|

Home Machine Tool Archive Machine-tools Sale & Wanted Universal Precision Milling Machine Alexander/Deckel Cutter Grinders If any reader can supply photographs of an Alexander in good, |

||

|

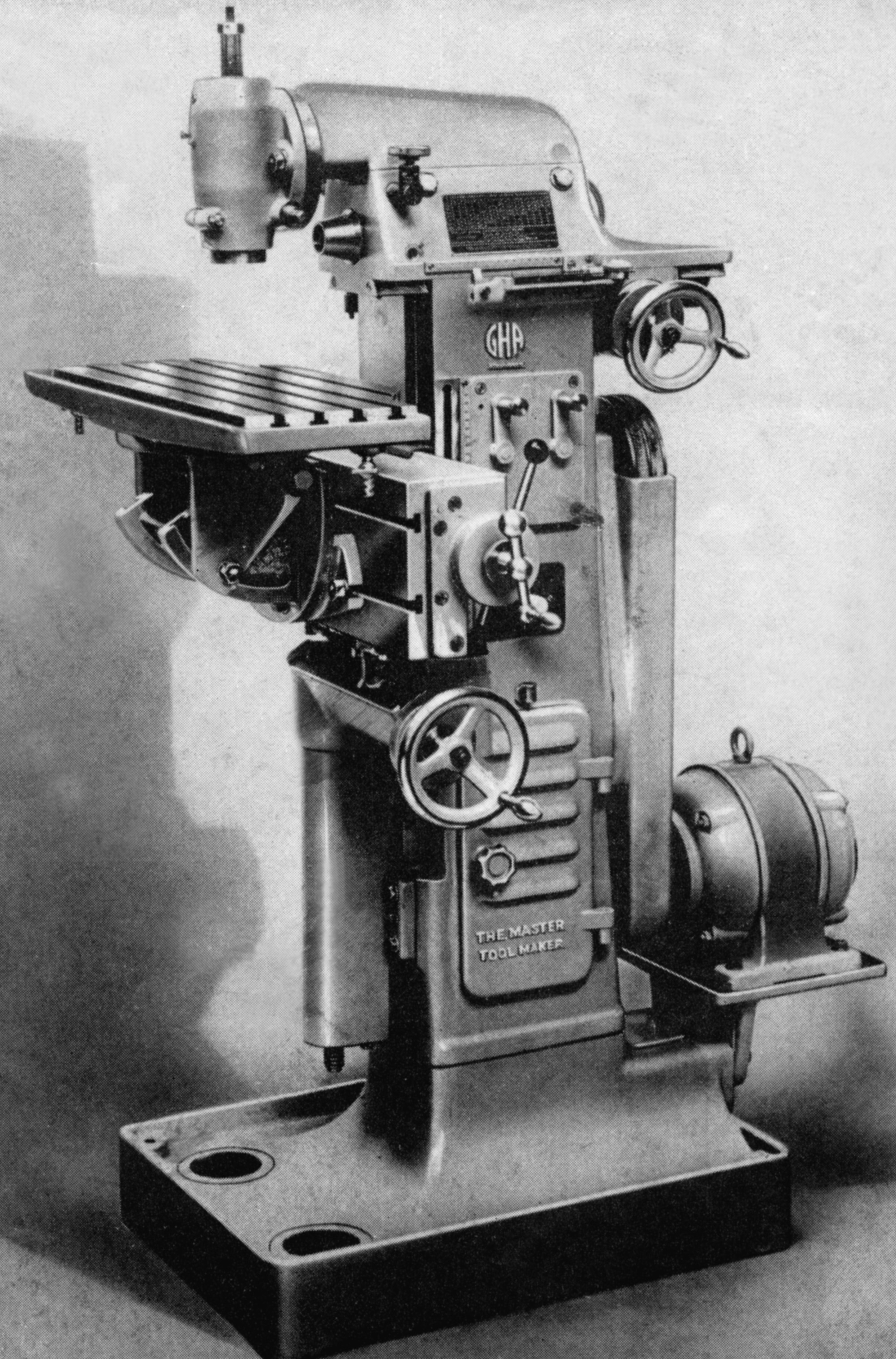

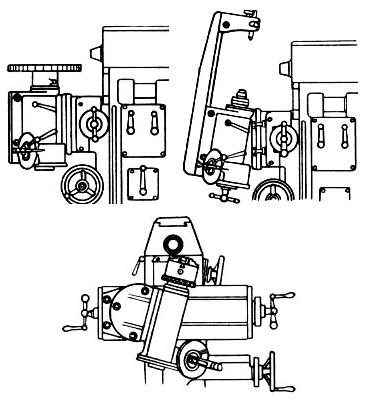

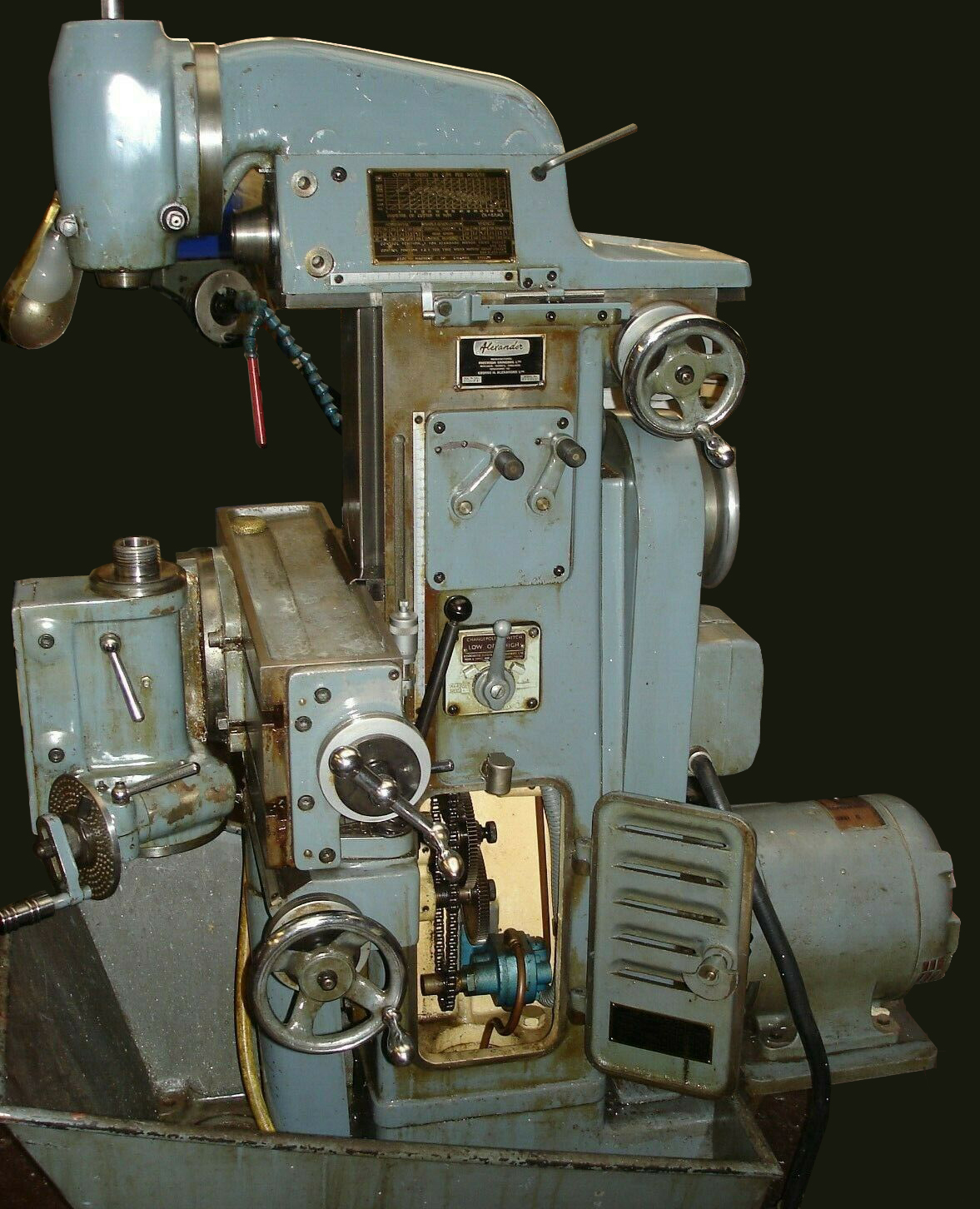

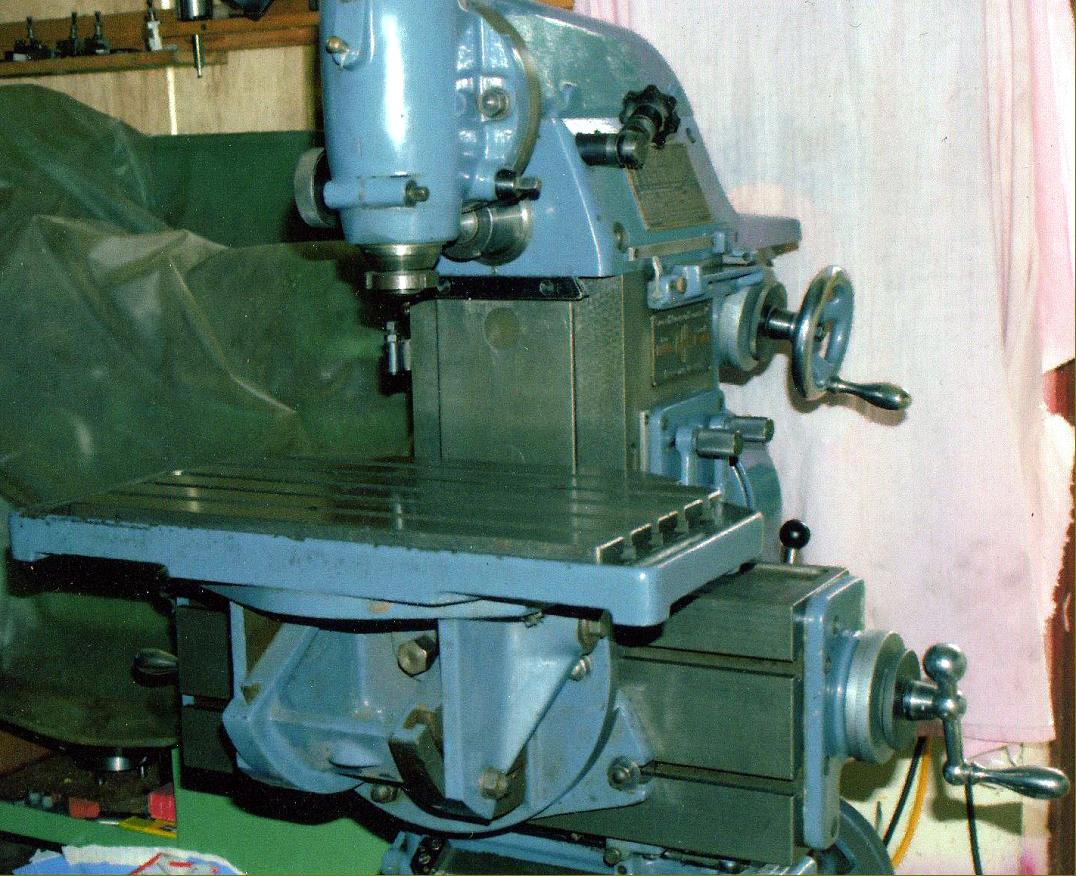

Like many other European and Russian makers the English firm of Alexander copied the original German Deckel FP1 Universal Toolroom Miller - itself similar in many ways to Maho, Thiel and other makes* . With its ingenious, adaptable and versatile design, the Alexander leant itself to solving a multitude of machining problems, the secret of the type's success being its ability to mount a number of different heads - horizontal, standard vertical and slotting - in combination with a variety of tables - plain, plain-tilting and compound swivelling. All the heads could be driven backwards and forwards across the top of the main column, by a handwheel working through reduction gearing, to provide an in-out feed, while the tables bolted to a flat, vertical T-slotted table equipped with power longitudinal and vertical feeds. By juggling the choice of heads and tables, and utilising other accessories, a skilled technician was seldom defeated in his attempts to produce the most complex of milled and drilled components - and all to a very high standard of accuracy. Alexander called their machine the "Master Toolmaker" and, as their advertising literature claimed, it really was: "The machine for the awkward job". |

