|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taylor 5-inch center height Capstan Lathe Type 1231 with self-contained motor drive and electrically-driven bar-feed unit as built during the late 1930s and 1940s. Even for its day this was already an old-fashioned, very simple production lathe yet well-made in good-quality materials; it was available with different centres heights (including 4, 5, 6 and 7 inches) and to various specification but all built to one general design with the headstock and bed cast as one unit and mounted on a cast-iron suds tray with a box plinth under the headstock end of the bed and a simple leg at the other. For the 5-inch lathe the drive came from a massively-heavy, two-speed, 1000/500 rpm (3/1.5 hp) motor with a 2.5-inch wide flat belt driving the roller-bearing supported, 0.4375" bore spindle at speeds of 175, 350, 444, 888, 1065 and 2130 rpm..

The 6-station capstan head with 0.75" bore sockets was, of course, self-indexing on its 3.5" the return stroke and the indexing mechanism, capstan plunger, guide bush and thimbles were all made from hardened and ground tool steel. The cut-off slide, with either screw or lever feed, could be wound along the bed by the action of a feedscrew driven by a handwheel acting through a bevel gearbox built into the lower front face of the headstock.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taylor 6-inch center height Capstan Lathe Type 1270 with self-contained motor drive and bar-feed unit as built from the late 1930s until the late 1940s.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taylor 4-inch center height Capstan Lathe Type 1263 with self-contained motor drive and bar-feed unit as built from the late 1930s until the early 1950s. This model was also available with the 3-pedal control shown on other Taylor lathes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

New style Taylor Capstan lathe of the early to mid 1950s.

From the early 1950s capstan lathes actually manufactured by Taylor's - as distinct from Wards and Herberts modified by them - were built in four sizes with through-collet capacities of 3/4", 11/16", 11/4", and 11/2".

The size of the holes in the capstan heads varied as follows: on the 3/4-inch capacity lathe the turret was bored for 5/8-inch stem tooling, on the 11/16-inch machine for 3/4-inch and on the 11/4 and 11/2-inch models for the more common 1-inch size.

The new lathes were described by the makers with refreshing honesty as: "plain and simple with no frills - ideal for unskilled labour." Despite this view of their lathes as rather prosaic creations they still fitted them with very useful foot-operated spindle start, stop and reverse controls and made available various productivity-improving optional extras including electrically-driven bar-feed attachments and air-operated collets and 3-jaw chucks.

Although the stands were significantly improved in comparison with the earlier models, with a heavy cast-iron box forming a rigid support for the deeper bed and more massive headstock, the time taken by the operator could change the spindle speed left something to be desired for a production lathe - the drive system being identical to that used on the spinning and brass-finishers' lathes. The arrangement consisted of a very heavy pivoting plate close to, and parallel with, the left-hand face of the headstock-end plinth that carried, at its rear, a motor that drove forwards through multi V-belts to a smooth-running, 3-step flat-belt countershaft. To change spindle speeds the headstock cover had to be lifted, the countershaft door opened, the pivoting plate clamping bolt slackened and the countershaft pivoted by a forwards-protruding lever - after which the belt could be moved by hand across the countershaft and headstock pulleys to the next speed.

The capstan lathes changed very little during 1950s and 1960s but some models were marketed with an improved spindle-speed control (to give "instant" start, stop and reverse) and one example with a relatively sophisticated automatic control system by Nickols of East Grinstead. Nickols's system was claimed to give the lathe a performance equivalent to that of a single-cam automatic - but at very much lower cost..

|

|

|

|

|

|

|

|

|

|

|

|

|

Taylor 1.25-inch capacity capstan lathe - the most largest and most sophisticated of the range with its standard-fit 3-speed power feed to the capstan slide. This model was also available with an "over-capacity" spindle for light machining of bars up to 1.5-inch in diameter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taylor 0.75-inch capacity capstan was the smallest in the range but still equipped with the useful foot-operated electrical controls.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

