|

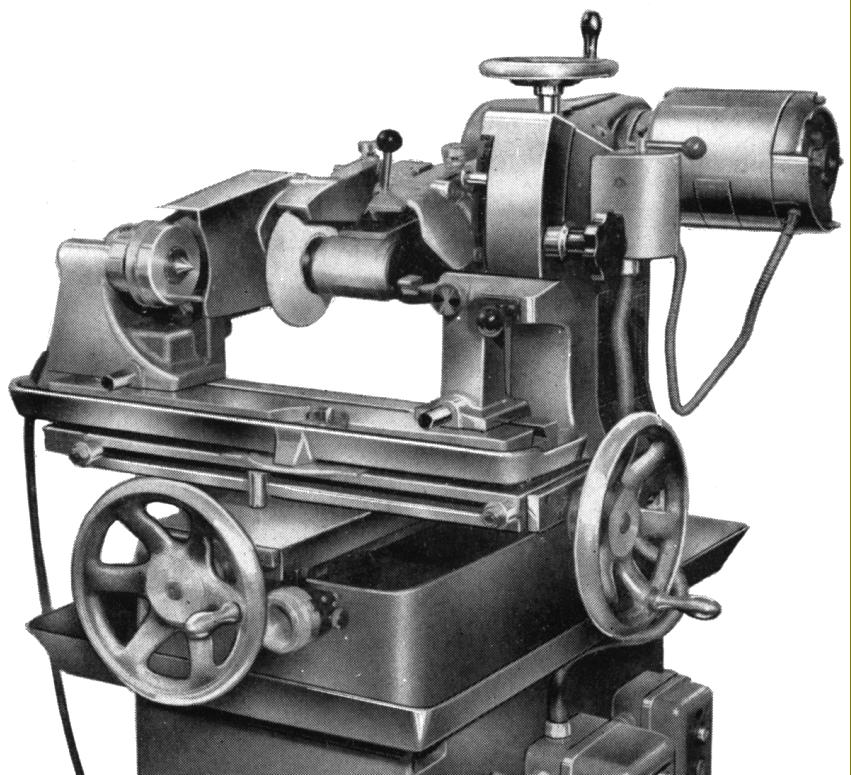

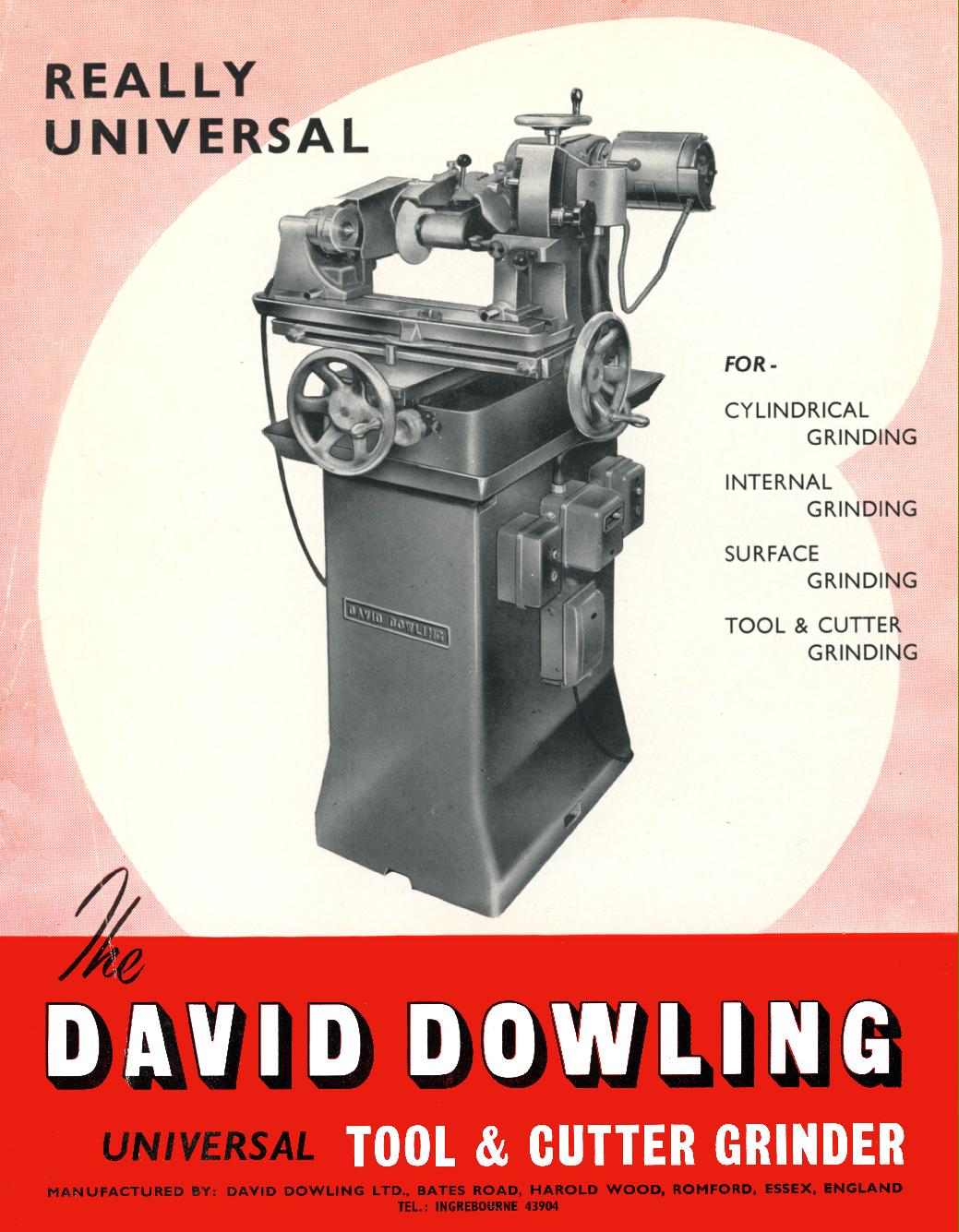

Manufactured by a British company better known for their pantograph engravers and die sinkers, the David Dowling Universal Tool and cutter grinder was able to perform, when fitted with the appropriate accessories, not just the usual tool sharpening jobs but also as act as a surface, cylindrical and internal grinder. With its grinding head carried on a rear mounted, elevating column the Dowling followed a popular trend, the same design being found, staring from the early years of the 20th century, on a number of machines including the