|

Continued:

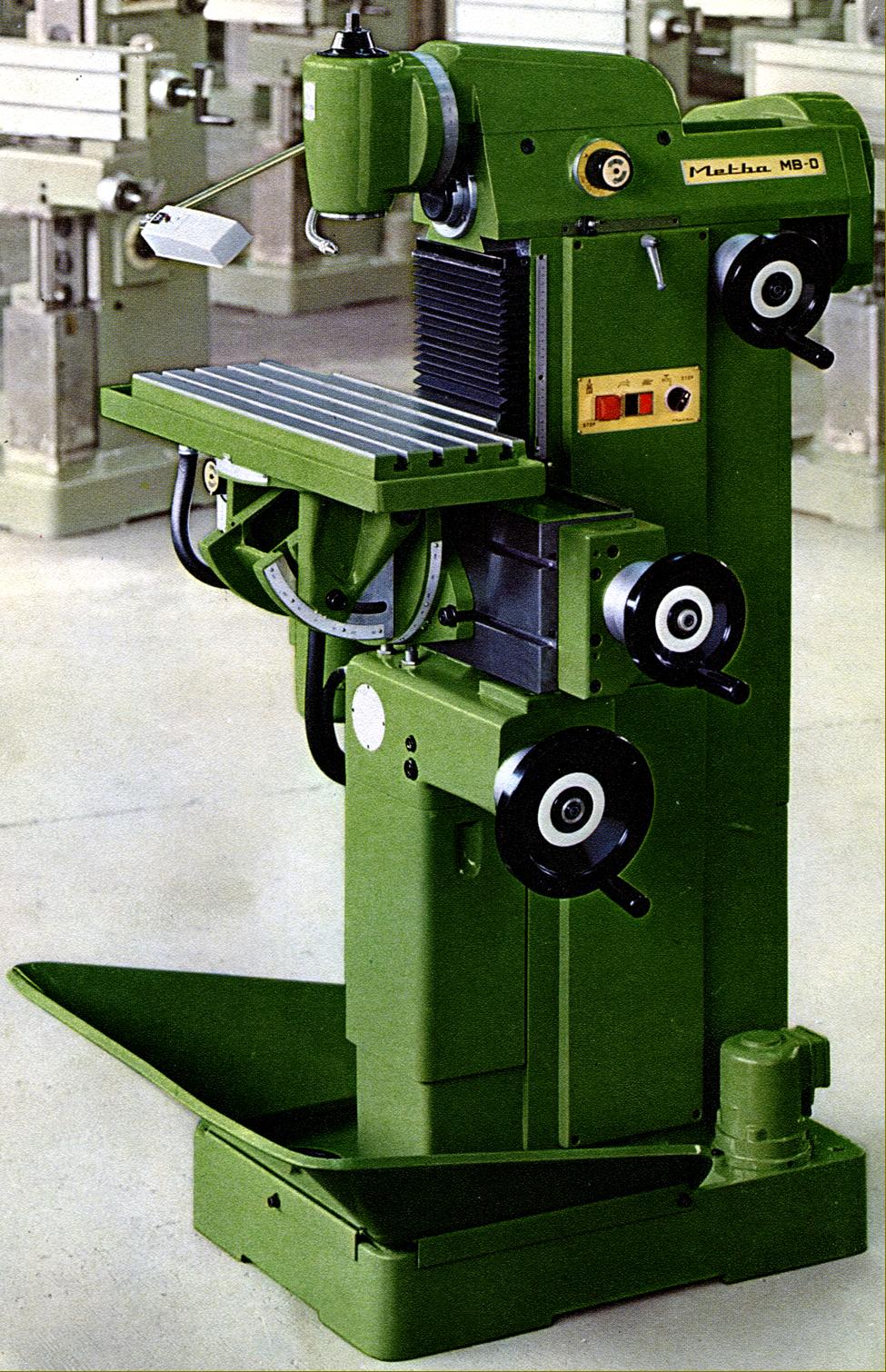

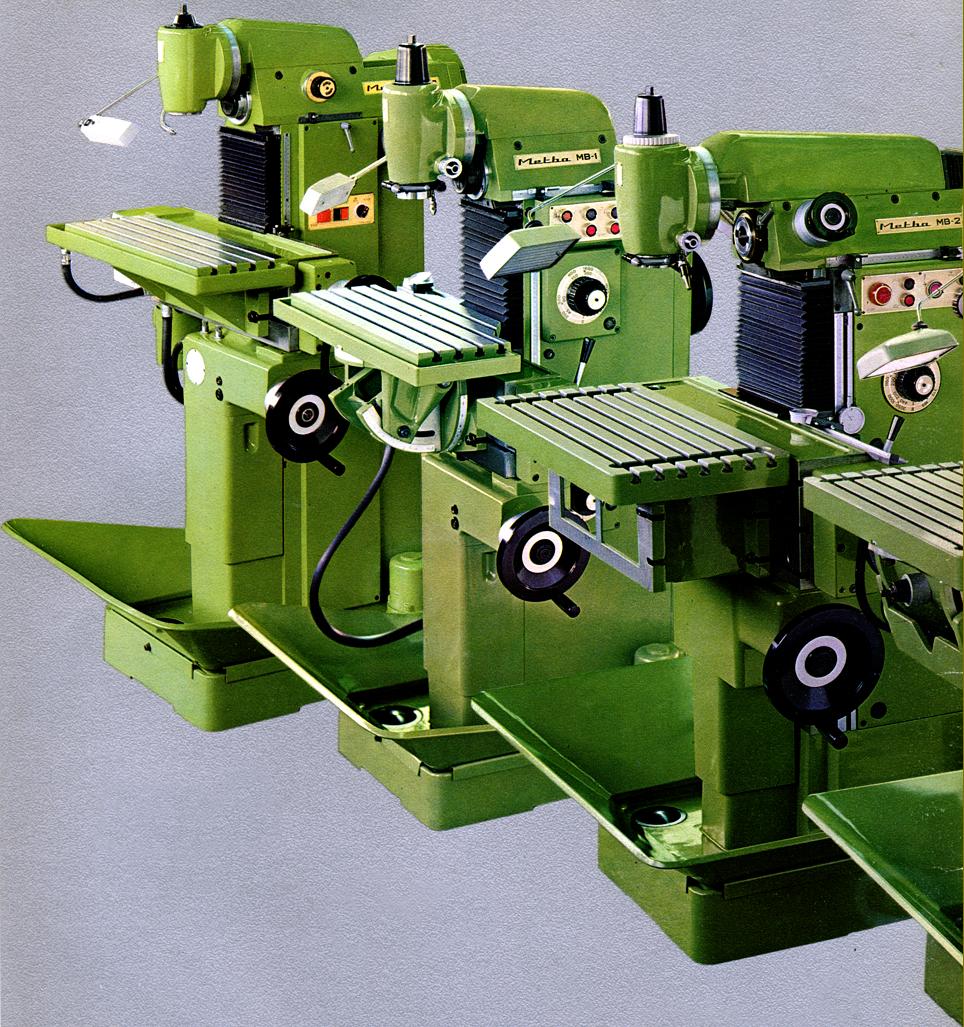

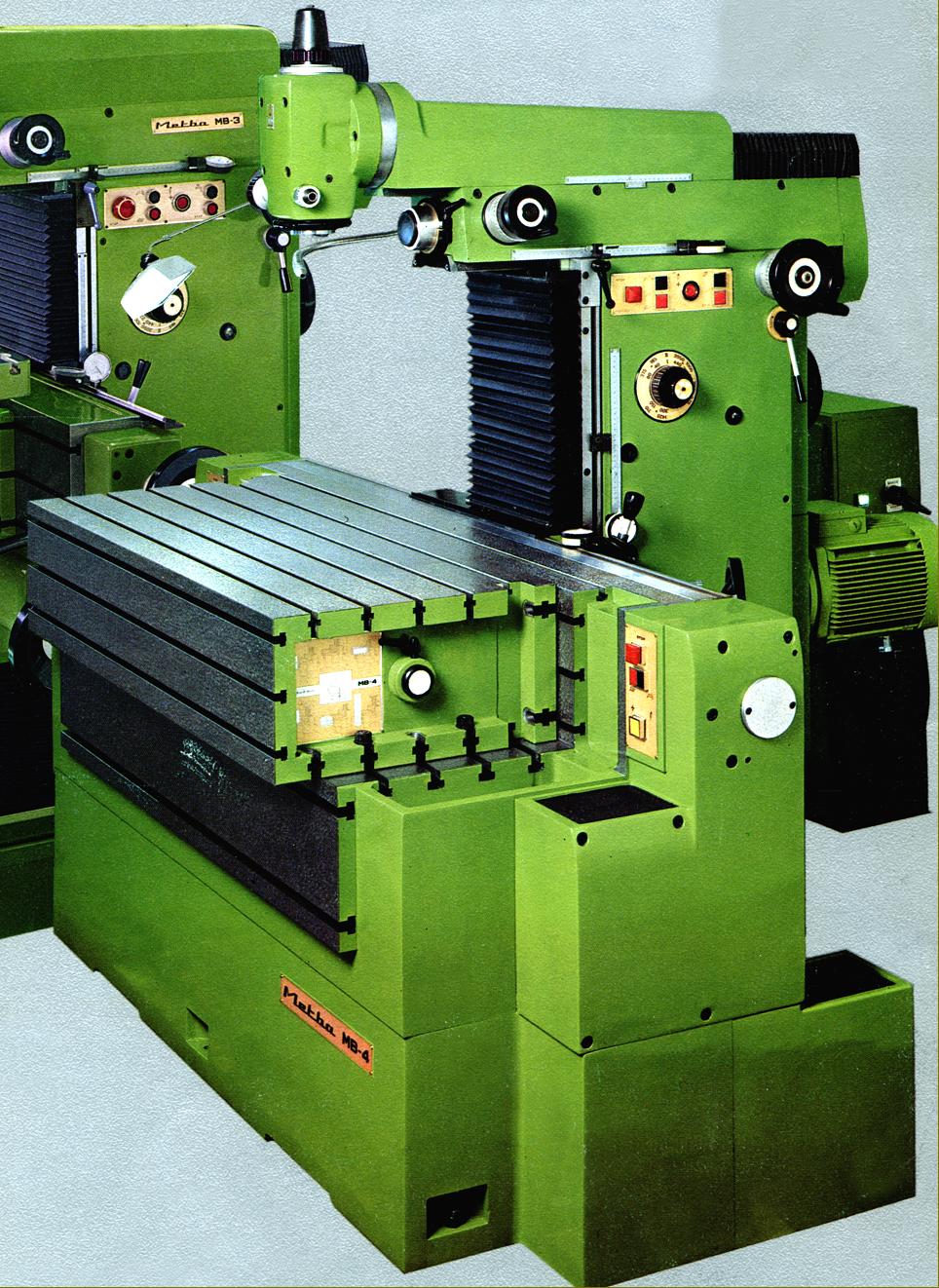

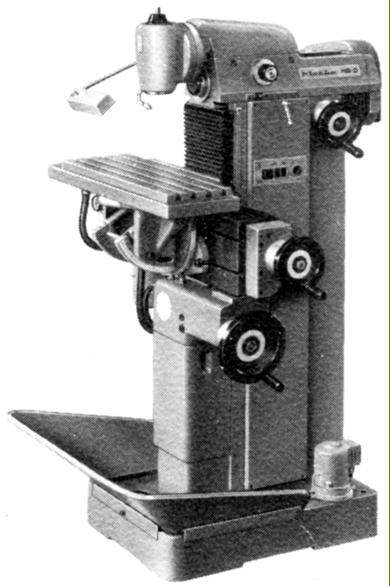

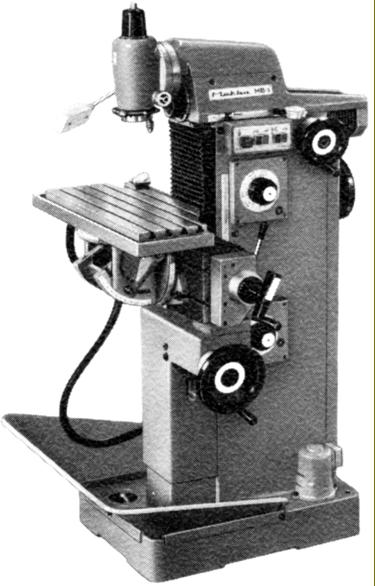

