|

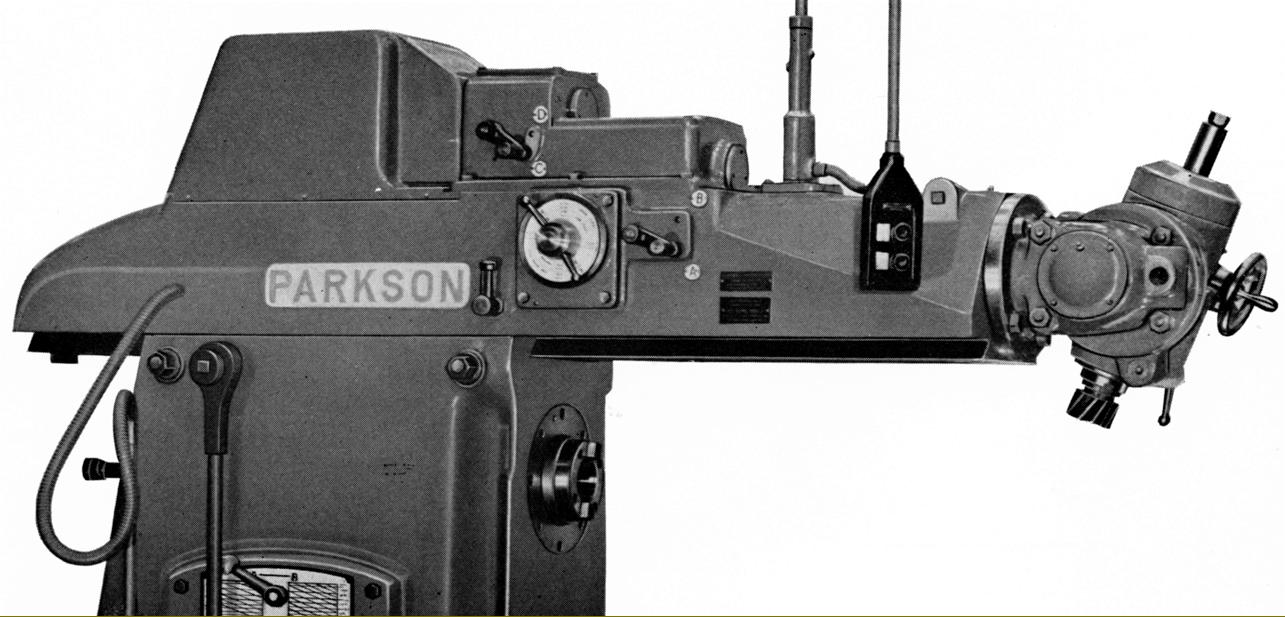

Home Machine Tool Archive Machine-tools Sale & Wanted a number of Parkson milling machines FOR SPARE PARTS and SERVICE for a VARIETY of PARKINSON MILLING MACHINES CONTACT the EX-PARKINSON SERVICE ENGINEER at collinsmrtnc@aim.com or phone: 01484-664538. Parts are also available for Stromag Heid and croft clutches for the Parkson machines plus numerous shafts, gears, mechanical clutches and pumps. I can also supply electrical drawings or mechanical drawings if the part is not in stock. |

