|

A recognised, high-class toolmaker, Joseph Buck was a resident of London. His lathes are rare, with the ones shown below and on this page being amongst the only known survivors. The Buck was almost of the "Bench Precision" type - a design first made by Stark in the United States with first examples being built by John Stark personally in 1862, well before any of his subsequent competitors, all mostly from the same Waltham area. Looking to have been built from as early as the 1850s, the Buck was of a plain-turning, precision type that continued to be made (in decreasing numbers) into the 1950s. Today the only surviving makers are Schaublin, in Switzerland, who continue manufacture of their 70 and 102 models and Derbyshire and Levin in the United States - and possibly Eguro in Japan..

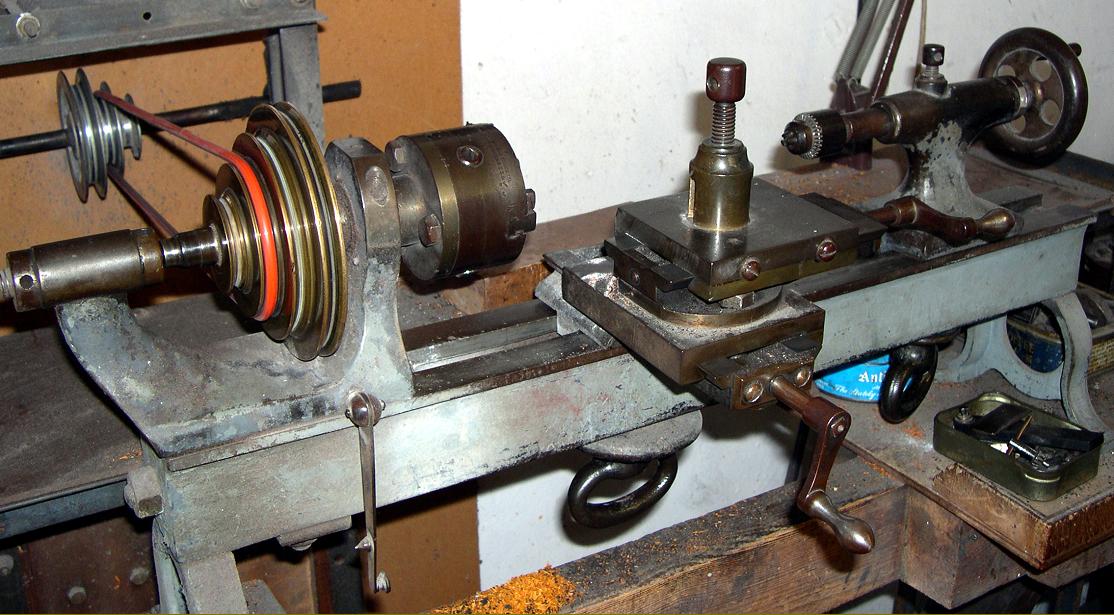

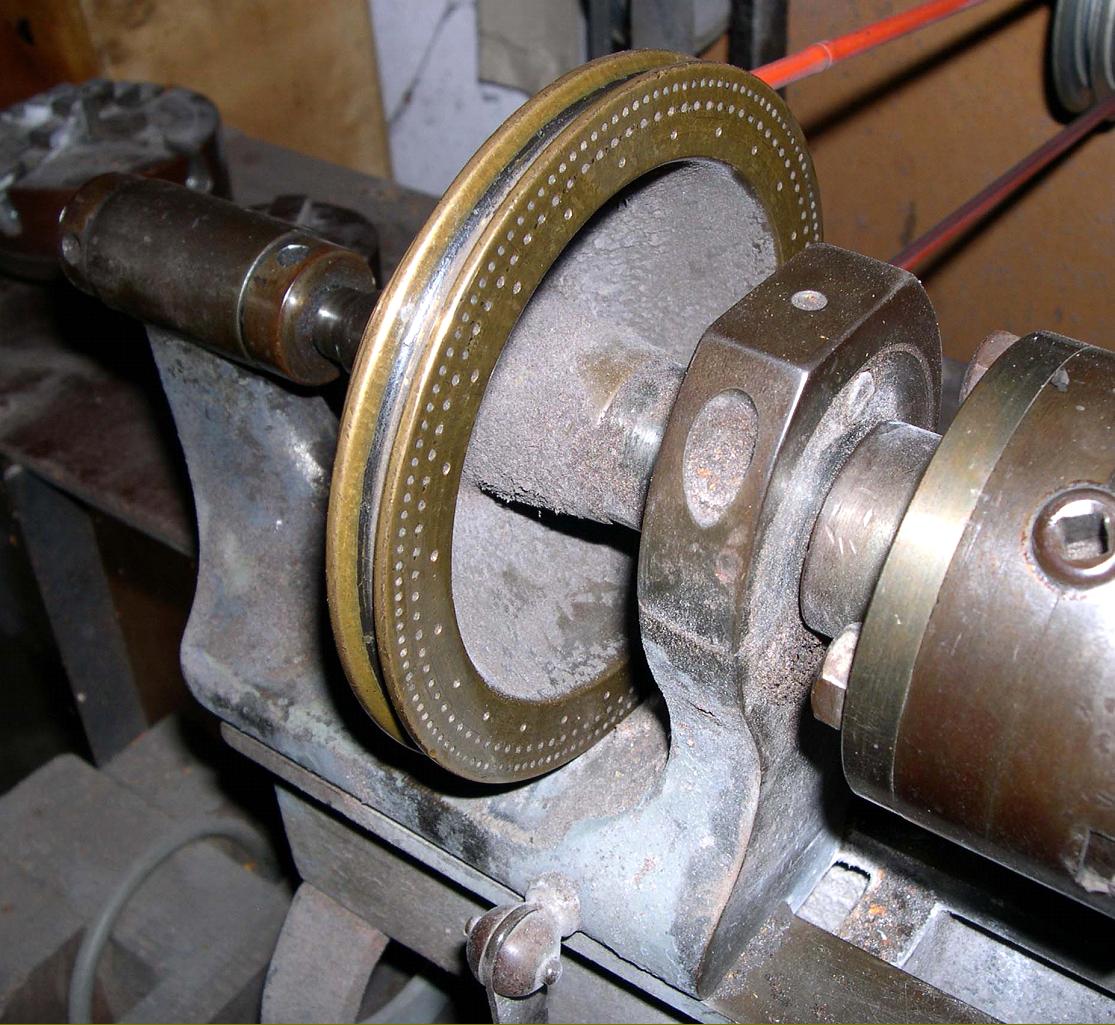

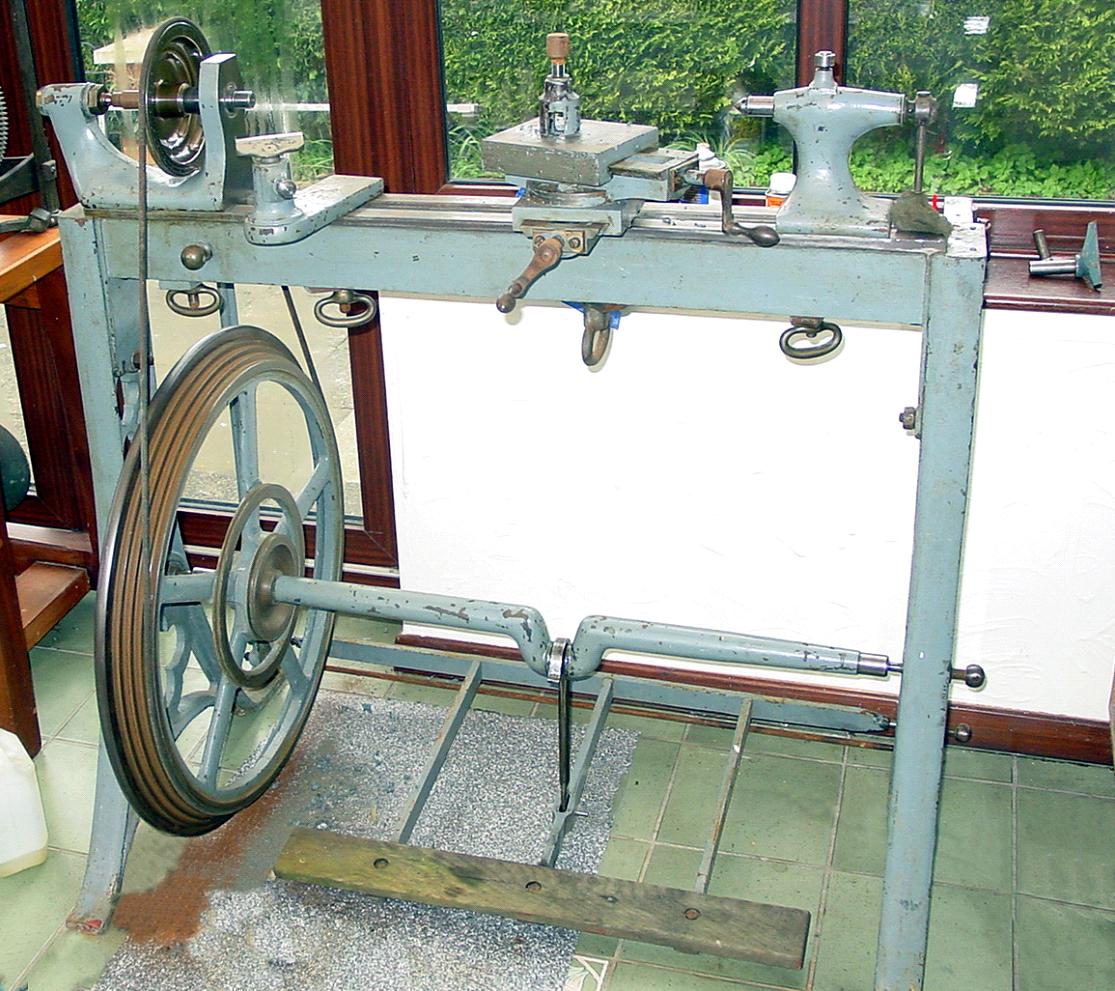

Buck made at least two - and possibly many more models of lathe - the more common being the essentially simple types illustrated on this page and a more complex, heavy model shown here. This latter 4.5" x 26" machine was mounted on particularly elegant cast-iron legs and fitted with treadle drive. The headstock was of the sliding-spindle type, with chase screwcutting by a "star" master thread, fitted with six different pitches, and able to be rotated to bring each into engagement. The front face of the headstock pulley was drilled with five circles of holes for division purposes.