original vintage Jones and Shipman and their later Model 310, the Bauerle, Cincinnati, Union/Harrison and K.O.Lee as well as examples intended for the amateur market from the English makers Perfecto, Quorn and Stent.

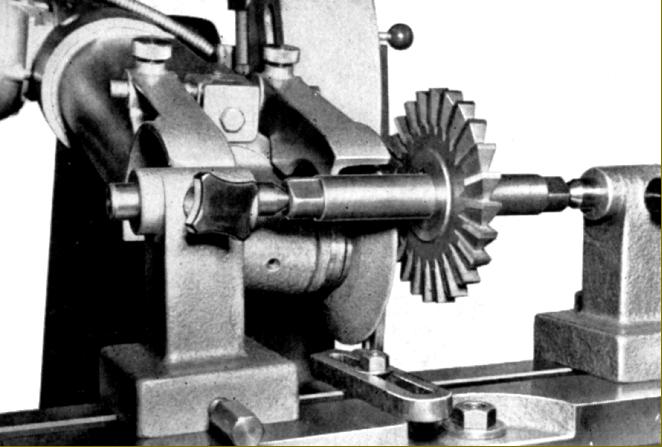

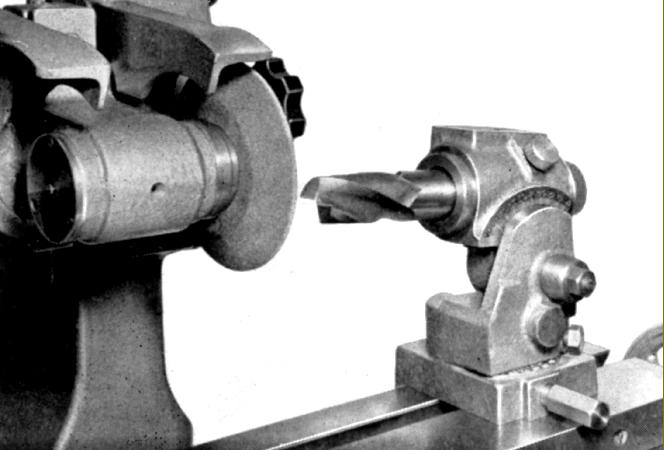

Able to be rotated through 180°, the wheelhead could, as a consequence, grind side and face cutters on their periphery and both sides at one setting. When the need arose to grind larger items, including saws up to 16 inches in diameter, a table-mounted "universal workhead" with a No. 4 Morse taper was offered as an optional extra.

