|

Home Machine Tool Archive Machine-tools Sale & Wanted "High-swing", ML7 Capstan, ML5, ML6, & Others - page 2 - Myford Home Page Myford Capstan Lathes Home Page Myford ML2 Capstan Myford Super 7B with 60" between centres |

||

|

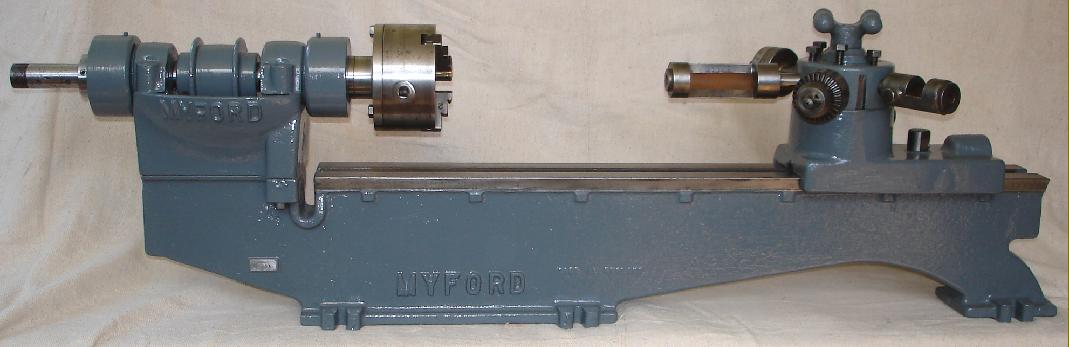

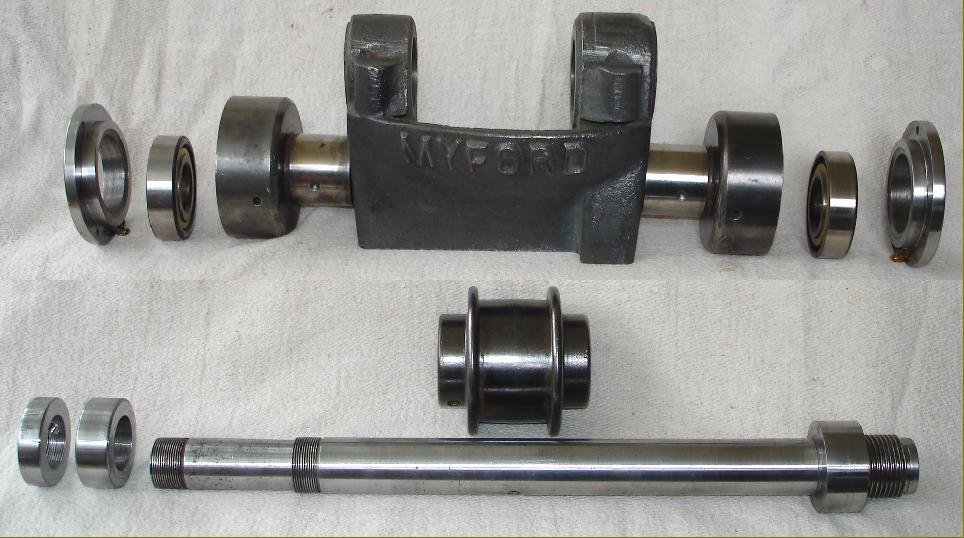

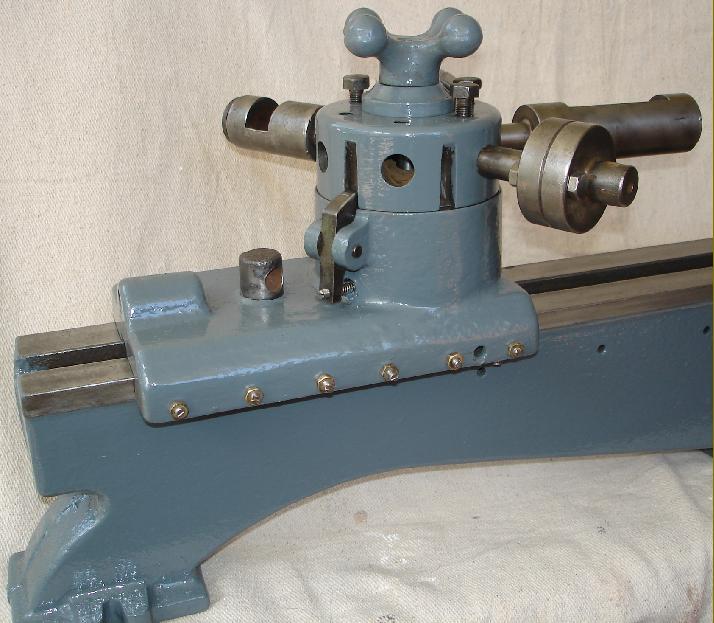

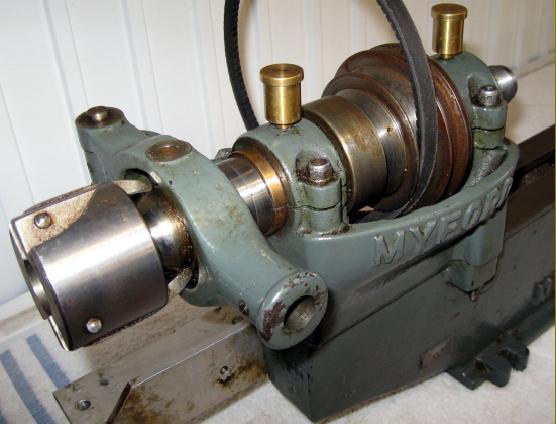

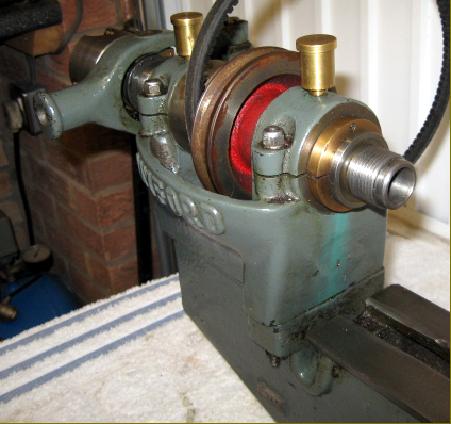

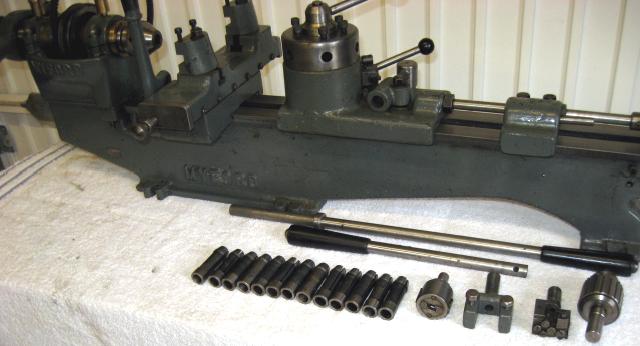

Although, during the late 1930s, Myford had produced a useful little capstan lathe that used the bed of a slightly modified ML4 lathe, this was not a machine capable of absorbing thousands of hours of hard use at the hands of unskilled operators. With war-time demand for any kind of production lathe running at a high level, and with little on the market as competition in the very smallest sizes, Myford introduced several capstan versions (of confusing specifications) including the short-lived ML6. While this used the same 6-station self-indexing capstan turret head and cut-off slide from the ML4 capstan, the headstock and bed were completely different. The large-bore spindle ran in massive ball or roller bearings and has been found fitted with a variety of pulleys: 1 and 2-step flat and 3-step V-belt, with the drive coming either directly from a 0.5 hp 3-phase motor or through a stronger version of the adjustable-type, swing-head countershaft as used on the ML2 and ML4 lathes. To stabilize small diameter stock as it was fed through the spindle, a properly-engineered adjustable steady was bolted to the left-hand face of the headstock. The spindle was fitted with a well-made, lever-operated collet closer that pivoted from a heavy bracket formed as an extension to the headstock casting behind the left-hand bearing. The closer operated through the usual toggle mechanism - and used collets of the standard and widely-employed "dead-length" type. The bed bore some cosmetic resemblance to that used on the 4-inch " Precision", and so deeper and much more heavily built than that of the amateur-market ML4. |

