|

Although to become famous for their high-quality wood-turning lathes and associated equipment, the Coronet Company began life as a maker of machine tools in a rather different field. At the Model Engineering Exhibition of 1946 they displayed not wood-working equipment but four new small precision lathes, three of which were plain-turning types and one backgeared and screwcutting. The plain lathes were the "Diamond" (with a flat-topped bed) and a pair with round, solid steel bar beds; the "Jewel", "Ruby". The screwcutting lathe was the 3" x 12" "Tiara" of which, unfortunately, no surviving example have been found nor any supporting paperwork.

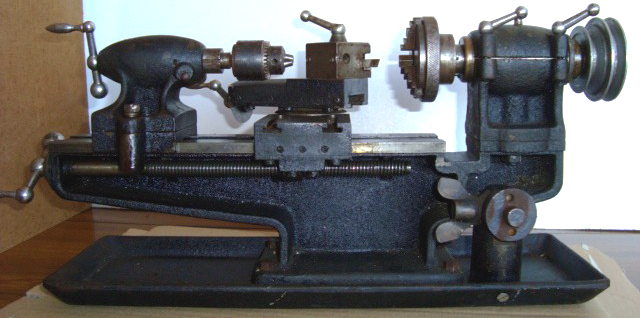

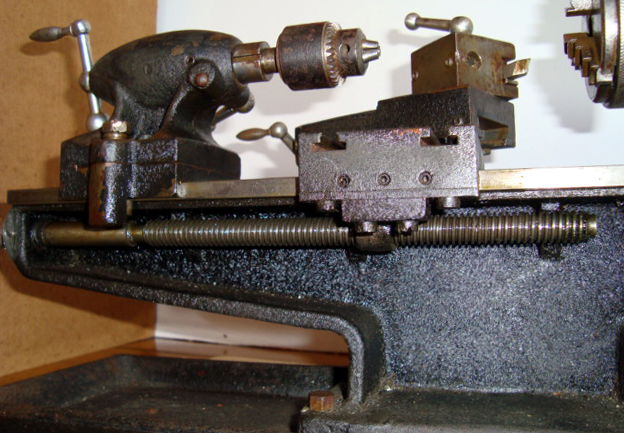

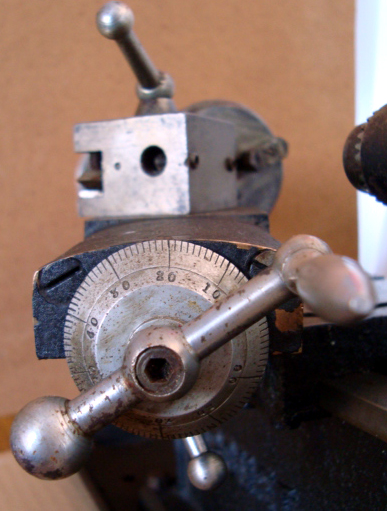

Of rather conventional appearance, with a flat-topped, cantilever-form bed, the 2.25" x 6" "Diamond" had a headstock assembly that could be unbolted from the bed and a base that allowed it to be swivelled 10° in either direction from central. The spindle (plain-bearing and ball-race) was, apart from a 11/16" x 20 t.p.i. nose thread and a No. 1 Morse taper, identical to that used on the other lathes and could be exchanged for the high-speed version. A hand-operated feed was provided for the carriage, the overhung leadscrew (complete with a zeroing micrometer dial) passing, rather unusually, down the rear of the bed. Unfortunately, only a single swivel slide was provided (though with a very large and easy-to-read micrometer dial) carried on a post that fitted into a hole formed in the front of the saddle - the design allowing it to be adjusted vertically over a small range. While this arrangement provided a quick and easy way of adjusting the tool height (just like the fitting on a Round Bed Drummond) it did nothing for rigidity, the cutting tool being cantilevered well away from its mounting. Of the ordinary screw-feed type, the tailstock could be set over for the turning of slight tapers and was fitted with a proper compression-type barrel lock. It appears that the Diamond might have been intended for production in some numbers, the micrometer dials on tool-slide and leadscrew being pressure die-cast in Zamak, just like the ones fitted to the contemporary Myford ML7.

