|

Maschinenbaugesellschaft Sinn, Dr. Ing. Ernst Cloos K.G. was situated in Sinn, a village near Wetzlar, in the west of Germany. The Company is best known for its range of superbly constructed universal precision milling machines manufactured from the 1950s to the 1970s. Of all the types made the most popular appear to have been the MS IIC and MS III toolmakers'.

Established in 1858, when Albert Doering started a mechanical-engineering workshop on the "Sinner Hof" premises. A gifted tinkerer and inventor, he not only did repair jobs but also built machines of every conceivable kind to his customers' specifications, from steam engines and mining equipment to fire engines and pumps. From the early 1950s onwards the company expanded and the product range was widened to include heavy valves and fittings, wear plates for the mining industry, and milling machines.

In the 1960s Doering was among those companies hit hard by the crisis in the lignite mining sector and, because of a production capacity beyond demand and increasing costs, the manufacture of heavy fittings and machine tools rose above the break-even point. A full history of the Company, with a number of interesting illustrations, can be downloaded here

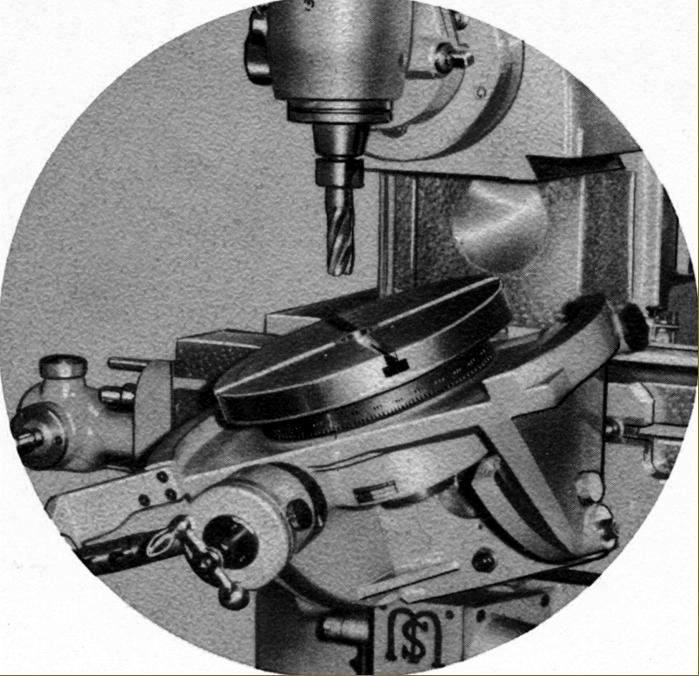

Based on the traditional Deckel, Thiel and Maho type of precision universal miller that had enjoyed such success*, the Sinn range of machines were ingenious, adaptable and versatile types. Lending itself to solving a multitude of machining problems, the secret of the type's success lay in its ability to mount a number of different heads - horizontal, standard vertical, high-speed vertical and slotting - in combination with a variety of tables - plain, plain-tilting and compound swivelling. All the heads could be driven backwards and forwards across the top of the main column to provide an in-out feed, while the tables bolted to a flat, vertical T-slotted table equipped with power longitudinal and vertical feeds. By juggling the choice of heads and tables, and utilising other accessories, a skilled technician was seldom defeated in his attempts to produce the most complex of milled and drilled components - and all to a very high standard of accuracy.

