|

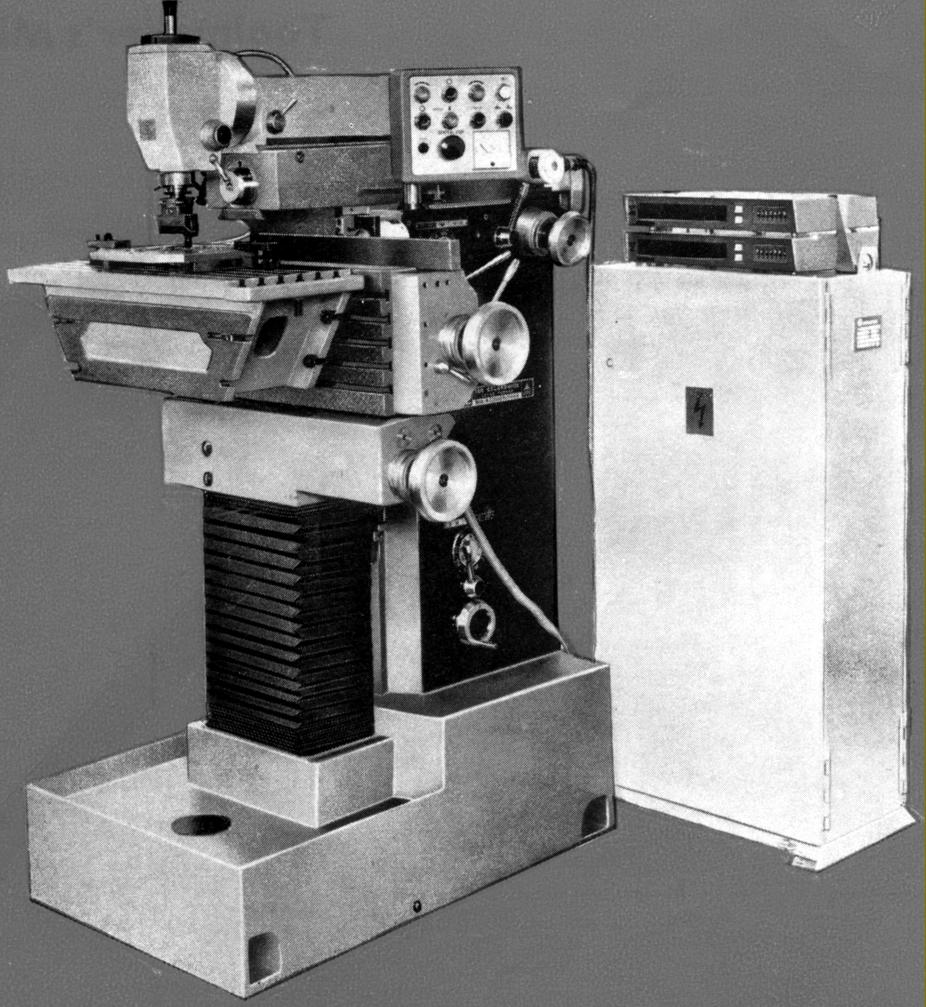

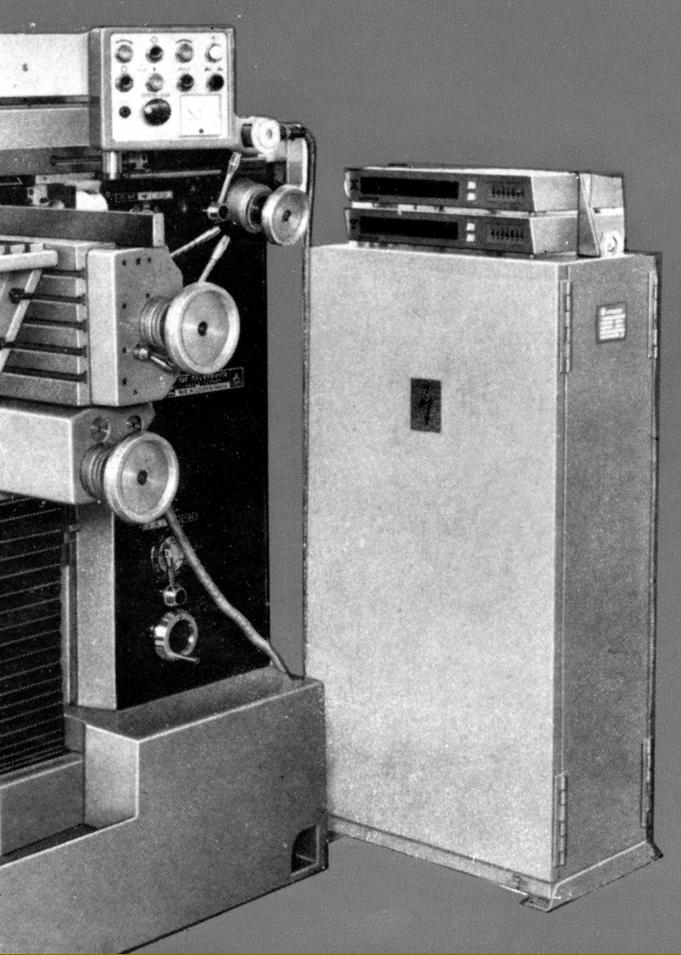

Developed from earlier models with rounded styling typical of the 1950s, the TOS FN range of precision universal milling machines was built in several versions including the FN20, FN32 and FN40 (another version, the FN22 was not updated). Later models, with more angular lines, continued to be manufactured into the 1980s in what was then the communist-controlled Czechoslovakian Republic. Several special versions were also offered, though these - for example the FNGJ-20, FNGJ-32, FN-32NC - differed only in the fitting of optical or digital read-out systems.

