|

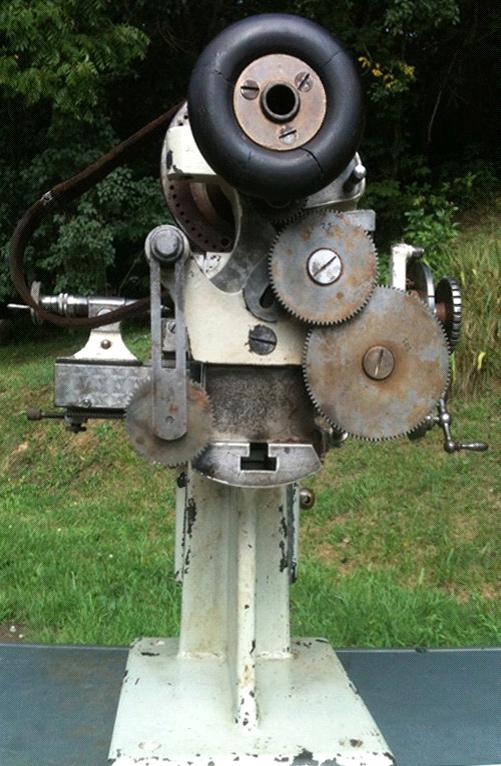

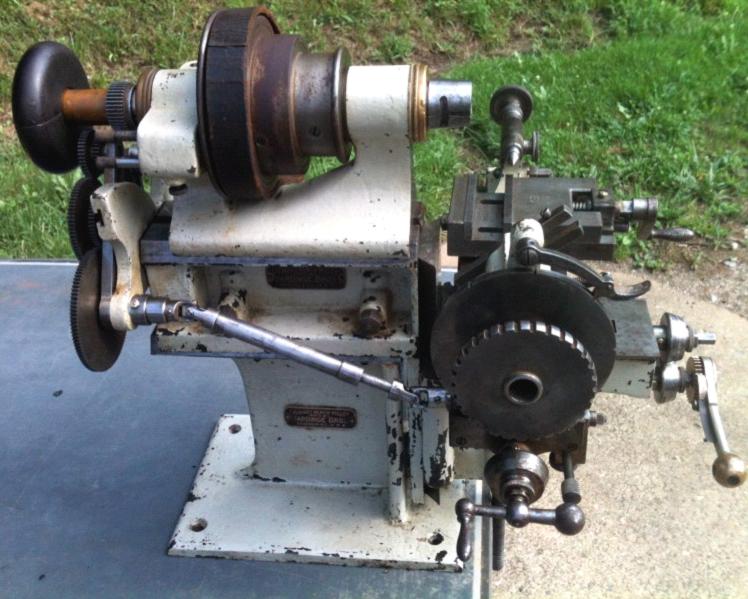

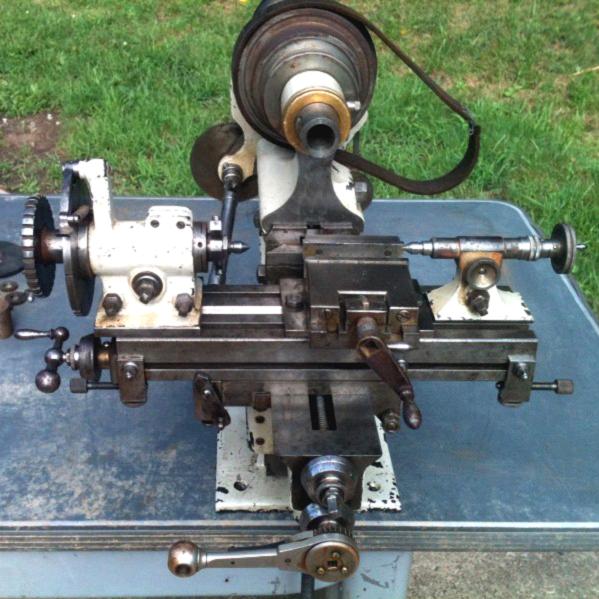

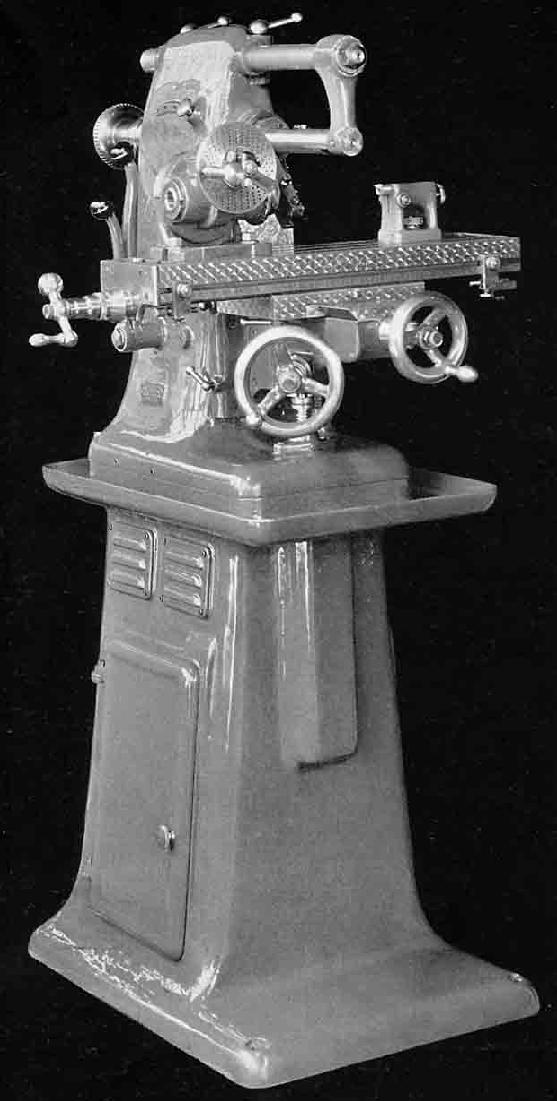

Manufactured by the American Hardinge precision lathe and collet company the first Cataract horizontal and vertical millers, constructed before World War 1, were small machines standing just 161/2" high. They made use of several already-existing parts - the main body casting being topped with a replica of a precision bench-lathe bed to which a slightly modified No. 3 or No. 4 lathe headstock was bolted, while the knee and compound table were identical to those offered as conversion kits to turn the company's lathes into horizontal millers. As a further economy the table power-feed arrangement was provided by the same drive used on the lathes as a screwcutting attachment - and also retained the very useful adjustable automatic knock off control (though later versions were given a custom-made fitting). There was no overarm support for the cutter and the machine would have been limited to work of a lighter duty only. The knee and compound table of the vertical miller were identical to those used for the horizontal and, while the head casting was completely different, it also used the same spindle and bearings found in the Cataract No. 3 lathe headstock.

A precise dating for the introduction of the bench miller is difficult: the Company's 1903 catalogue shows a No. 3 bench lathe but no milling machine - even through the headstock of that lathe (with its 3C collet fitting) was to be used on the miller. It is therefore reasonable to assume that the first examples would have been made circa late 1903 or 1904. Although the start date is uncertain, it is possible to identify the very first examples by their rather different construction, the main column being a solid casting with an I-section. By 1915, and probably earlier, this had become a very