|

Continued:

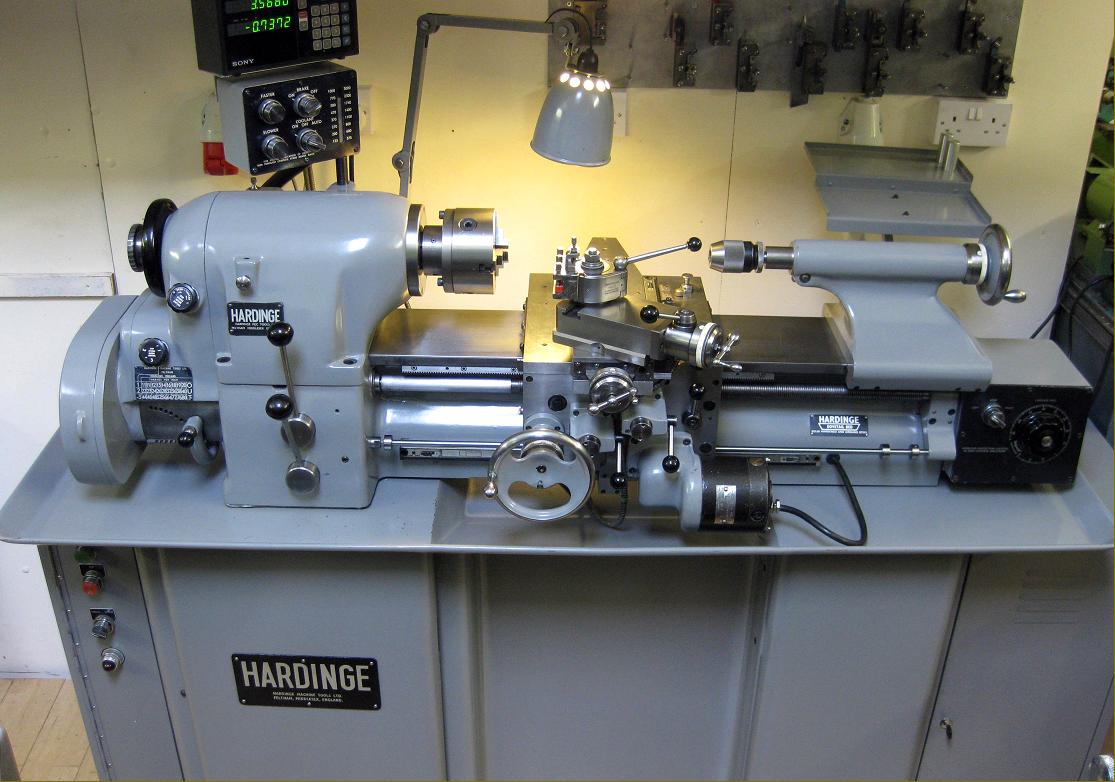

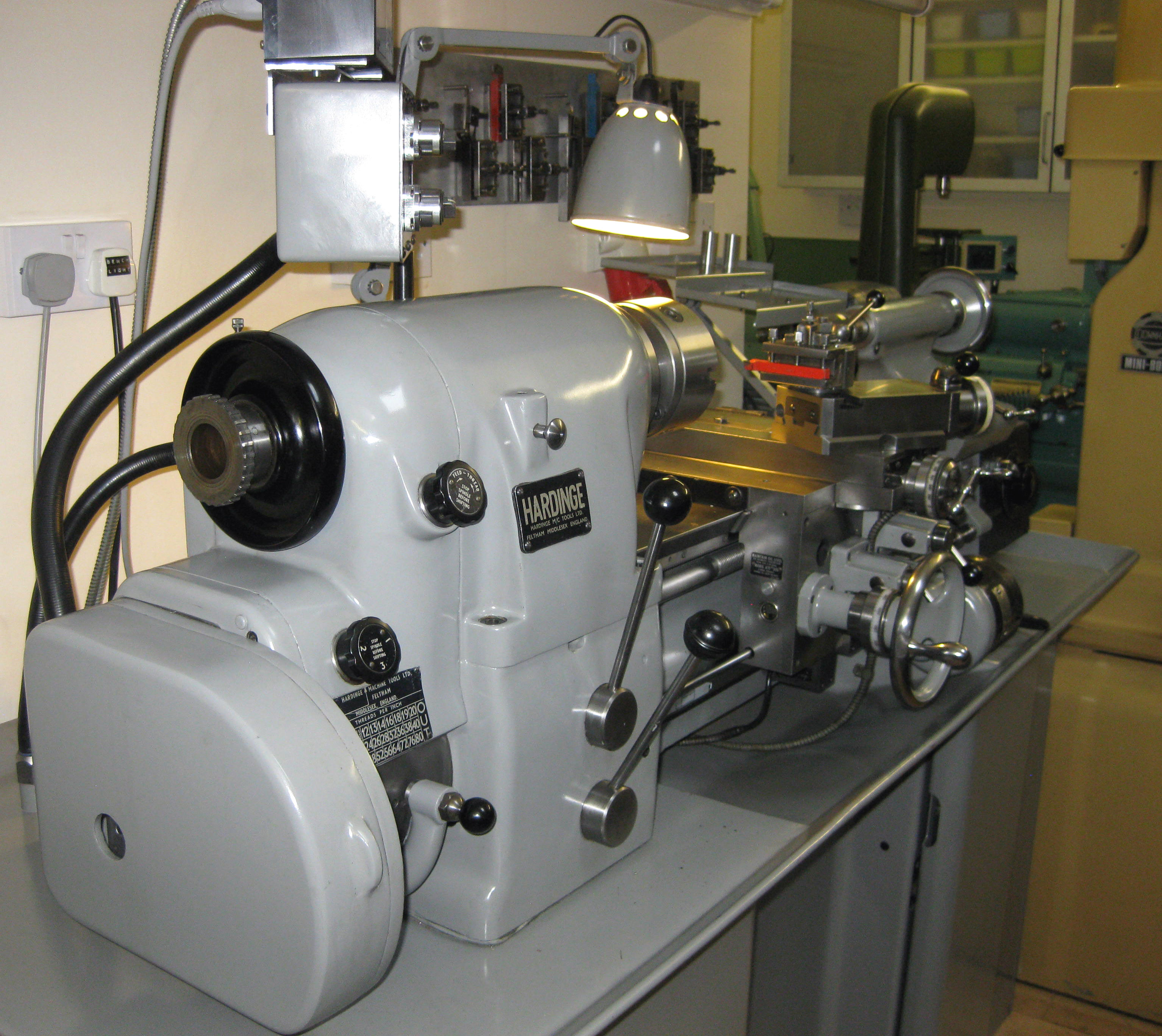

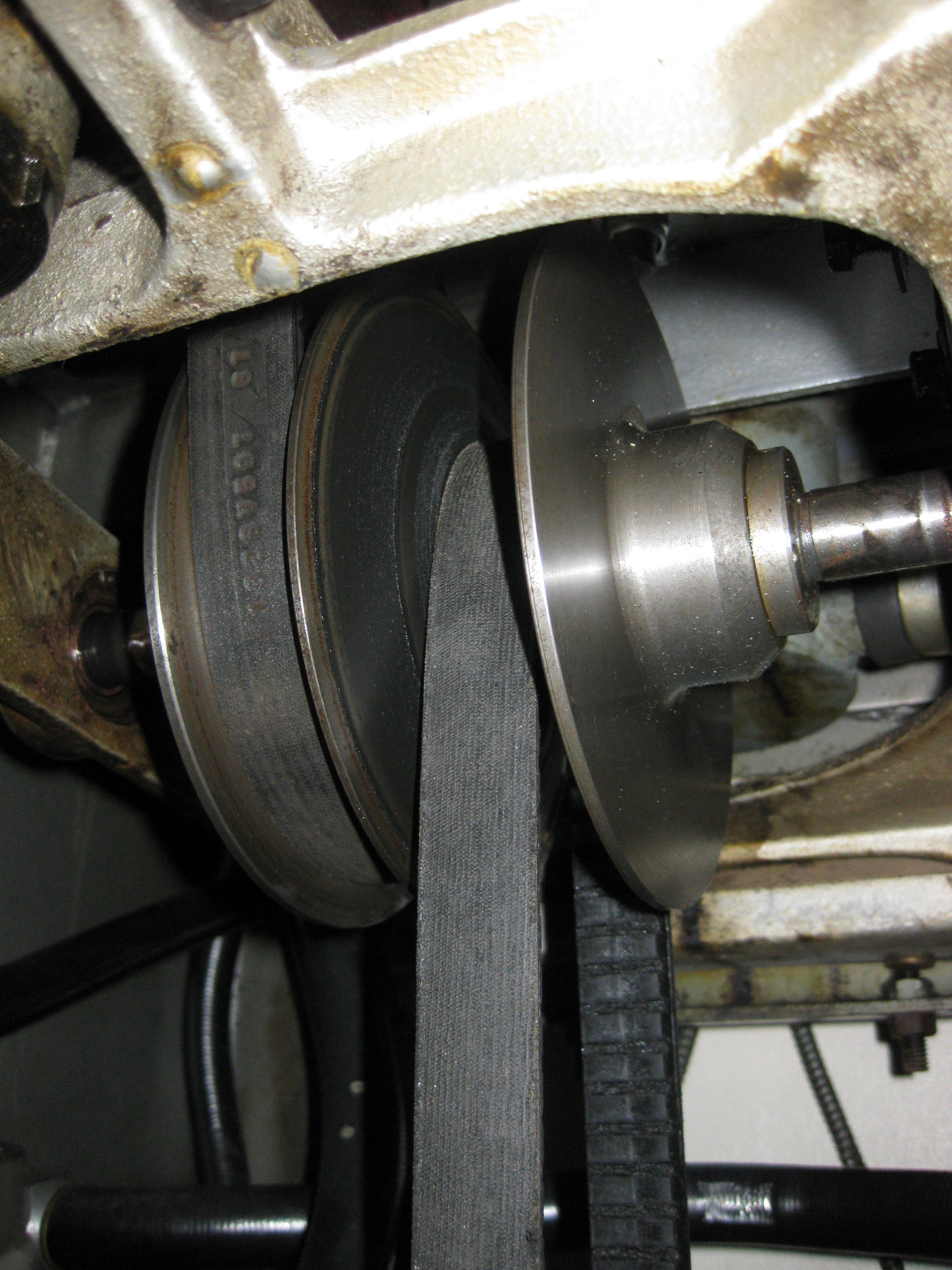

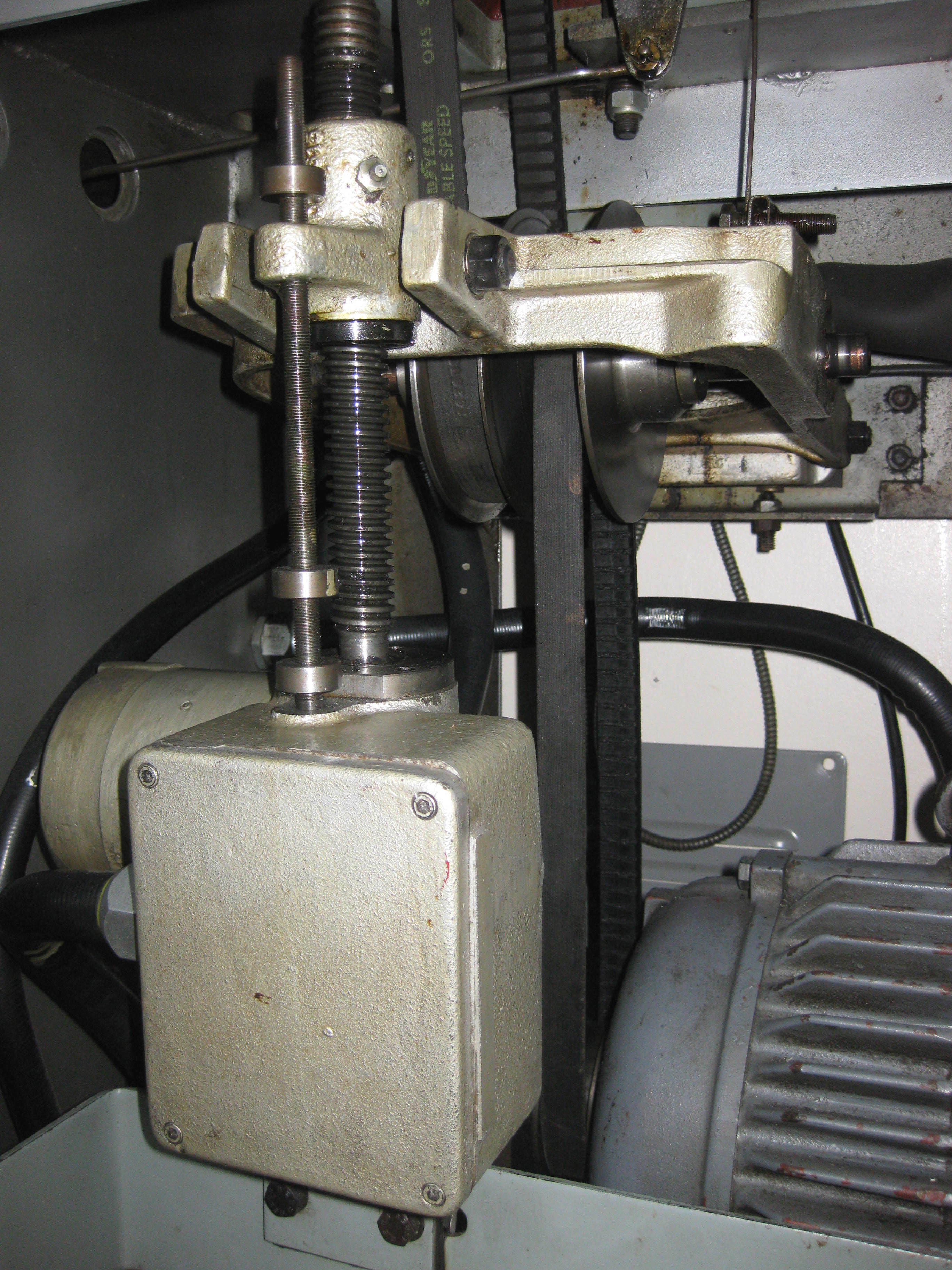

A continuously-variable ratio transmission system - with electrically-operated expanding and contracting pulleys - provided forward and reverse speeds from 125 to 3000 rpm and incorporated an ultra-reliable, switchable, automatic, solenoid-operated brake. The master electrical controls were mounted on the cabinet stand and consisted of a push-button starter, forward and reverse switch and a "power on" indicator light. The speed controls, set in a conveniently positioned binnacle atop the headstock, comprised one push-button for "faster", one for "slower", a brake on/off switch and the coolant controls; a vertical window provided an indication of the spindle speed. The lathe was normally supplied ready to accept 5C collets, with a maximum through capacity of 1.0625", operated by a quick-action collet closer mounted at the left-hand end of the spindle. It is important to know that this unit (which should be removed weekly for cleaning and lubrication) can be damaged if allowed to run without a collet in place.