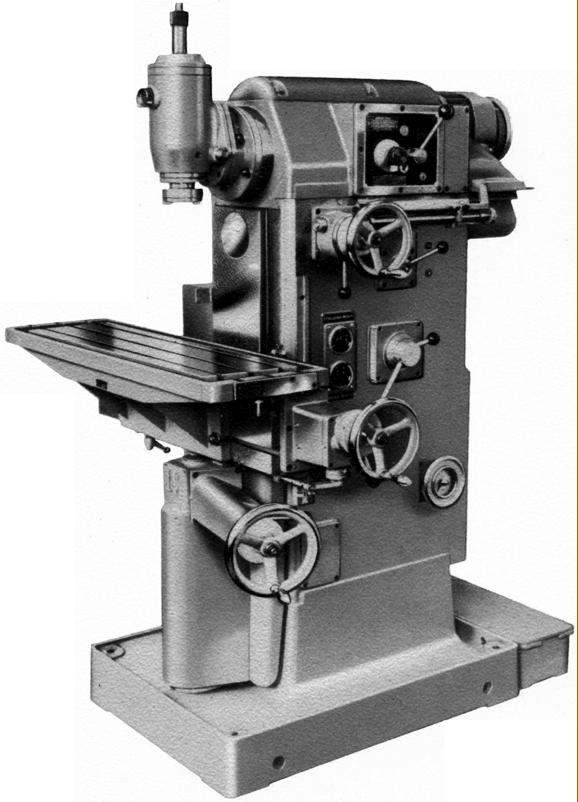

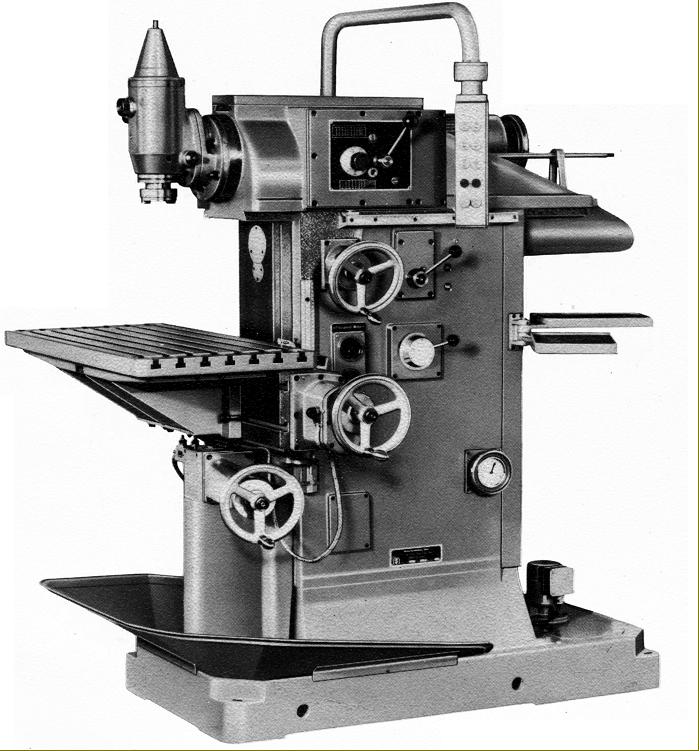

A relatively complex machine, the Sinn was built in at least five and probably more models - the ones known including the MS-11-B, MS-11-D, MS-111-D, MS-1V-D and MS-1V-DA. The make was not widely promoted in the UK, even though the well-known and very successful machine-tool merchants W.E.Norton Ltd were responsible for handling sales. Although a MS-1-D version was almost certainly built, it was never listed in the UK and details of its construction are unknown; hence, the smallest example imported was almost certainly the MS-11-D. About the size of a Deckel FP1, it was offered (as was the full range) with a choice of either an ISA-40 or No. 4 Morse taper horizontal spindle that turned in high-precision taper roller bearings. The two smallest models had a longitudinal table travel of 17.5" and the two larger 24". While all three of the largest machines had 17.5" of lateral travel (on the head), the MS-11-D was limited to 12.5"; all machines had the same 17.5" of vertical movement.

Each model had 18 spindle speeds that spanned 55 to 1630 r.p.m. (a range sufficient for the larger models but rather slow at the higher end for the smallest), with drive coming from a 2-speed 2 h.p./3 h.p. motor held within the base of the main column and connected to an oil-bath lubricated, 9-speed pre-selector gearbox supplied by Ortlinghuase.

Built as a complete, slide-out unit support on gibs, the table and head-feeds' splash-lubricated gearbox provided infinitely-variable table feed rates that, although they varied model to model, were the same on all three axes: MS-11-D 0.032 to 19"; in inches per minute these were: MS-11-D 0.032" to 19"; MS-111-D and MS-1V-D 0.032" to 36" and the MS-1V-DA 0.032" to 28".