Although the range of accessories did not quite match that offered by Western makers of similar models - there being, for example, no specialised milling attachment for intricate corner work or a high-speed head with fine down-feed - these were very substantially constructed precision millers (the FN-20 weighed 750 kg and the FN-32 1550 kg) - and offered at a price many thousands of pounds below that of the competition.

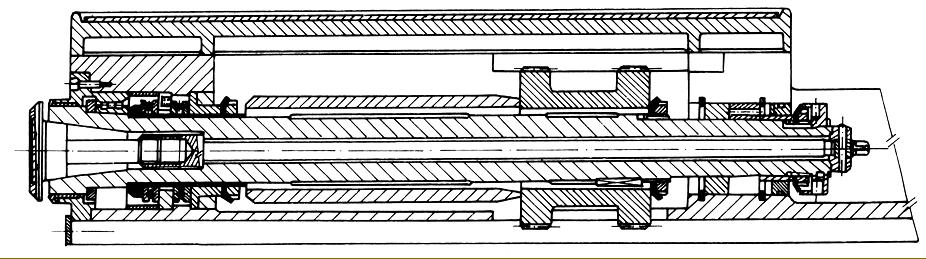

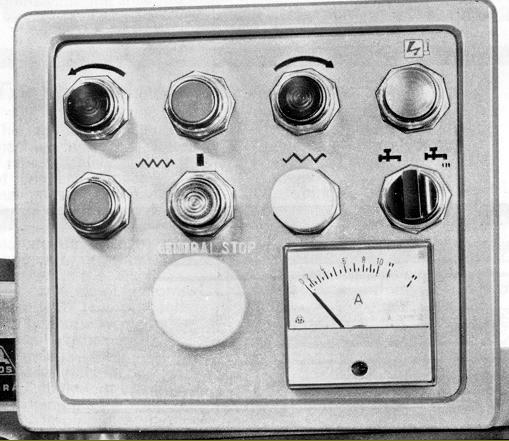

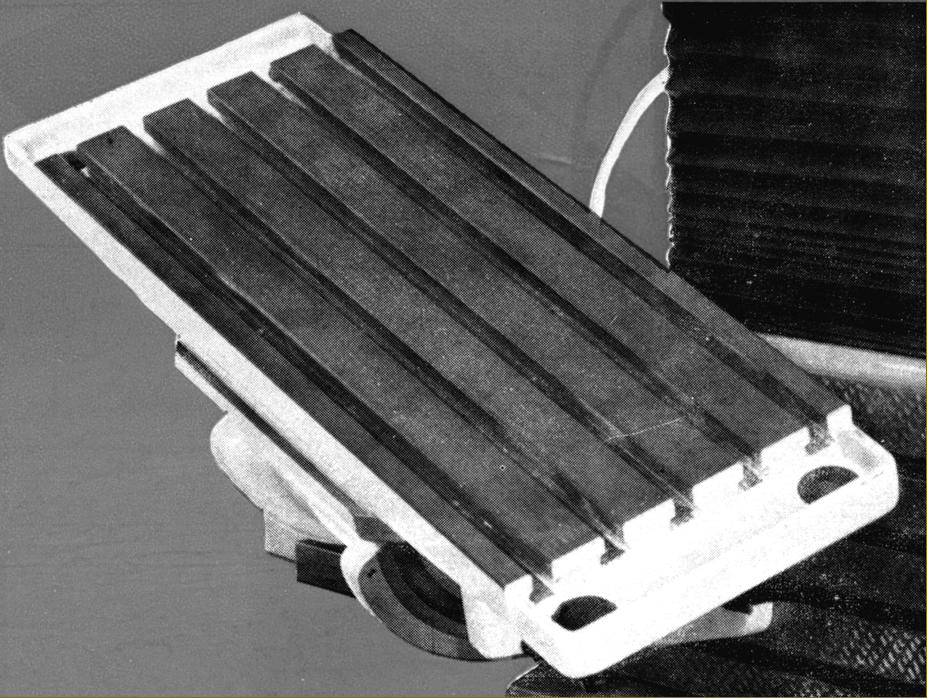

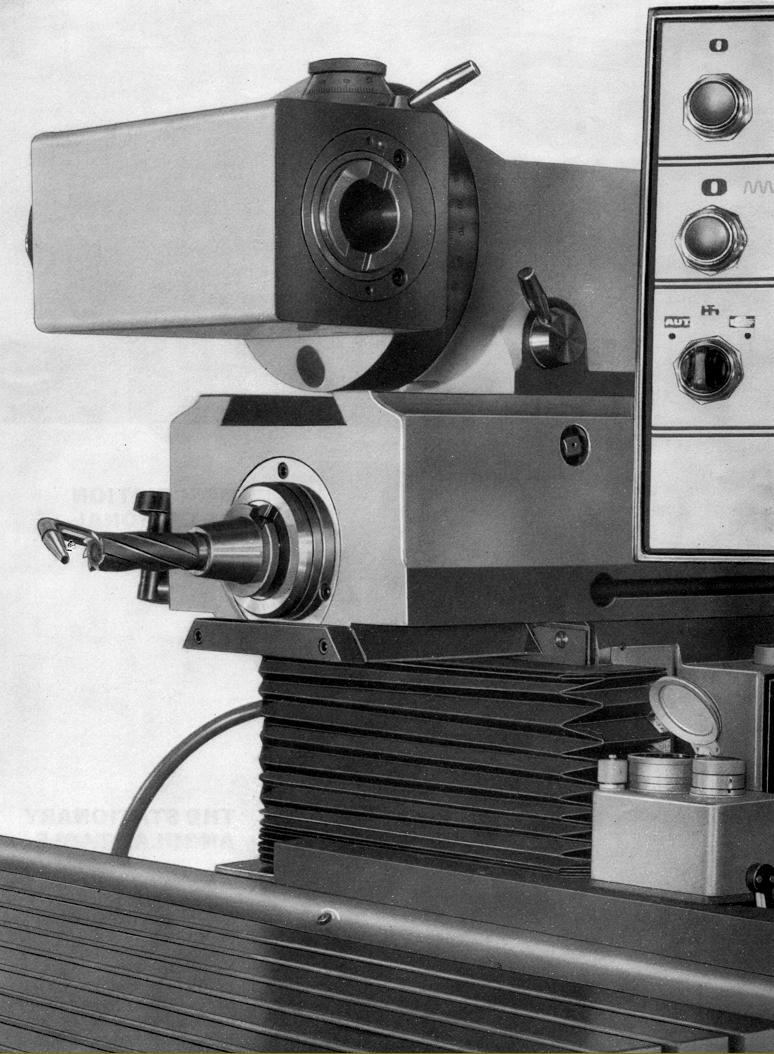

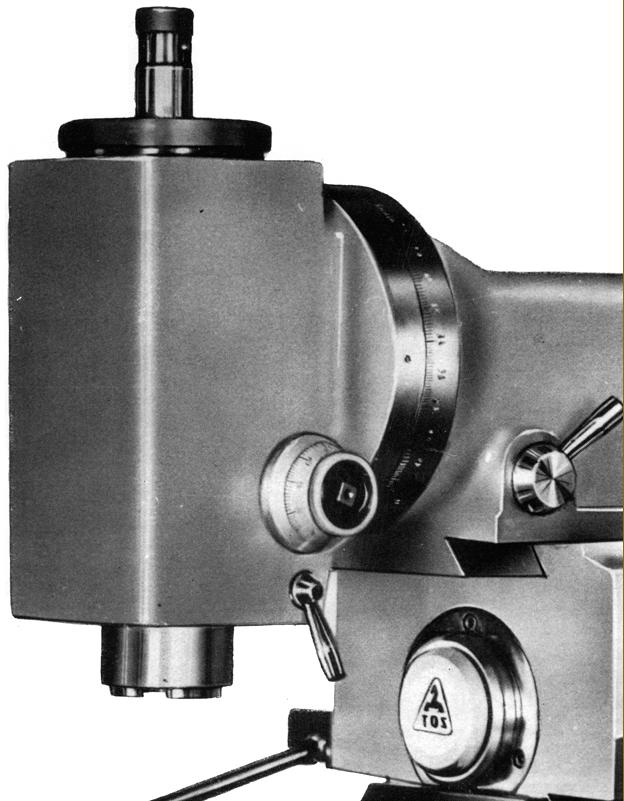

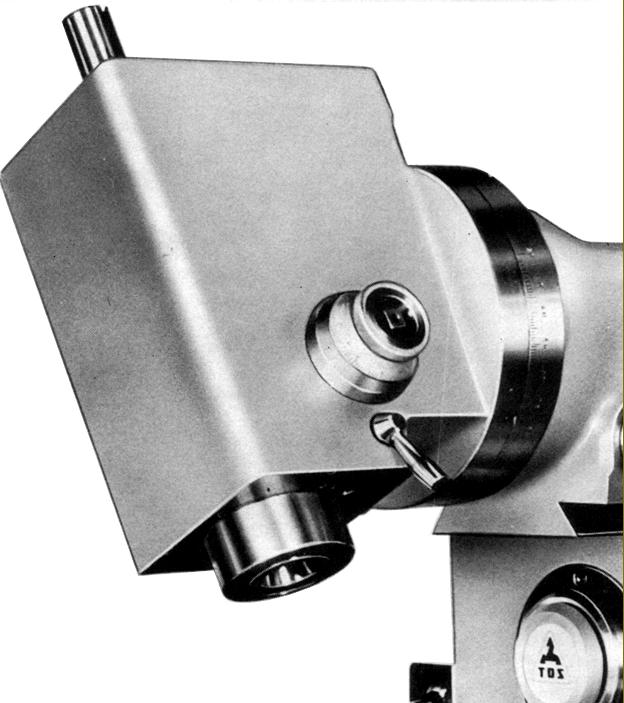

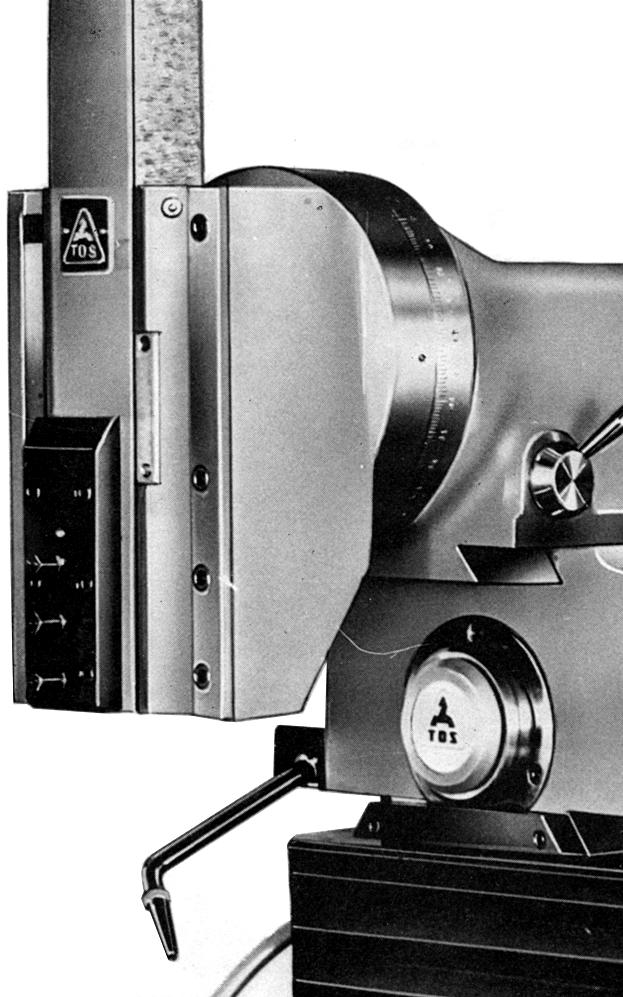

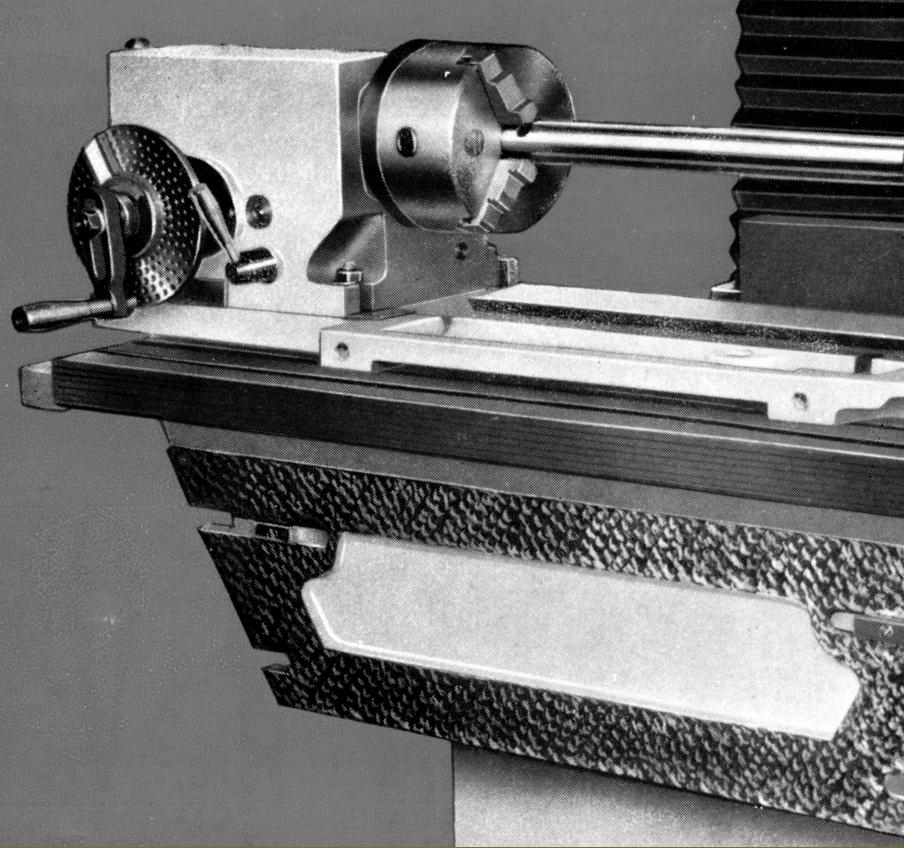

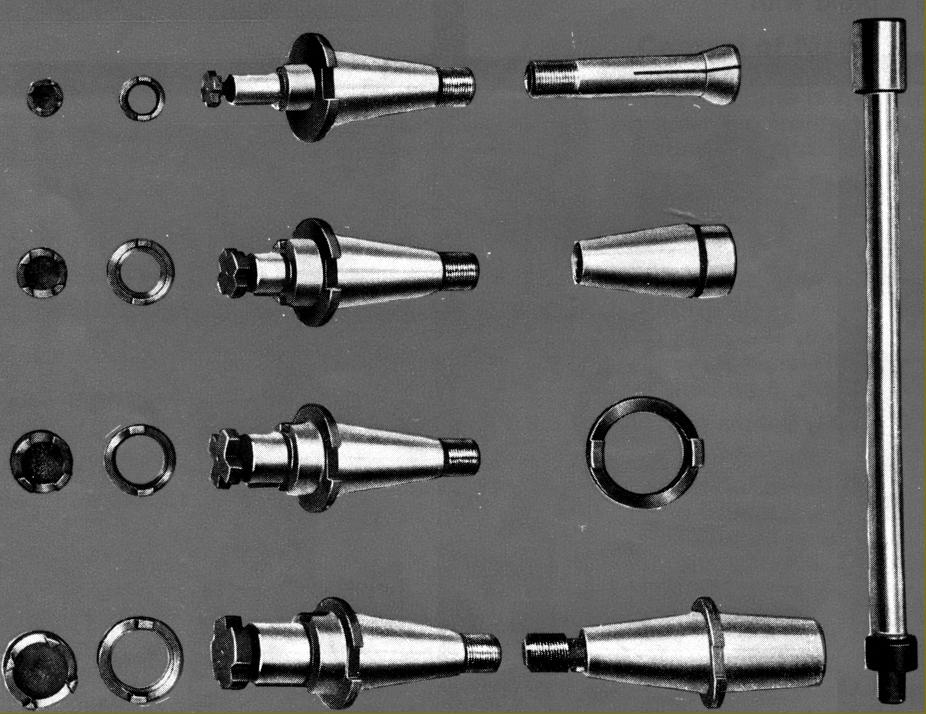