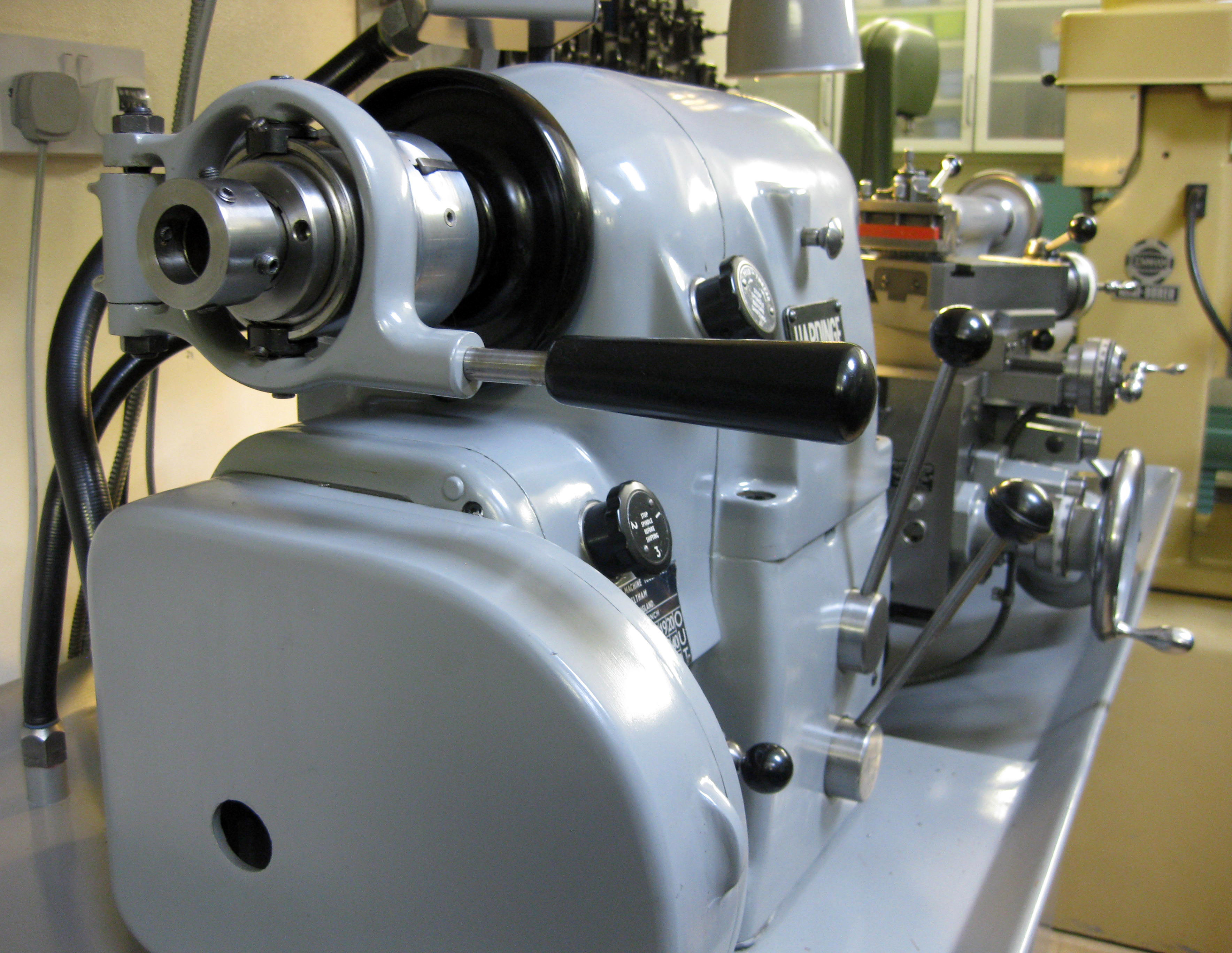

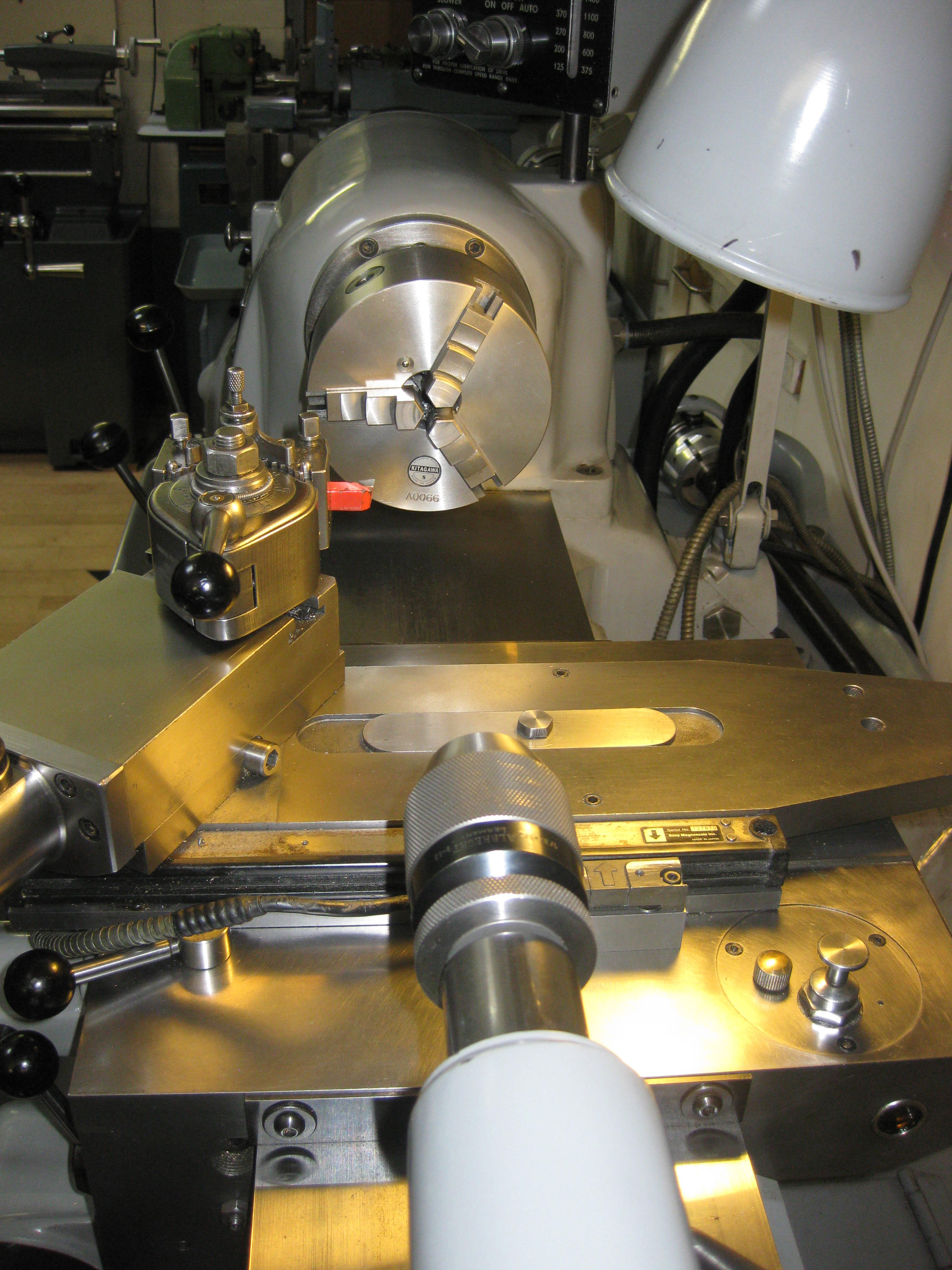

Although the early UK-made version of the lathe had an ordinary threaded nose, that from the USA had one with a 4° taper and a patented "peg" retention system with types both properly hardened and ground. While the taper type allows the rapid mounting and dismounting of spindle tooling, care must be taken to use it correctly: a fine line engraved on the vertical surface of the spindle nose indicates the location of a T-shaped shallow keyway that must register correctly with the chuck or backplate being fitted; original spindle fitments are marked with a line, circle or dimple to assist in this task. The item is then pushed on to the nose and twisted either left or right to lock it. An ordinary pin type spanner can be used to make the final tightening - do not use a punch and hammer but seek out the correct Williams or Armstrong spanner No. 460 (or a similar quality item). Chucks supplied by Hardinge had an integral backplate to match the spindle nose, so reducing overhang and making the most of the machine's between-centres' capacity. Over the years a number of different makes of chuck were supplied - Hardinge never made their own - including, on early models ones by Skinner and Union and later by Burnerd in England (these are stamped accordingly) and other with a badge proclaiming "Made in USA HARDINGE Mfg by Buck Chuck". It appears that chucks with a built-in Hardinge taper are no longer available and so have to be mounted on a separate backplate; these backplates can be either difficult to find or impossibly expensive, or both, but lathes.co.uk may be able to help.