||

|

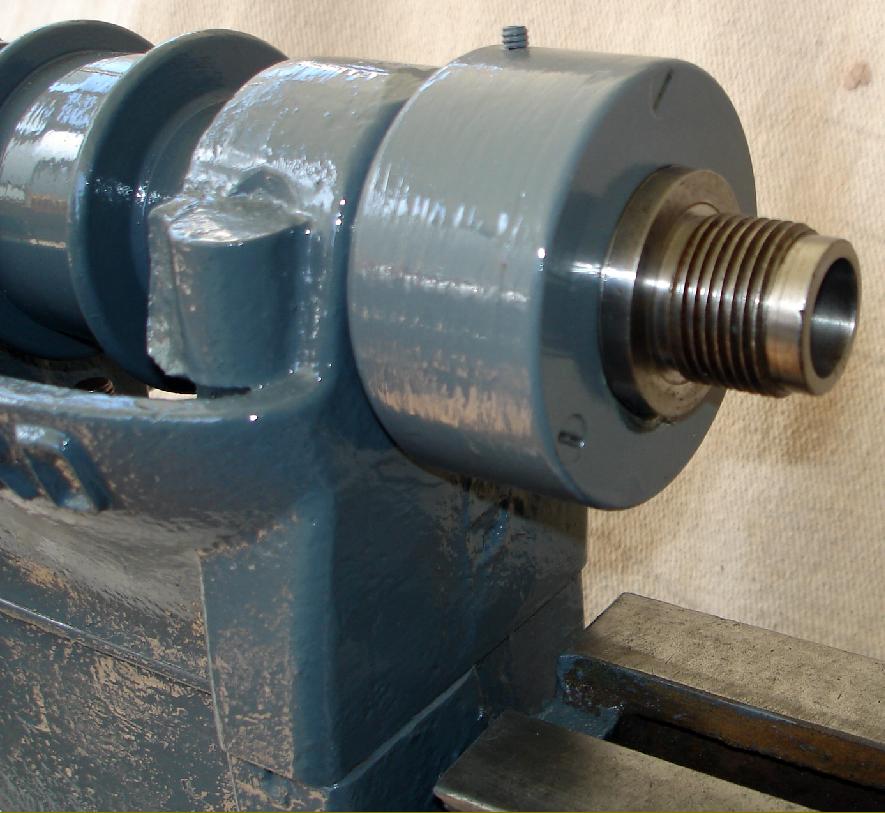

Another version of what may have been an ML5 - this example carrying the prefix "G" on its Serial Number plate. Note the single, wide headstock pulley, the "4-inch Precision" type headstock that used ball races carried in housings spigoted into the unsplit bearing holes. |