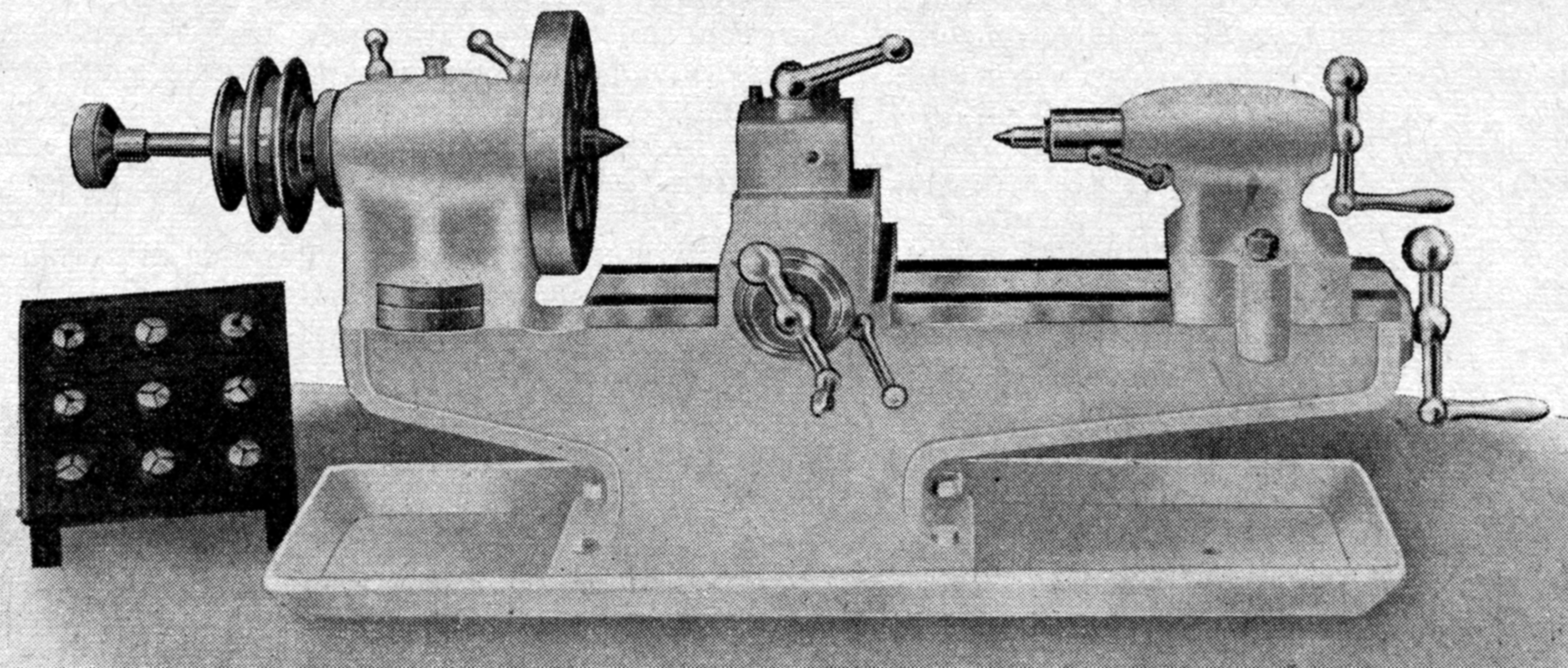

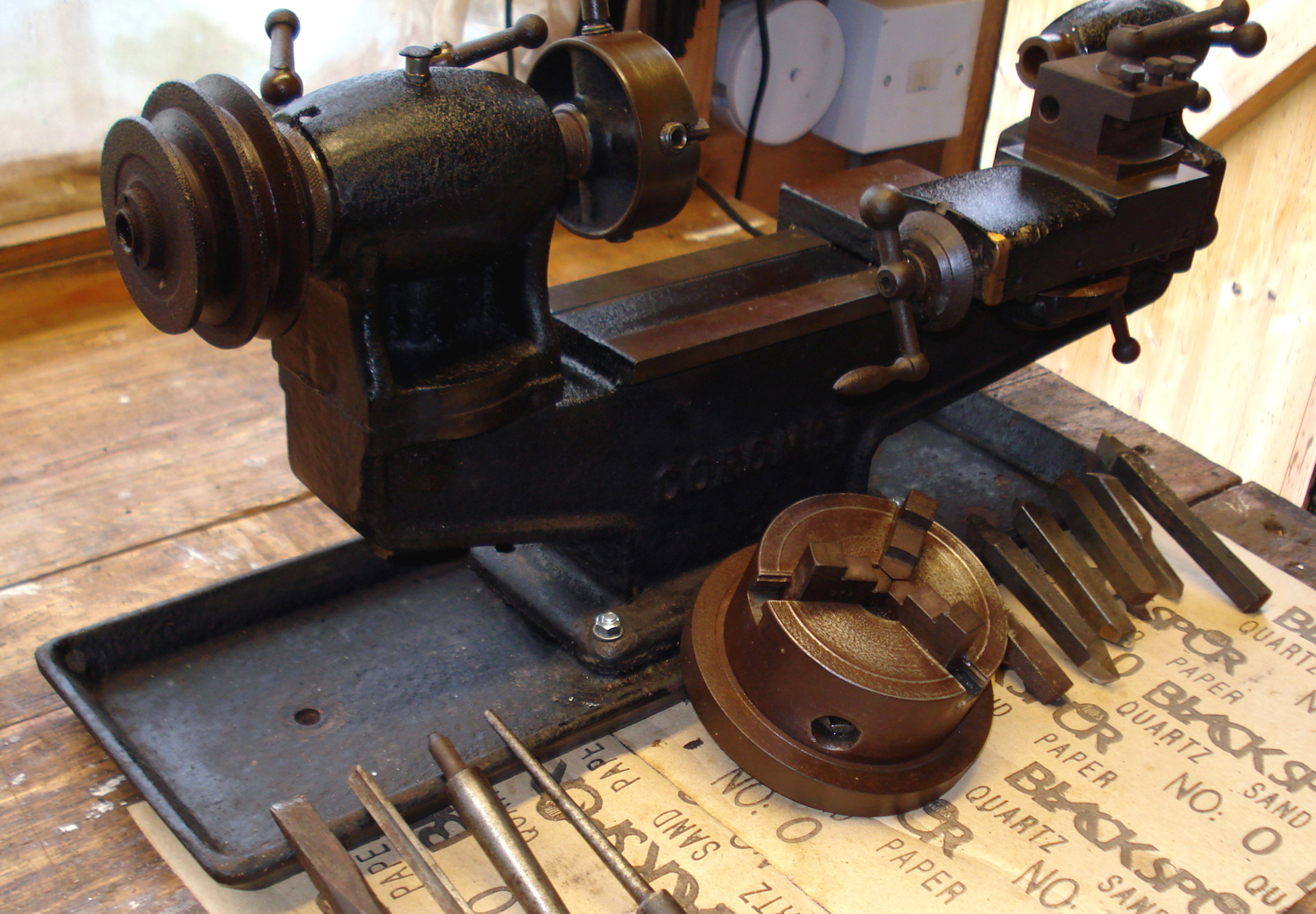

Described by the makers as The Watch and Clockmakers Lathe and Multi Propose Machine, the tiny, 1.5" centre height Ruby used a headstock casting that doubled as a mounting foot with a bolt-on motor as part of the optional equipment. However, as the latter carried just a 2-step pulley (when a 4-step could have been specified for only a few pence extra), the speed range was severely limited. The headstock pulley was overhung, an unusual and rather brave design decision for a precision lathe where the tradition of super-accurate bearings, of hardened steel, honed and lapped to perfection, with the pulley carried between them, had been established for over 80 years. By coincidence, the same decision had been reached by the English Pultra Company on their new range of 17/50 and 17/70 models, also announced in 1946/7. In the event, Coronet found themselves up against a number of competitors including not only continental makers such as Schaublin, but also Boxford who were manufacturing two miniature precision lathes, one a beautiful 3.3" x 9.25" plain-turning bench type and the other a dedicated capstan.