Like all of their type* they mounted, on top of the main column, a sliding housing containing a horizontal spindle driven by gear from a parallel shaft below. To the end of this could be fitted a variety of vertical milling and slotting heads and, above it, an overarm to support a horizontal cutter-holding arbor. The following notes apply to the Type FN-32, the FN-20 being of identical construction, but of smaller dimensions (as the years passed, the knee and table measurements changed slightly, but the following are typical of those offered). With a vertical, T-slotted knee some 860 x 275 mm and fitted with five 12/21 mm T-slots on 45 mm spacing, the front of the machine was intended to accept a choice of two rectangular tables - one plain and the other able to be inclined, tilted and swung and fitted with an in-out feed. Two motors were fitted: one, of 2.2 kW was used to drive the cutter spindle; the other, of 1.1 kW (and coupled to it by a duplex chain) the table-feeds' gearbox. Running in high-precision roller bearings (types NN-3010K and NN-3007-K), the ISA 40 horizontal spindle was made from a hardened and ground alloy steel and dynamically balanced - with axial loads were taken by two spring-loaded thrust bearings. Driven from a demountable, self-contained column-mounted gearbox holding hardened and ground gears (held on shafts running in ball and roller races), the spindle had 18 speeds that spanned 40 to 2000 r.p.m. (50 to 2500 on the FN-20). With a power-feed by roller chain, the overhead spindle had 250 mm of travel (200 on the FN-20) - but an additional 10 mm when moved by the handwheel.