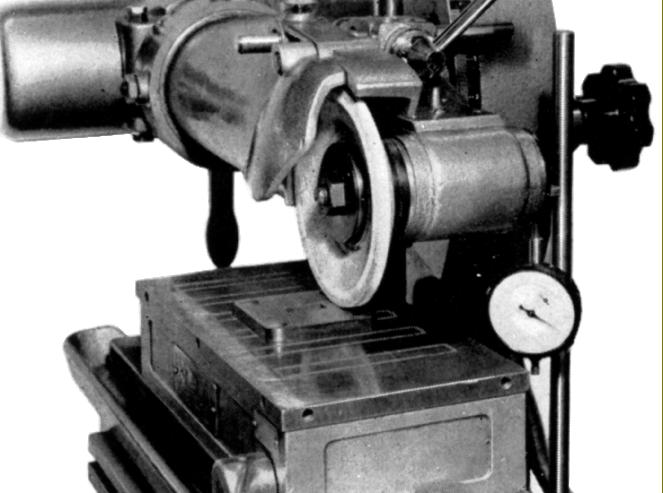

When set as a horizontal grinder - the maximum area able to be covered was 9 inches by 4 inches - the top table was set in line with the lower, the usual magnetic chuck bolted in place and a dial gauge, to measure the depth of cut, attached to a vertical rod at the rear of the table's right-hand end.

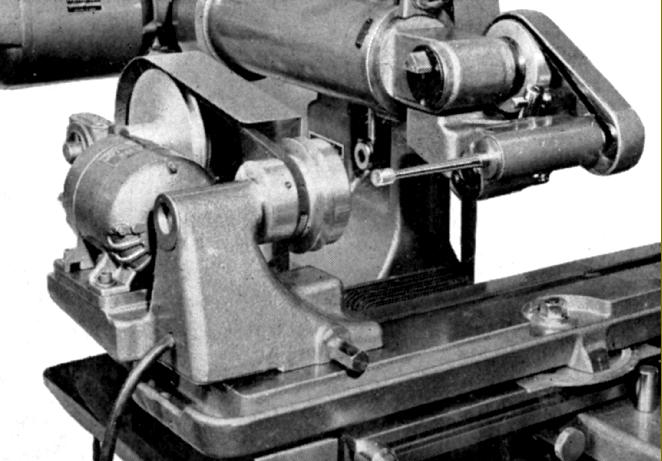

Cylindrical grinding required the addition of a self-contained, V-belt drive, 2-speed, table-mounted workhead together with a spring-loaded tailstock. Work up to 1.5 inches in diameter and 8 inches long could be accommodated; again a separate dial gauge had to be mounted, this time to measure the table's in-feed travel.

Internal grinding, which requires very high speeds, was achieved by mounting a second head to the right of the cylindrical grinding workhead. The right-hand head was driven by a tensioned flat belt from the main motor, in the opposite direction to the left-hand head, at 20,000 r.p.m.

As was common on this type of machine from almost all makers, the table assembly was arranged to be rotated in several ways with the whole unit able to be rotated on the heavy base casting and the main table topped by a sub table that could be set over at a precise angle and able to carry, located in a single, centrally-positioned T-slot, the accessories necessary to allow the various forms of grinding. Tool and Cutter grinders fall into three broad categories: (1) special types of limited functionality used, for example, for the sharpening of "D bits" and other cutters used by pantograph engravers; (2) standard machines for the grinding of the such ordinary items as end mills, slot drills, side-and-face cutters and slab mills and (3) the more versatile "universal" machines, such as the Dowling, where the design allowed other forms of grinding to be performed. When considering the purchase of a tool and cutter grinder be sure that it does not fall into category (1) - check that it has a similar range of movements and settings available on standard machines such as the Clarkson and Quorn. However, should you decide on a more versatile example, compare its design and functionality to the Dowling, LeBlond and Jones and Shipman Model 310 and 1014. While tool and cutter grinders are a most useful addition to any workshop, do beware of buying one without accessories; although some limited work is possible on a basic machine, to exploit it fully, rather more is required. Installed in a professional workshop a typical example might well be complete with a number of useful extras including: a radial grinding attachment; collets; a universal grinding head; universal (double swivel) work-holding fixture; a self-contained, table-mounted motor-driven workhead; sensitive workhead and a selection of precision, very slightly tapered arbors to hold workpieces..

|

|