|

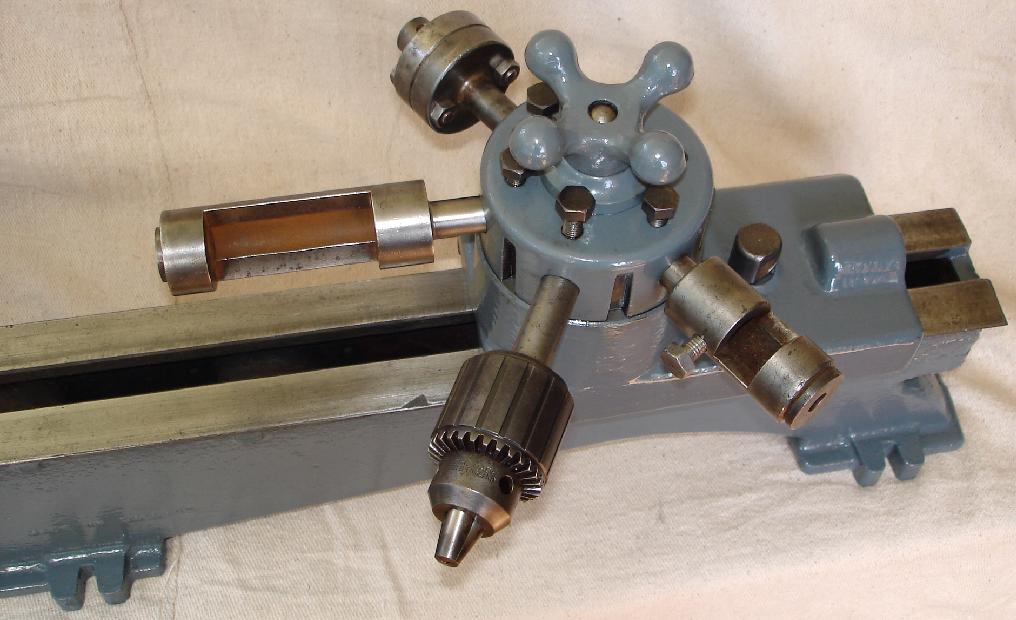

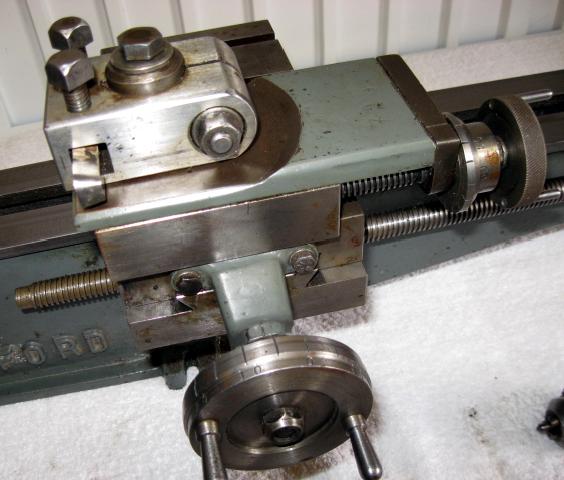

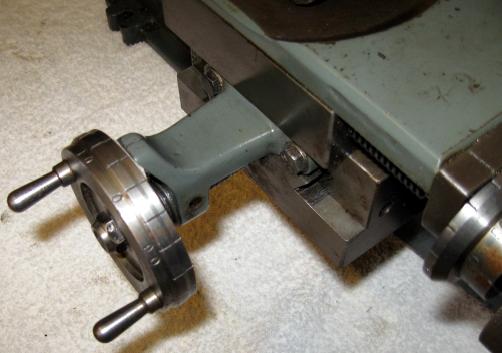

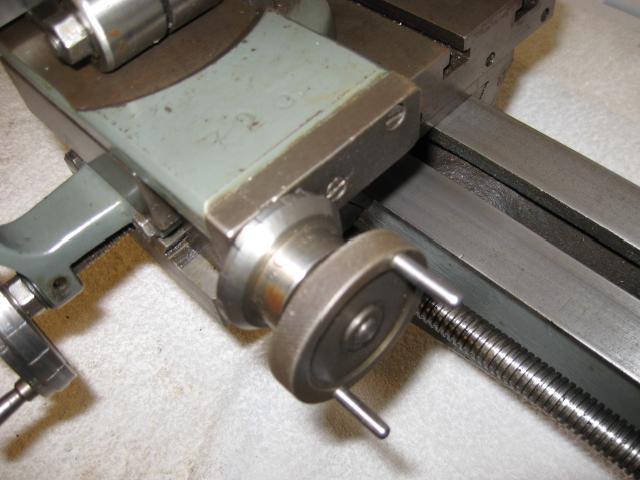

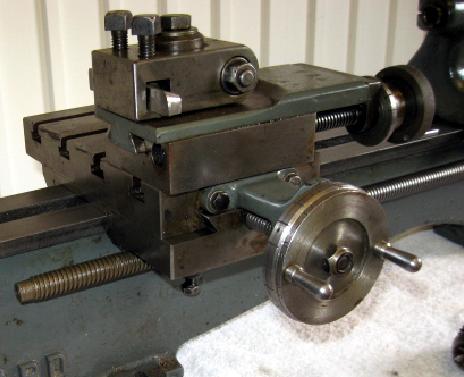

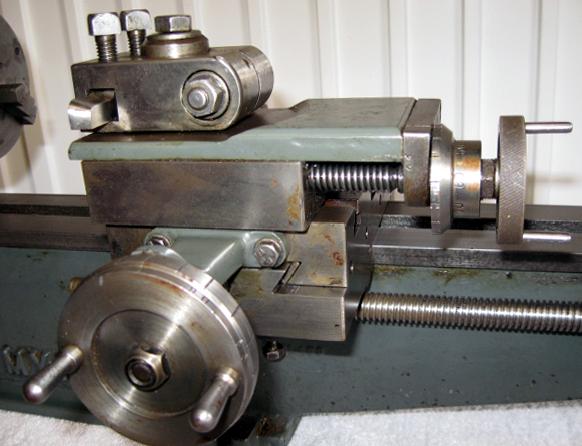

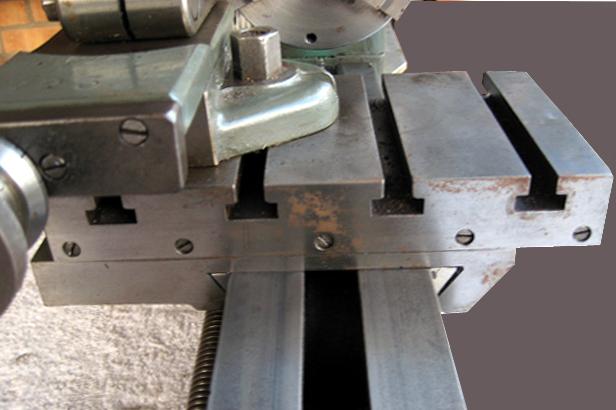

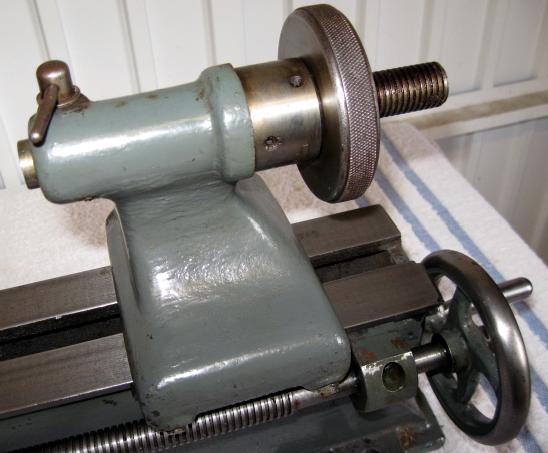

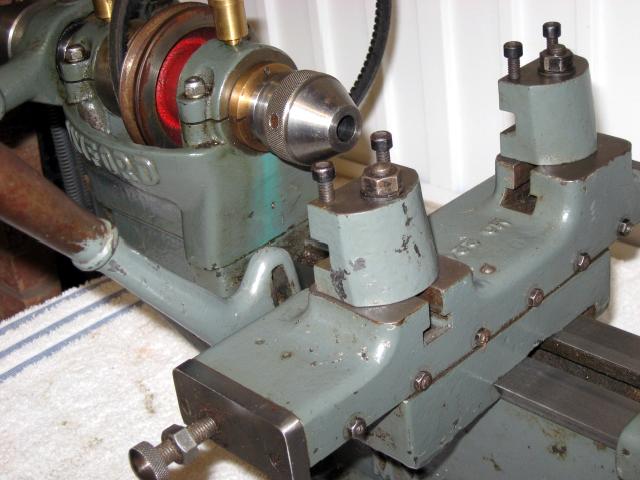

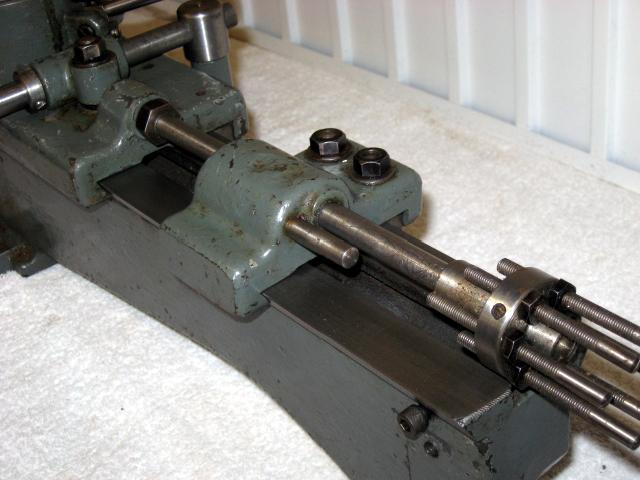

What appears to be a version of the ML5 capstan lathe set up as a centre lathe. It