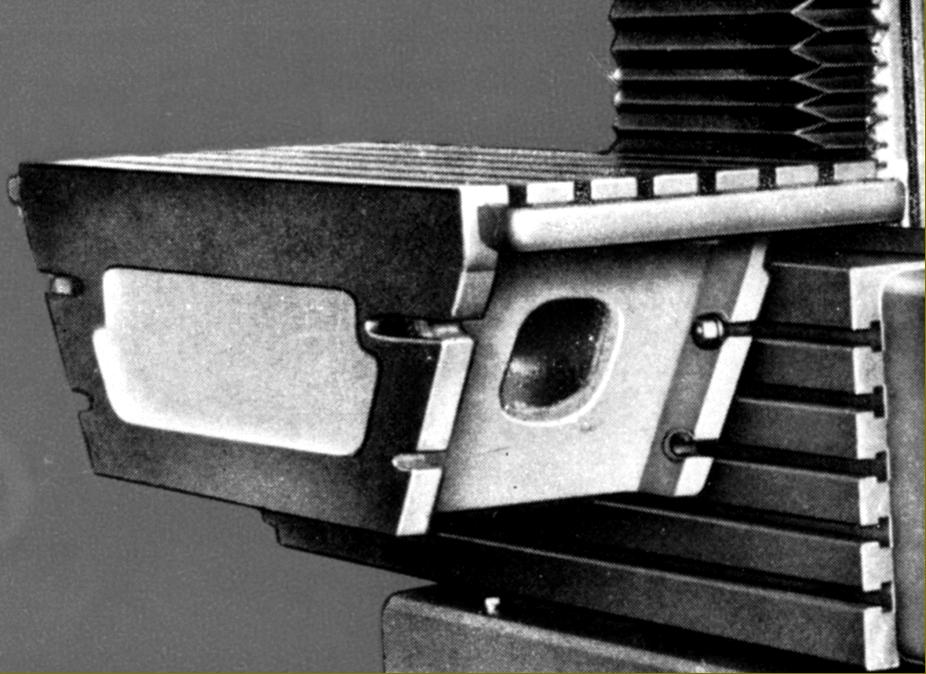

As part of the standard equipment, the miller was fitted with a generously-sized plain horizontal table of 700 x 300 mm (200 x 600 mm on the FN20) with six T-slots. Rather unusually, mountings were provided on both front and back surfaces, each face having provision for four retaining bolts. As an optional extra (and one essential to get the best out of the machine) was a 700 x 240 mm Universal swivelling, tilting and inclinable table. The table could be swivelled about its vertical axis within a range from 0 to 30 degrees, tilted horizontally by 45 degrees in each direction and by 30 degrees from level front to back. Positioning was by a large micrometer dial and the use of built-in fittings to accept dial indicators and gauge blocks. Table travels were 500 mm (FN-20 = 300 mm) horizontally and 400 mm vertically (FN-20 = 350 mm) under power (an additional 10 mm was available if moved by hand) with all traverses equipped with adjustable knock-off stops and provision to mount dial indicators and precision gauge blocks. The number of feeds and their rate were identical to those used on the head: 18 from 8 to 400 mm per minutes with rapids at 1240 mm per minute. As a safety precaution, the feed was taken through a "ball clutch" - any sudden overload (the maximum permitted torque was set at the factory) caused the drive to slip.

