|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||

|

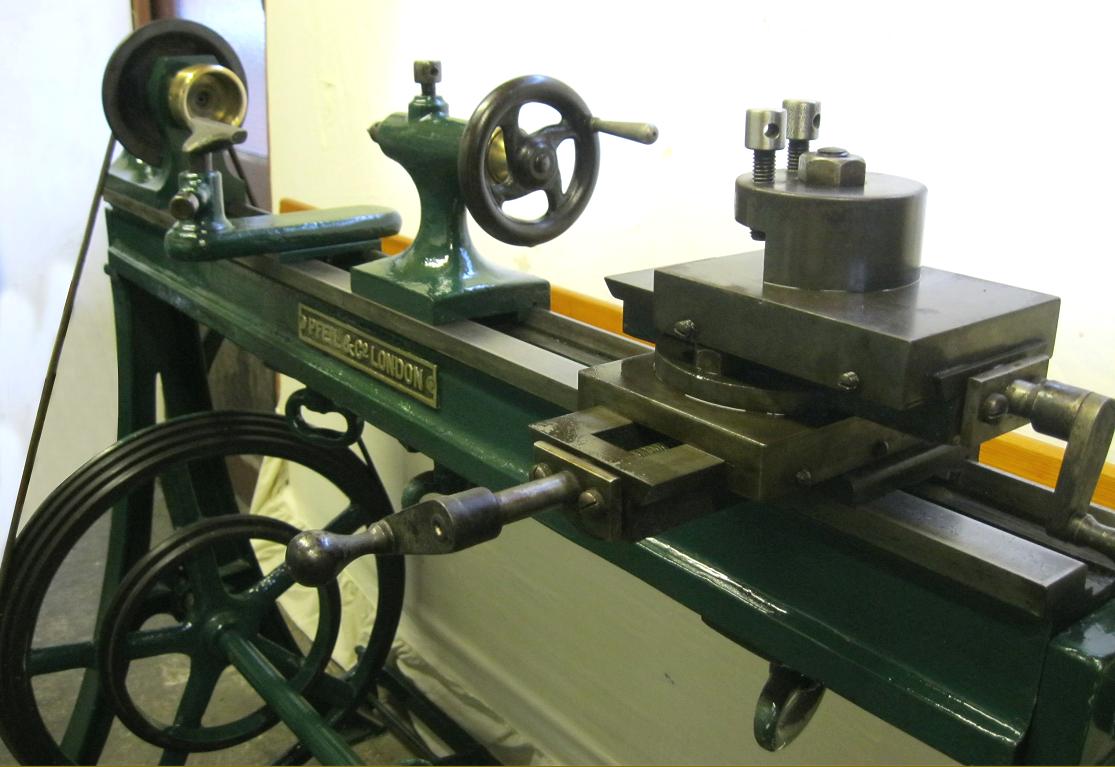

Pfeil were a firm established in the 19th century and based at 145, 147 and 149 John Street in the Clerkenwell district of London - with an associated company, Pfeil, Stedall & Son in Broad Street, Bloomsbury. By the end of the 1800s they had grown to become a major supplier of home-produced and imported engineering equipment (all illustrated in a large, beautifully-produced, hard-back catalogue) and also agents for several English and foreign machine-tool makers. They also "bought in" a range of shapers, small planers, drills and simple, plain-turning lathes which were sold under their own name and of which , dating from between 1870 and 1900, are shown on this page. |