|

|

|

|

||

|

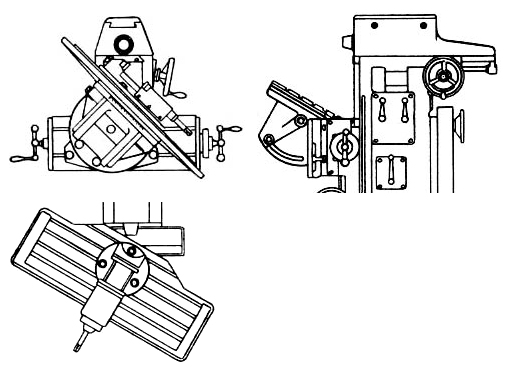

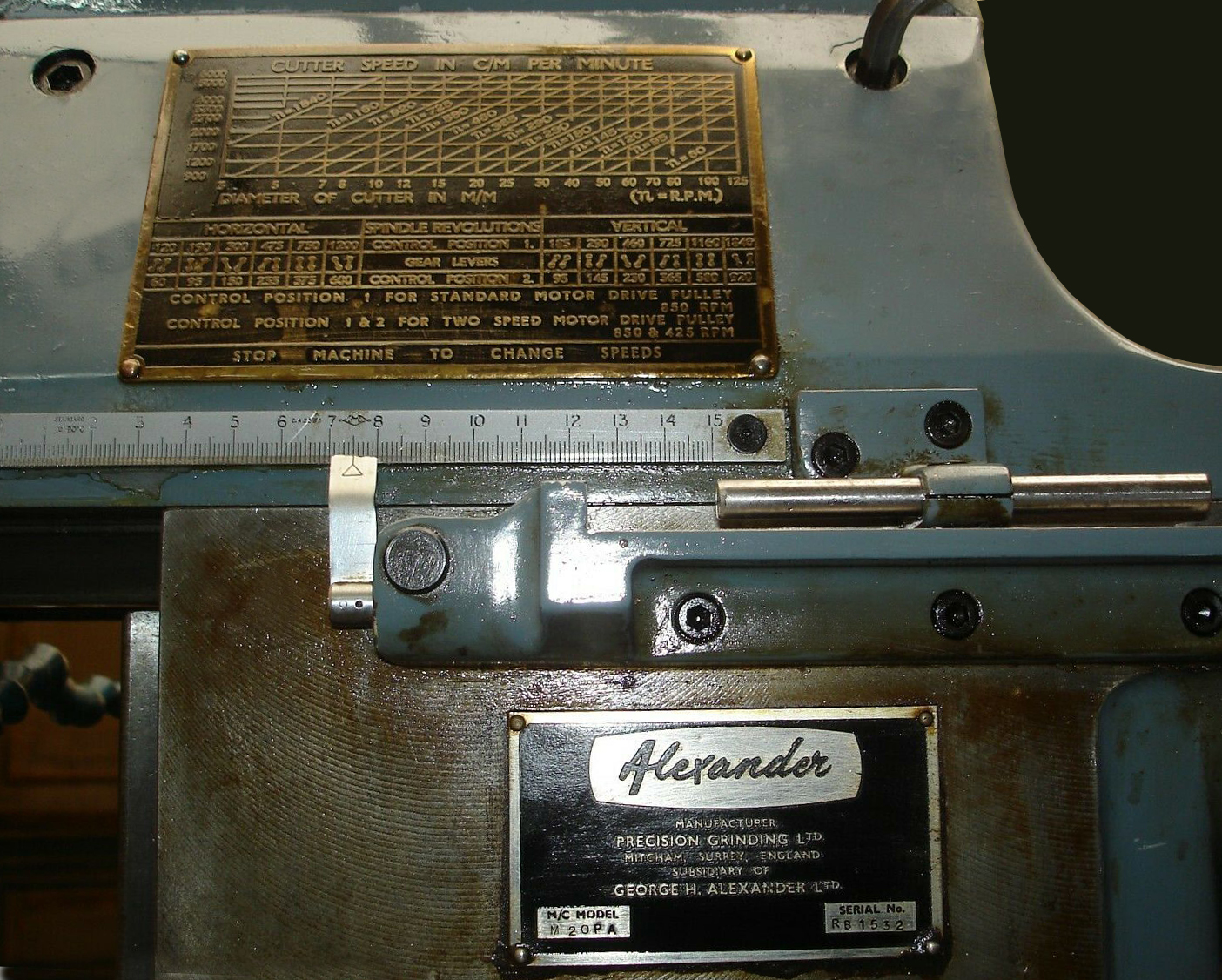

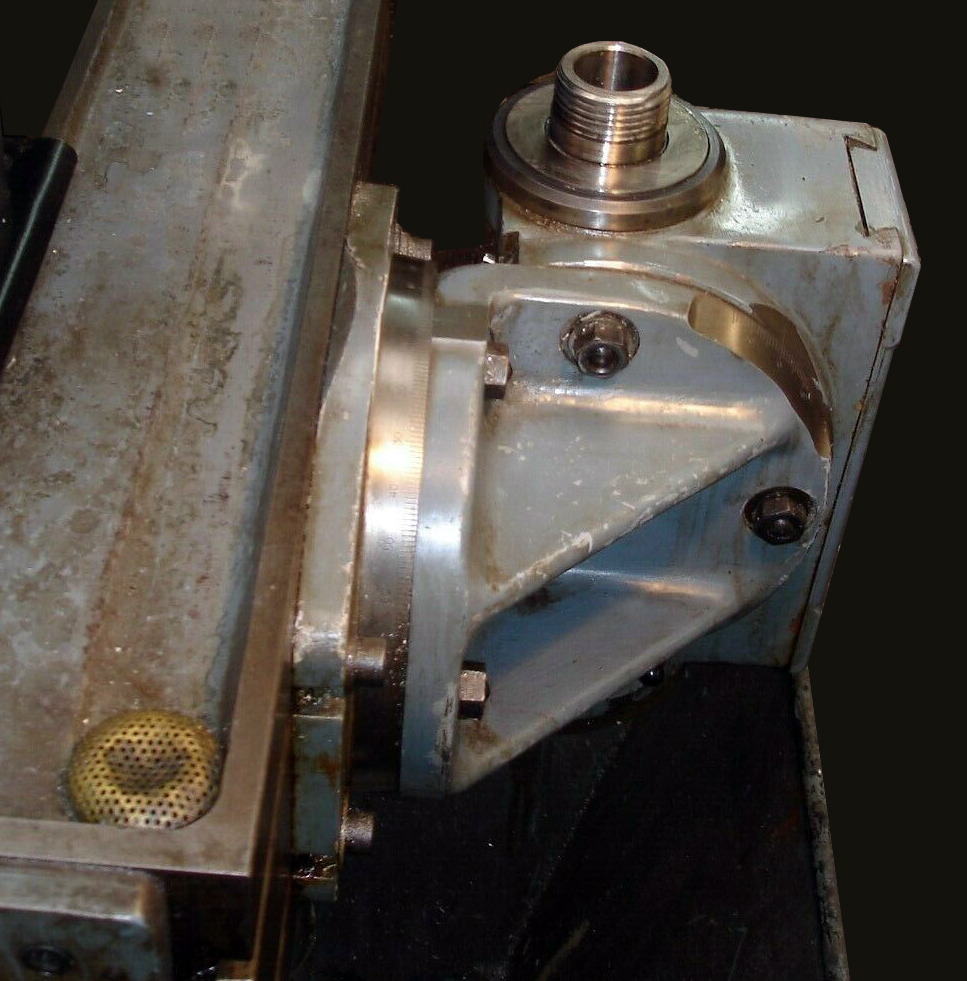

Alexander/Deckel standard vertical head. When fitted with the single-speed electric motor six spindle-speeds were available of 190, 300, 475, 750, 1200, and 1900 rpm. With the two-speed motor the range became: 95, 150, 190, 235, 300, 375, 475, 600, 750, 950, 1200 and 1900 rpm. |