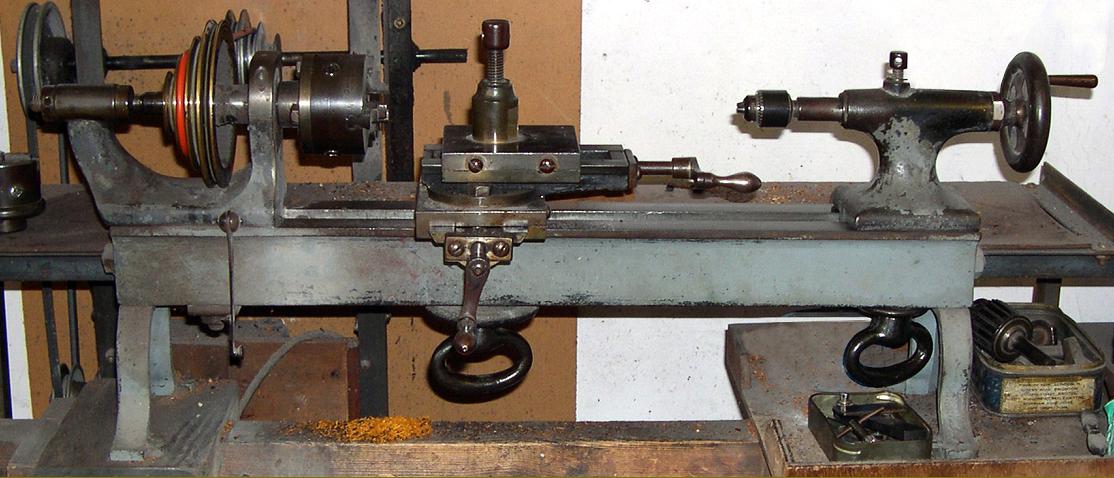

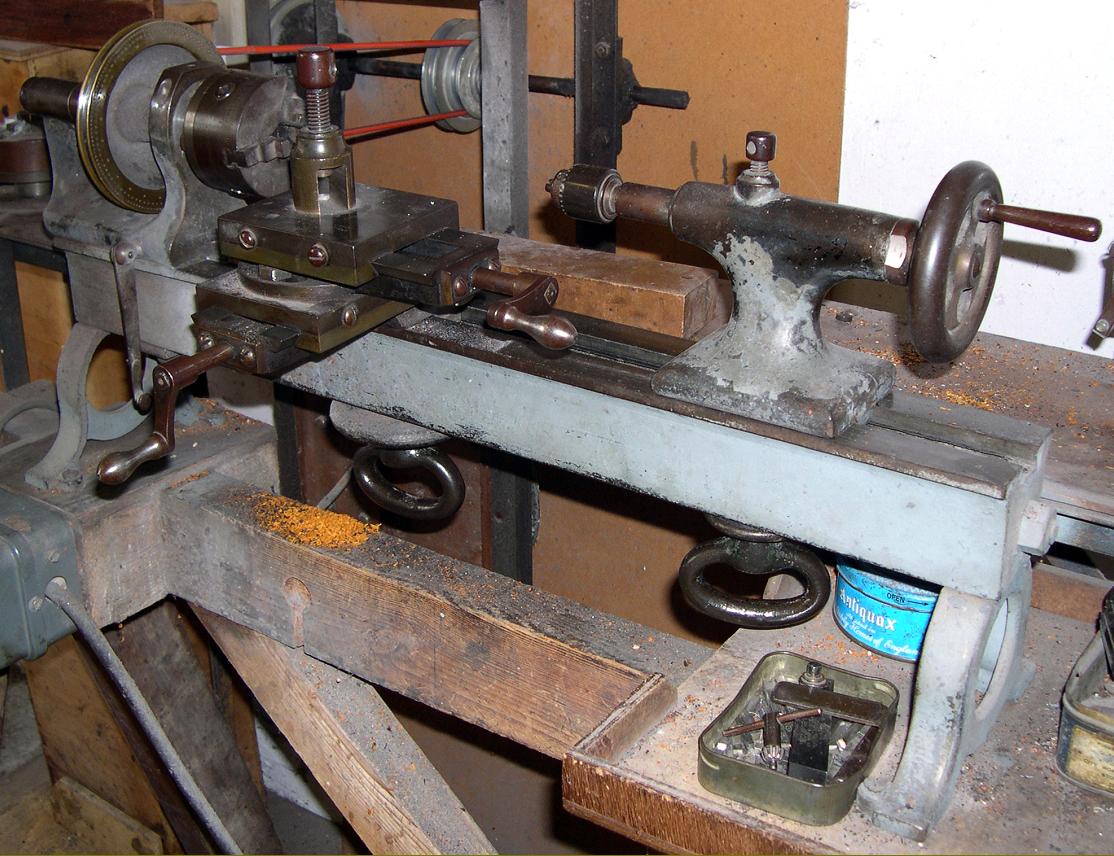

The lighter lathe, most around 27 inches long, with a centre height of 3.5 inches and taking 12.75 inches between centres, were typical of their time in the lighter class. The spindle ran in a single front bearing with the other end supported against an adjustable, hardened steel point, with drive by a round leather "gut" rope running over a 4-step V-pulley in bronze. Also typical for the time, the outer face of the largest diameter was equipped with three circles of division holes - almost certainly ones with as many useful factors as possible e.g. 120, 100 and 36. Held to the bed by the usual through-bolt with a large handle, the compound slide rests, in cast iron, showed some signs of quality with their adjustable gib blocks in bronze and the body of the toolposts in the same material. However, in other respects the lathes mirrored less successful practice in having flimsy end plates supporting the outer ends of the feed screws, awkward-to-use crank handles and, of course, no micrometer dials.

Lower down the page are typical, lightly-built examples of the Buck lathe from Victorian times mounted on treadle stands with flywheel drive. For the amateur class these were especially well-built, expensive machines, constructed from high-quality materials and assembled with great care.

Lathes of a similar but even lighter type from the same era (or ones made later into the 1920s as less-expensive machines), include various models branded by the well known and popular makers and distributors Pfeil and George Hatch, the German Wisser Company, the less common Scott-Homer, Hayward, Rolfe and various models of the interesting and rather specialised Swiss/English Mandrel and even a miniature version, the.Drummond Little Goliath

Should you have a Buck lathe or details of the Company, the writer would be interested to hear from you. More Buck lathe pictures on this page..

|

|