much more robust rectangular hollow box type with other identification features including spindle locking (like the early lathes) by a pin that could be inserted into one of four holed drilled into the outer flange of the smallest pulley. At the other end an indexing pin was provided that fitted into a circle of 60 holes drilled into the end flange of the largest pulley.

With a maximum clearance of 61/2" from the spindle, the table was 12" long by 33/16" wide; it carried one central T-slot (which had bevelled edges to locate fittings such as the dividing unit), and two plain outer T-slots for clamping work. The table had a cross travel of 4" and could be moved longitudinally through 51/2" by a screw feed or by 5" using a rack-operated lever mechanism that bolted to the same location used for the power-feed attachment. Before the lever feed could be engaged, the main slide nut had to be removed but, as this was exposed on the side of the knee casting, the job took only a moment. All of the indexing type, the micrometer dials were 17/16" in diameter and graduated to read in thousandths of an inch.

Another much larger and stronger miller, the No. 5, was also produced from around 1912 and continued to be manufactured, in a modified form with neat, enclosed drive systems and 2-speed motors, into the 1930s and 1940s.

Improved Cataract/ Hardinge millers, the types MD3, MD4, MD5, BB4, BB2V5, were introduced during the 1930s and mirrored, to some extent, the development of the company's bench lathes - having completely enclosed V-belt drive systems with the two-speed motors operated by neat, external levers. Later still, Hardinge dropped the Cataract label and advertised the machines, with further modifications and additions to the range, under their own name. All Hardinge Cataract millers were available with a range of high-quality accessories, some of which are shown lower down the page.

Continued below:

|

|