|

Well-known since the early 1940s, and still enormously popular today, and the Centec 2, 2A, 2B and 2C (and less well-known 3 and 4 Series and Automil) milling machines were originally manufactured by the Central Tool & Equipment Company at the "Centec Works" in Maylands Avenue, Hemel Hempstead, Hertfordshire, England. An earlier address, and one that appears on the maker's plates of some early models including the belt-drive Model 2A, was Church Terrace, Richmond, Surrey. This was the site of the Sunbeam Works, and is shown in contemporary Trade Directories as having been occupied by Centec from 1940 until 1956. The building still stands, only partially redeveloped and with part of it housing yet another service "industry" - a Tai restaurant.

Unfortunately, the serial number data for Centec millers is far from complete; the factory never issued complete lists and only US-based "Serial Number" book publishers give any information - and that, I suspect, given its paucity, was given only grudgingly. Hence, it's not unusual to find wide variations on what is shown below:

Serial Numbers recorded are, for the No. 2

1943.....429 1946

.738 1949

.933 1952

.1091 1955

.1194 1958

.1203

Serial Numbers for the 2A

1946

.79 1949

.372 1952

.1086 1955

.1560 1958

.1714 1961

.1886 1964

.2063

Serial Numbers for the 2B

1958

.5213 1961

.5519 1964

.5706

Under the ownership of a Mr Samuels, the millers were of compact design, beautifully constructed and versatile in use - hence, they have long been respected by enthusiasts who appreciate a product of outstanding quality. Lots of handwork are known to have gone into finishing each machine, with hand-scraped surfaces and a final running-in test under power before dispatch. The original design dates back to the early 1940s, when the first model was introduced as a development of the V.E.C. or "Victa" horizontal miller, a machine sometimes badged as a "Warwick". As a point of interest, during the 1940s and early 1950s, Victa also manufactured lathes using the "Warwick" name. Quite different to the rather advanced range of geared-head lathes sold under the "Hobson" brand, this was a machine intended for model-engineering. Backgeared and screwcutting, with a gap bed and using an all-V-belt drive, it had a 3.5" centre height and admitted 18" between centres. Later, having moved to Pool in Dorset, Victa also built the Eagle surface grinder, a model originally manufactured by Dronsfield Brother, makers of Marlow milling machines.