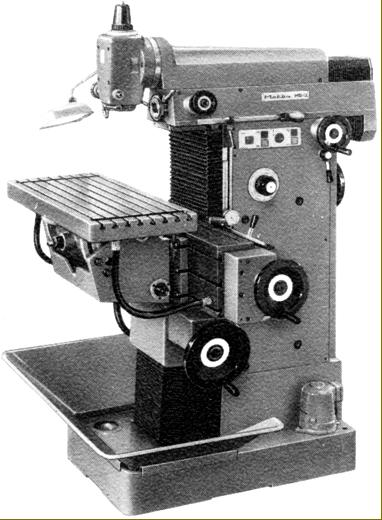

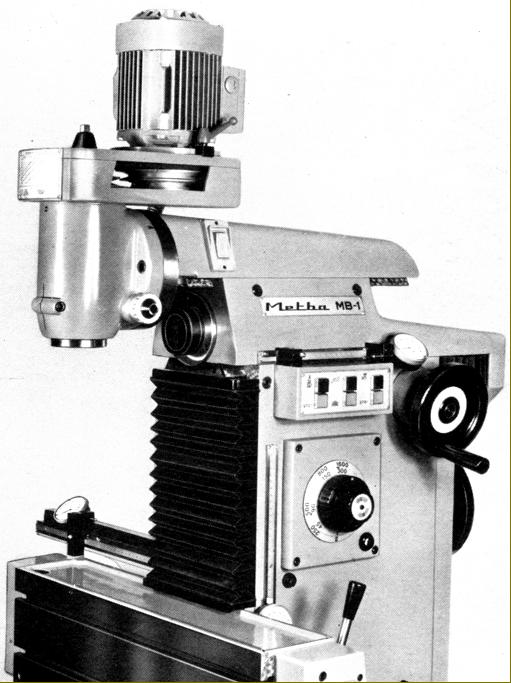

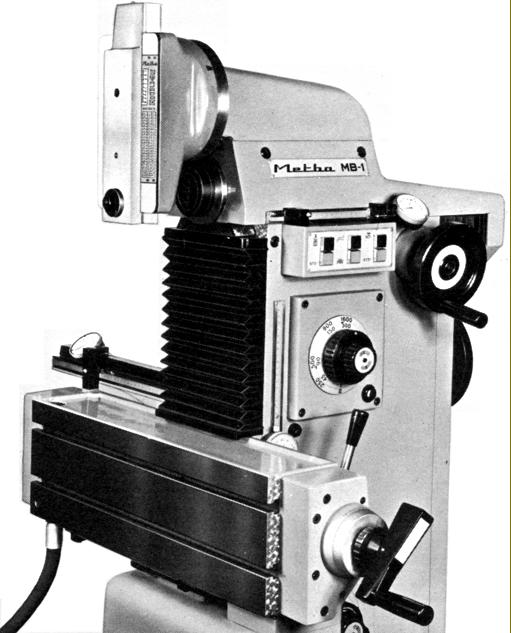

Push-button electrical and mechanical controls were grouped on the right-hand face of the column with a dial to select the spindle speeds - the latter (driven from a 2-speed motor in all cases) ran in twelve steps from 80 to 2000 r.p.m. on the MB-0 and 40 to 2000 r.p.m on the MB-1; all other types had 16 speeds from 40 to 2000 r.p.m. Supplied with each machine was the Standard Vertical Head, a unit that had the same number and range of speeds as the horizontal spindle. On the MB-0 no spindle feed was fitted, but on all other types a simple lever-operated quill was provided - though the micrometer dial was rather small.