||

|

|

||

|

|

|

|

|

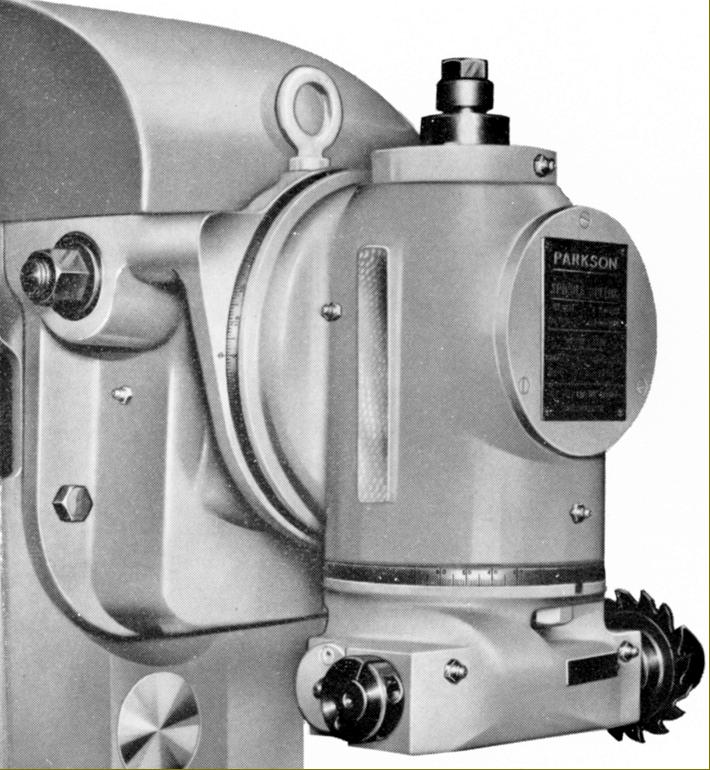

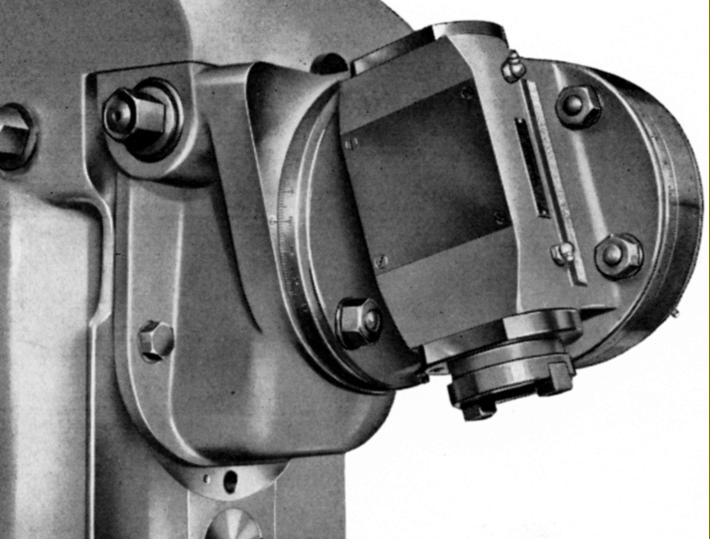

Style L Motor-Driven Universal Milling Head. Able to be used in place of the ordinary unit to support horizontal cutter arbors, the Style L carried a 2 h.p. 1450 r.p.m. motor that drove a gearbox to give a range of 16 speeds: 44, 71, 98, 112, 158, 170, 210, 250, 340, 378, 466, 540, 750, 815, 1200 and 1800 r.p.m. Final drive was by spiral bevel gears with the transmission spurs gears heat-treated, profile ground and lubricated by splash from a sump provided with a level glass. The end of the assembly carried a double-swivel head with the No. 40 taper spindle running in taper roller bearings and held in a 3-inch travel quill. Early versions of the overarm were fitted with a fine-feed handwheel that was not only awkwardly positioned but tricky to operate, being concentric with the spindle and moving the quill though a screw and nut. Later, this arrangement was completely redesigned to include a handwheel working through worm and wheel gearing with, as an extra-cost option, the addition of a quick-action lever feed. |

|

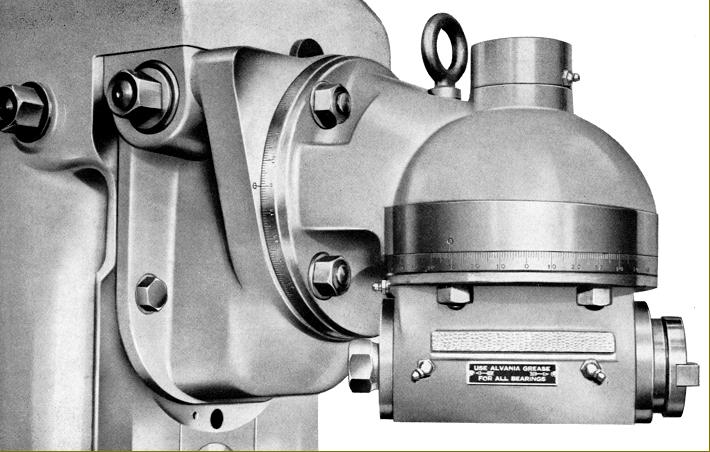

Standard Vertical Head: this was made in two versions, the Standard (with a No. 40 nose) and the Heavy (with a No. 50 nose). Each was bolted to the inside face of the column and also supported, for extra rigidity, by the dovetail slides of the overarm. Driven by the horizontal spindle, unlike similar heads offered by many other makers those supplied for Parkson millers included internal gearing to increase spindle speeds - the Standard doubling them and the Heavy increasing them by 25%. Unfortunately neither head was equipped with any form of quill feed. |