has a conventional screw-feed tailstock, a hand-turned, leadscrew-driven carriage assembly and a top slide and cross slide assembly possibly taken from a contemporary (1941-45) Myford/Drummond M-Type. On this machine is a modification that should have been applied to all versions of the M-Type - the cross-slide screw supported in an extension bracket to increase the slide's travel. |

|

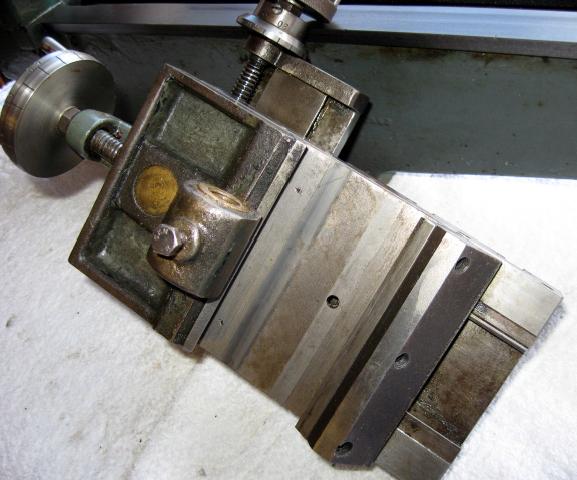

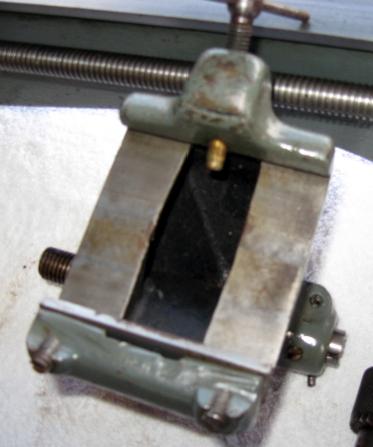

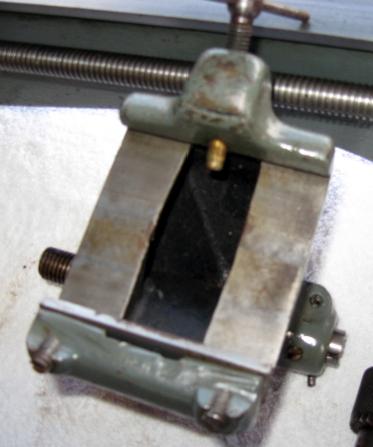