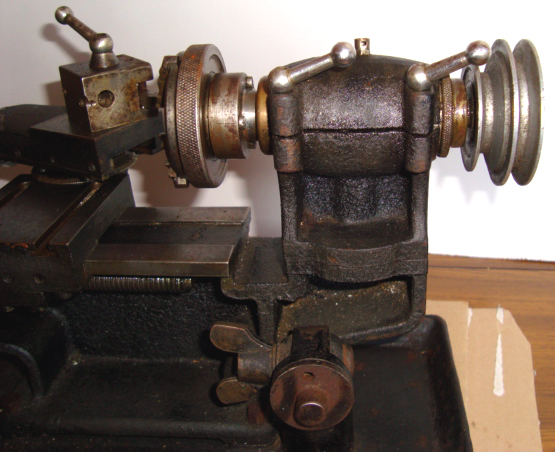

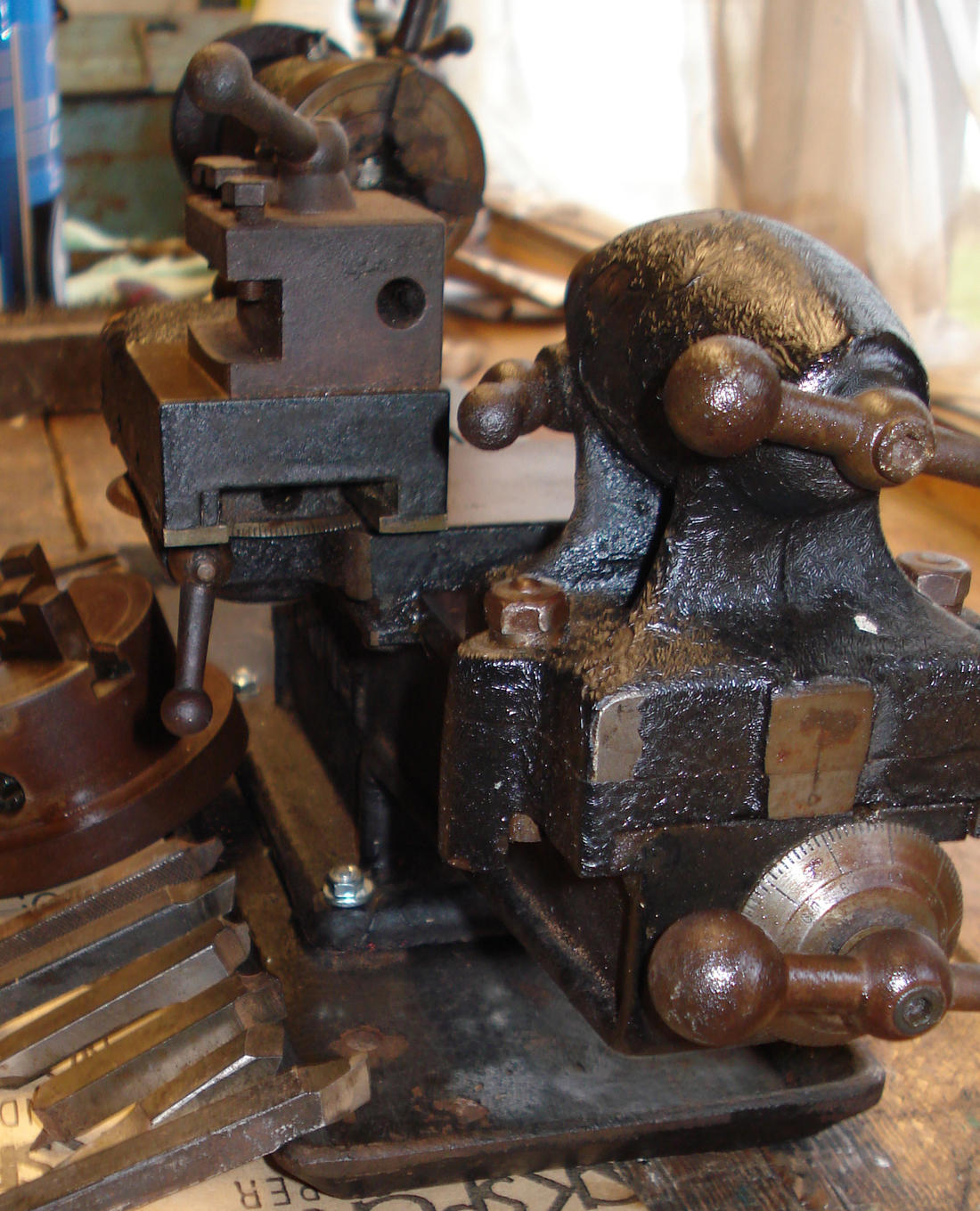

Intended to function either as a lathe or a precision drilling and milling machine, the Ruby was mounted on a heavy cast-iron base plate formed with a post socket at one end. With the lathe set as a drill, the bed was up-ended, dropped into the socket and held in place by a long through-bolt. The tailstock, already provided with a lever-action feed (by the simple expedient of peg passing through a slot cut through the top of the casting) was fitted with a collet-retained faceplate that acted as a drilling table - while the (optional-extra) compound-slide rest assembly could be pressed into service as a co-ordinate table for vertical milling. In order to provide the greatest versatility, the headstock was available with a choice of two cartridge spindles: one for ordinary work with an adjustable tapered bronze bush at the front and a single ball race at the back (an arrangement also used, in a non-cartridge form, on most of the Company's wood lathes) and the other, a high-speed unit, with ball races at both ends. The assembly (not unlike that used on the first Emco Unimat lathes from 1953 and resembling a bicycle hub) was clamped into the headstock by a single lever closing down a slot in the casting; hence it could be removed very easily and swapped over. With a 0.314" bore and a 5/8" x 26 t.p.i. nose thread, the spindle was designed, like the tailstock, to accept draw-in 8 mm collets.

Beautifully painted in black ripple enamel (crackle-black, a popular finish at the time and used to denote a quality product ) and with all the locking rings and adjusters beautifully knurled, the basic Ruby retailed for £18 : 18s : 6d without a motor (for comparison a backgeared and screwcutting ML7 was first listed at £36). Complete and ready to run the price rose to £24 : 18s : 0d. A compound slide was an extra £9 : 18s : 6d, a 2.5" precision 3-jaw chuck £6 : 15 : 0d, wire collets 7s : 6d each and stepped collets 12s : 0d. Supplied as standard with each machine was the cast-iron base plate, a hand T-rest, faceplate, driving pin, collet draw-in tubes for headstock and tailstock and one pair of precision centres mounted on collets. An interesting comparison can be made between the Ruby and the German Saacke miniature universal machine of the early 1950s - through the latter would, no doubt, have cost several times as much.