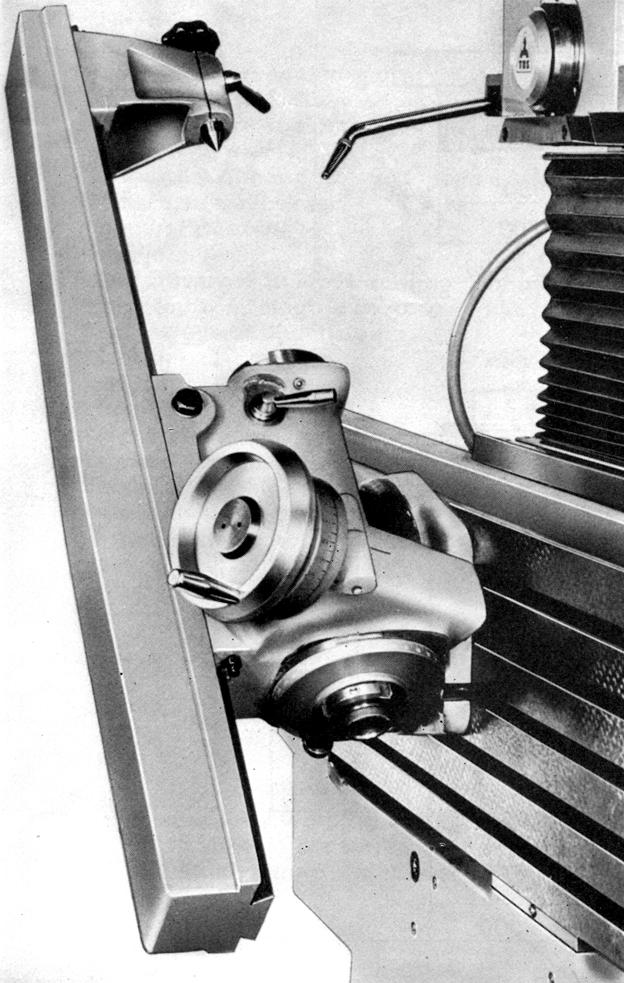

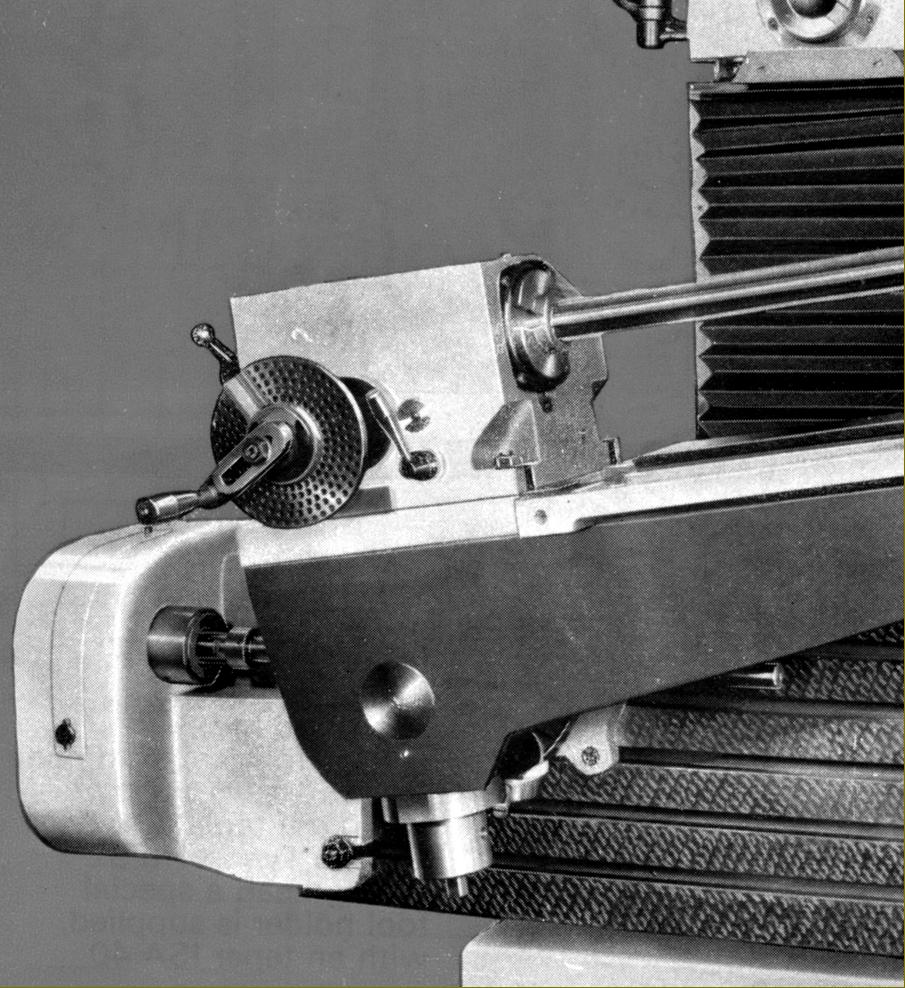

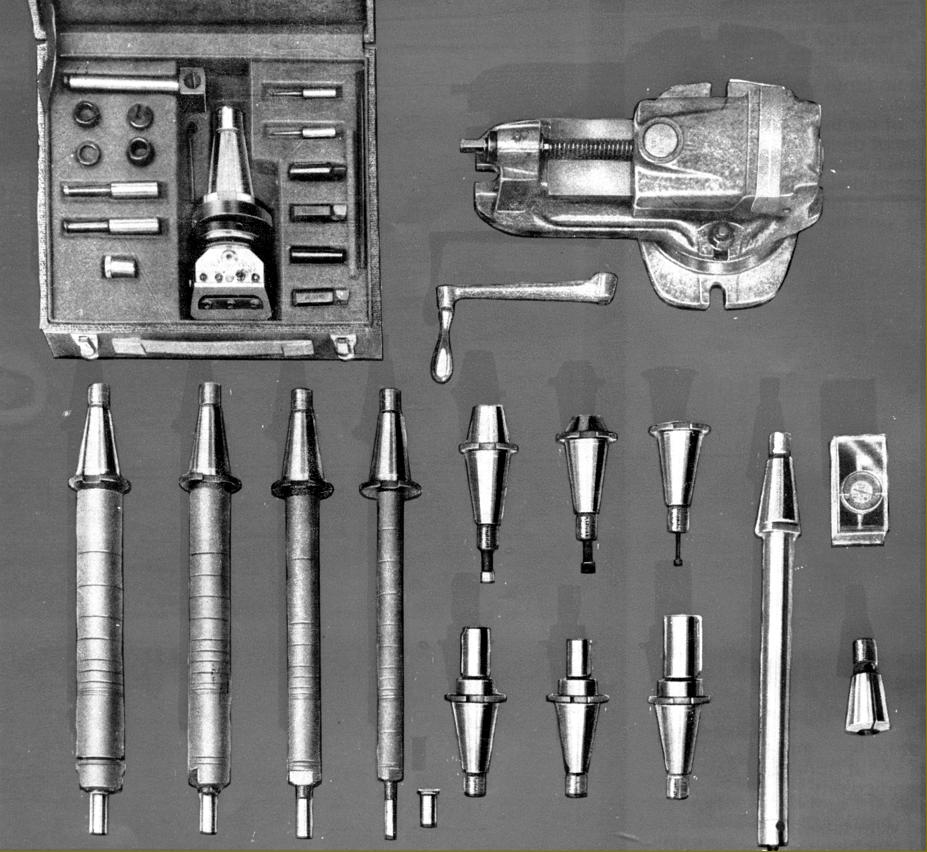

Able to be rotated through 360 degrees, the Type SH ordinary vertical head had an ISA40 spindle nose and a quill travel - under the control of a detachable lever - of 90 mm and 18 speeds ranging from 40 to 2000 r.p.m. With the same spindle travel, the self-contained motorised High-speed Head Type FP was driven by V-belt and had speeds from 200 to a useful 10,000 r.p.m. Dividing was taken care of by a robust, swivelling Universal Diving Unit that could be mounted on any of the tables, including the vertical. The ISA40 spindle nose could be set a maximum distance of 375 mm from the end centre and the unit swivelled away from the vertical position to the right and left by 90 degrees, swivelled towards the machine by 15 degrees and away from it by 10.