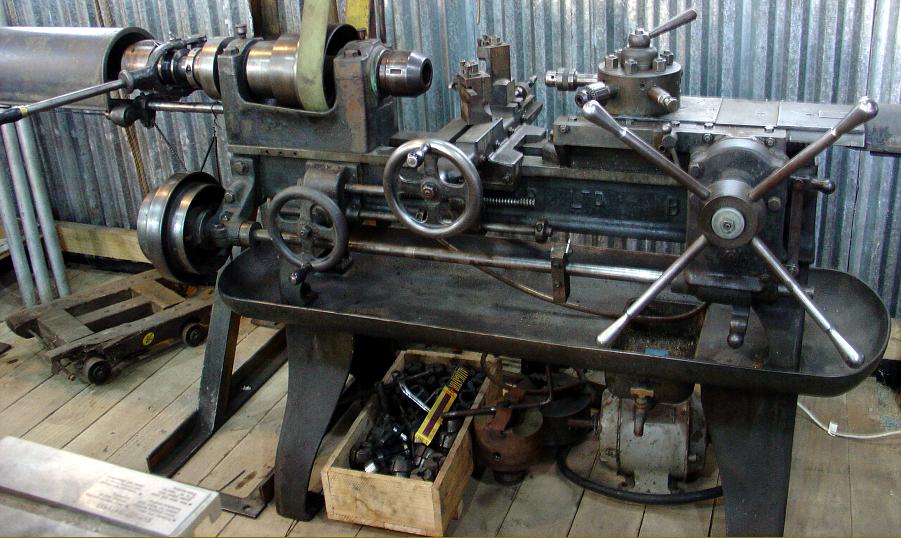

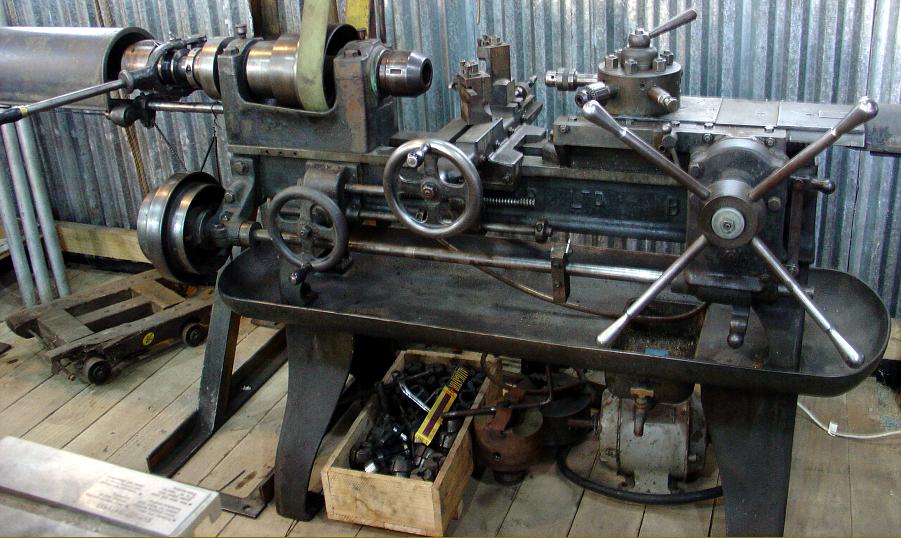

A rare survivor in New Zealand: an early Taylor Capstan lathe shown just before it was withdrawn from service

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remarkably, this Taylor capstan lathe is resident in Florida, and still, in 2018, being use. The owner explains: I am British and have lived in Florida for 22 years. I moved my manufacturing business here and, amongst machinery shipped, was the Taylor Lathe in the attached photos. I bought this Lathe 58 years ago in "Exchange and Mart" and have been married to it ever since. I use it for odd jobs as it is simple and quick to use and has always done what I wanted it to. In the factory it stands next to an Ikegai CNC machining center. The new

and the old together. I still use it and will continue to do so.

Best wishes Jerry Jackson.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air-operated opening and closing 3-jaw chuck

|

|

|

|

|

|

|

|

|

|

|

Air-operated unit for opening and closing the collet chuck

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The spindle Forward, Reverse and Stop foot-pedal controls

|

|

|

|

|

|

|

|

|

From the 1950s onwards the Spinning, Brass-finishers' and Capstan Lathes all shared a common drive system with a rear-mounted motor that drove forwards through a multi V-belt drive to a smooth-running, internal, 3-step flat-belt countershaft that was mounted on a very heavy pivoting plate close to, and parallel with, the left-hand face of the headstock-end plinth.