|

|

||

|

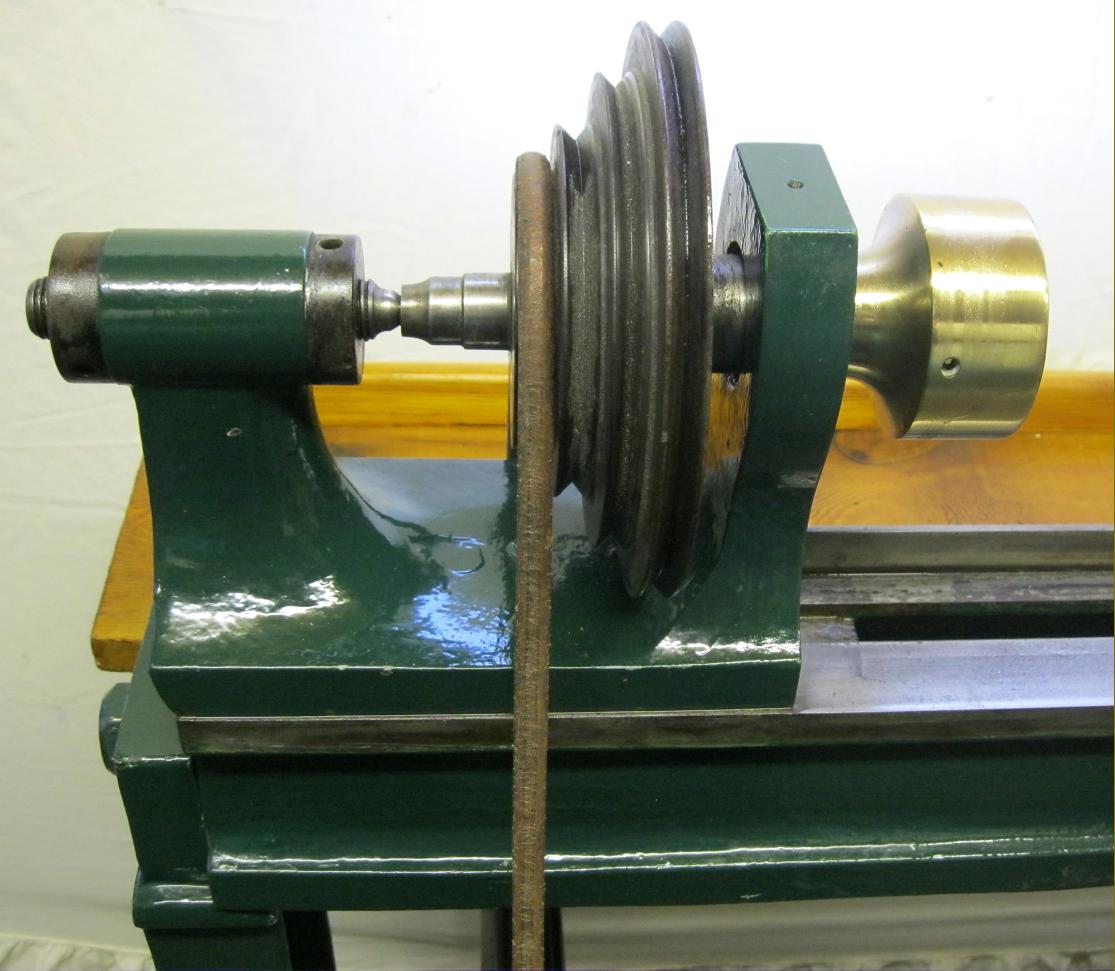

The solid spindle ran in a single bearing at the front - a tapered, hardened-steel bush - while the other end was supported against a hardened steel adjuster screw. The 4-step drive pulley was intended to be driven round leather belt - a so-called "gut" drive. |

|

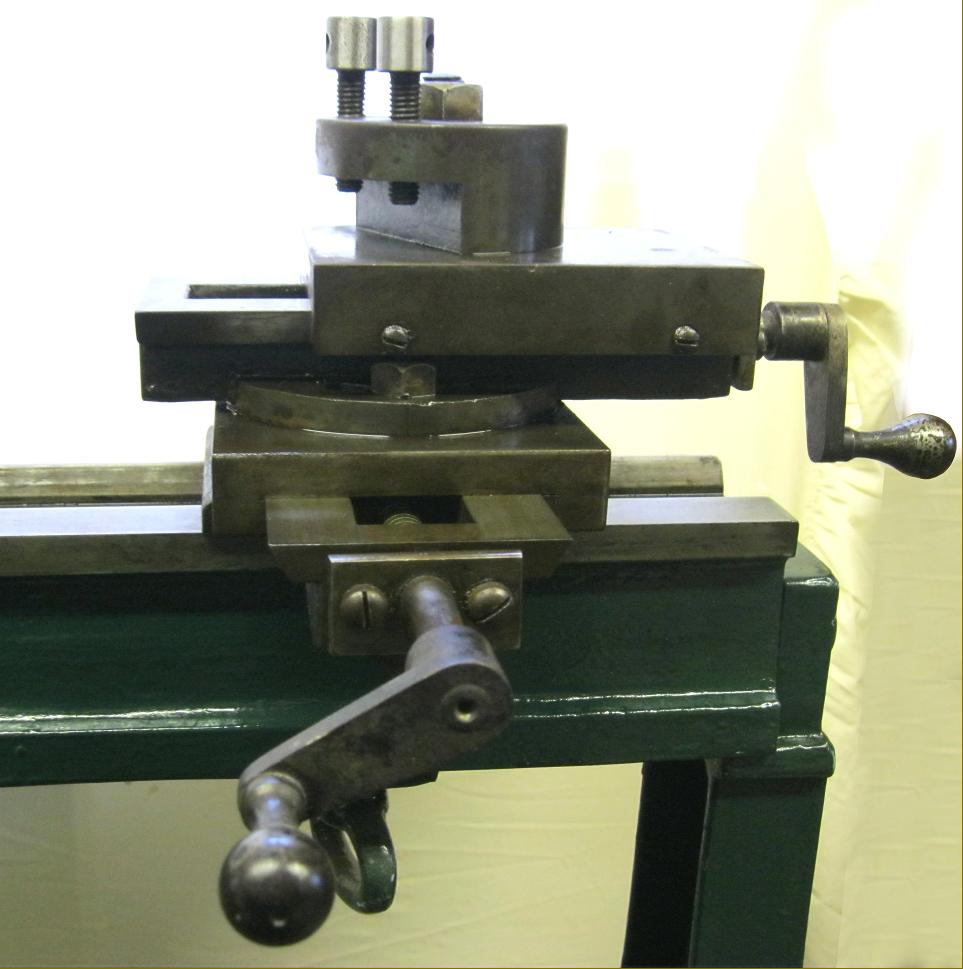

Simple crank handles and un-graduated feed screws were typical of the era. The top slide had only two gib-strip adjustment screws. |