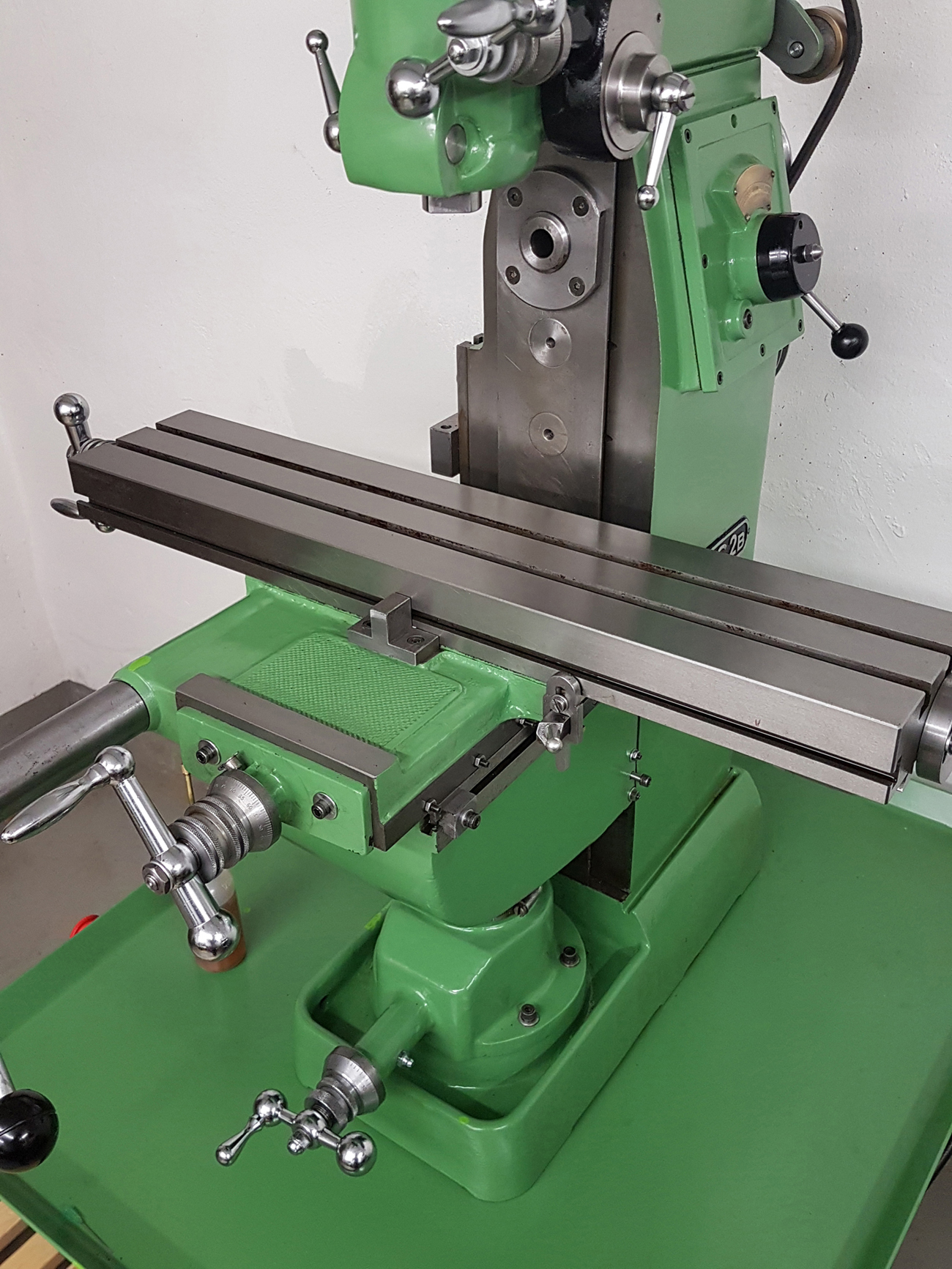

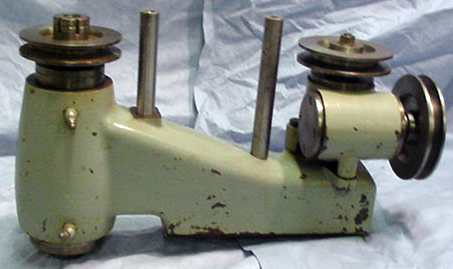

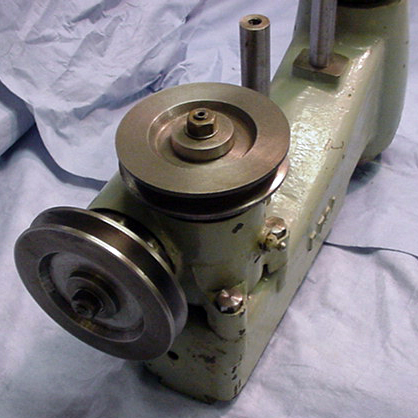

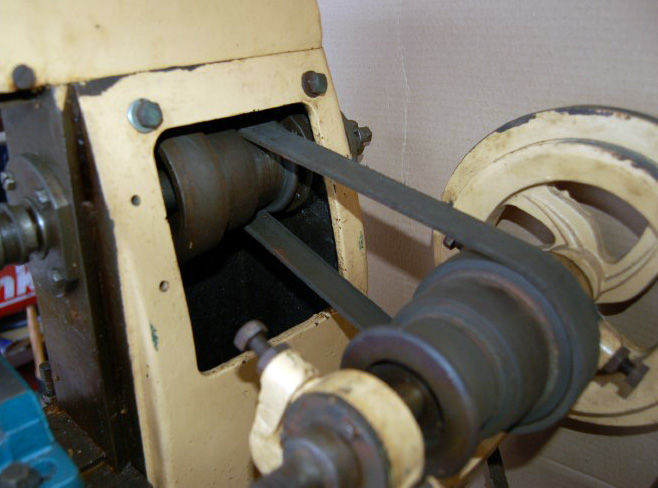

Built from 1943 to approximately 1949, and fitted with flat-belt drive, the original Centec had a 12" x 3.75" table, a round overarm and was a horizontal-only machine - there being no facility to fit a vertical head; the next model. The Centec 2 was a substantially modified machine with the round overarm replaced by a much more robust and rigid dovetail fitting (a move reflected across the industry and caused by the need to stiffen machines to take advantage of new cutting tools that permitted the use of deeper and faster cuts). The dovetail overarm slideways, machined into the top of the column, also allowed the fitting of a vertical head. While the same design of simple, side-mounted countershaft continued in use with flat belt drive, later machines benefited from a change to V belt. In 1949 the Centec 2 evolved into the 2A, with changes that included a slightly larger table of 16" x 4.25" and, of greater importance, a completely revised drive system consisting of a 6-speed gearbox built into the body of the main column. The new drive (with a 0.5 to 0.75 h.p. 3-phase motor) gave spindle speed ranges of: 85, 195, 395, 595, 890 and 1400 rpm or, alternatively (with a 2800 r.p.m. motor), 170, 390, 790, 1190, 1780 and 2800 r.p.m. Some versions have also been found with 1 h.p. 