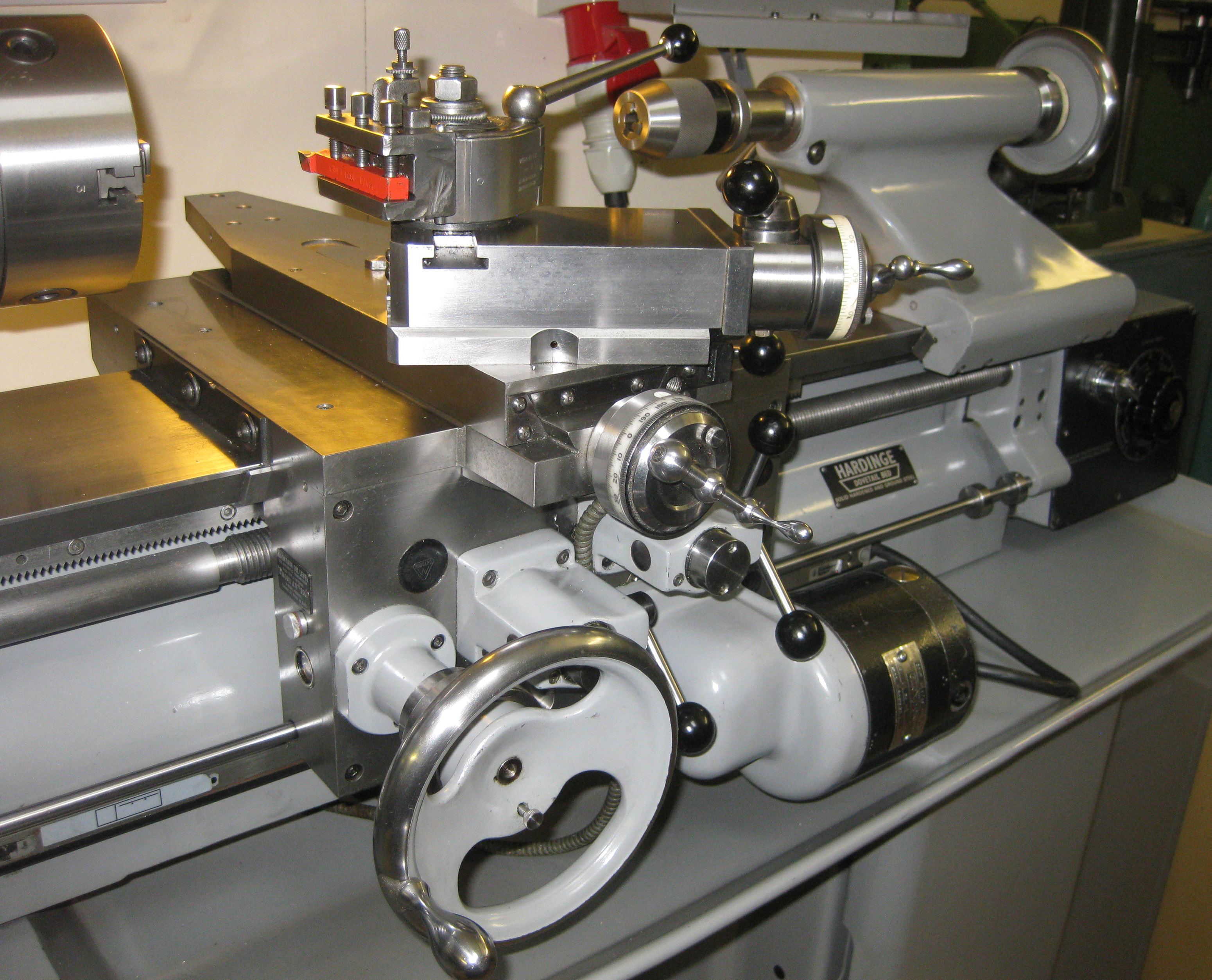

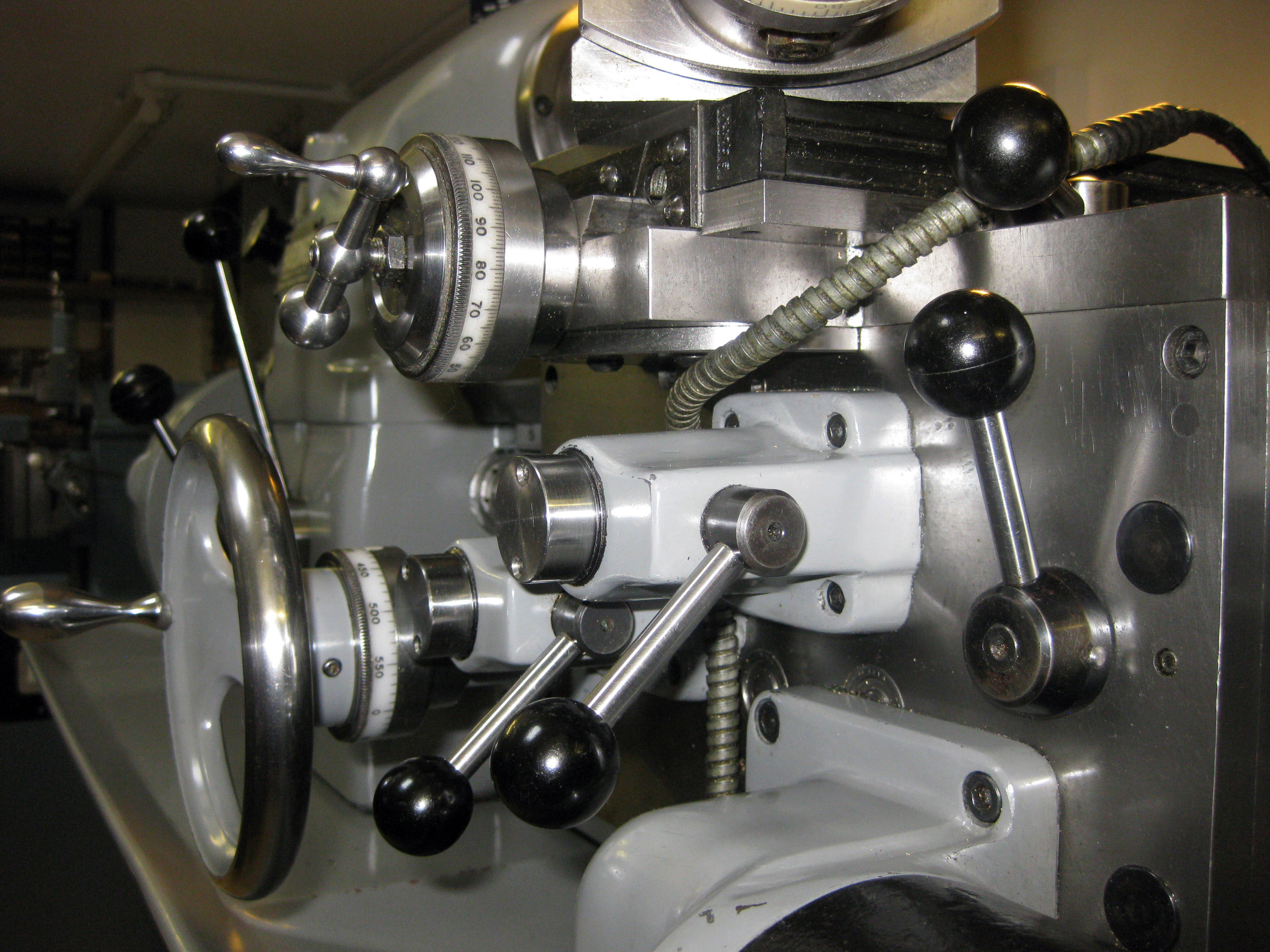

Fitted with easily-read black and white feed dials both top and cross slides moved with a silky smoothness whilst the power sliding and surfacing feeds were both fitted with finger-tip operated, flick-up engagement clutches - of a design identical to that found on the top-class English CVA and American Monarch toolroom lathes. The clutches were a friction type and spring-loaded; - they are not adjustable and any sign of slippage is an indication that the cutting tool is blunt - or the machine being overworked. For normal, none-screwcutting turning, the saddle was advanced by a variable-speed electric motor built into the apron and controlled by switchgear mounted at the tailstock end of the bed. The fact that the headstock spindle speed and tool-advance rate could be individually controlled meant that, while the initial setting could be at the text-book approved level, it could (if necessary) be changed by experimentation until the perfect setting was arrived at for the job in hand. Another important advantage of the drive was that it reduced the number of gears involved in the transmission of power - gear drives are bad news for surface finish, they induce vibrations that, whilst usually hidden in the "roughness" of ordinary turning, become much more evident in the finer finishes that high-quality lathes are able to produce.