|

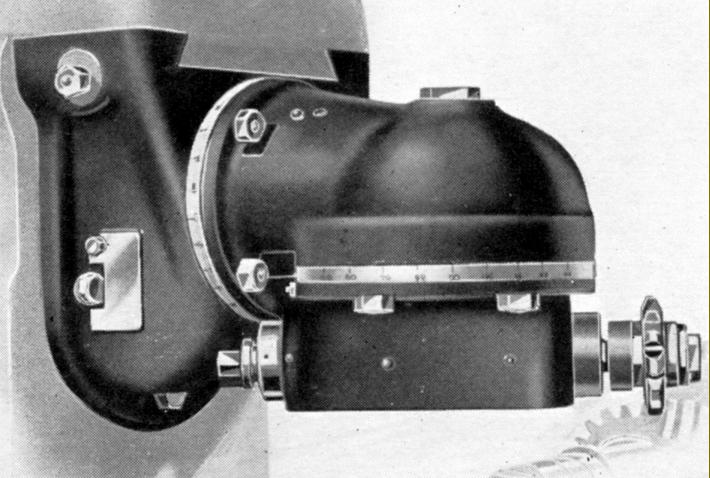

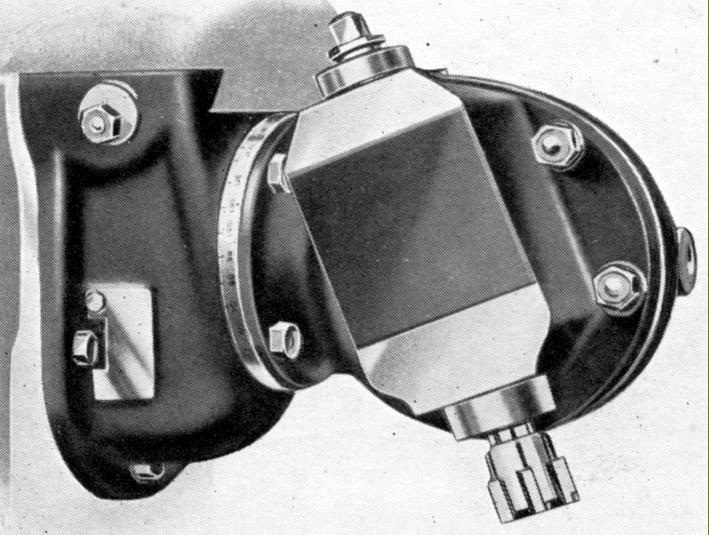

Universal Milling Attachment Style A. This unit mounted a horizontal spindle able to take milling cutters with a 1-inch bore. Able to be inclined at any angle, it was fitted with specially selected, high-precision taper roller bearings. |

|

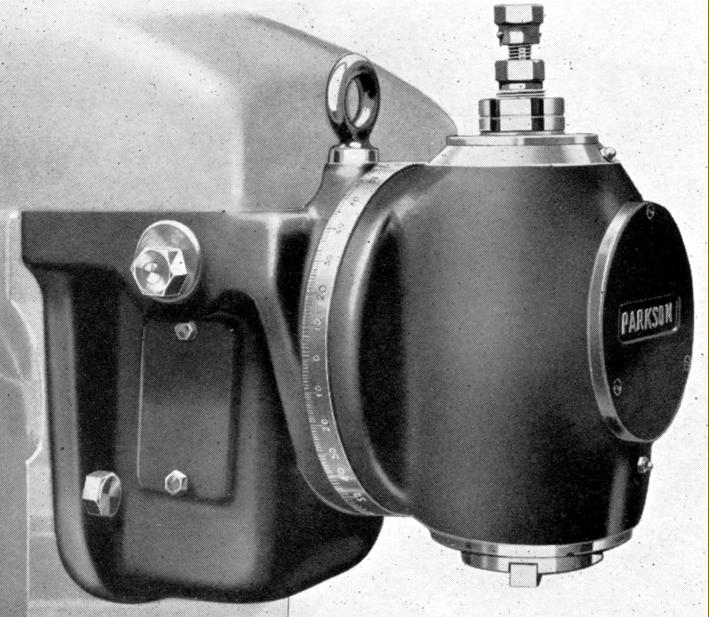

Universal Milling Attachment Style B. With its spindle running in High-precision taper roller bearings, this milling attachment would be inclined at any angle and contained gears that increased the horizontal spindle speeds by 25%. |

|

|

|

|

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||