|

|

|

|

|

|

|

|

|

|

|

|

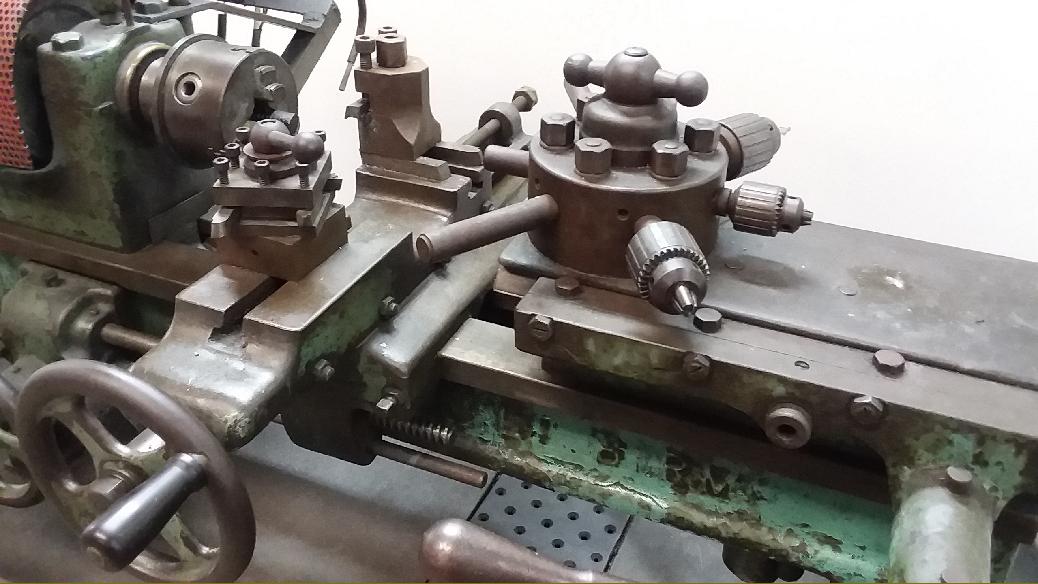

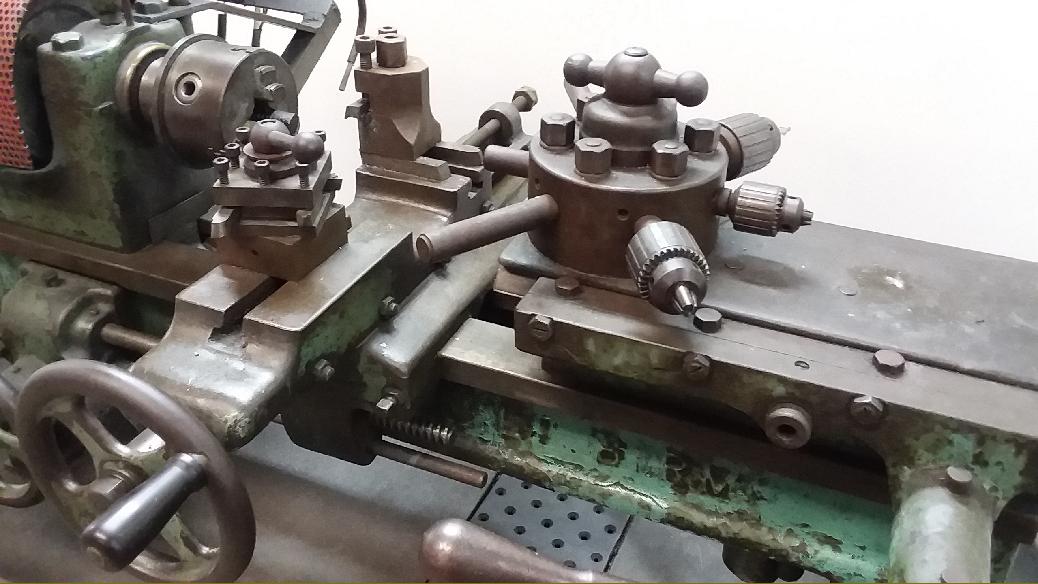

6-station turret head and cut-off slide. On the 3/4-inch capacity lathe the turret was bored for 5/8-inch stem tooling, on the 11/16-inch machine for 3/4-inch and on the 11/4-inch for the more common 1-inch size.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric bar-feed unit shown in the swung-forward loading position.

|

|

|

|

|

|

|

|

|

|

Optional 3-speed feed gearbox for the turret assembly with indexing, 4-position knock-off mechanism.

|

|

|

|

|

|

|

|

|

|

|

|

|