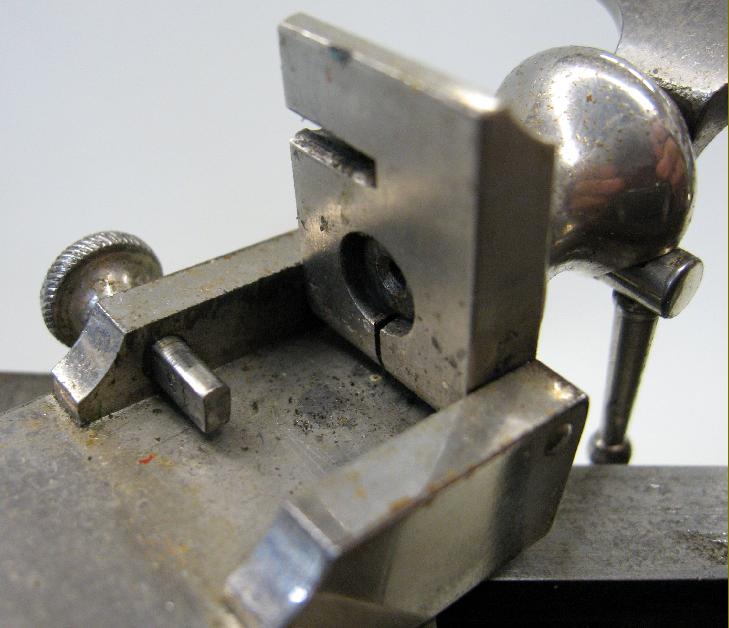

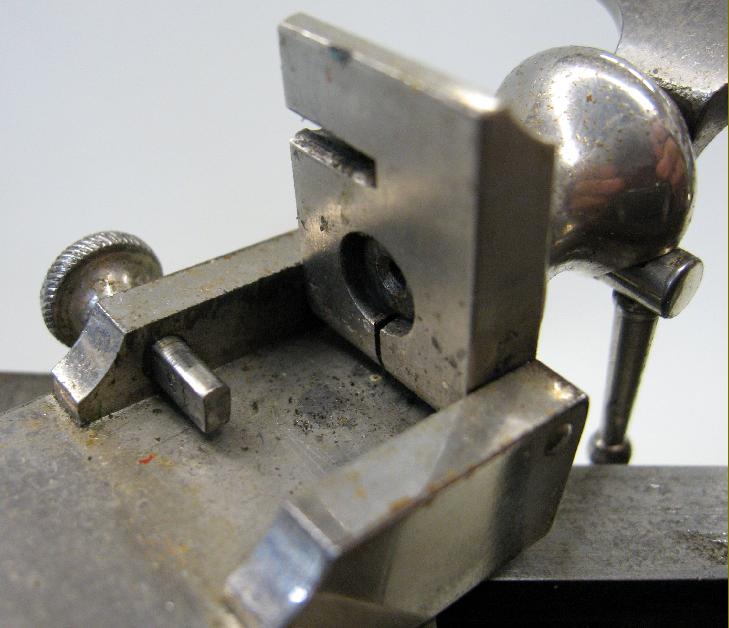

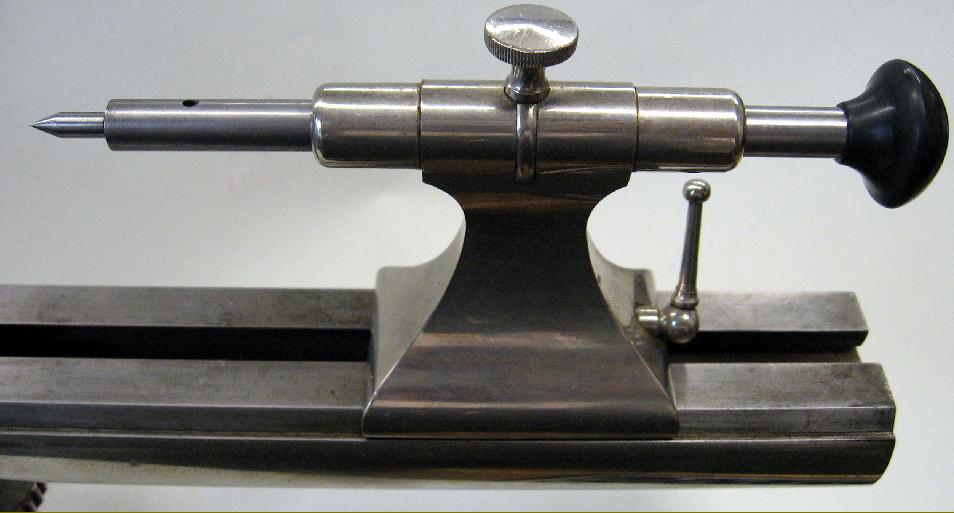

Swing Tailstock or Jewelling Tool: Designed originally for rapidly opening holes in clock plates to receive jewels the unit was developed to enable it to accurately finish bore holes to receive parts that might vary slightly in diameter from piece to piece. The aim of the device was to ensure the highest possible accuracy by holding, between a gauge plate and gauging finger at the top of the unit, the actual jewel (or lens, etc.) that was going to be fitted into the bored hole. If the setting instructions were followed, the bored hole would be exactly the same size as the part held by the gauging device.