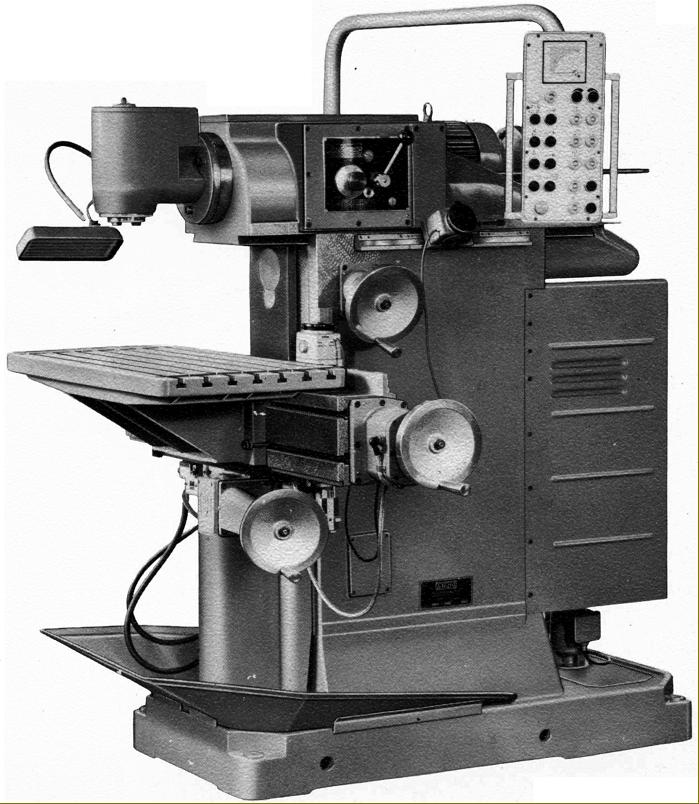

Driven from the 1.5 h.p. feeds' motor, rapids on all three axes were set at 40 inches per minute on the MS-11-D, at 80 inches per minutes on the MS-111-D and MS-1V-D and at 48 inches per minute on the MS-1V-DA - the latter machine also being fitted with creep feed (from a separate motor) at the rate of 0.040" per minute. Although other types had feeds engaged conventional mechanical means, on the three largest models the hardened and ground feedscrews were engaged by electrical push-buttons through toothed clutches, these acting as a safety device and automatically disengaging at a pre-set torque load. With such a control system it was possible to reverse a feed instantly without having to first stop it, a great time-saver on repetition jobs; in addition, each axis was equipped with an electrical safety limit switch. As befitted the most expensive model, the MS-1V-DA had a more powerful (2 h.p.) feeds' motor, adjustment of the feeds by remote control together with hydraulic clamping of its guidways (an option that may have been available at extra cost on other types).