|

|

|

|

|

Intended for both wood and light metal turning, the lathe would have been supplied with a selection of T-rests of various lengths. With its solid spindle, the tailstock centre has to be twisted out of its socket--a small hole being provided for this purpose. |

|

|

|

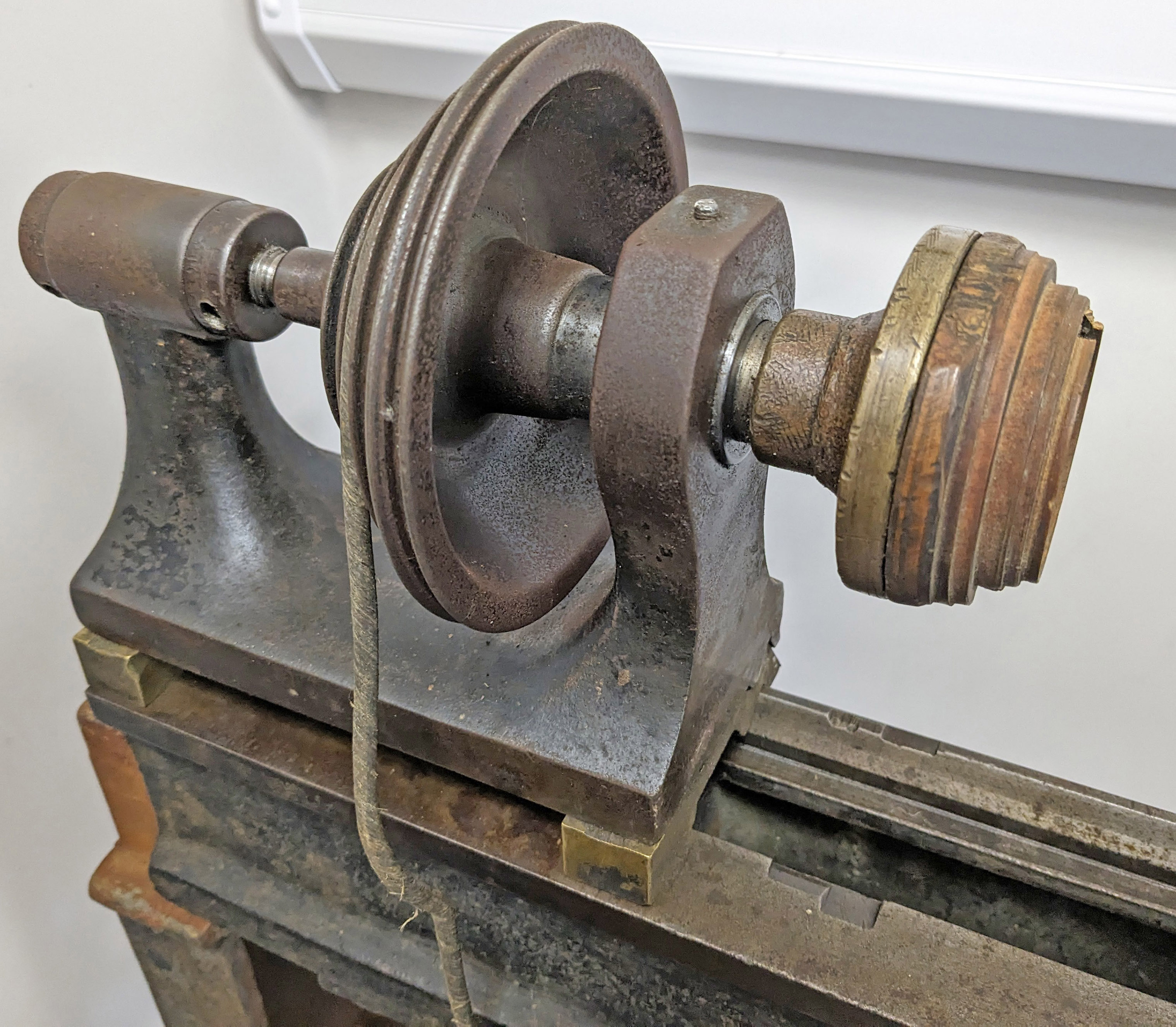

A remarkable survivor - a completely original Pfeil, even to the well-work wooden treadle bar. This lathe has a known history, having come from a clockmaker's/restorer's workshop in Clerkenwell, a business that was started around the end of the 19th century (though with master and apprentice links dating back from 100 years before. Hence, this lathe would have been made just around the corner in this area once famous for watch and clock work. |

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||