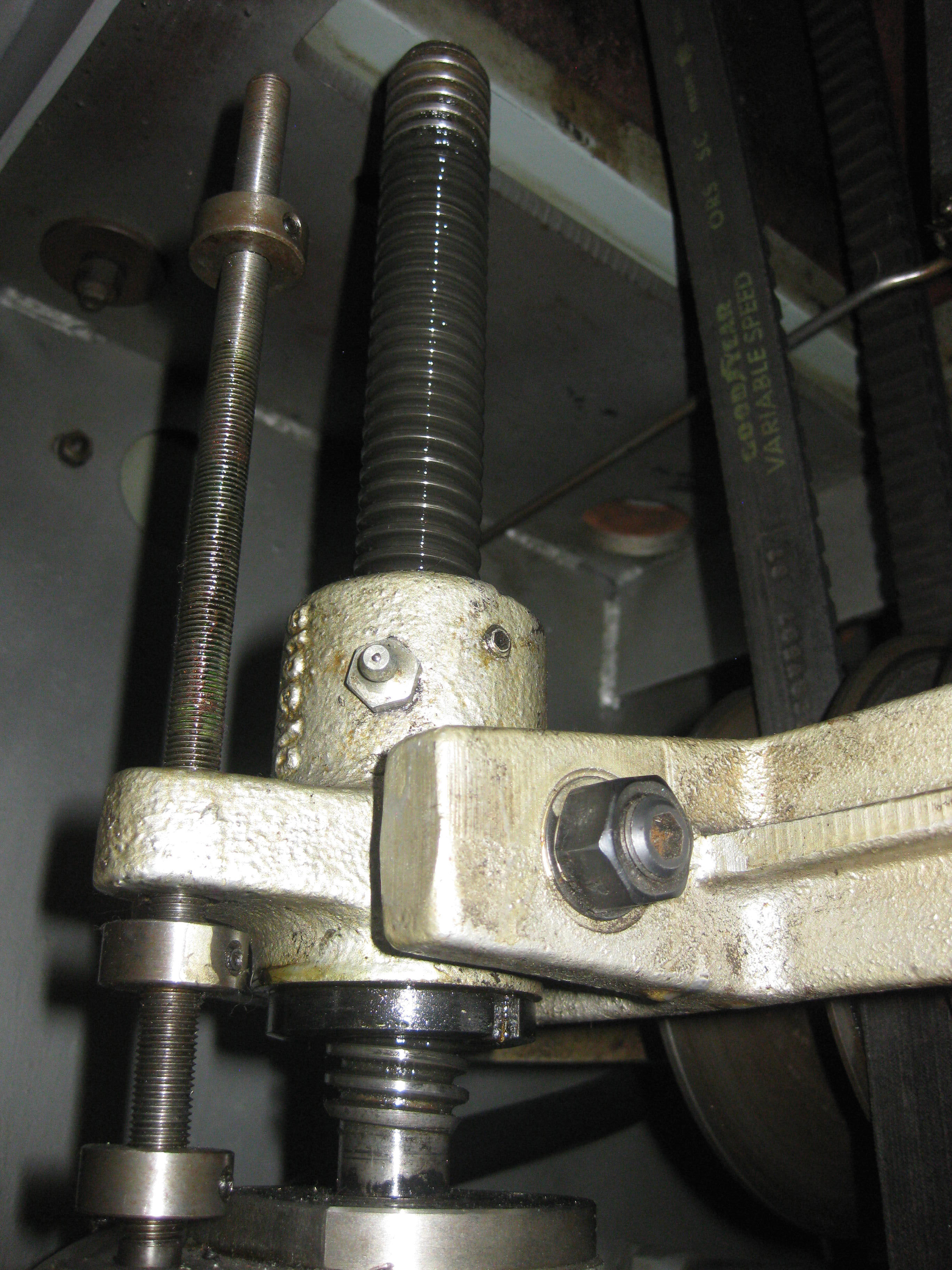

Screwcutting on the HLV-H was by one of three types of gearbox: English, metric or, more rarely, a dual English-metric unit (when the lathe was known as the HLV-EM). It is possible, as with most lathes, to convert the English and metric boxes to cut the "other" threads as well; however, in the case of the Hardinge, this means the purchase not only of the necessary changewheels - another set that included the usual 127t and 25 other gears - but another banjo as well, special ones being manufactured for each of the two conversions. To turners used to the difficulties of screwcutting on conventional lathes - for example, cutting to within a few thou of a shoulder or into a deep recess - the arrangements on the HLV appeared as nothing short of magic. The machine could be set to automatically disengage the screwcutting at any pre-determined point - and the drive would drop out flawlessly and accurately every time. While this was happening, the leadscrew and clasp nut stayed engaged (so there was no need to use a thread-dial Indicator) and all the operator has to do was to return the tool to its start point, apply more cut, and re-engage the drive. Not only did this does work with all pitches of thread and at modest speeds, but also at high r.p.m. - and returning to an "ordinary" lathe after experiencing secure, 500 r.p.m. screwcutting on an HLV was always going to be a disappointment. One refinement was a leadscrew held in tension and running in anti-friction bearings. For some time now a version of the Today, a version of the Cyclematic built in Taiwan and a lathe that may well be the same but branded as the SB1009 Super Precision Digital Threading Collet Lathe, has digital threading by means of a microprocessor-controlled, servo-driven leadscrew. Simply typing in the desired thread pitch - English or metric - on the numeric pad of the touchscreen LCD panel and starting the threading cycle is all that's required.

Another interesting feature of the HLV design was that both cross and longitudinal feeds could be operated simultaneously--which action generated a perfect 60-degree cone. The standard toolpost incorporated a screw-operated wedging arrangement designed to facilitate the quick setting of the cutting-tool height--while maintaining that all-important ingredient of successful turning, tool rigidity. Also available, in addition to the standard single-tool holder, were various types of special toolpost and individual toolholders.

A positive lubrication system was fitted to the carriage operated by a plunger fitted to the top rear of the saddle and to the right of the cross slide. Lifting and releasing the plunger several times during the working day was sufficient to keep the cross-slide and bed ways wet with oil. The double-wall apron and clutches had separate oil supplies - the level of which should be maintained at the half-way line on the sight-glass window fitted in the vertical surface of the saddle at the end nearer to the headstock.

Even the tailstock on the HLV was carefully thought out and, with the hardened and ground spindle extended six inches, a further 6 inches was retained within the casting. A zeroing, black-and-white micrometer dial was fitted as standard and the spindle engraved at 1/8" intervals>

Not all HLV-H lathes were created equal and some - due to the unavoidable vagaries of the manufacturing process - were found to be even more accurate than standard. In the past, these special lathes were marketed by the factory as "Super Accurate" and offered at a premium of several thousand dollars above the regular price.

While general maintenance on HLV-H lathes is straightforward (and the various handbooks very helpful) when it comes to any problem with the headstock spindle bearings (see above) these are best left to either the factory or expert re-builders. Obtaining the genuine bearings and fitting them correctly (mishandling will ruin them) is money well spent.