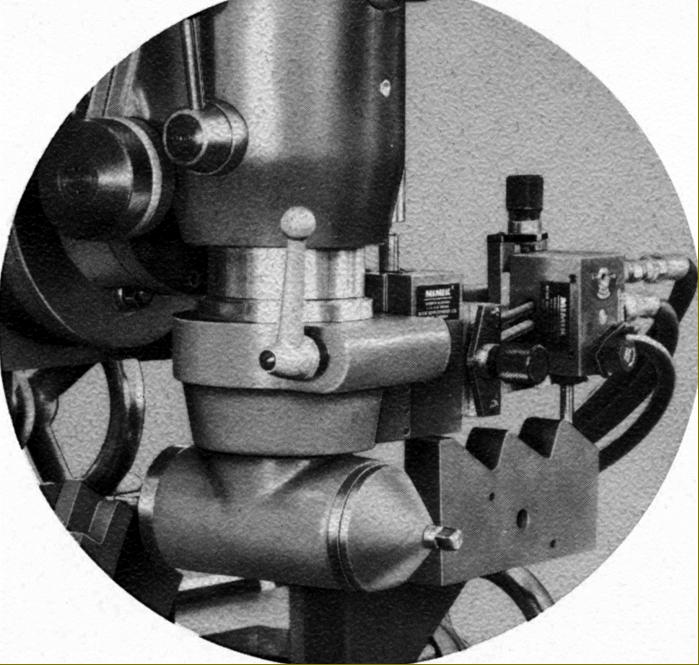

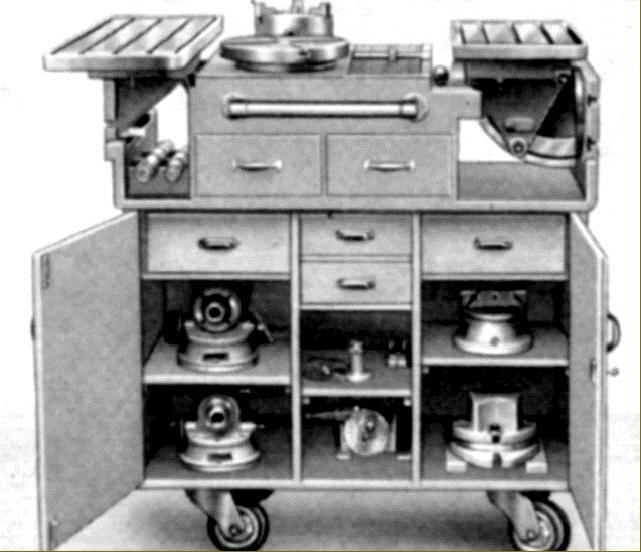

Although a wide range of accessories was available the importers chose not to specify details, but it is known that each machine could be fitted with a number of different tables including two sizes of plain rectangular; a fully compound tilting, angling and swivelling type with a T-slotted top or one that tilted and inclined with a built-in rotary table. Also offered were box tables; a helical milling attachment driven from the table feed-screw; a hydraulic copying attachment; a number of different rotary tables and dividing attachments with indexing plates and a tool-storage cabinet. A number of different vertical heads were available including a slotting type and a standard vertical that has been found without and quill feed and also with three different sliding quill arrangements: one operated by a very Deckel-like rack-and-pinion feed driven by a short handle that slipped over a square stud on the right-hand side, another with a short, permanently-fitted handle to the left and a third by a capstan handwheel. A high-speed head was also listed, driven by its own motor this self-contained unit had a top speed of 6000 r.p.m. and appears to have been the only head with a fine quill-feed drive. Two interesting head attachments were also available: one, a simple extension block, moved the head further out from the end of the overarm while the other (an ingenious contraption) resembled a crank arm that enabled the head to be swung in a circle to increase or decrease the clearance between spindle nose and table.

If you have a Sinn machine tool of any type the writer would be interested to hear from you. Sinn continued here and here

*Proof of the type's success - the genus Precision Universal Milling Machine - is evident from the number of similar machines made in various countries including:

Austria:

Emco Model F3

Belgium: S.A.B.C.A. Model JRC-2

Czechoslovakia: TOS FN Models

England: Alexander "Master Toolmaker" and the Ajax "00", an import of uncertain origin.

Germany: Hahn & Kolb with their pre-WW2 Variomat model

Wilhelm Grupp Universal- Fräsmaschine Type UF 20 N/120

Hermle Models UWF-700 and UWF-700-PH

Leinen Super Precision Micro Mill

Macmon Models M-100 & M-200 (though these were actually manufactured by Prvomajska); Maho (many models over several decades)

Ruhla

Rumag Models RW-416 and RW-416-VG

SHW (Schwabische Huttenwerke) Models UF1, UF2 and UF3

Thiel Models 58, 158 and 159

Wemas Type WMS

Italy: C.B.Ferrari Models M1R & M2R

Bandini Model FA-1/CB and badged as Fragola (agents, who also sold a version of the Spanish Meteba).

Japan: Riken Models RTM2 and RTM3

Poland: "Avia" and "Polamco" Models FNC25, FND-25 and FND-32 by Fabryka Obrabiarek Precyzyinych

Russia: "Stankoimport 676"

Spain: Metba Models MB-0, MB-1, MB-2, MB-3 and MB-4

Switzerland: Aciera Models F1, F2, F3, F4 and F5

Christen and Perrin Types U-O and U-1 (Perrin Frères SA, Moutier)

Hispano-Suiza S.A. Model HSS-143

Luthy

Mikron Models WF2/3S, WF3S, WF-3-DCM & WF-2/3-DCM

Perrin Type U-1

Schaublin Model 13 and Model 22

The former Yugoslavia: Prvomajska (in Zagreb with Models ALG-100 and ALG200)

Sinn Models MS2D & MS4D

"Comet" Model X8130, imported to the UK in the 1970s by TI Comet.

United States: Brown & Sharpe "Omniversal"

Sloane & Chace in the USA produced a miniature bench version and at least five Chinese-built models have also been made, including one from the Beijing Instrument Machine Tool Works. A number of the "clones" merely followed the general Thiel/Maho/Deckel concept whilst others, like Bandini and Christen, borrowed heavily from Deckel and even had parts that were interchangeable. Should you come across any of these makes and models all will provide "The Deckel Experience" - though you must bear in mind that spares are unlikely to be available and, being complex, finely-made mechanisms, they can be difficult and expensive to repair..

|

|