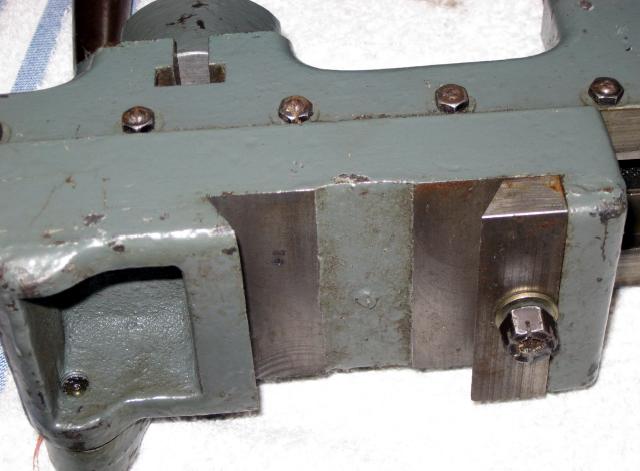

Cross and top-slide unit taken from a Myford/Drummond M-Type - though with an extension bracket supporting the end of the cross-feed to gave the slide an increased travel and larger - if crudely engraved - micrometer dial (though this may be a home-constructed part). |

||

|

|

|

Myford Super 7B with 60" between centres "High-swing", ML7 Capstan, ML5, ML6, & Others - page 2 - Home Machine Tool Archive Machine-tools Sale & Wanted |

||