2-speed, 3-phase motors that gave twelve speeds from 85 to 2800 r.p.m. Next, in 1958, came was the 2B - a miller that offered a number of improvements over earlier versions including a much more useful 25" x 5" table and the repositioning of the knee elevation handwheel - from its inconvenient location towards the rear of the column's left-hand face - to the front, where, not only could it be more easily manipulated, but also its action more easily observed. The castings of the 2B were strengthened and the knee benefiting from improved stiffness by being boxed in at the front. The final conventional Centec model was the 2C, this having a 29.5" x 6" table and mounted on a very heavy cast-iron stand.

Table travels of the various models were as follows:

2A - longitudinal 9", cross traverse 4.5", vertical 6"

2B - longitudinal 14" (less 1.25" with power feed) cross traverse 5", vertical 9.5"

2C - longitudinal 14" (including power feed), cross traverse 4.5", vertical 11.25"

2A - maximum distance from spindle centre to table 6.625"

2B - maximum distance from spindle centre to table 10.5"

2C - maximum distance from spindle centre to table 11.25"

For bench mounting the 2A weighed approximately 360 lbs - the 2B 500 lbs and the 2C (a comparatively rare and much more massive model stand fitted with a heftier main column, longer and wider table with a feeds gearbox and only supplied on a heavy cast-iron stand), weighing in at nearly half a ton.

