|

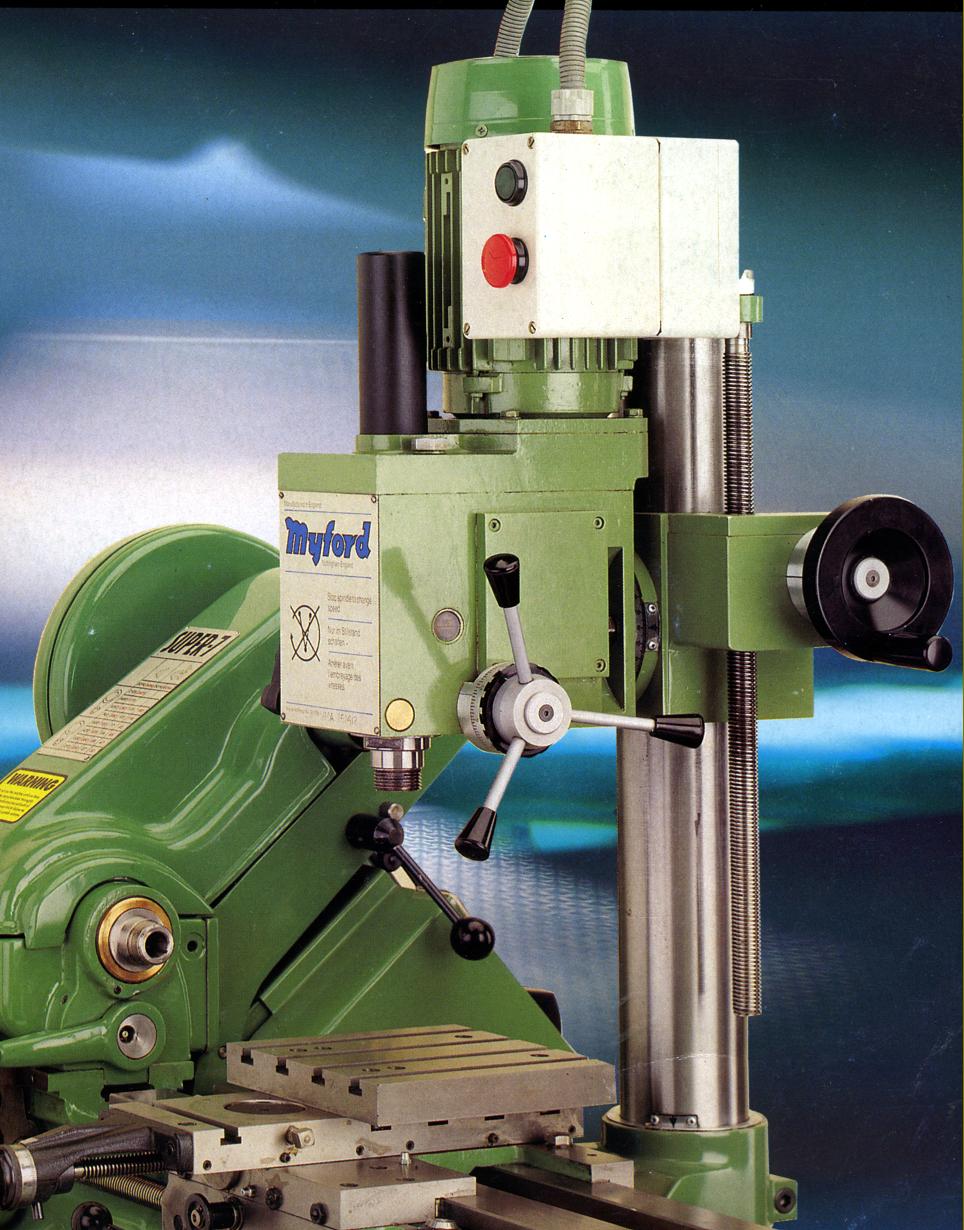

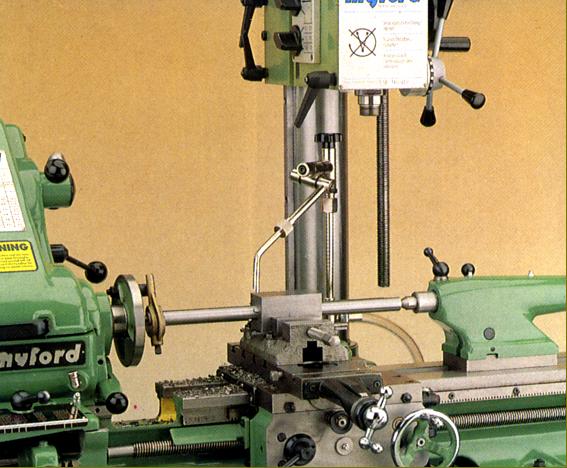

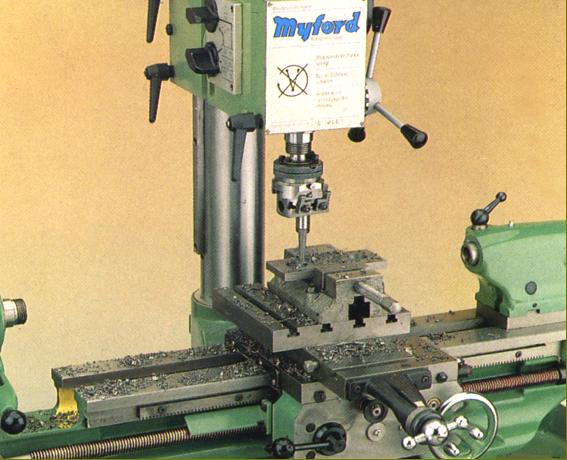

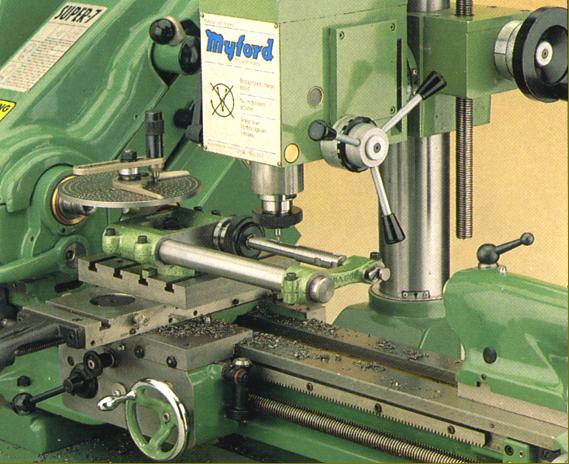

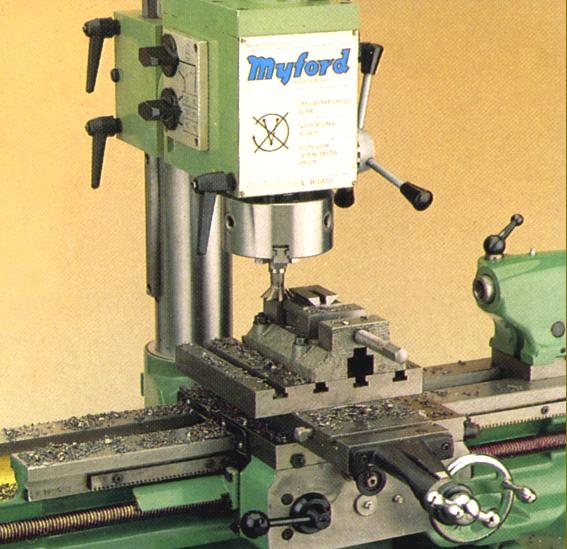

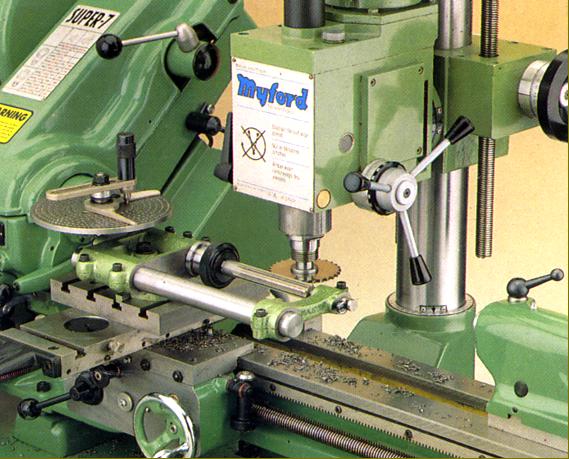

Introduced as an accessory during 1988, the VM-A milling and drilling attachment was manufactured by Rishton and intended for bolting to the back of the bed on Myford, ML7, Super 7 and 254 lathes - though the 7-Series models had to be mounted on the maker's cast-iron bed-raiser blocks to give sufficient clearance beneath the bracket into which the column fitted. The maximum clearance between spindle nose and the cross-slide of a Super 7 was 298 m, the minimum nil and the throat depth (from spindle line to the inside of the column) 163 mm. When sold by Richton, the head was fitted to a useful compound table - usually 615 x 150 mm - so making a complete, stand-alone machine listed as the VM60. Other Rishton milling machines included the smaller "Pormill" with a 350 x 150 mm table and the VM601 with a standard 615 x 150 mm table - both fitted with electronically-controlled variable speed drive.