A low-line 380 mm diameter rotary table able to be mounted either horizontally or vertically was available; equipped with 8 radial T-slots, it could be indexed through 24 direct divisions by plunger with indirect indexing from 2 to 360 degrees

For slotting TOS offered the usual type of head that could be rotated through 360 degrees; its stroke was adjustable over a range from 0 to 100 mm with 14 rates of double strike from 10 to 200 per minute.

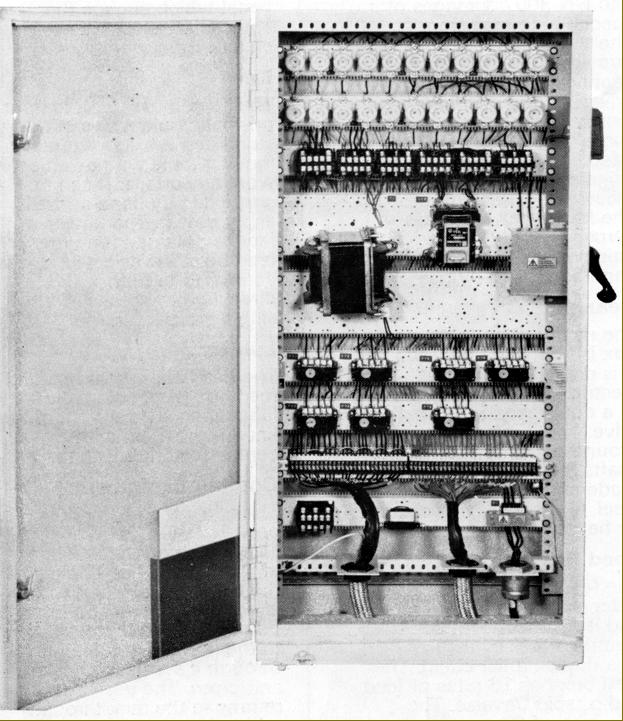

Supplied with each new FN-32 was a complete set of electrical equipment, ready to run, coolant tank and pump, a rigid plain table, a set of 37 collets and a collet adaptor for the spindle nose, four overhung arbors for stub milling, a taper sleeve ISA40 to Morse 4 converter, a set of spanners and other maintenance tools, a grease gun and an Operator's Manual (if you have one of the latter, the writer would be interested to hear from you)

*Proof of the type's success - the genus Precision Universal Milling Machine - is evident from the number of similar machines made in various countries including:

Austria:

Emco Model F3

Belgium: S.A.B.C.A. Model JRC-2

Czechoslovakia: TOS FN Models

England: Alexander "Master Toolmaker" and the Ajax "00", an import of uncertain origin.

Germany: Hahn & Kolb with their pre-WW2 Variomat model

Wilhelm Grupp Universal- Fräsmaschine Type UF 20 N/120

Hermle Models UWF-700 and UWF-700-PH

Leinen Super Precision Micro Mill

Macmon Models M-100 & M-200 (though these were actually manufactured by Prvomajska); Maho (many models over several decades)

Ruhla

Rumag Models RW-416 and RW-416-VG

SHW (Schwabische Huttenwerke) Models UF1, UF2 and UF3

Thiel Models 58, 158 and 159

Wemas Type WMS

Italy: C.B.Ferrari Models M1R & M2R

Bandini Model FA-1/CB and badged as Fragola (agents, who also sold a version of the Spanish Meteba).

Japan: Riken Models RTM2 and RTM3

Poland: "Avia" and "Polamco" Models FNC25, FND-25 and FND-32 by Fabryka Obrabiarek Precyzyinych

Russia: "Stankoimport 676"

Spain: Metba Models MB-0, MB-1, MB-2, MB-3 and MB-4

Switzerland: Aciera Models F1, F2, F3, F4 and F5

Christen and Perrin Types U-O and U-1 (Perrin Frères SA, Moutier)

Hispano-Suiza S.A. Model HSS-143

Luthy

Mikron Models WF2/3S, WF3S, WF-3-DCM & WF-2/3-DCM

Perrin Type U-1

Schaublin Model 13 and Model 22

The former Yugoslavia: Prvomajska (in Zagreb with Models ALG-100 and ALG200)

Sinn Models MS2D & MS4D

"Comet" Model X8130, imported to the UK in the 1970s by TI Comet.

United States: Brown & Sharpe "Omniversal"

Sloane & Chace in the USA produced a miniature bench version and at least five Chinese-built models have also been made, including one from the Beijing Instrument Machine Tool Works. A number of the "clones" merely followed the general Thiel/Maho/Deckel concept whilst others, like Bandini and Christen, borrowed heavily from Deckel and even had parts that were interchangeable. Should you come across any of these makes and models all will provide "The Deckel Experience" - though you must bear in mind that spares are unlikely to be available and, being complex, finely-made mechanisms, they can be difficult and expensive to repair..

|

|