|

|

|

|

|

|

|

|

|

|

The engraving "HARD" on the end of the bed refers to the advertising puff "All Hard" - an indication that the spindle and its bearings were properly made from glass-hard materials instead of the softer components used on cheaper machines

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Swing tailstock set up for making a hole of the exact diameter as a setting mounted in the headstock.

|

|

|

|

|

|

|

|

|

|

|

|

|

Rear view of the Swing Tailstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The rare Stark No. 1 watchmakers' lathe with a beautiful "miniature WW" prismatic-type bed 8 1/16" long, slightly less than one inch in diameter and with a centre height of just 30 mm. The headstock appears to have been fitted with the usual Stark hardened, ground and lapped steel conical bearings with the spindle accepting 4.7 mm collets (other collet dimensions and thread pitches are listed below). These lathes appear to have small differences over their production run and with the likelihood that late examples had a nickel-plated support leg - similar to that seen on the lathe at the top of the page..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The single headstock pulley, simple push tailstock spindle - and economical black paint finish - may signify a lathe originally intended for repetition production work

|

|

|

|

|

|

|

|

|

|

Headstock shaped to fit the miniature "WW" bed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions of a standard wire collet

|

|

|

|

|

|

|

|

|

|

|

A fine collection of Stark collets

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stark No. 2 watchmakers' lathe; this took the same 4.7 mm collets as the No. 1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A slightly different Stark No. 2 watchmakers' lathe. With a bed some 1/8" longer the T-Slot down the middle is slightly deeper, and the base of a different design - although the headstock and tailstock are interchangeable between the two lathes. The original finish looks to have been "blued"

|

|

|

|

|

|

|

|

|

|

Although mounted as a tailstock the unit on the end of the bed is probably a "sliding-spindle" headstock - a mechanism used to manufacture batches of precision components or, with a chase-screwcutting attachment, as a means of making very accurate threads

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

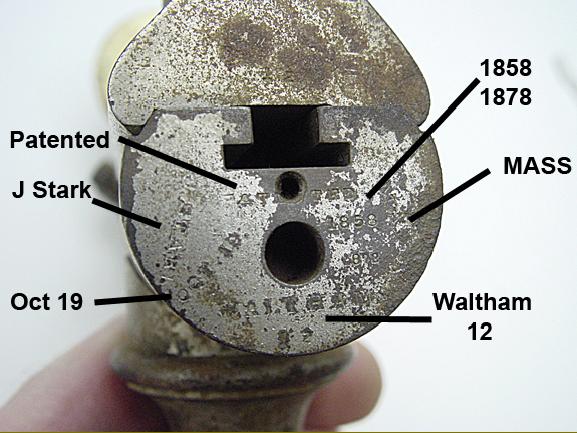

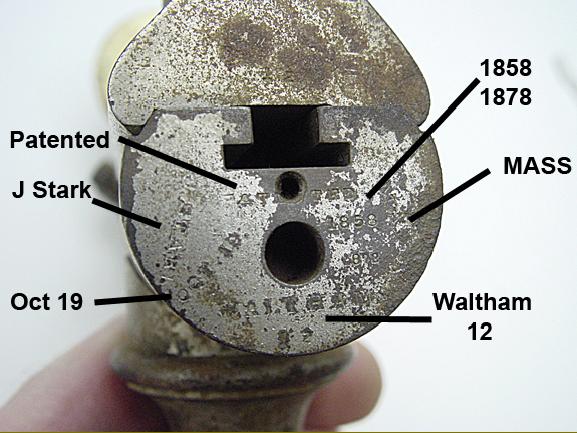

Stark No. 2 watchmakers' lathe showing the patent dates, town of

manufacture and production date - though unfortunately without the year

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A fine example of a Stark No. 3 or Model E Watchmakers'' lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A single ring of 40 indexing holes drilled into the face of the largest diameter pulley

|

|

|

|

|

|

|

|

|

|

|

Beautifully made and finished brass bearing covers

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

"Hard" was used to indicate properly hardened spindle and bearings - sometimes the term "All hard" being

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This early and elegant watchmakers' lathe is not marked as

by Stark, but evidence does point strongly to it being by that maker.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distinctive Stark collets

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|