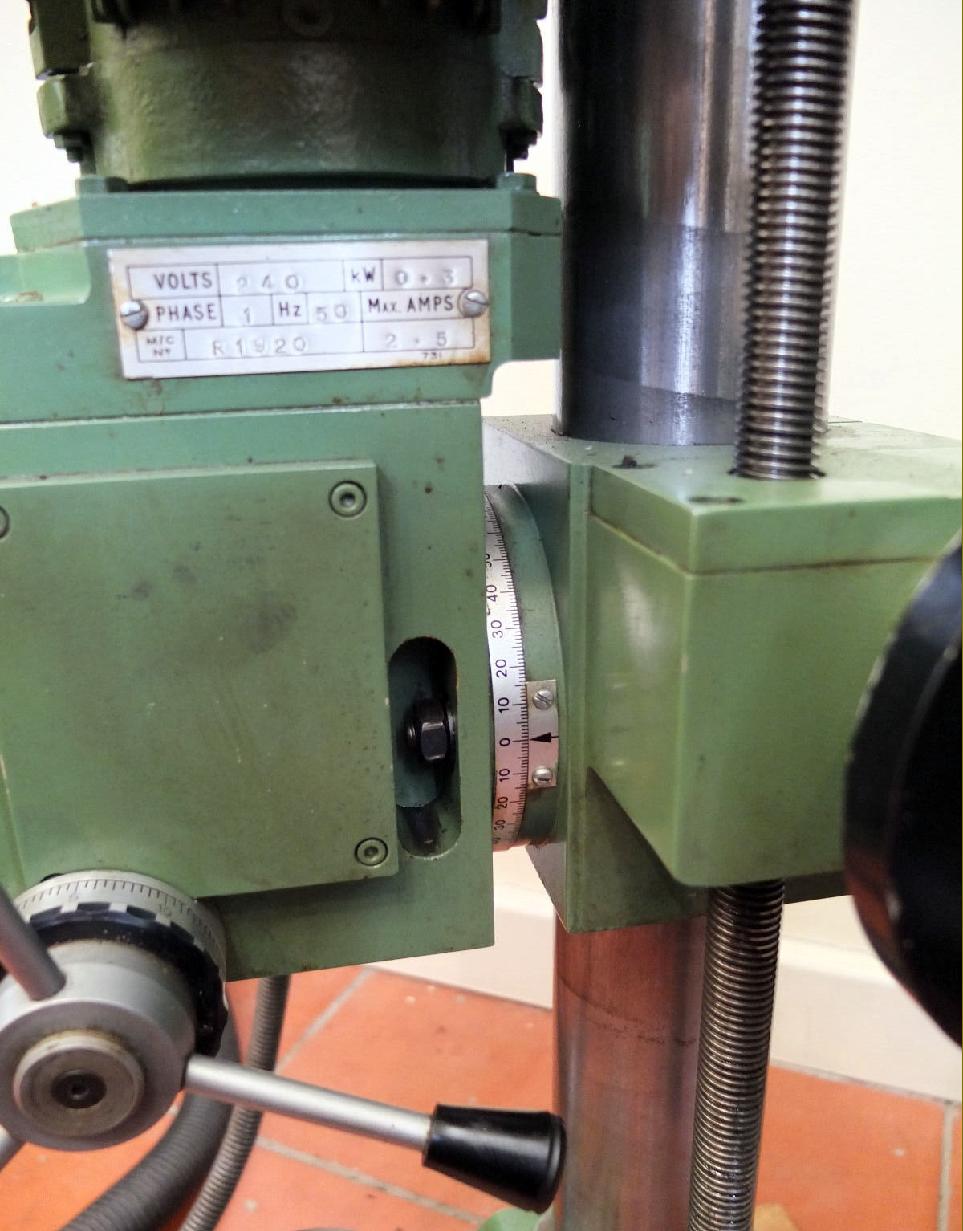

Able to be tilted 90° in each direction from upright, and turned through 180° on its vertical axis, the all-geared, oil-bath head was moved up and down the main column through a range of 314 mm by a combination of a screw thread and worm-and-wheel gearing. Cleverly, this design allowed the operating handwheel to be positioned horizontally (to the right hand side) - a decided improvement on the inconvenient and awkward-to-operate vertically handwheel on the similar units made by Emco. Running in a combination of ball and needle roller bearings, the spindle was held in a sliding quill with a travel of 40 mm under the control of a 3-spoke capstan handwheel. The micrometer dial fitted was of the zeroing kind, graduated at intervals of either 0.5 mm or (from 0 to 1.6") in increments of 0.02". Although the head could be inclined, the fine feed was only available in a vertical direction, not on the spindle axis, that being confined to the quick-action feed, a considerable drawback when attempting sensitive work.

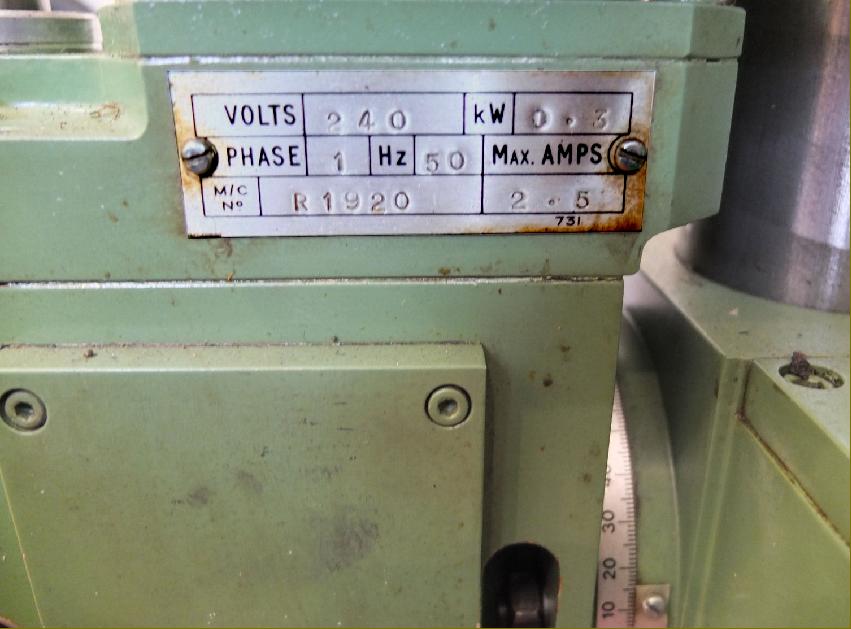

Bored with a No. 2 Morse taper nose, the spindle carried a standard Myford 7-series lathe spindle nose thread of 1.125" x 12 t.p.i. - its use allowing an owner to employ existing chucks, internal compression collets and other suitable fittings. Six spindle speeds were provided that spanned a very useful range: 130, 200, 370, 700, 1100 and 2000 r.p.m. driven by either a 1-phase or 3-phase 0.25 h.p. motor controlled by a simple no-volt release push-button starter.

In addition the the VMA attachment, Myford offered both a number of independent milling machines and milling attachments for their lathes - though non of either variety were constructed by the Company itself but bought in from various suppliers - both British and foreign. The earliest types were attachments intended for use on the ML7 and Super 7 lathes and consisted of the self-motorised Amolco and three designs by Rodney, one a full-size machine and the other two scaled down, simplified versions with the first of these sold as the "Mini-Miller" and the second (much later) as the VM-D - all taking their drive from the headstock spindle. An improvement was brought about by the subject of this page, the introduction of the self-contained, geared head VM-A, an attachment very similar indeed to those manufactured for many years by Emco on their Emcomat, Maximat & Mentor 7, V7, V7L, V8, 8.4, 8.6, V10 and V11 lathes. From the 1970s onwards, Myford introduced a series of proper, self-contained but Taiwanese-manufactured machines that comprised the smaller VM-B (built like a miniature jig-borer) and the larger turret-head VM-C, VM-E and VM-F...

|

|