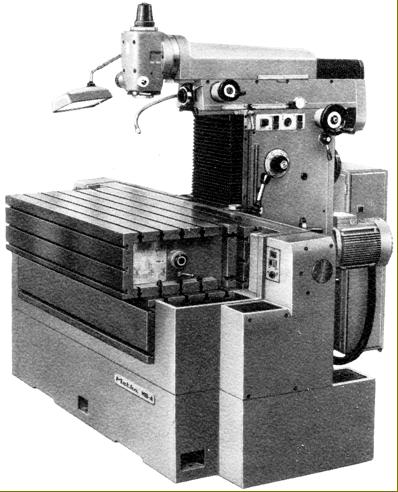

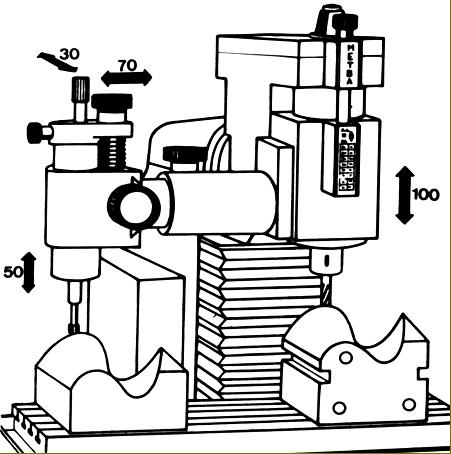

Table and head travels were measured by very large, satin-chrome plated micrometer dials, precision rulers and (at extra cost) fittings to take micrometer length rods. Table power feeds (but not on the head) were fitted to all models - with six rates from 16 to 340 mm/min on the MB-0; 12 from 11 to 500 mm/min on the MB-1 and sixteen from 11 to 500 mm/min on the others. Rapids were fitted on only the three largest types, at a single rate of 1500 mm/min - a figure might be regarded as too fast for safety in the vertical mode and where caution during its use would have been needed. Well finished, each model was well protected against the ingress of swarf and dirt: large sheet-metal covers guarded the lower part of the machine with bellows over the knee, table and ram feed screws and ways.

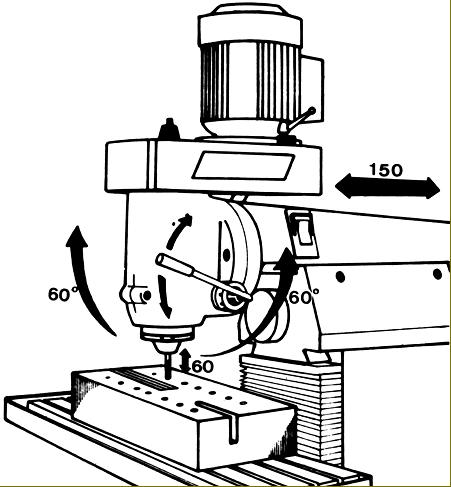

Besides normal horizontal and vertical milling operations all versions of the Metba were available with a very wide range of accessories - easily rivalling those offered by Deckel - to cover slotting, jig boring, jig grinding, spiral milling, punch milling, corner machining, copying and precision measuring and setting. One of the more useful attachments was the Independent High-speed Vertical Head, Ref. 23000.. Able to be swivelled 60 degree either side of vertical this had a spindle with 60 mm of travel, an ISA-40 nose and 4 speeds of: 2000, 3000, 4600 and 6000 r.p.m. driven by a 0.55 kW motor. Control of the quill feed was by a quick-action lever only - no handwheel-operated fine-feed being fitted, nor available as an extra.

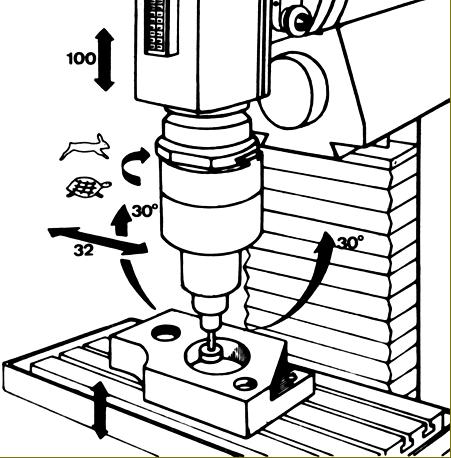

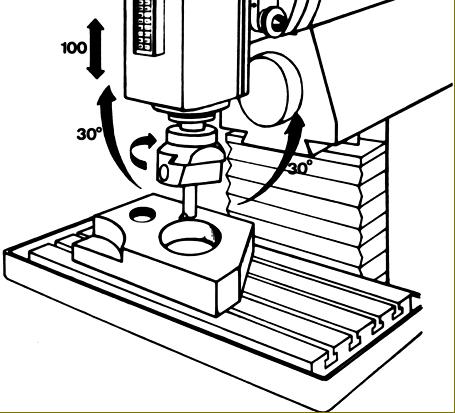

For jig boring and other high-precision tasks, the Automatic Boring Head Ref. 22600 was offered. This had 24 speeds, spanning 40 to 5000 r.p.m., 6 rates of power down-feed (at 0.01, 0.02, 0.03, 0.04, 0.06 and 0.012 mm/min) and a spindle travel of 100 mm.