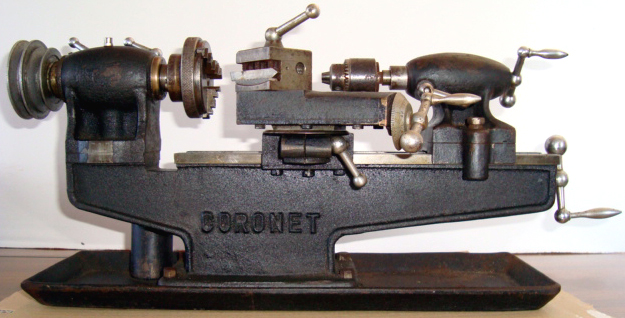

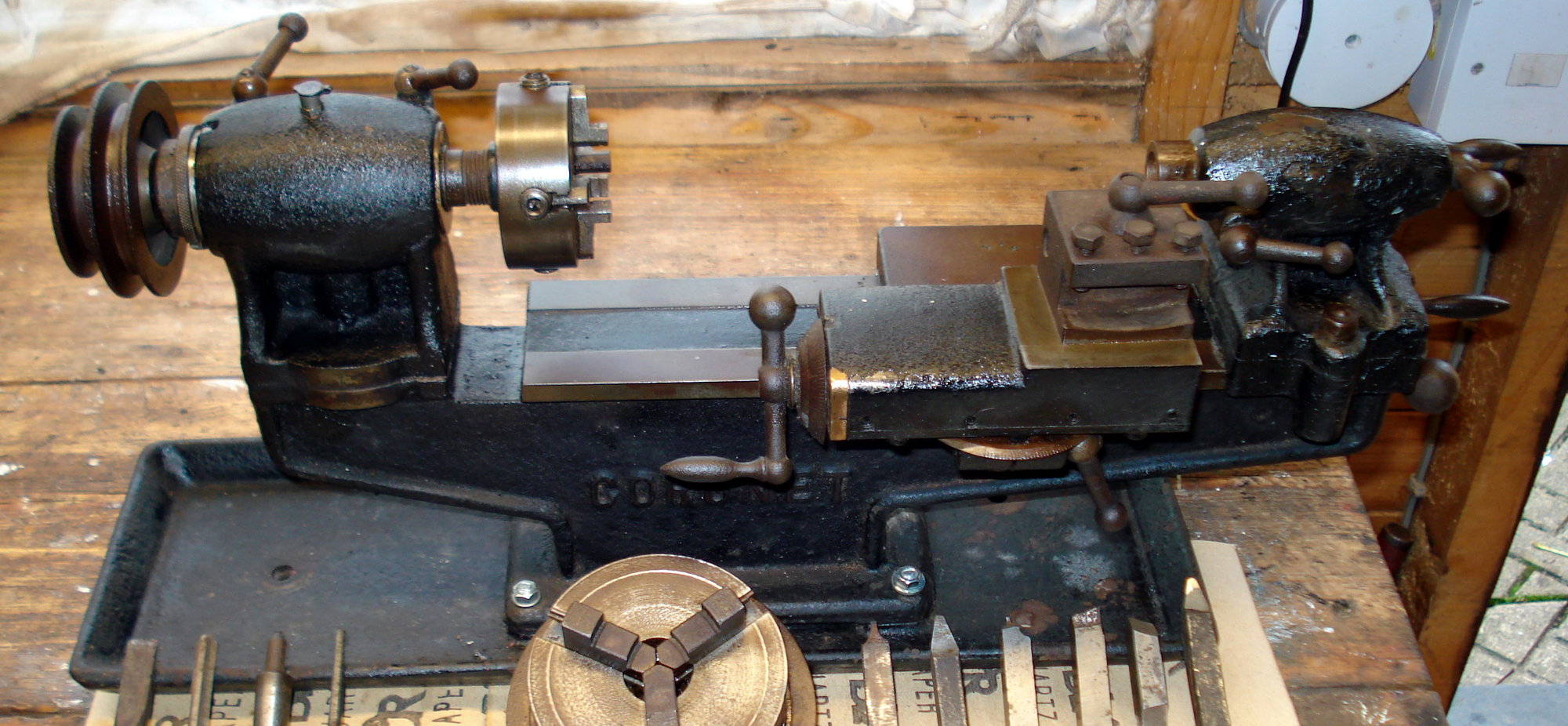

Using many components of the Ruby, including the complete headstock and tailstock units and a bar-bed, the "Jewel" was arranged conventionally with small splayed feet and a carriage driven by an overhung leadscrew running down the front of the bed. A single swivelling tool slide was fitted with the whole machine looking remarkably like the larger but much cheaper and less desirable Velox from the early years of the 20th century.

All versions of Coronet miniature lathes must have been made in very limited numbers, for today they are very rare - even the contemporary Boxford Boxford miniature precision, at an expensive £175, being relatively common in comparison.

If any reader has a Coronet miniature precision lathe, or any literature about them, the writer would be interested to hear from you.

Jewel Lathe Ruby Lathe

|

|