|

|

|

The slotting head is one of those items that can sit unused on the shelf for months but, when needed, proves to be a most valuable and versatile accessory. Depending upon the motor fitted, six slotting-stroke rates from 48 to 475 or twelve from 24 to 475 were available. The head would swivel 35 degrees from vertical and the length of stroke could be adjusted from 0 to 3". Like the vertical head, the unit could be traversed horizontally in the direction of the horizontal spindle by 57/8" |

||

|

In combination with the tilting table many difficult jobs could be tackled with relative ease of setting up. |

||

|

Fitting a boring head to either the horizontal or vertical spindle opened up a host of new possibilities for both simple and complex boring operations. |

||

|

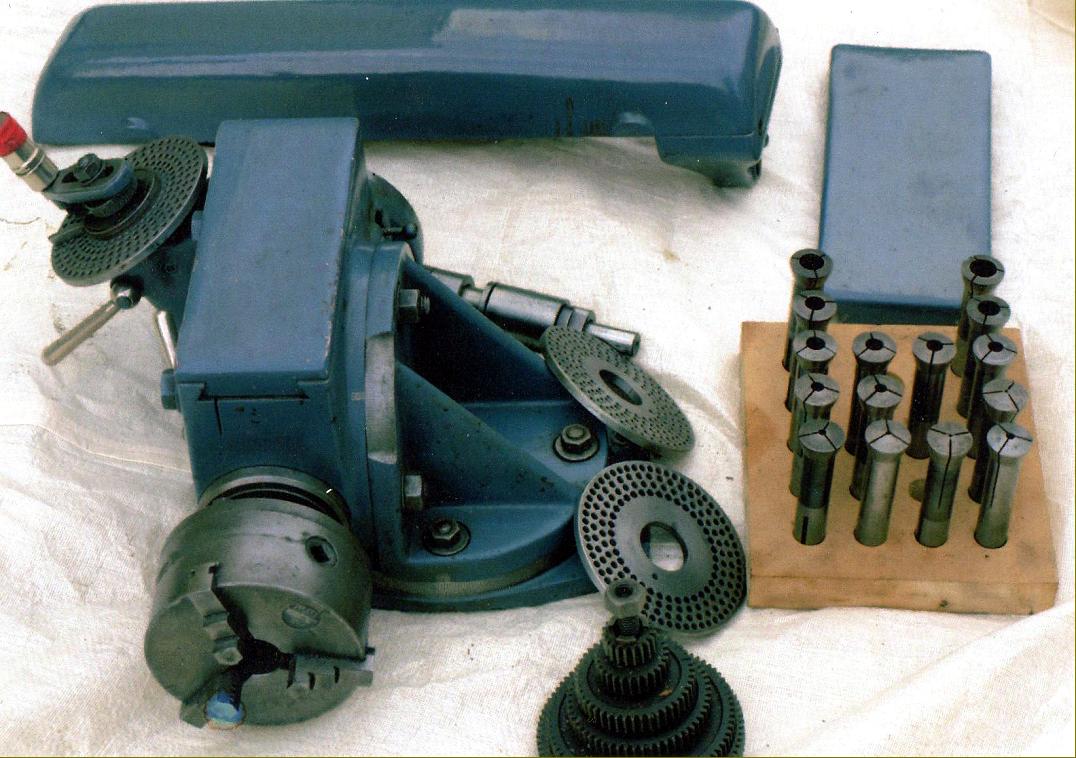

An expensive, beautifully made, versatile and now highly-sought-after Universal Dividing Head was available for the miller. It was designed for direct or indirect dividing and for any angular pitch in degrees. For indirect dividing the worm was swung into mesh with the wheel and the appropriate dividing plate mounted on the fixture. For direct dividing the worm was clamped in the disengaged position and movements of the spindle then controlled by a plunger engaging in a plate provided with ten notches. |

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted Universal Precision Milling Machine Alexander/Deckel Cutter Grinders If any reader can supply photographs of an Alexander in good, |

||