The HLV-H has also been copied by several Taiwan firms including Barer, Cyclematic, Sharp, ProMach and 'South Bend' In addition, some of these makers have supplied machines with "alternative" branding for distribution by dealers worldwide. Feeler was the brand name used by the "Fair Friend Company Limited", originally of 11/F No. 665, Tun-Hwa South Road, Taipei, Taiwan with a factory at No. 805, Chung-Shan Road, Shen-Kang Shiang, Taichung-Hsien, Taiwan. Another branding, from a similar address - Factory No.90-2, ShenChou Road, Shen-Kand, Shiang, Taichung Hsien - was Alex-Tech.

Sharp's copy was beautifully made and sold as standard with a hardened bed and a 5 h.p. Japanese Yaskawa drive; however, they also offered the "Acra", a less well-finished model with a soft bed and minor changes to cut production costs. ProMach, of whom few details are known, referred to their version as the "ProLathe" and sold it until at least the mid-1990s, and possibly later. The "Victor", made as the standard CTL-618, the Cyclematic CTL-618EM and CTL-618EVS with an improved electronic variable-speed drive, was by an unknown manufacturer, but distributed through the Taiwan Machinery Trade Centre in California.

If you have further details of these or other clones, the writer would be pleased to hear from you.

Hardinge also made other machines of interest to the model and experimental engineer: the "Five-Nine Super-Precision Model Shop Lathe" (DV59) and a range of very high quality vertical and horizontal milling machines - some of which were badged, during the 1930s, using the Cataract name.

Surviving Serial Number records

HLV-H (US production):

1960…..0100 1961…..0210 1962…..0554 1963…..1042 1964…..1540 1965…..1905

1966…..2345 1967…..2864 1968…..3327 1969 to 1971 ……? 1972…..5014-K

HLV (UK production - the only data ever discovered)

1955…..Serial Number 0207 to 1958….. Serial Number 0442.

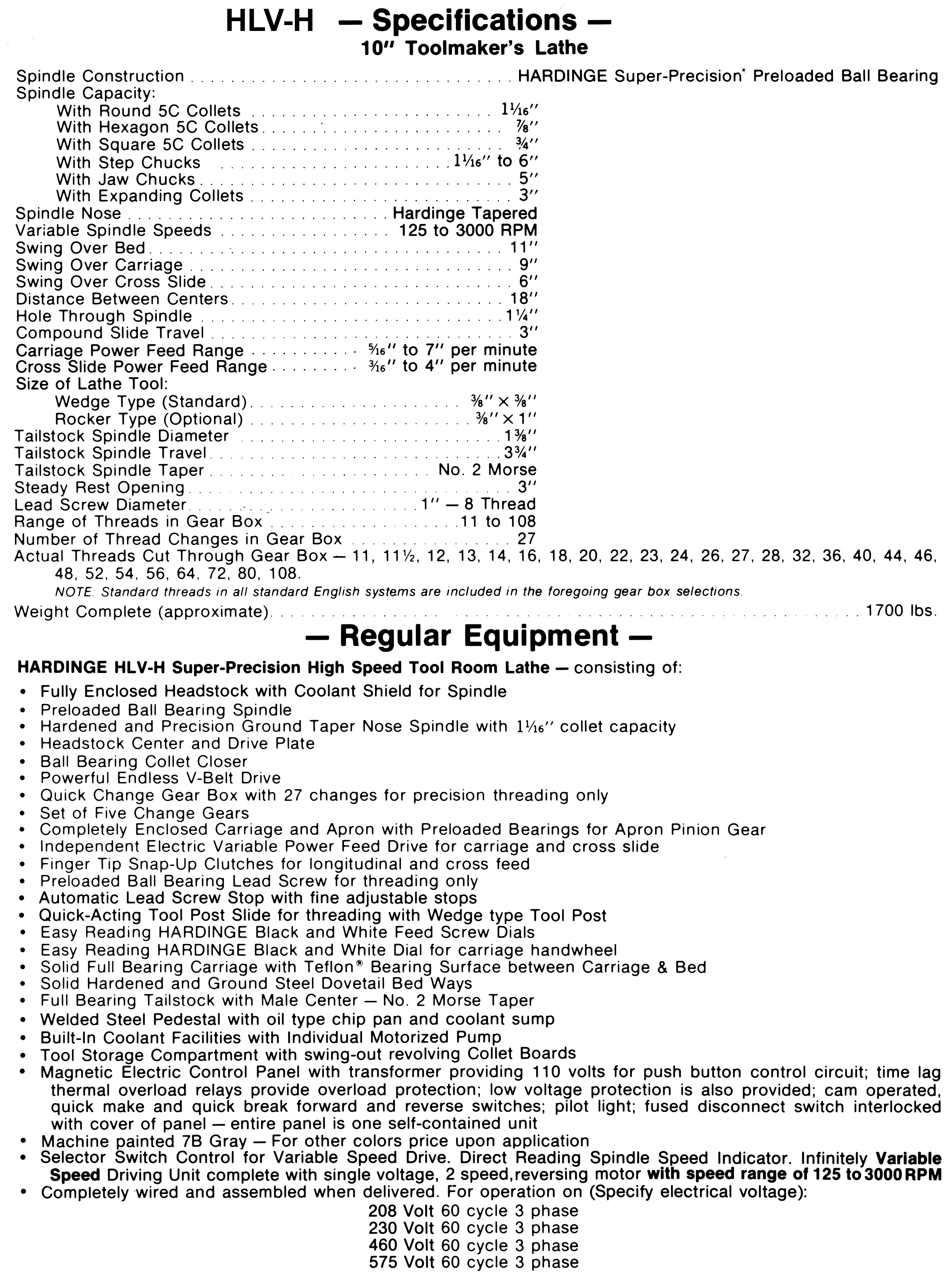

The HLV-H had an overall length of 68 inches, a width of 30 inches and stood around 58 inches high. It's weight, with standard equipment was listed as being 1700 lbs. A complete specification sheet is at the bottom of the page..

|

|