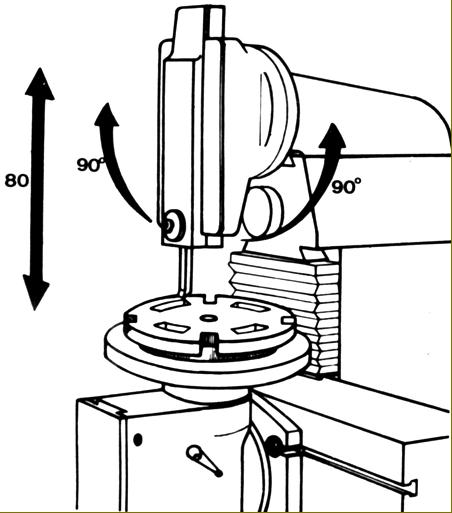

An unusual addition was a small 170 x 170 mm Precision Compound Table Ref. 22800 with 100 mm of travel in X and Y directions. It was intended to be mounted on the Dividing Unit, Ref. 32100, and, in combination with the use of DTIs, indexing plates and its ability to be rotated through 360-degrees in a horizontal plane (and partially inclined), was intended for the machining of small, complex components.

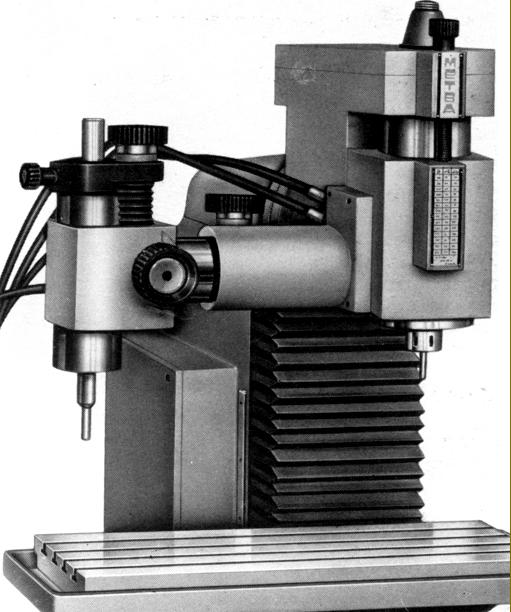

Attached to the end of the standard vertical head, the Universal Multi-angle Head Ref: 23400 was designed to tackle machining into tight corners, typically on dies and similar jobs. 12 speeds were available, from 65 to 3000 r.p.m. with the spindle end accepting collets to take cutters in diameters of 3, 4, 5, 6, 7 and 8 mm.

*Proof of the type's success - the genus Precision Universal Milling Machine - is evident from the number of similar machines made in various countries including:

Austria: Emco Model F3

Belgium: S.A.B.C.A. Model JRC-2

Czechoslovakia: TOS FN Models

England: Alexander "Master Toolmaker" and the Ajax "00", an import of uncertain origin.

Germany: by several companies including:

Hahn & Kolb with their pre-WW2 Variomat model

Hermle Models UWF-700 and UWF-700-PH

Leinen Super Precision Micro Mill

Macmon Models M-100 & M-200 (though these were actually manufactured by Prvomajska); Maho (many models over several decades)

RUHLA UMF

Rumag Models RW-416 and RW-416-VG

SHW (Schwabische Huttenwerke) Models UF1, UF2 and UF3

Thiel Models 58, 158 and 159

Wemas Type WMS

Italy: C.B.Ferrari Models M1R & M2R

Bandini Model FA-1/CB and badged as Fragola (agents, who also sold a version of the Spanish Meteba).

Japan: Riken Models RTM2 and RTM3

Poland: Fabryka Obrabiarek Precyzyinych as the "Avia" and "Polamco" Models FNC25, FND-25 and FND-32

Russia: "Stankoimport 676"

Spain: Metba Models MB-0, MB-1, MB-2, MB-3 and MB-4

Switzerland:

Aciera Models F1, F2, F3, F4 and F5

Christen and Perrin Types U-O and U-1 (Perrin Frères SA, Moutier)

Hispano-Suiza S.A. Model HSS-143

Mikron Models WF2/3S, WF3S, WF-3-DCM & WF-2/3-DCM

Perrin Type U-1

Schaublin Model 13

The former Yugoslavia: Prvomajska (in Zagreb with Models ALG-100 and ALG200)

Sinn Models MS2D & MS4D

"Comet" Model X8130, imported to the UK in the 1970s by TI Comet.

Sloane& Chace in the USA made a miniature bench version and at least five Chinese-built models have also been made, including one from the Beijing Instrument Machine Tool Works. A number of the "clones" merely followed the general Thiel/Maho/Deckel concept whilst others, like Bandini and Christen, borrowed heavily from Deckel and even had parts that were interchangeable. Should you come across any of these makes and models all will provide "The Deckel Experience" - though you must bear in mind that spares are unlikely to be available and, being complex, finely-made mechanisms, they can be rather difficult and expensive to repair..

|

|