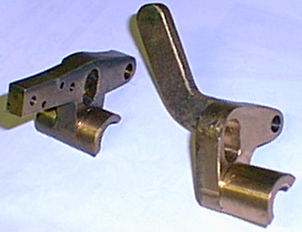

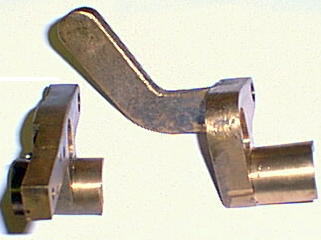

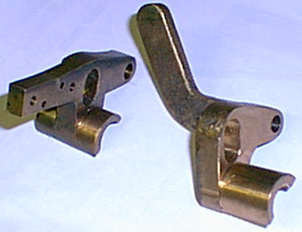

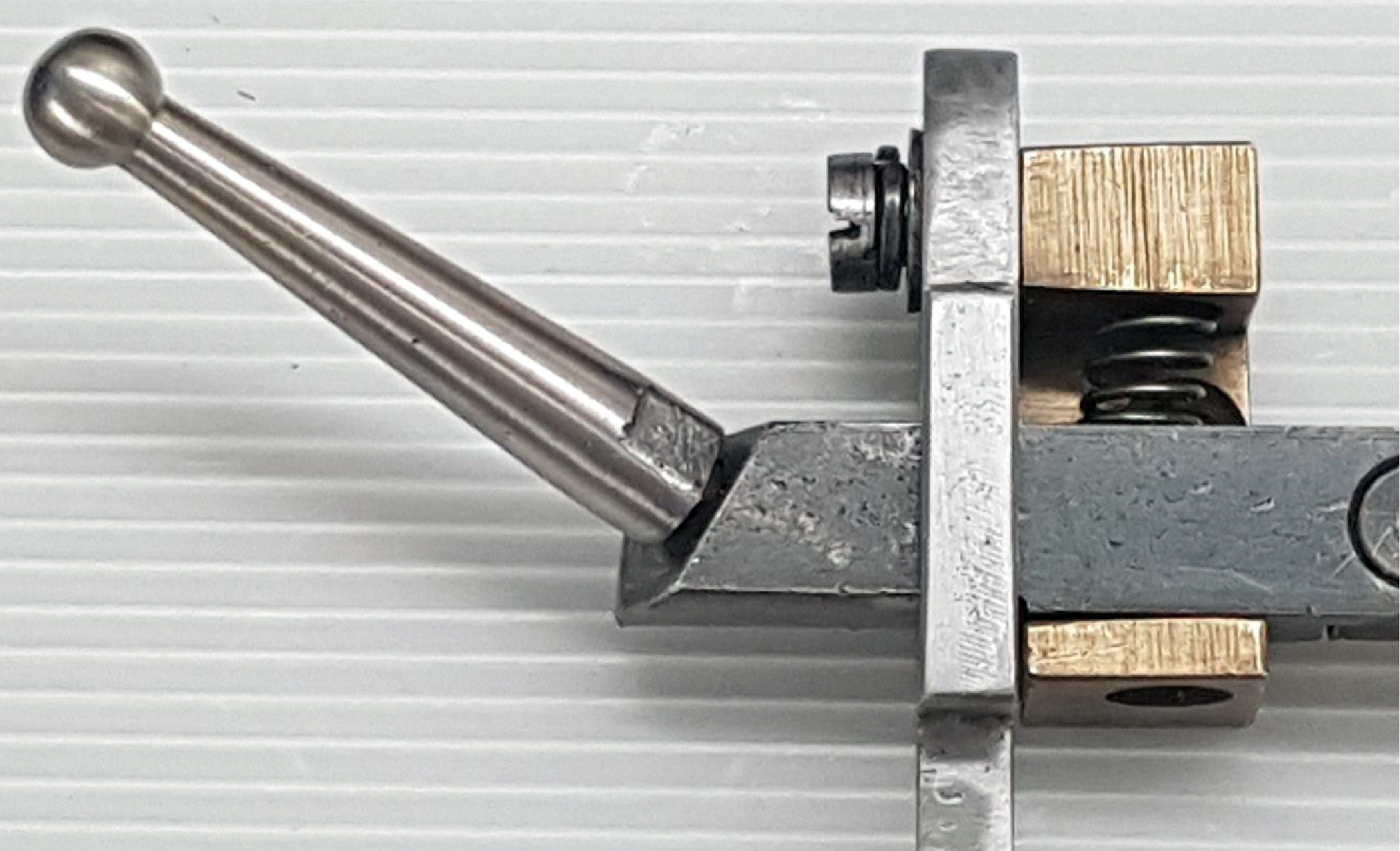

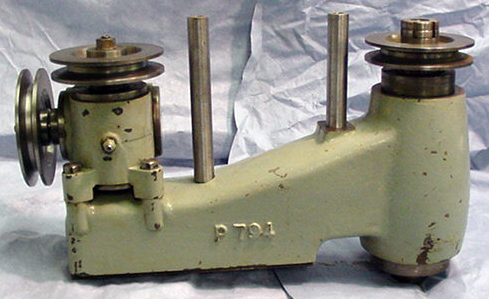

One important and desirable accessory was the vertical head, by which means any ordinary horizontal model from the 2A onwards could be transformed into a very much more useful vertical and (when equipped with the optional swivelling table) a "Universal" model. The vertical head slotted into the same dovetail as the overarm and, being rather short of clearance as standard, could easily be raised in height by using a suitable raiser block with dovetails top and bottom. Three distinctly different versions of the head were manufactured: the first (Mk. 1), was an expensive-to-produce unit that mounted an enclosed bevel box at the back that turned the drive through ninety degrees - from where it was taken by an exposed V-belt forwards to the spindle; the Mk. 2 had its drive completely enclosed within the body but unfortunately, like the first, had no quill feed. The Mk. 3 version (and by far the most eagerly sought after) was a beautifully constructed unit that incorporated both a fine down-feed through worm-and-wheel gearing and a quick-action, rack-and-pinion driven drilling feed by a handle. The change from one type of feed to the other was through an all-metal cone clutch that, if properly set up, could be flicked into and out of engagement with just light finger pressure. The very first versions of this head had two horizontal slots across the bottom of the casting - one closed down by a nut and bolt to set the quill-to-bore clearance, the other equipped with a ball-ended handle to provide a means of locking the quill in the desired position. A picture the only known head of this type can be seen on this page.

As a point of interest, when a Centec is changed from horizontal to vertical drive the spindle will, unless the motor is fitted with a reversing switch, turn in the wrong direction.

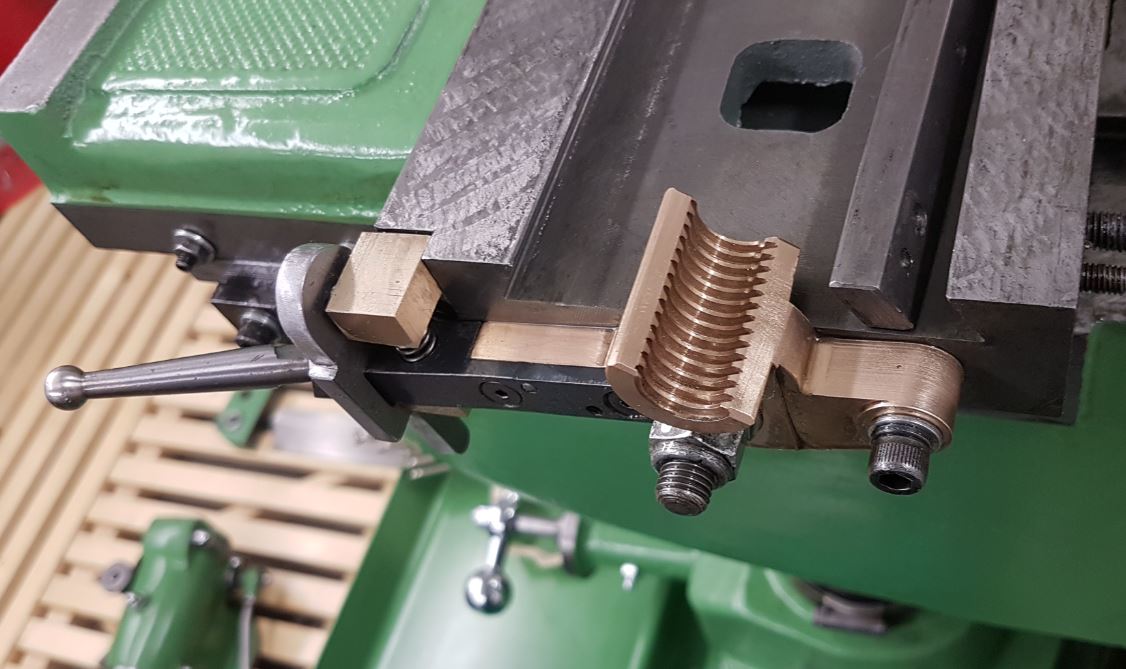

While a table power-feed assembly was standard on the 2C it was an option on the 2A and 2B; when fitted four rates of feed were provided: 0.65, 1.19, 2.18 and 4 inches per minute each selected by combining any two from four pick-off gears stored under a cover on the right-hand end of the table. All later Centec millers had large, easily gripped, chrome-plated "balanced" handles on their table feed screws and clearly engraved, angled-faced micrometer dials. Early table feed screws were 1/2" x 10 t.p.i. square thread, later changed to a more robust and longer-lasting 5/8" x 10. t.p.i. - though the thread remained square. Feed-screw nuts on tables fitted with the quick-action, rack-and-pinion lever-operated feed were of the "half" type and, being pivoted and fitted with a cast-in handle, could be quickly dropped into and out of mesh. The quick-feed attachment on early models was relatively crude and used a pinion gear with a tapered end onto which fitted a handle with its mounting boss bored with a matching taper - so allowing the operator to set its position, or leave it loose and hanging down when not in use. A much-improved version, with a circular face ratchet tightened by a knurled ring, was eventually to replace it.

Besides longer tables, the 2B and 2C Models both had a more robust knee, with a front rather than side-mounted operating handle, and a wider cross slide. Because the 2C was intended for heavier work and more rapid rates of metal removal, the top of the main column was machined with a wider dovetail to accept a much heaver overarm. As a consequence, in order to allow the standard vertical head to be fitted, the makers supplied a step-down adaptor plate - a fitting that was thick enough to give the effect of a small raiser block. Although most types of Centec are found fitted to underdrive stands, the 2A was also available as a bench model with a motor mounting provided in the form of 4 raised T-slots cast into the right-hand face of the main body.

Continued below:.

|

|